Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Erection of Col - and Beam, Stair

Caricato da

ChandruTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Erection of Col - and Beam, Stair

Caricato da

ChandruCopyright:

Formati disponibili

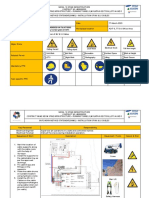

Risk Assessment/Management Form

Ref:

Section / Dept: Preheater / civil Risk Assessment-

Activity:

ERECTION OF COLUMN,STAIR

CASE AND BRACING

Sl Basic Job Potential Hazard Consequence Current control measure

Probability

Probability

N. Steps Risk rating Risk rating

Residual

Additional

Initial control

risk

P E A R Risk measure P E A R

Use guide rope during shifting of

materials and always keep away

Get Injury/ from swing area.Daily tool box talk

Fall of materials

Fatality before starting of job by crew

supervisor.

Failure of wire rope Get Injury All the wire rope sling & D-shackle

sling/D-shackle must be visually checked . Tested

sling must

Skilled be colour

workmen shallcoaded by a

be engaged

specific colour

for hooking .aily tool box talk

of material.Hook of hydra

before

must bestarting of job

provided byhook

with crewlatchaily

Hooking of material Get injury supervisor.

tool box talk before starting of job by

crew supervisor.

People should maitain safe distance

from the load while lifting and

shifting.Guide rope to be fixed on

both ends of the

Shifting of material material.Communication with the

hydra operator will be one to one talk

and signal will be issued by the

signal man with blue helmet.

People should not unhook the sling

Unhooking of

Shifting of Injury to person during tension. Only skilled person

material

the will remove the sling from the hook.

1 materials by Marking of SWL at different lifting 1 0 0 1 2 2

Hydra up to hooks of hydra.

max. 2 MT Only Trained & experienced operator

Toppling of Hydra

due to excess Injury / Fatality will operate the hydra.Material

loading above the safe working load

mentioned at the lifting position shall

not be lifted.

Deploy one hydra helper with whistle

wearing of floroscent jacket walking

minimum 3m.away from hydra(left

side) and 2persons are to be

Man/Materials standing for the guidence of guide

Traffic Control

loss rope & Hydra speed can be resticted

, Reverse horn sounds during

reversal of hydra.

Deploy one hydra helper with whistle

wearing of floroscent jacket walking

Man/Materials minimum 3m.away from hydra(left

Traffic Control side) and 2persons are to be

Loss

standing for the guidence of guide

rope&Hydra speed can be

restricted.Reverse horn sounds

during reversal of hydra.

Stacking of All the materials shall be stacked at

Tripping Get Injury

materials designated place

Height of stacked materials shall be

Unloading &

2 Get Injury maintained as per safety norms & 1 0 0 0 2 2

Stacking

users convenience

Stacking shall be done as per the

shape,size & weight of the materials

Lifting of materials up to 40m.to be

done by Crawler Crane & Rest of

height shall be done by Tower Crane

Slip of Tools Get Injury

1of3

Sl Basic Job Potential Hazard Consequence Current control measure

Probability

Probability

N. Steps Risk rating Risk rating

Residual

Additional

Initial control

risk

P E A R Risk measure P E A R

Slip of Tools Get Injury

All the tools should be tied up with

Lifting of rope while using

3 2 0 0 1 2 4

materials

All the loose materials should be

lifted by gunny bag with rope pully

system/winch m/c

Fall of materials Get Injury

Area should be barricaded and

nobody allow under the suspended

load

Ascending and Descending of

workmen shall be done through the

Erected stair and the stair must be

fitted with hand rails

All slings and D-shackles used for

erection shall have third party inspection

certificate

Erection of Capacity of Hydra/Crane must be in

Get

4 Col.fitted Failure of slings accordance with the weight of the load 2 0 1 1 2 4

Injury/Fatality

with bracing During erection the signal man must be

wearing of reflective jacket

Load must be lifted as per sequence of

load chart

After erection the structures will be

anchor bolted/grouted

Erection team employed in erection

must be skilled & identified

All supporting members should be

bolted/welded properly

To arrange the working platform out side

the preheater building for the erection of

Erection of supporting members

Get

5 supporting Fall from height 2 0 0 1 2 4

Injury/Fatality While person working out side the

members

preheater he must be wearing of double

rope safety harness and it should be

tied up with the fixed structure above the

head height

Take Wah permit before starting the

activity

Use double rope full body harness for

ascending and descending

Co-ordinated

Working at Get Always anchor the safety belt above the 3 0 0 2 2

6 Fall from height 6 Tool box talk 2 0 0 0 2 4

height Injury/Fatality head height daily

Proper scaffold as work platform shall

be made

The erection team employed in erection

must be skilled & identified

Only Trained & Experienced personnel

shall be allowed for welding

Get Injury

To take charging approval

Electric shock /Respiratory

Welding m/c.should be connected with

problem separate earthing

To use welding appropriate PPE Co-ordinated

7 Welding 2 0 0 2 3 6 Tool box talk 2 0 0 1 2 4

Looking at welders ARC should be daily

avoided while working with in the vicinity

Damage of of welding

Eye Injury

both eyes Use welding screen of correct

specification

Use of proper PPE

All hose pipes shall be inspected for

any kind of damage or leakage prior

to start the days work.

Take hot work permit before starting

the activity

Leackage of hose Get Injury due to Proper hose clamp shall be provided

pipe fire at both cylinder side and torch side.

Binding wire shall never be used or

allowed inplace of hose clamp

Gas cutting 2of3

8 2 1 0 0 2 4

activity

Sl Basic Job Potential Hazard Consequence Current control measure

Leackage of hose Get Injury due to

Probability

Probability

N. Steps Risk rating Risk rating

pipe fire

Residual

Additional

Initial control

risk

P E A R Risk measure P E A R

Colour code for separate hose pipe

(Red for DA and blue for Oxygen)

Gas cutting shall be maintained and never be

8 2 1 0 0 2 4

activity mixed

Only striking lighter shall be used to

light the torch and torch shall be

checked for any kind of damages

prio to start the job

Fire due to use of

improper lighting Get Injury Flash Back arrester shall be

tools & torch provided to all the outlets of cylinders

Pressure guages (both for working

pressure and cylinder pressure) shall

be maintained

Cleaning of torch from dirt required

on daily basis

To stop the work and reassess the

condition

Avoiding high tonnage erection(>5T)

DURING NIGHT HOURS

Natural

9 High wind Velocity Injury/Fatality 1 0 0 0 4 4

Calamity Any work stopped due any reasonin the

late night more than 1/2 hr.idle people

should not restin the work area.They

should come back to site office for relax

Prepaired by: Approved by: Reviewed by:

3of3

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hira For Excavation ManuallyDocumento1 paginaHira For Excavation ManuallyChandru100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- False CeilingDocumento1 paginaFalse CeilingChandru67% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Erection of Col - and Beam, StairDocumento3 pagineErection of Col - and Beam, StairChandru100% (1)

- Dismantling of StagingDocumento1 paginaDismantling of StagingChandruNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Dismantling of WallDocumento1 paginaDismantling of WallChandruNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Drilling Work by MCDocumento1 paginaDrilling Work by MCChandruNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Dismantling of ShedDocumento1 paginaDismantling of ShedChandruNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- CuringDocumento1 paginaCuringChandruNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Dismantling of Concrete Pump TowerDocumento1 paginaDismantling of Concrete Pump TowerChandruNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Deshuttering WorkDocumento2 pagineDeshuttering WorkChandru100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Concrete WorkDocumento1 paginaConcrete WorkChandruNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Dismantling of Cement SiloDocumento1 paginaDismantling of Cement SiloChandruNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Chipping Work by MCDocumento1 paginaChipping Work by MCChandruNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Al Door&WindowDocumento1 paginaAl Door&WindowChandruNessuna valutazione finora

- DewateringDocumento1 paginaDewateringChandruNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Back FillingDocumento2 pagineBack FillingChandruNessuna valutazione finora

- Chipping Work (Manually)Documento1 paginaChipping Work (Manually)ChandruNessuna valutazione finora

- Boilermaker Resume AustraliaDocumento4 pagineBoilermaker Resume Australiamuwebuwynug3100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Operating/maintenance Instructions: I-Beam Pillar and Wall-Mounted Jib CranesDocumento44 pagineOperating/maintenance Instructions: I-Beam Pillar and Wall-Mounted Jib Cranesrochim_putech_126885Nessuna valutazione finora

- CranesDocumento36 pagineCranesbeshoy100% (4)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Brochure - Complete Floating Crane Barges SCREEN (Id 50444) - Original - 50444 PDFDocumento4 pagineBrochure - Complete Floating Crane Barges SCREEN (Id 50444) - Original - 50444 PDFDiana AnghelacheNessuna valutazione finora

- 16.10 Site Equipment (72dpi)Documento24 pagine16.10 Site Equipment (72dpi)Jack JeffNessuna valutazione finora

- Demag DMR (Brochure)Documento20 pagineDemag DMR (Brochure)Hendra HalimNessuna valutazione finora

- Penjajuća Oplata K PDFDocumento52 paginePenjajuća Oplata K PDFMala MuNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Dock Labour Regulations: - Who Made This RegulationDocumento35 pagineDock Labour Regulations: - Who Made This RegulationAku RajNessuna valutazione finora

- L-759 Lifting Calculation For Lift PlanDocumento9 pagineL-759 Lifting Calculation For Lift Plantouggourt30008514Nessuna valutazione finora

- Safety Score Card SampleDocumento48 pagineSafety Score Card Samplejithin shankarNessuna valutazione finora

- Mto PDFDocumento1 paginaMto PDFRigonDEC100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Swms For LV, MV Cable Laying 17.12.22Documento5 pagineSwms For LV, MV Cable Laying 17.12.22Md Shahbaz AlamNessuna valutazione finora

- GroveDocumento100 pagineGroveSarra Chouchene100% (1)

- TechCon Offshore and Subsea LiftingDocumento16 pagineTechCon Offshore and Subsea LiftingLeonardo RoncettiNessuna valutazione finora

- En Operators Manual Tb175w Aw3e004 175400095Documento221 pagineEn Operators Manual Tb175w Aw3e004 175400095grunwald100% (1)

- List of Useful Hydroelectric Standards Guides and Manuals .Documento3 pagineList of Useful Hydroelectric Standards Guides and Manuals .Raúl Castillo100% (1)

- QJ330 1107 English PDFDocumento226 pagineQJ330 1107 English PDFMichael Davenport100% (4)

- Jadual Kadar HargaDocumento11 pagineJadual Kadar HargaprincessfadzNessuna valutazione finora

- TM 5-3810-300-34PDocumento762 pagineTM 5-3810-300-34PsvaasandNessuna valutazione finora

- Crane SafetyDocumento22 pagineCrane SafetynincatNessuna valutazione finora

- Rigging Basic Learner Workbook Marking Guide ANSWERS SAMPLEDocumento25 pagineRigging Basic Learner Workbook Marking Guide ANSWERS SAMPLEMoha WlweeaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Part 4: Mobile Crane Stability - Adding It All TogetherDocumento3 paginePart 4: Mobile Crane Stability - Adding It All TogetherJuan CarlosNessuna valutazione finora

- Optimization of The Tank Rotating Machine in Estanc AsDocumento81 pagineOptimization of The Tank Rotating Machine in Estanc AssauravNessuna valutazione finora

- Prosedur Handling Dan Lifting Instalasi Mla 1bDocumento32 pagineProsedur Handling Dan Lifting Instalasi Mla 1blon wayNessuna valutazione finora

- Ans of State Level MCQ Practice Test On Emerging Trends in Civil Engineering (22603) Organize by GPJDocumento27 pagineAns of State Level MCQ Practice Test On Emerging Trends in Civil Engineering (22603) Organize by GPJ39 Najima PatelNessuna valutazione finora

- Risk Assessment - Steel Erection WorksDocumento11 pagineRisk Assessment - Steel Erection Worksmahmoud nadaNessuna valutazione finora

- RTC8035Documento6 pagineRTC8035Mauricio JerezNessuna valutazione finora

- StrucTemp Brochure PDFDocumento23 pagineStrucTemp Brochure PDFMinh HoangNessuna valutazione finora

- RA-Chlorination & Disinfectionof Water Supply SystemDocumento11 pagineRA-Chlorination & Disinfectionof Water Supply SystemSanto ENessuna valutazione finora

- Rigging Study Lifting Study - October 2018 HaGun InstituteDocumento46 pagineRigging Study Lifting Study - October 2018 HaGun InstituteKadiriJaelani GunawanNessuna valutazione finora