Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DC Mar07 Eikill

Caricato da

Hamed NazariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DC Mar07 Eikill

Caricato da

Hamed NazariCopyright:

Formati disponibili

DRILLING RIGS

Rig design philosophy key for harsh-environment

drilling in Barents Sea, Haltenbanken area

By Geir Ove Eikill, Bjorn Cristoffer Oftedal, a substantial amount of advanced and • Large deck area and storage capaci-

Statoil ASA challenging production drilling, comple- ties to ensure efficient logistics.

tion and workover operations on the

HIGHER RIG RATES have led Haltenbanken and in the Barents Sea • High air gap in operation condition

to an impressive newbuild program of area. Statoil hopes that some of the new and in survival.

semisubmersible drilling units. Will multi-purpose 6th-generation semisub- • Arctic design.

these new rigs be built for operational

safety and efficiency in a harsh envi- • Environmental care.

ronment? Year-around offshore drilling Statoil is generally A medium-capacity drilling facility, 4,500

operations in the north of Norway on the

Haltenbanken and the Barents Sea area

concerned for some of the to 5,000 tonnes variable deck load, with

a large deck area, should be sufficient

is a challenge against forces of nature new rig construction proj- because the majority of offshore drilling

in an extremely harsh environment with

the following special environmental

ects with regards to lack operations north on the Norwegian con-

tinental shelf will be performed in water

characteristics: of operational personnel

depths varying from 150 m to 450 m.

Barents Sea involved in the early project

Drilling-related expenditure is a main

• Polar low pressures. planning phase. contributor to overall field development

costs in a harsh environment. Indirect

• Low temperatures. operational drilling cost is affected by

• Ice and snow. concept design factors such as:

mersible drilling units will be built with

• Drifting ice. the objective to improve the unit perfor- • Waiting on weather.

mance considerably and fully meet the

Haltenbanken challenging present and future opera- • Back-loading and requirements for

tions and area conditions. temporary boat storage.

• Atlantic Ocean hurricanes.

• Weather window required for position-

• Strong current. RIG DESIGN FACTORS ing the rig over the well location.

Rig design philosophy is key for opera- • Uptime/reliability of equipment/rig in

• Long wave periods.

tional safety while performing opera- cold weather conditions.

A rig design philosophy with the main tions in a harsh environment on the

focus on the required operations is key Haltenbanken and the Barents Sea area. • Working environment.

to success in these waters.

The following rig design factors should • Environmental care.

The majority of the 4th-generation rigs be established as basis for a rig design

operating on the Norwegian continental made for these conditions: MOTION CHARACTERISTICS

shelf today were built in the ’80s and

• Rig motion characteristic. The wave conditions experienced on

hence designed for exploration drilling

Haltenbanken are special. Very long

operations. Today Statoil is performing • Natural heave period.

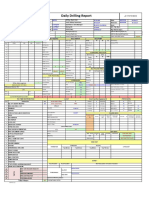

KPI operation factors

100 %

80 % Uptime

60 % 3’part down time (downhole)

WoW + W logistic

40 %

Planned maintenance

20 % Rig Equipment down time

0%

Rig 1 Rig 2 Rig 3 Rig 4 Rig 5 Rig 6 Rig 7 Rig 8 Rig 9

Rigs on contract for Statoil 2005

Figure 1 shows that statistical uptime for the rigs on contract for Statoil in 2005 was improved along with improved rig motion

characteristic and good logistic facilities.

84 March/April 2007 D R I L L I N G CONTRACTOR

DRILLING RIGS

optimal motion characteristics. The

optimization relative to variable deck

load capacity, equipment capacities, unit

geometry and motion characteristics

have to be considered from the unit con-

cept phase.

Additional cost issues are:

• Additional column height to fulfil air

gap requirements.

• Additional spacing between columns in

order to gain restoring stability moment.

• Breadth and depth under the water

table of the pontoons in order to get

damping effect to fulfil natural heave

period and motion characteristic

requirements.

Noroff Instituttet Stavanger

ENVIRONMENTAL CARE

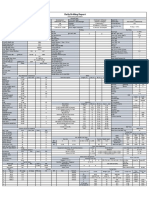

This illustration shows the seamless product line for drilling waste minimization and the

The Barents Sea area in particular is

safe, efficient transport of drill cuttings onto the deck of a service vessel. The environ-

an important breeding area for fish vul-

ment must be considered in rig design for the Barents Sea area in particular. nerable to potential pollution from any

drilling operation. Environmental issues

period waves (over 21-sec period and 6 2005 was improved along with improved

in the Barents Sea area has gained an

-7 m high) are experienced at a yearly rig motion characteristic and good logis-

increasingly political focus in Norway,

basis during periods with relatively tic facilities.

requiring drilling operations to go hand

moderate weather conditions when the

Other factors affecting the rig’s KPI per- in hand with the fishing industry.

rigs can be in full operation. The special

conditions are a result of past distant formance typically are:

In order to fulfil Statoil’s ambitions with

Atlantic storms adding to the local condi- • Location and season of the year. regards to environmental care, focus

tions. This type of wave occurs as one should be on the following design factors

among normal period waves, and drilling • Type of operation and third-party for the new rig projects:

units with lower natural heave response downhole equipment used.

period will suddenly heave 6-7 m. • 2nd barrier philosophy with dedicated

slope tanks and drain water cleaning

Safety: Natural heave period exceeding 6TH-GEN RIG CONCERNS system designed to clean emulsified oil

21 seconds is an important design crite- There is a possible conflict between in water, in order to minimize transport

ria for a drilling rig performing efficient increased drilling facility capacity for of slope to shore. As a minimum, the fol-

conventional completion or workover ultra-deepwater and the rigs motion lowing drain/tanks should be included:

operations in the Haltenbanken area, in characteristic required for comple-

order to avoid a possible compensator tion and workover operations in the 1. Drain from non-hazardous clean

stroke out, or a surface flow tree collid- Haltenbanken area. There is a consider- areas.

ing into the drill floor when the comple- able cost impact for the substructure to

2. Drain from non-hazardous polluted

tion riser is attached to the well head. maintain the rig’s motion characteristic

areas.

required for the Haltenbanken area as

Cost: The magnitude of nonproductive the top side drilling capacities are scaled 3. Drain from hazardous polluted

time is affected by the rig’s motion char- up to meet the requirement for ultra- areas.

acteristic while operating in relatively deep drilling.

moderate sea state conditions. • Low NOX-emission from diesel genera-

The hull structure made for a typical tors.

Efficient rigs with low wait-on-weather ultra-deep drilling rig planned to be

score is usually achieved with rigs hav- operating in relatively moderate sea • Transport of all water-based cuttings

ing good rigs motion characteristic in conditions will typically focus on gain- to shore after installing the BOP.

low amplitude sea state conditions. ing high variable deck load (VDL) at the

• Primary cutting transport system

An efficient rig for a harsh environment lowest possible cost. The most cost-effi-

should be based on allocate tanks, pneu-

is usually achieved by large displace- cient way of increased VDL is usually

matic cuttings transport, and offloading

ment, large spacing between columns achieved by increasing the column diam-

system for cuttings treatment equipment

having relatively small total water plan eter or to add blisters on the column in

and logistic to boat.

area, and wide pontoons with the top of order to gain higher stability restoring

the pontoons positioned relatively deep moment, and hence increase the variable • Secondary cutting transport sys-

under the water table. deck load capacity of the rig. tem should be based on pneumatic or

vacuum cuttings transport and logistic

Figure 1 shows that statistical uptime A unit designed for both the ultra-deep

to boat by using skips handled by the rig

for the rigs on contract for Statoil in and harsh environment drilling needs

cranes.

to have both the large capacities and

86 March/April 2007 D R I L L I N G CONTRACTOR

DRILLING RIGS

ARCTIC DESIGN designed for -25°C minimum design tem- • Working environment, including noise

perature (standby mode). exposure and sheltering of working

The design temperatures in the Barents

areas.

Sea area vary, with the lowest tempera- • Redundant Automatic Truster Assist

tures northeast with the Russian border. (ATA) positioning system in order to • Late introduction of arctic design

The water depths vary from 150 m to 400 fulfil Statoil’s requirements for shallow issues.

m, with some areas with low satellite water depths and low satellite coverage

coverage. in the Barents Sea area. Further, it is considered important with

an early establishment of an extensive

In order to fulfil Statoil’s ambitions with and realistic operational QA/QC- and

regards to arctic operation, focus should STATOIL NEW MODUS commissioning program including the

be on the following design factors: EXPERIENCE following:

• The rig’s exposed areas, such as the Statoil is generally concerned for some • Selection of a construction yard with

derrick, drill floor, muster stations, of the new rig construction projects with good QA/QC systems, dry dock capacity

pipe and riser deck, etc, should be fully regards to lack of operational personnel and top side drilling equipment assembly

sheltered or enclosed in order to ful- involved in the early project planning experience.

fil Statoil’s ambitions for the working phase. Focus on early involvement of

environment while operating under cold operational personnel in the project can • Change management to focus on

conditions. reduce the number of variation orders weight control and associated prioritiz-

at a later stage in the project phase. The ing of VDL capacity against motion char-

• All critical equipment, escape ways following operational issues should be acteristic).

and muster stations should be heat addressed at an early stage of a new rig

traced. building project: • Commissioning of electrical systems,

PLS, IT, ESD and fire and gas detection

• Utility systems should be placed • Safe and efficient logistic design (inter- systems.

in enclosed heated voids under deck nal on the rig and external to supply

in order to avoid environmental and boats). • Integrated sea trail testing of complex

mechanical damage. mooring ATA and DP3 positioning sys-

• Third-party equipment such as logging tems, all motion compensating systems.

• Safety systems such as well control unit, cement unit, test plant, workover/

equipment, positioning systems, fire- This article is based on a presentation made

completion equipment. at IADC World Drilling 2006, 21-22 June,

fighting and escape systems should be Prague, Czech Republic.

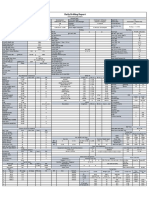

Diana/Hoover platform rig G10,000 drillship Pride Africa DSS20 semi Maersk Explorer CJ70 jack-up Maersk Innovator Ensco 7500 semi-submersible

GustoMSC FOR BOTH NEW BUILD AND CONVERSION/UPGRADE OF MODU’s.

GustoMSC provides complete, innovative, A total of 55 MODU’s have been built to our

field-proven and cost-effective designs: designs (7 units are arctic class). A total of

• jack-ups (CJ40, CJ46, CJ50, CJ54, CJ62, CJ70) 18 MODU’s are currently under construction.

• semi-submersibles (DSS20, DSS40, DSS50, DSS60) The MODU designs are complemented with our

• drillships (Pelican, G10,000, P10,000 and PRD12,000 engineered products supply, such as:

class) • rack & pinion and positive engagement jacking systems

• tender(-assist) drilling barges and semi-submersibles • X-Y cantilever systems

• platform drilling rigs • rack fixation systems

• thruster retrieval systems

GustoMSC

FORESIGHT IN OFFSHORE www.GustoMSC.com

D R I L L I N G CONTRACTOR March/April 2007 87

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Daily Drilling ReportDocumento3 pagineDaily Drilling ReportHamed NazariNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Mehdi Soltani: Curriculum VitaeDocumento3 pagineMehdi Soltani: Curriculum VitaeHamed NazariNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- DDR1402 02 09Documento26 pagineDDR1402 02 09Hamed Nazari100% (1)

- Daily Drilling ReportDocumento25 pagineDaily Drilling ReportHamed NazariNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- غزالDocumento1 paginaغزالHamed NazariNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Mehrdad Mohammadpour MD Resume: OphthalmologyDocumento15 pagineMehrdad Mohammadpour MD Resume: OphthalmologyHamed NazariNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- MD-1 NPT-Farvardin 1400: DescriptionDocumento5 pagineMD-1 NPT-Farvardin 1400: DescriptionHamed NazariNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 4 5963071420547203453Documento85 pagine4 5963071420547203453Hamed NazariNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Da13 DDR N1 14000305 254 0Documento3 pagineDa13 DDR N1 14000305 254 0Hamed NazariNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Da DDR N1 1Documento3 pagineDa DDR N1 1Hamed NazariNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpDocumento26 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud PumpHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Da13 DDR N1 14000229 247 0Documento3 pagineDa13 DDR N1 14000229 247 0Hamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNessuna valutazione finora

- Full Field Study & MDP Preparation For Asmari Reservoir of Parsi FieldDocumento60 pagineFull Field Study & MDP Preparation For Asmari Reservoir of Parsi FieldHamed NazariNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Daily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationDocumento25 pagineDaily Drilling Report: Bha Tally Bit Record Mud Report Mud Pump Drilling InformationHamed NazariNessuna valutazione finora

- Da13 14000103 190 0Documento3 pagineDa13 14000103 190 0Hamed NazariNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Da13 DDR N1 14000104 191 0Documento3 pagineDa13 DDR N1 14000104 191 0Hamed NazariNessuna valutazione finora

- Da13 DDR N1 13991207 164 0Documento3 pagineDa13 DDR N1 13991207 164 0Hamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- Da14 DDR N2 14000103 175 0Documento3 pagineDa14 DDR N2 14000103 175 0Hamed NazariNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Daily Drilling ReportDocumento3 pagineDaily Drilling ReportHamed NazariNessuna valutazione finora

- Daily Drilling Report: Danan Oilfield DevelopmentDocumento3 pagineDaily Drilling Report: Danan Oilfield DevelopmentHamed NazariNessuna valutazione finora

- 1 PBDocumento8 pagine1 PBAnnisa DwiNessuna valutazione finora

- Solid Waste Management For HouseholdDocumento70 pagineSolid Waste Management For HouseholdsonNessuna valutazione finora

- Vacuum Regulator Gas Feed Systems Theory and MaintenanceDocumento62 pagineVacuum Regulator Gas Feed Systems Theory and Maintenancezhigang dingNessuna valutazione finora

- Avaleha Criticalreview PDFDocumento9 pagineAvaleha Criticalreview PDFArunNessuna valutazione finora

- BOQ Fountain Water Body (1) .XLSXBDocumento6 pagineBOQ Fountain Water Body (1) .XLSXBPrashant Singh Chauhan60% (5)

- LIT1307 Test StandsDocumento4 pagineLIT1307 Test StandsFabio Peres de LimaNessuna valutazione finora

- BS 1881-5 Testing ConcDocumento15 pagineBS 1881-5 Testing Conchz135874Nessuna valutazione finora

- A Scheme For The Colorimetric Determination of Microgram Amounts of ThiolsDocumento3 pagineA Scheme For The Colorimetric Determination of Microgram Amounts of ThiolsAlexandru SavaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Haefele AH A4 Mar 15 8.12-8.24Documento13 pagineHaefele AH A4 Mar 15 8.12-8.24khurram1810Nessuna valutazione finora

- 2007 - Huber Et Al. - Synergies Between Bio and Oil Refineries For The Production of Fuels From Biomass PDFDocumento18 pagine2007 - Huber Et Al. - Synergies Between Bio and Oil Refineries For The Production of Fuels From Biomass PDFMayank KumarNessuna valutazione finora

- Test Farma En-Ro, Ro-EnDocumento3 pagineTest Farma En-Ro, Ro-EnIuliaUngurNessuna valutazione finora

- Stycast 1264 A/B: Low Viscosity, Transparent, Epoxy EncapsulantDocumento2 pagineStycast 1264 A/B: Low Viscosity, Transparent, Epoxy EncapsulantRosli YaacobNessuna valutazione finora

- Multiple Choice LachingDocumento3 pagineMultiple Choice Lachingraghu_iict100% (1)

- Gas Processing Fundamentals Manual1Documento12 pagineGas Processing Fundamentals Manual1Ahmed Khamees ShatlaNessuna valutazione finora

- Inventory Price Listing: Sky Pharmaceuticals (PVT) LTDDocumento9 pagineInventory Price Listing: Sky Pharmaceuticals (PVT) LTDOwen F MarimiraNessuna valutazione finora

- The Effects of Different Debittering Methods On The Production of Lupin Bean Snack From BitterDocumento16 pagineThe Effects of Different Debittering Methods On The Production of Lupin Bean Snack From BitterMalak BattahNessuna valutazione finora

- A New Methodology For Determining The Moisture Diffusion Coefficient of Transformer Solid InsulationDocumento4 pagineA New Methodology For Determining The Moisture Diffusion Coefficient of Transformer Solid InsulationabetieNessuna valutazione finora

- Fluidized-Bed Reactors - Kuralay TilegenDocumento16 pagineFluidized-Bed Reactors - Kuralay TilegenKuralay TilegenNessuna valutazione finora

- Electroanalytical Methods: Presented ToDocumento36 pagineElectroanalytical Methods: Presented ToSyed UmairNessuna valutazione finora

- Introduction To TextileDocumento30 pagineIntroduction To Textileumar.niift3049100% (1)

- Surface Water Treatment Operator Certification Manual - Tratamiento de Aguas ResidualesDocumento311 pagineSurface Water Treatment Operator Certification Manual - Tratamiento de Aguas ResidualesJhon Jairo Mazuera GuzmanNessuna valutazione finora

- Guideline For Butt Saddle and Socket FusionDocumento10 pagineGuideline For Butt Saddle and Socket FusionKenNessuna valutazione finora

- Module 02 PHYSICAL SCIENCEDocumento2 pagineModule 02 PHYSICAL SCIENCEJM Robles RemoladoNessuna valutazione finora

- SolidificationDocumento10 pagineSolidificationAnonymous RY3dAWN9o100% (1)

- Kinetics of The Iodination of Acetone PDFDocumento6 pagineKinetics of The Iodination of Acetone PDFsamNessuna valutazione finora

- January - February 2013 - International Aquafeed Magazine - Full EditionDocumento68 pagineJanuary - February 2013 - International Aquafeed Magazine - Full EditionInternational Aquafeed magazineNessuna valutazione finora

- Eimco Colossal Automatic Filter Press (AFP)Documento4 pagineEimco Colossal Automatic Filter Press (AFP)Milan SjausNessuna valutazione finora

- Classics in Chemical Neuroscience: Diazepam (Valium) : Nicholas E. Calcaterra and James C. BarrowDocumento8 pagineClassics in Chemical Neuroscience: Diazepam (Valium) : Nicholas E. Calcaterra and James C. BarrowEga Trikuntianti100% (1)

- MCAT Topic Focus Biology Electrophoresis and Blotting FSQ DrillDocumento1 paginaMCAT Topic Focus Biology Electrophoresis and Blotting FSQ DrillAnjalie GulatiNessuna valutazione finora

- Merck Index Front MatterDocumento14 pagineMerck Index Front MatterCristian Meneguzzi100% (1)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthDa EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthValutazione: 4 su 5 stelle4/5 (59)

- Crazy for the Storm: A Memoir of SurvivalDa EverandCrazy for the Storm: A Memoir of SurvivalValutazione: 3.5 su 5 stelle3.5/5 (217)

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailDa EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailValutazione: 4.5 su 5 stelle4.5/5 (309)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveDa EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNessuna valutazione finora

- Merle's Door: Lessons from a Freethinking DogDa EverandMerle's Door: Lessons from a Freethinking DogValutazione: 4 su 5 stelle4/5 (326)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderDa EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderValutazione: 4 su 5 stelle4/5 (283)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsDa EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNessuna valutazione finora