Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

All Testing Apparatus

Caricato da

Anil PuvadaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

All Testing Apparatus

Caricato da

Anil PuvadaCopyright:

Formati disponibili

All testing apparatus/measuring instruments shall be periodically checked and calibrated and

records of such checks/calibration shall be maintained.

Thrust block considerations

f) Manhole/Valve Chamber Construction

Hydrostatic test for NP pipes

Obtaining Manufacturing Certificates.

The leakage or quantity of water to be supplied to maintain the test pressure during the period of 10

minutes shall not exceed 0.2 liters/mm dia. of pipes per kilometer length per day.

Sewer-Protection Protection of sewer structures by coating against H2S attack can also be

considered if other methods of control are impracticable

g) glands and bolts for mechanical flexible joints; - glands, bolts and locking rings or segments for

restrained joints.

h) Gasket - Sealing component of a joint.

Ia) Norminal dia DN

i) Norminal Pressure . PN ,

ii) Allowable operating pressure ( AOP ), &

iii )Allowable Max Operating Pressure

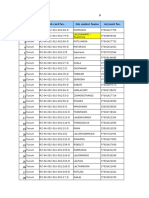

a) Manufacture certification

b) Third party test certificates (pipes, fittings. valves)

c) test to ensure Rubber gasket quality as per IS 5382/1985.

d) Ovality Test

e) Wall thickness

f) The wall thickness of pipe ‘e’ in mm shall be calculated as a function of the nominal

diameter by the following equation with

g) minimum of 5 mm for K=7,

h) For 6mm K=8

i) And 7mmforK=12.

e = K (0.5 + 0.001) DN . . .

(1) where e = wall thickness in mm, DN = the nominal diameter, and K = the whole number

coefficient.

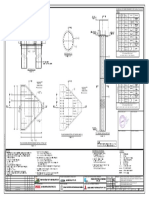

a) Pipes :- For screwed on flange Pipes

b) welded on flange pipes :-0the minimum classes as per working pressure criteria are given

below: Flanged Pipes should be preferably of Ductile Iron of 420 MPa minimum tensile strength

and 5 percent minimum elongation at break and maximum hardness 250 HB.

c) Minimum Class for Ductile Iron Flanged Pipes

d) JOINTS The joint design i)

i) Push-on-Joint - In case of push-on flexible joints, the spigot ends shall be suitably chamfered

or rounded off to facilitate smooth entry of pipe in the socket fitted with the rubber gasket.

ii) For high pressure mains where working pressure isgreater than 2.4 MPa, suitable flexible joint

may be preferred when the joint is restrained against axial movement.

iii) Flanged Joint:-

Flanged joints for working pressure ratings For screwed on flanged pipes, the method of 1.0,

1.6,2.5 and 4.0 MPa

The ductile iron pipes having screwed on flanges shall be sealed at the threaded joint between

the pipe and theflange by a suitable sealing compound. U

Iv ) Flexiable and Interconnection Joints :-a) Socket & Spigot Flexible Push-on Joints

Permissible delfection :- 2 degress for 700mm pipe

Rubber Gasket : - A) SBR (Styrene Butadyne Rubber) or EPDM (Ethylene Propylene Diene Monomer)

conforming to IS:5382 are used with Ductile Iron push-on joint pipes.

B) Restrained Joint Push-on Type:- Tooth gasket Restrained Joint B) Bolted Restrained Joint

Max Delfection : -5 degrees

C) The mechanical acceptance tests – for 700 dia -60 pipes

a) Tensile Test :-

b) Elongation Test Acceptable for Pipes 800 to 1000 Tensile tests ----420MPA----- Elongation -10 %

c) Hardness Test :- Brine11 Hardness Test :- When tested in accordance with IS 1500, the

Brine11 hardness shall not exceed 230 HB on the external un-machined surface.

d) HYDROSTATIC TEST:- To perform the test, pressure shall be applied internally and shall be

steadily maintained for a period of 10 s. The pipes shall withstand the pressure test and shall not

show any sign of leakage, sweating or other defects of any kind

for DN 80 to 300 p = 0.05 (K + 1)2

for DN 350 to 600 p = 0.05 (K)2

for DN 700 to 1 000 p = 0.05 (K- I)

Potrebbero piacerti anche

- AECOM Bill Janauary 20Documento16 pagineAECOM Bill Janauary 20Anil PuvadaNessuna valutazione finora

- AECOM Bill Janauary 20Documento16 pagineAECOM Bill Janauary 20Anil PuvadaNessuna valutazione finora

- AECOM Bill Janauary 20Documento16 pagineAECOM Bill Janauary 20Anil PuvadaNessuna valutazione finora

- Booked AmountDocumento3 pagineBooked AmountAnil PuvadaNessuna valutazione finora

- Vijayawada Tirupati: 11:00 PM 6:30 AMDocumento3 pagineVijayawada Tirupati: 11:00 PM 6:30 AMAnil Puvada100% (1)

- Details of Projects in Execution 29 10 2019Documento5 pagineDetails of Projects in Execution 29 10 2019Anil PuvadaNessuna valutazione finora

- Art District MEP ObservationsDocumento3 pagineArt District MEP ObservationsAnil PuvadaNessuna valutazione finora

- Technoarchitecture - Inc: Ground Floor ExcavationDocumento26 pagineTechnoarchitecture - Inc: Ground Floor ExcavationAnil PuvadaNessuna valutazione finora

- 1.vol 1 Vol 2 Vol 3 - Draft - RFP Sports Arena V. 01 - Final - 10oct2018 PDFDocumento585 pagine1.vol 1 Vol 2 Vol 3 - Draft - RFP Sports Arena V. 01 - Final - 10oct2018 PDFAnil PuvadaNessuna valutazione finora

- 397 - MONTHLY REPORTS OF TIRUPATI - Aug 2019 - 21 Oct 2019Documento1 pagina397 - MONTHLY REPORTS OF TIRUPATI - Aug 2019 - 21 Oct 2019Anil PuvadaNessuna valutazione finora

- HDPE PRESSURE TESTING Labours As On 05.10.2016 FinalDocumento12 pagineHDPE PRESSURE TESTING Labours As On 05.10.2016 FinalAnil PuvadaNessuna valutazione finora

- 18B061 SDG MCRT FDN DD 001 R0 V1Documento1 pagina18B061 SDG MCRT FDN DD 001 R0 V1Anil PuvadaNessuna valutazione finora

- Tirupati Smart City Corporation Ltd. Aecom India Pvt. Ltd. Force Structural Engineers Pvt. LTDDocumento1 paginaTirupati Smart City Corporation Ltd. Aecom India Pvt. Ltd. Force Structural Engineers Pvt. LTDAnil PuvadaNessuna valutazione finora

- Imlibun - Bill - Ra - 03Documento179 pagineImlibun - Bill - Ra - 03Anil PuvadaNessuna valutazione finora

- Master+Estimate+9 1+modifiedDocumento123 pagineMaster+Estimate+9 1+modifiedAnil Puvada100% (1)

- All The BestDocumento2 pagineAll The BestAnil PuvadaNessuna valutazione finora

- Estimate of Site OfficeDocumento6 pagineEstimate of Site OfficeAnil PuvadaNessuna valutazione finora

- AECOM Tirupati Smart City Office InventoryDocumento3 pagineAECOM Tirupati Smart City Office InventoryAnil PuvadaNessuna valutazione finora

- ReadmeDocumento1 paginaReadmeAnil PuvadaNessuna valutazione finora

- 103 - Revised DPR Submission Letter - SEP 10 2018Documento2 pagine103 - Revised DPR Submission Letter - SEP 10 2018Anil PuvadaNessuna valutazione finora

- Farhan CV Tirupati FormatDocumento12 pagineFarhan CV Tirupati FormatAnil PuvadaNessuna valutazione finora

- Is 783Documento79 pagineIs 783abhijit_xp8880Nessuna valutazione finora

- 103 - Revised DPR Submission Letter - SEP 10 2018Documento2 pagine103 - Revised DPR Submission Letter - SEP 10 2018Anil PuvadaNessuna valutazione finora

- Is 783Documento79 pagineIs 783abhijit_xp8880Nessuna valutazione finora

- 002325200037530Documento2 pagine002325200037530Anil PuvadaNessuna valutazione finora

- 1270-Dsn-Tw-D-017-R0-Details of Insert For Anchoring FMS Tower of Launching Girder PDFDocumento2 pagine1270-Dsn-Tw-D-017-R0-Details of Insert For Anchoring FMS Tower of Launching Girder PDFAnil PuvadaNessuna valutazione finora

- 1270-Dsn-Tw-D-017-R0-Details of Insert For Anchoring FMS Tower of Launching Girder PDFDocumento2 pagine1270-Dsn-Tw-D-017-R0-Details of Insert For Anchoring FMS Tower of Launching Girder PDFAnil PuvadaNessuna valutazione finora

- Naresh Babu CV 02-07-2019Documento7 pagineNaresh Babu CV 02-07-2019Anil PuvadaNessuna valutazione finora

- Imprest StatementDocumento1 paginaImprest StatementAnil PuvadaNessuna valutazione finora

- Proceedings of The Commissioner On RFP NW Jio 20 Feb 2020Documento13 pagineProceedings of The Commissioner On RFP NW Jio 20 Feb 2020Anil PuvadaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Photography Is The: PictureDocumento3 paginePhotography Is The: PictureJrom EcleoNessuna valutazione finora

- Potential of Osmotic Power Generation by Pressure Retarded Osmosis Using Seawater As Feed Solution: Analysis and ExperimentsDocumento8 paginePotential of Osmotic Power Generation by Pressure Retarded Osmosis Using Seawater As Feed Solution: Analysis and ExperimentsAugusto MeloNessuna valutazione finora

- Tokopedia Engineer CultureDocumento25 pagineTokopedia Engineer CultureDIna LestariNessuna valutazione finora

- GM 302 - Update - 10-2004Documento26 pagineGM 302 - Update - 10-2004Naser JahangiriNessuna valutazione finora

- EMI EMC Project ReportDocumento55 pagineEMI EMC Project ReportAshish Agarwal80% (5)

- 03-Instruction Set ArchitectureDocumento40 pagine03-Instruction Set ArchitectureccoccoheadNessuna valutazione finora

- Repair Parts Sheet: A Unit of Applied Power IncDocumento2 pagineRepair Parts Sheet: A Unit of Applied Power IncLukas EzequielNessuna valutazione finora

- 032 Wire Rope Sling 76.5 TonDocumento4 pagine032 Wire Rope Sling 76.5 TonHario PramuditoNessuna valutazione finora

- RAMS Knowledge SharingDocumento29 pagineRAMS Knowledge SharingJAYNessuna valutazione finora

- Regulation JigDocumento16 pagineRegulation JigMichaelZarateNessuna valutazione finora

- PDH DFE1000 BrochureDocumento2 paginePDH DFE1000 Brochuremajdi1985Nessuna valutazione finora

- Workbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFDocumento2 pagineWorkbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFarielveron50% (2)

- WSO&WSP Excel Shortcuts Cheat SheetsDocumento7 pagineWSO&WSP Excel Shortcuts Cheat SheetsAndy ZouNessuna valutazione finora

- Isuzu REDTech 4J Lit SheetDocumento2 pagineIsuzu REDTech 4J Lit SheetVăn Tuấn NguyễnNessuna valutazione finora

- Wallenius Wilhelmsen HistoryDocumento28 pagineWallenius Wilhelmsen Historymanayani52100% (1)

- FFSA BriefDocumento4 pagineFFSA Briefcontactnandu7415Nessuna valutazione finora

- Sample Maths Exam PDFDocumento11 pagineSample Maths Exam PDFAnonymous oJ0Dl7rWNessuna valutazione finora

- India International Centre India International Centre QuarterlyDocumento15 pagineIndia International Centre India International Centre QuarterlySruti UNessuna valutazione finora

- UNIC Jakarta Internship ApplicationDocumento4 pagineUNIC Jakarta Internship ApplicationMuhammad IkhsanNessuna valutazione finora

- 1st Quarter EIM 4Documento6 pagine1st Quarter EIM 4Victor RosalesNessuna valutazione finora

- Practice - Creating A Discount Modifier Using QualifiersDocumento37 paginePractice - Creating A Discount Modifier Using Qualifiersmadhu12343Nessuna valutazione finora

- ASHRAE - HVAC Noise and Vibration ControlDocumento93 pagineASHRAE - HVAC Noise and Vibration Controlmnt6176100% (3)

- GeothermalenergyDocumento2 pagineGeothermalenergyapi-238213314Nessuna valutazione finora

- Tuirum Adhaar Update Tur ListDocumento4 pagineTuirum Adhaar Update Tur ListLalthlamuana MuanaNessuna valutazione finora

- HabaCHIAN Slat Conveyor ChainsDocumento128 pagineHabaCHIAN Slat Conveyor Chainsjunico76Nessuna valutazione finora

- White Paper - SuperUserDocumento16 pagineWhite Paper - SuperUsermdsauberNessuna valutazione finora

- Describe in Detail The Method You Use To Parallel The Alternator and Share LoadDocumento4 pagineDescribe in Detail The Method You Use To Parallel The Alternator and Share LoadDen EdiNessuna valutazione finora

- Accenture Global Pharmaceutical and Company Planning Forecasting With Oracle HyperionDocumento2 pagineAccenture Global Pharmaceutical and Company Planning Forecasting With Oracle HyperionparmitchoudhuryNessuna valutazione finora

- UHP Water Jetting Unit: Ultrabar 10 ECDocumento1 paginaUHP Water Jetting Unit: Ultrabar 10 ECFrederik CañabiNessuna valutazione finora

- Generator Hydrogen Cooling InfoDocumento21 pagineGenerator Hydrogen Cooling InfovarsbsNessuna valutazione finora