Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Palmeira 2005

Caricato da

rivai sargawiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Palmeira 2005

Caricato da

rivai sargawiCopyright:

Formati disponibili

GSP 141 International Perspectives on Soil Reinforcement Applications

Geosynthetic Reinforcement for Soft Foundations: Brazilian Perspectives

E.M. Palmeira

University of Brasilia, Department of Civil and Environmental Engineering – Faculty

of Technology, 70910-900 Brasilia, DF, Brazil; Tel.: 55-61-273 7313; Fax: 55-61-

307 3065 or 55-61-273 4644; E-Mail: palmeira@unb.br

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

Abstract

Brazil has large regions of its territory covered with soft soil deposits. Some of these

deposits can be over 40m deep with very low shear strength. These types of

situations pose important challenges for designers and contractors in civil

engineering works. In this context geosynthetics can be effectively employed as

reinforcement and its use has increased markedly in the last decades in the country.

The same applies to the use of prefabricated vertical drains for the acceleration of

soft soil consolidation. This paper presents the Brazilian perspectives on the use of

geosynthetics in such applications. A case-history is also presented and discussed.

Introduction

Soft soil deposits can be challenging materials to work with in geotechnical

engineering. When not properly designed and constructed, embankments on such

soils can fail prematurely or experience large deformations which may damage or

limit the functionality of structures on it. Geosynthetics has been extensively used in

the last decades as reinforcement or as vertical drainage layers for the reinforcement

and stabilization of soft soil deposits under embankments. The presence of

reinforcement layers speeds up the construction process, saves fill material, allows

the use of steeper embankments and reduces differential settlements. Prefabricated

vertical drains accelerate soft soil consolidation, are quicker and easier to transport

and install than traditional granular drains and can be very cost-effective in regions

were granular materials are scarce or have their exploitation limited by environment

protection regulations.

Large and some times very deep deposits of soft soils are common along the

Brazilian territory. These deposits can bring several technical problems to the design

and construction of geotechnical engineering works which may demand very

expensive solutions.

The application of new technologies for the stabilization of embankments on soft soil

has increased significantly in Brazil during the last decades, in particular with regard

to the use of the soil reinforcement technique. Among these techniques the most

popular are the use of geosynthetic reinforcement to improve short term stability of

embankments on soft soils and prefabricated vertical drains for the acceleration of

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

consolidation settlements. This paper presents and discusses design practices

commonly used in Brazil for these types of problems.

Stabilizing Solutions and Design Practices in Brazil

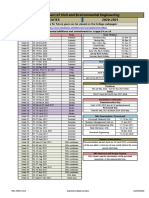

Table 1 summarises some methods for the stabilization or construction of

embankments on soft foundations and their applicability in Brazil. The use of a

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

specific solution, or combinations of solutions, depends on the characteristics of

project, for instance, if large settlements are acceptable or not. Techniques such as

the use of electrosmosis or vacuum to accelerate soft soils consolidation in important

engineering projects are yet inexistent in Brazil to the knowledge of the author, being

restricted to research. Almost the same applies to the use of low weight fill materials,

although some few applications of geofoams have been reported in abutments on soft

soils. The use of stabilising berms is still common when fill material is cheap and

there are no space restrictions to the use of such berms. Piled embankments are

expensive solutions and still restricted to situations where embankment settlements

have to be significantly and immediately reduced, finding applications mainly in

bridge abutments and railways embankments on soft soils (Fahel, 1998, Montez,

2003). Vertical drainage is very common to accelerate consolidation settlements,

with prefabricated vertical drains gaining ground in the last decades in comparison to

the use of traditional sand drains.

The use of geosynthetic as basal reinforcement in Brazil is not yet as wide spread as

in developed countries, but certainly is one of the techniques which has experienced

the most marked increase in usage in the past 15 years. The main limitations for an

even greater increase in its use are associated with the high cost of high strength

reinforcement materials available in the country and the lack of knowledge of old

engineering professionals on the potentials of the solution. The use of geosynthetics

in piled embankments is still very limited compared to the situation in other

countries, although the interest in this type of solution is increasing slowly.

The most common design practices for geosynthetic reinforced embankments on soft

soils in Brazil involve the use of limit equilibrium methods for the determination of

the required tensile strength of the reinforcement for a target overall safety factor for

the embankment. Reduction factors are applied to the reinforcement strength to

account to the effects of creep, mechanical damages, degradation and material

uncertainties. When circular failure surfaces are acceptable, slope stability analysis

methods such as the Modified Bishop and Janbu methods are commonly employed,

particularly the former (Palmeira et al., 1998, Palmeira, 2002). For non circular

failure surfaces, Janbu’s method seems to be the most popular. Solutions based on

design charts such as those by Low et al. (1990) and Milligan and Busbridge (1983)

have also been used. For the analysis of the possibility of soft soil expulsion, limit

equilibrium analysis is also employed. Overall safety factors for the reinforced

embankment range typically from 1.2 to 1.5, depending on the project characteristics.

In general, the use of more sophisticated numerical analyses, based on finite element

or finite difference methods, as design tools is still limited to special situations, and

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

the utilization of computer codes such as PLAXIS and FLAC are very common for

these analyses.

Table 1. Types of solutions for the construction of embankments on soft soils.

Type of solution Usage Cost

Electrosmosis or vacuum Inexistent Very high

Geosynthetic reinforcement Rather common High

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

Low weight fill materials Very rare High

Piled embankments Only in specific situations, like High

bridge abutments

Stabilising berms Common Usually low

Replacement of soft soil Only for shallow depths (< 3m) Usually low

Vertical drainage Very common Average

Federal Regulations or Guidelines

The Brazilian Department of Transportation Infrastructure (DNIT) has established

standards to be followed for the design and construction of embankments on soft

soils in federal highways, including the use of geosynthetics (PRO 380/98 and PRO

381/98, DNIT 1998a and b). The standards PRO 381/98 also prescribes minimum

numbers of laboratory and field tests to be carried out, applicability of construction

solutions, use of geotechnical instrumentation and classifies highway embankments

on soft soils in three categories. Class I embankments are those constructed close to

important existing structures, such as bridges, pipelines, etc. Class II embankments

are those not so close to existing structures but greater than 3m in height. Class III

embankments are those away from existing structures and lower than 3m. The more

expensive and restrictive solutions regarding soft soil stability and deformations are

associated to the construction of classes I and II embankments.

For geosynthetics reinforced embankments PRO 381/98 (DNIT, 1998b) establishes

that the design tensile strength of the reinforcement must be given by

Tref

Td = (1)

f md f env

where Td is the design reinforcement strength, Tref is the reinforcement reference

tensile strength, ƒmd is the reduction factor for mechanical damages and ƒenv is the

reduction factor for degradation of the reinforcement caused by the environment.

The reference tensile strength of the reinforcement is determined dividing the result

obtained in a index tensile test (wide strip tensile tests) by a reduction factor to

account for creep, taking into account the temperature to which the reinforcement

will be subjected, the life time of the project (or the period along which the

reinforcement function will be required) and uncertainties regarding test results

(scatter, extrapolations, etc). Values of ƒmd ranging from 1.1 to 1.7 are prescribed,

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

depending on the type of fill material and reinforcement type and characteristics. A

minimum value of ƒenv of 1.1 must be adopted. Minimum values for the product

ƒmdƒenv in equation 1 must be attended depending on the class of the embankment,

which are: for Class I, ƒmdƒenv 2, for Class II, ƒmdƒenv 1.75 and for Class III,

ƒmdƒenv 1.5.

Regarding the use of geodrains for consolidation acceleration, PRO 381/98 (DNIT,

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

1998b) prescribes the requirements presented in Table 2. The installation of

prefabricated vertical drains must be done with the drain encased to avoid

mechanical damages and the casing must have a cross-section area smaller than 70

cm2 to reduce soft soil disturbance during drain installation. The drains must be

driven through a drainage blanket at the top of the soft soil layer with thickness

greater than 0.3 m which must also allow the traffic of construction vehicles without

compromising its drainage function. Other prescriptions are also presented with

regard to this drainage blanket. For design purposes, depending on the class of the

embankment, the following average percentage of consolidation (U) values are

required before the removal of the surcharge on top of the embankment:

• For Class I embankments: U = 96 %;

• For Class II embankments: U = 90 %;

• For Class III embankments: U = 80%.

Table 2. Requirements for prefabricated drains according PRO-381/98.

Minimum discharge capacity, m3/yr 1000

Minimum tensile strength, kN 2.5

Minimum tensile strain at failure, % 30

Minimum spacing between drains, m 0.9

The standard PRO-380/98 (DNIT, 1998a) deals with minimum required types and

numbers of tests to be performed on geosynthetics for their use in federal highways,

regarding quality control. Tests such as mass per unit area, thickness determination,

wide strip tensile tests, normal permeability and in-plane permeability are required,

depending on the geosynthetic type and function. The tests must be performed by

accredited laboratories and the results may lead to the acceptance or rejection of the

products based on standardised statistical analyses and on the comparison between

test results and products’ data presented in manufacturers’ catalogues.

Case History of Reinforced Embankment on Soft Soil

The BR-101 highway is one of the most important Brazilian highways. During the

last decade works have been taking place for the duplication of this highway, which

is very important for tourist and economical reasons. A large portion of the highway

crosses regions of very soft soil deposits which complicated the construction works,

particularly in river and channel crossings. The case-history presented below shows

the design and performance of reinforced abutments for the crossing of river

Inferninho, in the state of Santa Catarina, south region of Brazil (Fahel, 2003).

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

The crossing of the river Inferninho involved the construction of two reinforced

abutments, referred hereafter as North and South abutments, with total heights equal

to 6m. During construction a 1.5 m high fill surcharge layer was installed to work in

combination with prefabricated vertical drains to compensate for consolidation

settlements. Figures 1(a) and (b) present the geometric characteristics of the

abutments. The duplication of the highway in this region was made with the

extremity of the new embankment resting on the side of the old one. Because uni-

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

axial grid reinforcement was used and the strongest grid direction was orientated

parallel to the embankment axis, the designers used 30 m wide berms along the

embankment side slopes (Fig. 1b) to increase the stability of these slopes. The author

does not know why the designers chose uniaxial grids rather than biaxial ones for

that matter. Perhaps, that decision was due to economic reasons. The tensile strengths

of the geogrid used were 200 kN/m and 15 kN/m, depending on the direction

considered (machine and cross-machine, respectively). Figure 2 shows one of the

geogrid layers being placed in the field. For the reinforcement of the abutments 8

geogrid layers were used with a spacing equal to 0.4 m.

At the time of the construction of the abutments, the construction of the bridge was

in its final stages. Because of that, 18 m berms facing the river were also constructed

(Fig. 1a) to minimise horizontal displacements of the soft soil that might damage the

bridge foundations. The presence of the bridge certainly was another reason for the

designers to orient the strongest reinforcement direction parallel to the abutment axis.

The soft soil deposit in the region consisted of a organic clay with layers and lens of

sand and with a total thickness varying between 12 and 17m. The undrained shear

strength (field vane and CPTU tests) varied through depth between 10 kPa and 40

kPa. CPTU tests yielded values of horizontal consolidation coefficient ranging from

334 m2/yr to 1278 m2/yr. The fill material used in the reinforced zone of the

abutments was a coarse sand with dry unit weight of 15.5 kN/m3 and friction angle of

33o. Above the reinforced zone the fill material consisted of a mixture of rock

elements, sand and clay.

Prefabricated vertical drains were installed to accelerate consolidation settlements.

The drains had cross section dimensions of 5 mm by 100 mm, with a rather rigid

plastic core encased by a nonwoven geotextile. The spacing between vertical drains

used was equal to 1.3 m. A drainage blanket 0.4m thick was placed at the base of the

embankments.

Eight layers of a uniaxial geogrid reinforcement were used to reinforce the

abutments. The characteristics of the geogrid are presented in Table 3. The spacing

between reinforcement layers was equal to 0.4m. The strongest reinforcement

direction was oriented along the abutment axis.

Field instrumentation of the embankments consisted of vibrating wire and

Casagrande piezometers, inclinometers, magnetic extensometers, settlement plates, a

full profile settlement gauge (horizontal inclinometer) and vibrating wire strain

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

meters in the reinforcement layers. Figure 3 shows the location of the instruments

used.

8 layers of geogrid, 30 m long, spacing L

C

equal to 0.4m

bridge

fill 1.5

6.0 m 1 18

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

0.4 soft clay

17.0

soft clay

prefabricated vertical drains soft clay

(a) Cross-section parallel to the abutment axis

surcharge existing embankment

new embankment

18 3.0 18

reinforcement

1,5

berm 1.5

30 1 1.5

1 6.0

3.0

? ? ? ? ?

0.4

5.0

soft clay

17.0

soft clay

4.0

vertical drains (spacing equal to 1.3 m)

Dimensions in meters

(b) Cross-section normal to the abutment axis.

Figure 1. Geometrical characteristics of the reinforced abutments.

Table 3. Reinforcement characteristics

Mass per unit area (g/m2) 775

Tensile strength (wide strip tests), kN/m 200 / 15(*)

Maximum tensile strain, % 12

Tensile stiffness (wide strip tests), kN/m 1800

(*) Machine and cross-machine directions, respectively.

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

Figure 2. Installation of a geogrid layer in the field.

existing highway

Florianópolis

R12 R9 Tijucas

C3 I3 R6 R3

Inferninho river

I1 R5 R2

P1

R7 R4 R1

P1 a P4 R10

C2 I2 C1

South

I4 15 5 5 15 North

abutment

abutment

berm berm

I2 - inclinometer full profile settlement gauge

P4 - piezometer C1- Casagrande piezometer

R3 - settlement plate

Figure 3. Instrumentation of the case-history.

Figures 4(a) and (b) show the horizontal displacements measured by inclinometers I3

and I4 in the South abutment. Inclinometer I3 was installed in the slope facing the

river, while inclinometer I4 was installed at the lateral slope (Fig. 3). It can be noted

that the horizontal displacements of the soft foundation towards the river (I3) were

considerable smaller than those observed along the direction normal to the abutment

axis (I4). The smaller values of horizontal displacements measured by inclinometer

I3 can be a consequence of the combined effects due to the presence of the 18 m

wide berm facing the river and of the greater reinforcement stiffness along the axis

direction. The greater berm width (30 m) along the lateral slopes was not sufficient to

reduce the horizontal displacements normal to the abutment axis to as much as those

observed along the axis direction. It is believed that the reinforcement layers

influenced little the displacements along the direction normal to the abutment axis

because of their length and stiffness along that direction.

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

The horizontal movements of the abutments caused cracks along the border of the

existing highway pavement, as shown in Figure 5.

Parametric Study by the Finite Element Method

The results in Figure 4 suggest that the presence of the reinforcement may have

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

another beneficial effect which is the reduction of the horizontal displacements of the

soft foundation. Indeed, numerical analyses also predict this type of benefit brought

by the use of basal reinforcement in embankments on soft soils. Figure 6 shows the

geometrical characteristics of a numerical analyses on an hypothetical situation using

the computer code PLAXIS (Brinkgreve and Vermeer, 1998) to investigate the

influence of the construction of an embankment on soft soil close to the foundations

of an existing structure (Macedo, 2002). Table 4 summarises the properties of the

soil layers used in the parametric study. The reinforcement layers were modelled

using the “geotextile element” present in the computer code employed.

abutment height (m)

0

4.2 0

4 1.8

2

8

Depth (m)

4

Depth (m)

3.5

12 6 2.4

16 8

abutment height (m)

20 10

24 12

-2 0 2 4 6 0 5 10 15 20 25

Horizontal displacements (cm) Horizontal displacements (cm)

(a) Inclinometer I3 (b) Inclinometer I4

Figure 4. Horizontal displacements along depth measured by inclinometers I3 and I4.

Figure 7 shows the variation of maximum horizontal displacements ( hmax) predicted

in the piles as a function of reinforcement stiffness (J) for varying distances (d) of the

piles to the embankment toe (Fig. 6). It can be observed that the numerical analyses

predicted significantly smaller horizontal displacements of the piles in reinforced

embankments in comparison to the unreinforced case (J = 0 in Figure 7). It can also

be observed that the influence of the reinforcement decreases as d increases, although

the proximity of the piles to the embankment toe also influences the mobilized

horizontal displacements of the soft soil. These results corroborate field observations

such as the one presented in the case history presented above. Additional numerical

analyses showed even greater horizontal displacement reductions when vertical

drains were combined with basal reinforcement of the embankment (Macedo, 2002).

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

Figure 5. Cracks along theborder of the existing pavement.

neighbouring structure

reinforcement

Aterro

fill d

Reforço

soft soilSolo Mole

Figure 6. Geometrical characteristics and finite element mesh used in the

numerical analyses (Macedo, 2002).

Table 4. Soil properties used in the numerical analysis.

Property Material

Soft soil Fill

Soil unit weight, , kN/m3 13 19

Permeability coefficient, k, m/day 0.001 1

Young modulus, E', kPa 1730 15000

Poisson ratio, ' 0.3 0.3

Shear modulus, G', kPa 665 5769

Cohesion, c', kPa 5 1

Friction angle, ', degrees 25 30

Dilatancy angle, , degrees 0 0

Earth pressure coefficient at rest 0.57 0.5

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

0.8

d

0.6

(m)

0.4

hmax

0.2

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

0

0 1000 2000 3000 4000 5000 6000

J (kN/m)

d=1m d=3m d=6m

Figure 7. Maximum horizontal displacements in the pile.

Conclusions

This paper presented and discussed the Brazilian perspectives regarding the

geosynthetic reinforcement of embankments on soft soils. A case history describing

the performance of a geogrid reinforced abutment was also presented. An analysis of

the current trends in the design and construction of such works suggest that, in spite

of the still usefulness of limit equilibrium methods for routine works, in the coming

years better design methodologies will be pursued, with emphasis to the application

of more powerful numerical tools. The performance of the case history presented

suggests that geosynthetic reinforcement, particularly when combined with vertical

drains, can promote significant reductions of horizontal deformations in the soft

foundation soil. This is particularly relevant when there are structures close to the

embankment to be built (bridge abutments, for instance). In these cases, the

beneficial effects of the reinforcement in reducing soft soil deformation can only be

predicted with more powerful numerical tools.

An increase in the use of geosynthetics in combination with piles in situations where

low settlements are required it is also expected to occur. The presence of the

reinforcement improves arching mechanisms in the fill, reducing settlements of the

embankment surface and allowing the use of a larger spacing between piles.

It is also believed that in the near future regulatory procedures and guidelines

enforced by state or federal agencies will be implemented on a wider basis for the

design and construction of embankments on soft soils and quality control of

geosynthetic products to be employed in this type of work.

References

Brinkgreve, R.B.J. and Vermeer, P.A. (1998). PLAXIS: a finite element code for soil

and rock analyses – version 7. A.A. Balkema, The Netherlands.

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

GSP 141 International Perspectives on Soil Reinforcement Applications

DNIT (1998a). PRO 380/98 – Utilisation of geosynthetics in highways. National

Department of Transportation Infrastructure, Brazil, 9 p.

DNIT (1998b). PRO 381/98 – Design of embankments on soft soils for highways.

National Department of Transportation Infrastructure, Brazil, 37 p.

Fahel, A.R.S. (1998). Instability and construction problems in geosynthetic

reinforced works. MSc. Thesis, University of Brasilia, Brasilia, DF, Brazil (in

Portuguese), 117 p.

Downloaded from ascelibrary.org by Kungliga Tekniska Hogskola on 01/28/16. Copyright ASCE. For personal use only; all rights reserved.

Fahel, A.R.S. (2003). The performance of geogrid reinforced bridge abutments on

soft soils. DSc. Thesis, University of Brasilia, Brasilia, DF, Brazil (in

Portuguese), 247 p.

Low, B.K., Wong, H.S. Lim, C. and Broms, B.B. (1990). Slip circle analysis of

reinforced embankments on soft ground. Geotextiles and Geomembranes,

9(2), 165-181.

Macedo, I.L. (2002). Numerical analyses of geosynthetic reinforced abutments on

soft soils. MSc. Thesis, University of Brasilia, Brasilia, DF, Brazil (in

Portuguese), 194 p.

Milligan, V. and Busbridge, J.R. (1983). Guidelines for the use of Tensar in

reinforcement of fills over weak foundations. Golder Associates report to the

Tensar Corp., Ontario.

Montez, F.T. (2003). Personal communication.

Palmeira, E.M. (2002). Embankments. Book on Geosynthetics and Their

Applications, S.K. Shukla Ed., Thomas Telford, UK, p. 95-124.

Palmeira, E.M., Pereira, J.H.F. and Silva, A.R.L. (1998). Backanalyses of

geosynthetic reinforced embankments on soft soils. Geotextiles and

Geomembranes, 16(5), 274-292.

Copyright ASCE 2005 Soil Reinforcement Applications

International Perspectives on Soil Reinforcement Applications

Potrebbero piacerti anche

- 99 - Structural Design For Eccentric Loading of Footing PDFDocumento5 pagine99 - Structural Design For Eccentric Loading of Footing PDFsanthosh kpNessuna valutazione finora

- Design of JoistDocumento26 pagineDesign of Joistallen2912Nessuna valutazione finora

- Timber DesignDocumento36 pagineTimber DesignKristine May Maturan100% (1)

- Four Point BendingDocumento307 pagineFour Point BendingFathia AlkelaeNessuna valutazione finora

- Analysis Methods For Fatigue of Welds: Jeff Mentley HBM - Ncode ProductsDocumento52 pagineAnalysis Methods For Fatigue of Welds: Jeff Mentley HBM - Ncode ProductsEvelin StefanovNessuna valutazione finora

- Evaluation and Analysis of Soil Stabilization With Some Non Conventional Additives IJERTV9IS070265Documento8 pagineEvaluation and Analysis of Soil Stabilization With Some Non Conventional Additives IJERTV9IS070265slv buildersNessuna valutazione finora

- Solid MechanicsDocumento461 pagineSolid MechanicsVinit AhluwaliaNessuna valutazione finora

- SAP2000 Presentation 200428 Solid ElementDocumento23 pagineSAP2000 Presentation 200428 Solid ElementCSEC Uganda Ltd.100% (2)

- Science Grade 8 TosDocumento1 paginaScience Grade 8 TosChristyRubioMillena78% (9)

- Control of CrackingDocumento29 pagineControl of CrackingMohd Sulahuddin RamlyNessuna valutazione finora

- Geosynthetics - ConstrofacilitatorDocumento20 pagineGeosynthetics - ConstrofacilitatorConstro FacilitatorNessuna valutazione finora

- A Non-Linear Continuous Fatigue DamageDocumento17 pagineA Non-Linear Continuous Fatigue DamageMaroua MahouachiNessuna valutazione finora

- EXPERIMENT: Tensile Test: AIM: To Determine The Tensile Strength and The Elongation at FractureDocumento4 pagineEXPERIMENT: Tensile Test: AIM: To Determine The Tensile Strength and The Elongation at FractureSafran Mohomed100% (1)

- Application of Geosynthetics For Ground Improvement An Overview PDFDocumento4 pagineApplication of Geosynthetics For Ground Improvement An Overview PDFIkhsan Jati KertapernataNessuna valutazione finora

- A.M. Gresnigt Plastic Design of Buried Pipelines in Settlement Areas PDFDocumento115 pagineA.M. Gresnigt Plastic Design of Buried Pipelines in Settlement Areas PDFEnrique Rodulfo GómezNessuna valutazione finora

- Experimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFDocumento7 pagineExperimental Study of Geotextile Effect On Improving Soil Bearing Capacity in Aggregate Surfaced Roads PDFmojeebmashalNessuna valutazione finora

- Dafalla Et Al 2011 Design Guide For Rigid Foundation Systems On Expansive SoilsDocumento9 pagineDafalla Et Al 2011 Design Guide For Rigid Foundation Systems On Expansive SoilsxfvgNessuna valutazione finora

- Experimental and Numerical Studies On Geotextile Reinforced Subgrade SoilDocumento14 pagineExperimental and Numerical Studies On Geotextile Reinforced Subgrade SoilweeerieNessuna valutazione finora

- A Review On The Design Applications and NumericalDocumento24 pagineA Review On The Design Applications and NumericalJanaki RamNessuna valutazione finora

- Monitoring Performance of Geosynthetic-Reinforced and Lime-Treated Low-Volume Roads Under Traffic Loading and Environmental ConditionsDocumento10 pagineMonitoring Performance of Geosynthetic-Reinforced and Lime-Treated Low-Volume Roads Under Traffic Loading and Environmental ConditionsAzer LotfiNessuna valutazione finora

- Almeida Et Al. (2023) (SR) Ground Improvement Techniques Applied To Very Soft Clays State of Knowledge and Recent AdvancesDocumento32 pagineAlmeida Et Al. (2023) (SR) Ground Improvement Techniques Applied To Very Soft Clays State of Knowledge and Recent AdvancesandreasgavrasNessuna valutazione finora

- Group 7Documento6 pagineGroup 7Ann Gabrielle SuarezNessuna valutazione finora

- No. Yea R Researcher /author Title Needs Solution Differentiation Benefits 1Documento5 pagineNo. Yea R Researcher /author Title Needs Solution Differentiation Benefits 1Cole Jade DayoNessuna valutazione finora

- Adams 1997Documento7 pagineAdams 1997badisnoveNessuna valutazione finora

- Use of Bamboo in Soft Ground Engineering-2 PDFDocumento9 pagineUse of Bamboo in Soft Ground Engineering-2 PDFAlexandru BratuNessuna valutazione finora

- NitishDocumento19 pagineNitishMujeeb Ul RehmanNessuna valutazione finora

- (Asce) GT 1943-5606 0002836Documento19 pagine(Asce) GT 1943-5606 0002836Raiane MachadoNessuna valutazione finora

- 1 s2.0 S0266352X14002328 MainDocumento11 pagine1 s2.0 S0266352X14002328 MainYOGESH KUMAR SHARMANessuna valutazione finora

- Effect of Geosynthetic Reinforcement Creep On The Long Term Performance of An EmbankmentDocumento10 pagineEffect of Geosynthetic Reinforcement Creep On The Long Term Performance of An EmbankmentQUAMAR TABISHNessuna valutazione finora

- Effect of Bamboo Grid and Geonet On ClayDocumento5 pagineEffect of Bamboo Grid and Geonet On ClayEko Indra WatiNessuna valutazione finora

- Clay Reinforcement Using Geogrid Embedded in Thin Layers of SandDocumento12 pagineClay Reinforcement Using Geogrid Embedded in Thin Layers of SandMalik RizwanNessuna valutazione finora

- Design ProjectDocumento26 pagineDesign ProjectNayana RNessuna valutazione finora

- Elongationfactoringeosynthetics Proc Slope 2015Documento8 pagineElongationfactoringeosynthetics Proc Slope 2015dm IqbalNessuna valutazione finora

- Diagnóstico e Tratamento de Patologias em Pavimentos FlexíveisDocumento1 paginaDiagnóstico e Tratamento de Patologias em Pavimentos FlexíveisRita de Cássia LimaNessuna valutazione finora

- Zhang Et Al 2022 3d Numerical Analysis of A Single Footing On Soft Soil Reinforced by Rigid InclusionsDocumento13 pagineZhang Et Al 2022 3d Numerical Analysis of A Single Footing On Soft Soil Reinforced by Rigid InclusionsxfvgNessuna valutazione finora

- Soil Sub Grade Improvement Using Human Hair FiberDocumento5 pagineSoil Sub Grade Improvement Using Human Hair FiberNarendra maddulurNessuna valutazione finora

- Sand Column: International Research Journal of Engineering and Technology (IRJET)Documento9 pagineSand Column: International Research Journal of Engineering and Technology (IRJET)Dhanya Kumar 4PA19EC003Nessuna valutazione finora

- Compaction and Volume Change Behavior of Embankment Soil: Gamiller@ou - EduDocumento19 pagineCompaction and Volume Change Behavior of Embankment Soil: Gamiller@ou - EduarifinpgsNessuna valutazione finora

- Geosynthetics in Pavements: North American ContributionsDocumento20 pagineGeosynthetics in Pavements: North American ContributionsmercedesNessuna valutazione finora

- Reinforcement NigerianDocumento15 pagineReinforcement NigeriananjamNessuna valutazione finora

- 6 Thigs Final Paper To SubmitDocumento5 pagine6 Thigs Final Paper To SubmitBitbitterNessuna valutazione finora

- Clay Reinforcement Using Geogrid Embedded in Thin Layers of Sand PDFDocumento12 pagineClay Reinforcement Using Geogrid Embedded in Thin Layers of Sand PDFThãshñêëShävNessuna valutazione finora

- Sustainability 14 09275 v2Documento21 pagineSustainability 14 09275 v2Lovely Joy BarronNessuna valutazione finora

- 29mt 1943-5533 0002476Documento13 pagine29mt 1943-5533 0002476Angelo Anthony AllenaNessuna valutazione finora

- RamjiramThakur2021 Article ImprovementInCBRValueOfSoilReiDocumento10 pagineRamjiramThakur2021 Article ImprovementInCBRValueOfSoilReiB Divya jyothiNessuna valutazione finora

- Review On Geotextiles in Road ConstructionDocumento4 pagineReview On Geotextiles in Road ConstructionRam TulasiNessuna valutazione finora

- Mohammed Hamud 2019 IOP Conf. Ser. Earth Environ. Sci. 357 012038Documento18 pagineMohammed Hamud 2019 IOP Conf. Ser. Earth Environ. Sci. 357 012038Dhanu SekarjatiNessuna valutazione finora

- DB Mam Paper 1Documento13 pagineDB Mam Paper 12020CEM009 QUAMARTABISHNessuna valutazione finora

- DownloadDocumento12 pagineDownloadsamithaNessuna valutazione finora

- 3D FE Analysis of Flexible Pavement With Geosynthetic ReinforcementDocumento14 pagine3D FE Analysis of Flexible Pavement With Geosynthetic ReinforcementVgkBharadwajNessuna valutazione finora

- PTC PosterDocumento1 paginaPTC PosterMicaiah HendricksNessuna valutazione finora

- Geosynthetic S:-Its Recent Advancement S& Application: by Karamjeet ChahalDocumento12 pagineGeosynthetic S:-Its Recent Advancement S& Application: by Karamjeet ChahalSudip GhimireNessuna valutazione finora

- Behavior of Structures With BasementsDocumento13 pagineBehavior of Structures With BasementsAlly TNessuna valutazione finora

- Silo - Tips Case Studies On The Usage of Geosynthetics in Earthen Dams and EmbankmentsDocumento6 pagineSilo - Tips Case Studies On The Usage of Geosynthetics in Earthen Dams and Embankmentsrf123_456Nessuna valutazione finora

- UseofGeotextilesinRoadsOverWeak LNCE Springer V137Documento10 pagineUseofGeotextilesinRoadsOverWeak LNCE Springer V137Sultan AlfaqeehNessuna valutazione finora

- 10 1016@j Jestch 2019 12 006Documento9 pagine10 1016@j Jestch 2019 12 006Jungle BookNessuna valutazione finora

- IJEAS0303031Documento6 pagineIJEAS0303031erpublicationNessuna valutazione finora

- 2 Experimental Study On Uplift Behavior of Shallow Anchor PlatesDocumento10 pagine2 Experimental Study On Uplift Behavior of Shallow Anchor PlatesAna Sofía Arango BermúdezNessuna valutazione finora

- Laboratory Studies On Geotextile Reinfo PDFDocumento4 pagineLaboratory Studies On Geotextile Reinfo PDFAbdullah MansoorNessuna valutazione finora

- Ground Treatment/Improvement Ground Treatment/Improvement: Materials Existing orDocumento8 pagineGround Treatment/Improvement Ground Treatment/Improvement: Materials Existing orShahzada PhookNessuna valutazione finora

- Geosynthetics Types and ApplicationsDocumento50 pagineGeosynthetics Types and Applicationscivil vlits100% (1)

- 1 s2.0 S0266114419300974 MainDocumento11 pagine1 s2.0 S0266114419300974 MainAswin R CNessuna valutazione finora

- Dessouky, 2015, Pavement Repairs Long-Term Performance Over Expansive SoilDocumento8 pagineDessouky, 2015, Pavement Repairs Long-Term Performance Over Expansive SoilChristopher TanjungNessuna valutazione finora

- Mechanism of Geocell Reinforcement-Formatted PaperDocumento4 pagineMechanism of Geocell Reinforcement-Formatted PaperMohd Sulahuddin RamlyNessuna valutazione finora

- Physical and Mechanical Characterization of Fresh Bamboo For Infrastructure ProjectsDocumento10 paginePhysical and Mechanical Characterization of Fresh Bamboo For Infrastructure ProjectsLuanna Silva de Pires Campos AlvesNessuna valutazione finora

- Institutional Affiliation Student's Name Course Title Due DateDocumento12 pagineInstitutional Affiliation Student's Name Course Title Due DatebrianNessuna valutazione finora

- Terra Ex MachinaDocumento1 paginaTerra Ex MachinaKenneth WilsonNessuna valutazione finora

- Blue Green Illustrative Presentation Skills Infographic PosterDocumento1 paginaBlue Green Illustrative Presentation Skills Infographic Posterpriyaah23Nessuna valutazione finora

- A Review On Effects of Stabilizing AgentsDocumento7 pagineA Review On Effects of Stabilizing AgentsGabriel SalgadoNessuna valutazione finora

- New Ground Improvement Technologies Under Restricted Conditions in JapanDocumento6 pagineNew Ground Improvement Technologies Under Restricted Conditions in JapanEdgar AguilarNessuna valutazione finora

- Paper-Sand Cemented GroutDocumento8 paginePaper-Sand Cemented GroutSajid IqbalNessuna valutazione finora

- CEE 586 - Rock Mechanics & Behavior: Course SyllabusDocumento3 pagineCEE 586 - Rock Mechanics & Behavior: Course Syllabusrivai sargawiNessuna valutazione finora

- 2020 2021 Useful Dates MScWebPagesDocumento1 pagina2020 2021 Useful Dates MScWebPagesrivai sargawiNessuna valutazione finora

- International Society For Soil Mechanics and Geotechnical EngineeringDocumento12 pagineInternational Society For Soil Mechanics and Geotechnical Engineeringrivai sargawiNessuna valutazione finora

- 2020 2021 Useful Dates MScWebPagesDocumento1 pagina2020 2021 Useful Dates MScWebPagesrivai sargawiNessuna valutazione finora

- International Society For Soil Mechanics and Geotechnical EngineeringDocumento12 pagineInternational Society For Soil Mechanics and Geotechnical Engineeringrivai sargawiNessuna valutazione finora

- Reinforcement With GeosyntheticsDocumento7 pagineReinforcement With GeosyntheticsFarhanNessuna valutazione finora

- Reinforcement With GeosyntheticsDocumento7 pagineReinforcement With GeosyntheticsFarhanNessuna valutazione finora

- CEE 586 - Rock Mechanics & Behavior: Course SyllabusDocumento3 pagineCEE 586 - Rock Mechanics & Behavior: Course Syllabusrivai sargawiNessuna valutazione finora

- Load Testing Reg FormDocumento2 pagineLoad Testing Reg Formrivai sargawiNessuna valutazione finora

- Reinforcement With GeosyntheticsDocumento7 pagineReinforcement With GeosyntheticsFarhanNessuna valutazione finora

- Reinforcement With User DefinedDocumento8 pagineReinforcement With User Definedrivai sargawiNessuna valutazione finora

- Stabilization of Rock Slopes: 6, ChapterDocumento31 pagineStabilization of Rock Slopes: 6, Chapterrivai sargawiNessuna valutazione finora

- Load Testing Reg FormDocumento2 pagineLoad Testing Reg Formrivai sargawiNessuna valutazione finora

- PITCSL TIP Webinar RegistrationDocumento2 paginePITCSL TIP Webinar Registrationrivai sargawiNessuna valutazione finora

- Chow1996 PDFDocumento12 pagineChow1996 PDFrivai sargawiNessuna valutazione finora

- Won2005 PDFDocumento12 pagineWon2005 PDFrivai sargawiNessuna valutazione finora

- Displacement - Based Seismic Stability Analyses of Reinforced and Unreinforced Slopes Using Planar Failure SurfacesDocumento10 pagineDisplacement - Based Seismic Stability Analyses of Reinforced and Unreinforced Slopes Using Planar Failure Surfacesrivai sargawiNessuna valutazione finora

- PITCSL TIP Webinar RegistrationDocumento2 paginePITCSL TIP Webinar Registrationrivai sargawiNessuna valutazione finora

- Design of 20 M Deep Excavation With Permanent AnchoredDocumento10 pagineDesign of 20 M Deep Excavation With Permanent Anchoredadiccto87Nessuna valutazione finora

- Hassiotis 1997Documento10 pagineHassiotis 1997rivai sargawiNessuna valutazione finora

- Gao 2015Documento17 pagineGao 2015rivai sargawiNessuna valutazione finora

- Esser2007 PDFDocumento11 pagineEsser2007 PDFrivai sargawiNessuna valutazione finora

- Midas Dia 1000mDocumento5 pagineMidas Dia 1000mrivai sargawiNessuna valutazione finora

- Goh2003 PDFDocumento4 pagineGoh2003 PDFrivai sargawiNessuna valutazione finora

- Bruggers 2011Documento10 pagineBruggers 2011rivai sargawiNessuna valutazione finora

- 126 198 1 SMDocumento14 pagine126 198 1 SMrivai sargawiNessuna valutazione finora

- Diyaljee 2000Documento12 pagineDiyaljee 2000rivai sargawiNessuna valutazione finora

- Diyaljee 2014Documento15 pagineDiyaljee 2014rivai sargawiNessuna valutazione finora

- Bonzanigo 2007Documento24 pagineBonzanigo 2007rivai sargawiNessuna valutazione finora

- Aaron 2017Documento10 pagineAaron 2017rivai sargawiNessuna valutazione finora

- MIT Physics Mechanics Notes Chapter26 Elastic Properties of Materials v10Documento11 pagineMIT Physics Mechanics Notes Chapter26 Elastic Properties of Materials v10Andrew ZhighalovNessuna valutazione finora

- Dissertation2007 Asinari PDFDocumento177 pagineDissertation2007 Asinari PDFLou Melvin CruzNessuna valutazione finora

- Testing Concrete ConstructionDocumento10 pagineTesting Concrete ConstructionKaye Ibañez CastilloNessuna valutazione finora

- PAS Kelas X - BDocumento1 paginaPAS Kelas X - BArif Raya HarahapNessuna valutazione finora

- Hysteresis Model For Reinforced Concrete MembersDocumento7 pagineHysteresis Model For Reinforced Concrete MembersJohnFiftyFiveNessuna valutazione finora

- Aci 5501R-01Documento16 pagineAci 5501R-01JoseagushNessuna valutazione finora

- Gravity Loads and Structural Forms PDFDocumento34 pagineGravity Loads and Structural Forms PDFyashavant patilNessuna valutazione finora

- Timber Columns: A. Axially Loaded ColumnsDocumento2 pagineTimber Columns: A. Axially Loaded ColumnsClarenz BragaNessuna valutazione finora

- Ductility by ChinnarajuDocumento76 pagineDuctility by ChinnarajuRamen KishoreNessuna valutazione finora

- Shear Strength of Brazed and Soldered JointsDocumento5 pagineShear Strength of Brazed and Soldered JointsseenudesignNessuna valutazione finora

- 26may2014 1Documento16 pagine26may2014 1Desai NileshNessuna valutazione finora

- Comparison Between UBC-IBC CodesDocumento50 pagineComparison Between UBC-IBC CodesAshraf ZayedNessuna valutazione finora

- Effect of Pile Diameter On Modulus of Sub-Grade ReactionDocumento354 pagineEffect of Pile Diameter On Modulus of Sub-Grade ReactionShang Feng Liu100% (1)

- 4 Partial Loss of PrestressDocumento51 pagine4 Partial Loss of Prestresslester john bacudioNessuna valutazione finora

- RF PDFDocumento21 pagineRF PDFAndres Barra SalauesNessuna valutazione finora

- Pino PDFDocumento1 paginaPino PDFENessuna valutazione finora

- Goodno Mechanics of Materials BooksDocumento3 pagineGoodno Mechanics of Materials BooksMichael0% (1)

- Tema IV.1 - Earth Pressure at RestDocumento21 pagineTema IV.1 - Earth Pressure at RestEduardo Alemany PerretNessuna valutazione finora