Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aalco Metals LTD - Stainless Steel 201201L202204 - 97 PDF

Caricato da

Naman PrajapatiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aalco Metals LTD - Stainless Steel 201201L202204 - 97 PDF

Caricato da

Naman PrajapatiCopyright:

Formati disponibili

Stainless Steel

201~201L~202~204

SPECIFICATIONS ALLOY DESIGNATIONS

AISI 201 stainless steel corresponds to the following

Commercial 200 Series

specifications:

UNS20100 / EN1.4372 / JIS SUS 201

200 Series stainless steels are not new – In fact they AISI 201L stainless steel corresponds to the following

have been around for many years. To date they have

specifications:

traditionally not proved very popular outside the USA.

UNS20103 / EN1.4371

However, since they have a much lower Nickel content

than 300 Series Austentics, the very high Nickel price

AISI 202 stainless steel corresponds to the following

over recent years has led to significantly more interest.

specifications:

Equally, stainless steel producers have an ongoing

UNS20200 / EN1.4373

programme of development designed to enhance

existing grades and produce new grades. These new

AISI 204C stainless steel corresponds to the following

grades are sometimes developed for specific end uses

specifications:

and sometimes to improve upon an existing grade.

UNS20400 / EN1.4597

Features:

~ Lower nickel than 300 series – with it being replaced SUPPLIED FORMS

by Manganese

~ Thus lower cost than 300 series • Sheet

~ Similar mechanical & physical properties to 300 • Plate

series

~ Similar fabrication performance to 300 series,

including deep-drawing GENERIC PHYSICAL PROPERTIES

~ Corrosion resistance similar to 430 (i.e. not nearly as

good as 300 series) Property Value

~ High carbon may cause stress corrosion cracking,

Density 7.80 g/cm³

especially after welding thicker material

~ Non Magnetic Thermal Expansion 17 x10-6 /K

Modulus of Elasticity 200 GPa

Performance Comparison:

~ Formability: Similar to 304, better than 430 Thermal Conductivity 15 W/m.K

~ Strength: Stronger than 304 (and 430)

~ Corrosion Resistance @20 C: Similar to 304, better

than 430 but susceptible to stress corrosion cracking / MECHANICAL PROPERTIES

intergranular corrosion especially after welding

Property Value

CHEMICAL COMPOSITION Proof Stress 310 Min MPa

Tensile Strength 655 Min MPa

Element % Present

Elongation A50 mm 40 min %

Chromium (Cr) 16.00 - 18.00

Manganese (Mn) 6.80 - 8.50 See attached page for full mechanical properties.

Note that there are some differences in the requirements of AISI 200

Nickel (Ni) 2.00 - 5.00 series types and the EN standards - The above is taken from AISI.

EN 1.4372, the EN equivalent to AISI 201 has a minimum proof of 350

Nitrogen (N) 0.0 - 0.25 and a tensile range of 750 to 950 whilst minimum elongation is 45%

Iron (Fe) Balance

See attached page for full chemical analysis and mechanical properties

[1 OF 3] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

© Copyright: Aalco Metals Ltd, Parkway House, Unit 6 Parkway Industrial Estate, Wednesbury WS10 7WP

Stainless Steel

201~201L~202~204

APPLICATIONS

200 series austenitics are typically used to replace

types 304 and 301 as well as Carbon (Chrome-

Manganese) Steels mainly for indoor use for low

corrosion applications at room temperature

Furniture

Bins

Cookware & Serving Bowls

Window Channel Spacers

Safety Shoes (mid-sole protector)

Deep drawn kitchen equipment – e.g. Cookware &

Sinks

Hose Clamps

Trailer Frames

Industrial Strapping

Railway Rolling Stock

There is also grade 201LN for welded constructions,

structural uses and low temperature applications -

Examples include sides & roofs of trains, liquified gas

storage vessels, structural members/chassis of railway

rolling stock, trucks & trailers, coal handling equipment CONTACT

PERFORMANCE COMPARISON Address: Please make contact directly with your local

service centre, which can be found via the

The 200 series grades perform at a similar level to Locations page of our web site

Web: www.aalco.co.uk

grades 304 and 301 in low corrosion, mainly indoor

applcations at room temperature.

REVISION HISTORY

CORROSION RESISTANCE

The 200 series grades perform at a similar level to Datasheet Updated 14 November 2018

grades 304 and 301 in low corrosion, mainly indoor

applcations at room temperature.

Not recommended for use in Chloride environments. DISCLAIMER

This Data is indicative only and as such is not to be relied upon in place of

the full specification. In particular, mechanical property requirements vary

HEAT RESISTANCE widely with temper, product and product dimensions. All information is

based on our present knowledge and is given in good faith. No liability will

be accepted by the Company in respect of any action taken by any third

Oxidation resistance is similar to grade 1.4310 (301)

party in reliance thereon.

up to 840 Centigrade.

Please note that the 'Datasheet Update' date shown above is no guarantee

of accuracy or whether the datasheet is up to date.

WELDABILITY

The information provided in this datasheet has been drawn from various

Reasonable, although sensitive to intergranular recognised sources, including EN Standards, recognised industry references

(printed & online) and manufacturers’ data. No guarantee is given that the

corrosion in the heat affected zone where thickness information is from the latest issue of those sources or about the accuracy of

exceeds 6mm. those sources.

Post-weld cleaning and passivation is crucial. Material supplied by the Company may vary significantly from this data, but

will conform to all relevant and applicable standards.

As the products detailed may be used for a wide variety of purposes and as

the Company has no control over their use; the Company specifically

excludes all conditions or warranties expressed or implied by statute or

otherwise as to dimensions, properties and/or fitness for any particular

purpose, whether expressed or implied.

Advice given by the Company to any third party is given for that party’s

assistance only and without liability on the part of the Company. All

transactions are subject to the Company’s current Conditions of Sale. The

extent of the Company’s liabilities to any customer is clearly set out in those

Conditions; a copy of which is available on request.

[2 OF 3] CONTINUED

Aalco is a registered trademark of Aalco Metals Ltd

© Copyright: Aalco Metals Ltd, Parkway House, Unit 6 Parkway Industrial Estate, Wednesbury WS10 7WP

Stainless Steel

201~201L~202~204

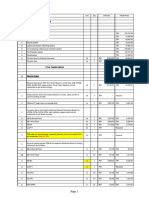

Typical Chemical Composition

% 201/201L 202 204C

C Max 0.15/0.03 0.15 0.15

Cr 17 18 16

Mn 6 8.5 7

Ni 4.5 5 2

N 0.25 Max 0.25 Max 0.15

Mechanical Properties

Grade 201 201L 201LN 202 204C

Tensile Strength (KSi) 75 Min 95 Min 95 Min

Proof Stress 0.2% (KSi) 38 Min 38 Min 45 Min

Elongation % (Min) 40 Min 40 Min 40 Min

Extract from BS EN 10088-2: Chemical Compositions

Designation Chemical composition % by mass max unless stated

EN C Si Mn P S N Cr Mo Ni Others

201 1.4372 0.15 1.00 5.5/7.5 0.045 0.015 0.05/0.25 16.0/18.0 - 3.5/5.5 -

201L 1.4371 0.030 1.00 6.0/8.0 0.045 0.015 0.15/0.20 16.0/17.0 - 3.5/5.5 -

202 1.4373 0.15 1.00 7.5/10.5 0.045 0.015 0.05/0.25 17.0/19.0 - 4.0/6.0 -

B:0.0005/

0.0050

204C 1.4597 0.10 2.00 6.5/8.5 0.040 0.030 0.15/0.30 16.0/18.0 1.00 2.00

Cu: 2.00/

3.5

Extract from BS EN 10088-2: Mechanical Properties

Product Proof strength

Tensile

Steel Steel Max Elongation

Rp0.2 Rp1.0 strength Rm

name number Form thickness %

N/mm2 N/mm2 N/mm2

mm

C 8 350 380 750/950 45

201 1.4372 H 13.5 330 370 750/950 45

P 75 330 370 750/950 40

C 8 300 330 650/850 45

201L 1.4371 H 13.5 280 320 650/850 45

P 75 280 320 630/830 35

C 8 340 370 680/880 45

202 1.4373 H 13.5 320 360 680/880 45

P 75 320 360 600/800 35

C 8 300 330 580/780 40

204C 1.4597

H 13.5 300 330 580/780 40

[3 OF 3]

Aalco is a registered trademark of Aalco Metals Ltd

© Copyright: Aalco Metals Ltd, Parkway House, Unit 6 Parkway Industrial Estate, Wednesbury WS10 7WP

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- ACI 330R-08 - Design & Construction Guidlines PDFDocumento83 pagineACI 330R-08 - Design & Construction Guidlines PDFlyricmpNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- General Input:-: Flexural Crack Width Calculation For Rectangular RC According ACI350-06 &ACI224R-01Documento6 pagineGeneral Input:-: Flexural Crack Width Calculation For Rectangular RC According ACI350-06 &ACI224R-01Donny. B TampubolonNessuna valutazione finora

- Schematic View of Rollers: WaterDocumento11 pagineSchematic View of Rollers: Watersuhas k100% (1)

- Handbook of International Alloy Compositions and Designations. Volume I. TitaniumDocumento240 pagineHandbook of International Alloy Compositions and Designations. Volume I. TitaniumdaymonNessuna valutazione finora

- BS 6480 Paper Insulated CablesDocumento66 pagineBS 6480 Paper Insulated CablesPrafulla SupekarNessuna valutazione finora

- ChemExpo 2023Documento22 pagineChemExpo 2023Gulshan Mishra100% (1)

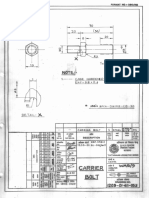

- Digitally Signed by HARI Narayan Meena Date: 2019.05.02 11:34:15 IST Reason: IREPS Document Location: IREPS-CRISDocumento1 paginaDigitally Signed by HARI Narayan Meena Date: 2019.05.02 11:34:15 IST Reason: IREPS Document Location: IREPS-CRISNaman PrajapatiNessuna valutazione finora

- Signature Not VerifiedDocumento1 paginaSignature Not VerifiedNaman PrajapatiNessuna valutazione finora

- Pipe Bender MachineDocumento3 paginePipe Bender MachineNaman PrajapatiNessuna valutazione finora

- CH 15: Measurement and Testing of GearDocumento14 pagineCH 15: Measurement and Testing of GearNaman PrajapatiNessuna valutazione finora

- BTMDocumento1 paginaBTMNaman PrajapatiNessuna valutazione finora

- Dense Graded Bitumen Mixes For PavementsDocumento4 pagineDense Graded Bitumen Mixes For PavementsPamirNessuna valutazione finora

- Trapezoidal CSG DamDocumento8 pagineTrapezoidal CSG Dam박래건Nessuna valutazione finora

- Types of Synthetic RopeDocumento4 pagineTypes of Synthetic RopeMitanshu ChadhaNessuna valutazione finora

- C1560-Accelerated AgeingDocumento2 pagineC1560-Accelerated AgeingBrinder DhanoaNessuna valutazione finora

- TECHNICALDocumento48 pagineTECHNICALPuneeth KumarNessuna valutazione finora

- T2785 1U Glamo HousingDocumento12 pagineT2785 1U Glamo HousingLiesa StoneNessuna valutazione finora

- Bignozzi 2015Documento8 pagineBignozzi 2015eclerNessuna valutazione finora

- Materials Today Communications: S. Deniz Varsavas, Cevdet KaynakDocumento10 pagineMaterials Today Communications: S. Deniz Varsavas, Cevdet KaynakbnechitaNessuna valutazione finora

- 99-STONE ITALIANA-Installation Maintenance GuideDocumento1 pagina99-STONE ITALIANA-Installation Maintenance GuideSuresh JainNessuna valutazione finora

- Li Register20210805Documento134 pagineLi Register20210805Erick HernandezNessuna valutazione finora

- Experimental and Investigation On Dissimilar Material Welding ofDocumento9 pagineExperimental and Investigation On Dissimilar Material Welding ofVenukanth S-2019Nessuna valutazione finora

- Alternate Building Materials: Bachelor of TechnologyDocumento21 pagineAlternate Building Materials: Bachelor of TechnologyKalyan Reddy AnuguNessuna valutazione finora

- How To Improve The Glass Curtain Wall FlatnessDocumento3 pagineHow To Improve The Glass Curtain Wall FlatnessHan JoeNessuna valutazione finora

- Uog-Ctc Boq Non PricedDocumento68 pagineUog-Ctc Boq Non PricedHavanah AshuNessuna valutazione finora

- Effect of Lithium Disilicate Veneers of Different Thickness On The Degree of Conversion and Microhardness of A Light-Curing and A Dual-Curing Cement.Documento5 pagineEffect of Lithium Disilicate Veneers of Different Thickness On The Degree of Conversion and Microhardness of A Light-Curing and A Dual-Curing Cement.Danny Eduardo RomeroNessuna valutazione finora

- Hall - Petch Effect Carlton 2007Documento8 pagineHall - Petch Effect Carlton 2007Jorge MatarNessuna valutazione finora

- Paper Rehabend 2020Documento10 paginePaper Rehabend 2020Mălíķ ĂsfęnđýårNessuna valutazione finora

- Matrial Stringing Schedule. MP-1Documento3 pagineMatrial Stringing Schedule. MP-1Khumaidi HambaliNessuna valutazione finora

- SRI-ITP-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22146R0Documento8 pagineSRI-ITP-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22146R0Dito NarendraNessuna valutazione finora

- Thermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationDocumento2 pagineThermal Insulation Systems: High Performance Heat Shield With Superior Thermal InsulationMikeNessuna valutazione finora

- Indorama Eleme Petrochemicals Limited PP HOMOPOLYMER ...Documento2 pagineIndorama Eleme Petrochemicals Limited PP HOMOPOLYMER ...UKNessuna valutazione finora

- Astm C884C884M-16Documento3 pagineAstm C884C884M-16adolfo camayoNessuna valutazione finora

- 1 2423-Mapequickaf701s-AusDocumento2 pagine1 2423-Mapequickaf701s-Ausnw86n6dd84Nessuna valutazione finora

- Lecture 16Documento9 pagineLecture 16Hardhik GamerNessuna valutazione finora