Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process-Based Auditing - ASQ

Caricato da

Selvaraj SimiyonDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process-Based Auditing - ASQ

Caricato da

Selvaraj SimiyonCopyright:

Formati disponibili

Process-based Auditing

Dennis R. Arter

The Audit Guy

Columbia Audit Resources

Kennewick, WA, USA, 99336

dennis@auditguy.net

Summary

Process-based auditing is a new name for an old topic. It requires an in-depth understanding of

the business and control processes of the organization before the audit starts. It requires

performance data from the activities being audited. Audit results must be presented in a form that

promotes continual improvement. These are not new concepts.

Before an audit starts, audit team members must first map and then understand the business,

production, and control processes within the scope of the audit. They prepare individual (and

unique) work papers to define audit criteria and objective evidence needs. Then they gather

evidence through observations, interviews, and examinations. The data are assembled into

findings, such that stakeholders have a desire to change deficiencies and continue good practices.

Keywords

Audit, process, improvement

Audits provide information for decisions

To audit is to compare gathered evidence to established requirements. The observations, both

good and bad, are analyzed to form findings or positive practices. The sum of the information is

further analyzed to form conclusions that stakeholders can use for making decisions. Thus, the

purpose of any audit is to assist decision-makers in managing the enterprise.

Rather than examine the operations to artificial criteria, such as document control or instrument

calibration, auditors may assist the operations by examining business processes and how they are

controlled. This requires seven steps.

Step 1: What do they make?

Every organization produces a product. In order to evaluate the controls used to make the

product, the auditor must first know about the product. This is not just for manufacturing

operations. Product actually comes in four forms: (Reference 1)

1. Tangible manufactured goods, such as autos and appliances

2. Tangible processed items, such as pharmaceuticals, plastics, and puppy chow

3. Software instructions for computers to use

4. Service activities, such as loaning and laundering

The first step is to define the goods and services provided by the organization to be audited. This

is usually fewer than a half-dozen things.

Step 2: How do they make it?

A product is the result of one or more processes. (Reference 1) The auditor must identify the

various process steps used to make the product. A simple list of steps can suffice. Many auditors

find the flowchart to be a useful tool. Try to diagram the process steps on a single sheet of paper,

using eight to ten boxes. Keep it simple. Each box of the flowchart should start with a verb, to

emphasize the transformation of inputs into outputs. String several processes together and you

have a system.

Step 3: Understand the processes

There are three ways of examining processes for deeper understanding. The first is the simple

four-box model: Inputs, outputs, controls, and resources make up the boxes. This is an elegant

model and quite useful in getting the various process parameters defined. Unfortunately, it also

depends upon the memory of the individual doing the analysis. Important aspects could be

forgotten. The second model for analyzing processes leaves less to memory. This model

examines the six universal process affecters, initially captured by Ishikawa (Reference 2) and

used in the fishbone diagram approach to problem solving. These six affecters are:

1. Methods. These are the instructions we provide for the task. They are often called

documents.

2. Material. There are the things used by the process.

3. Manpower (and womanpower!). These are the human competencies needed for the task.

4. Measurement. These are the data taken on the process and their use.

5. Machinery. This is the equipment used to perform the action.

6. Environment. These are the outside influences on the process.

Manpower Machinery

Material Process

Process Methods

Environment Measurement

Figure 1: Universal Process Affecters

Using this second model, the six affecters, can be quite complex. The auditor could spend days

in examining all the affecters in all the processes to be audited.

Fortunately, there is a third model, which combines the simplicity of the four-boxes and the

thoroughness of the process affecters. This third model is often called the turtle diagram because

it looks (somewhat) like a turtle. The turtle diagram has six boxes for each process:

1. Inputs (List the things coming into the process.)

2. Outputs (What has changed and is being passed on to another process?)

3. With What (What are the materials and equipment used by the process?)

4. With whom (What are the people requirements for this process?)

5. How (What are the supporting processes and methods used for the transformation?)

6. What results (What are the performance indicators for the process?)

With What? With Whom?

(Materials & Equipment) (Competence, Skills, Training)

Inputs Outputs

Process

How? What Results?

(Support Processes, (Performance Indicators)

Procedures & Methods)

Source: AIAG 2003

Figure 2. The Turtle Diagram

Step 4: Define objective evidence needs

Every audit requires a set of work papers to assist in data gathering. These are the tools to guide

the auditor in obtaining necessary facts while performing the audit. They should be objective and

based on the requirements defined in step 3 (turtle diagram) above. A typical quality

management system audit will use 30-40 pages of checklist questions. While it is fine to start

from a common base, the final list should reflect the specific processes being examined. They

should include questions drawn from external requirements, high-level internal requirements,

process specific procedural requirements, and product specific specifications.

Step 5: Gather objective evidence

This is the performance phase of the audit. (References 3 and 4) After a brief opening meeting,

the auditor collects five kinds of information:

• Physical evidence, such as size, shape, color, and temperature

• Sensory evidence, from sight, sound, smell, and sometimes even taste

• Paperwork, including both documents (before the activity) and records (after the activity)

• Interviews, obtained by talking to people in their work areas

• Patterns, including percentages, trends and ratios

The auditor will normally obtain this evidence through the use of tracing, a technique of

following the actions (processes) from step to step. All this information is captured in the work

papers, which act as auditor’s field notes.

Step 6: Analyze data by sorting

Now, the auditor must review the field notes and identify observations. These are the facts

gathered during the course of the audit. They may be good (requirement was met) or bad

(requirement was not met). Make a master list of good facts and bad facts. Once the master list is

made, sorting the data by problems and strengths. This is classic data chunking. Stack the bad

facts on top of the related problem. Stack the good facts on top of the related strength. Amazing

as it seems, there will always be one or two piles bigger than the rest. Ignore the small piles and

focus on the big ones.

Turn the piles upside-down and you have a finding or a positive practice. These are statements

about the system weaknesses or strengths, supported by examples. (Reference 5) Placed on a

single sheet of paper, they are called finding sheets (or positive practice sheets).

Step 7: Present your conclusions

Examine all the findings and positive practices, along with sights and sounds of the entire audit

experience, to develop an overall conclusion. This is a one or two paragraph summary of the

audit experience. Are processes defined and in control? Are operations safe and within

regulatory boundaries? Are external and internal customer needs being met? Findings, positive

practices, and conclusions are presented at the closing meeting and formally captured in the audit

report.

Conclusion

There are seven steps in the process approach to auditing:

1. Define the products

2. Define the processes used to make those products

3. Analyze and understand those processes

4. Develop objective evidence needs to explore the processes

5. Gather field data during the actual audit

6. Analyze the gathered data by sorting into piles

7. Present the information to the process owners

In order to use the process approach, the auditor must first understand how the business

processes relate to the objectives of the enterprise. Then data are gathered to see how these

processes are being controlled. Finally, conclusions must show how the identified strengths and

weaknesses affect the operation of the business.

References

1. ANSI/ISO/ASQ Q9000-2000, Quality management systems-Fundamentals and vocabulary,

2000, ASQ Quality Press, Milwaukee

2. Ishikawa, Kaoru, Guide to Quality Control, 1992, Quality Resources, White Plains, NY

3. Arter, Dennis, Quality Audits for Improved Performance, 3rd ed., 2003, ASQ Quality Press,

Milwaukee

4. Arter, Dennis, Auditorías de Calidad para Mejorar La Productividad, Tercera Edición, 2003,

ASQ Quality Press, Milwaukee

5. Arter, Dennis, et. al., How to Audit the Process-Based QMS, 2003, ASQ Quality Press,

Milwaukee

Potrebbero piacerti anche

- The Auditor 117 - 1975: It's A Good Thing They TurnedDocumento7 pagineThe Auditor 117 - 1975: It's A Good Thing They TurnedAndreas GroßNessuna valutazione finora

- EN BO Scientology Training Course Manual 1957 Comm Course PDFDocumento25 pagineEN BO Scientology Training Course Manual 1957 Comm Course PDFSio Z BhanNessuna valutazione finora

- Supplier Quality Assurance Manual - Rev. 06Documento40 pagineSupplier Quality Assurance Manual - Rev. 06Sundaramoorthy ArumugamNessuna valutazione finora

- The ASQ Quality Improvement Pocket Guide: Basic History, Concepts, Tools, and RelationshipsDa EverandThe ASQ Quality Improvement Pocket Guide: Basic History, Concepts, Tools, and RelationshipsNessuna valutazione finora

- Management Review How To Rev1Documento23 pagineManagement Review How To Rev1tony sNessuna valutazione finora

- Audit Working PapersDocumento5 pagineAudit Working PapersDlamini SiceloNessuna valutazione finora

- Procedure For Management Review PDFDocumento5 pagineProcedure For Management Review PDFSelvaraj Simiyon50% (2)

- Objectives of Internal AuditDocumento14 pagineObjectives of Internal AuditDasthagiriBhasha100% (1)

- What Is Wrong With Scientology - Healing - Rathbun, Mark 'Marty'Documento296 pagineWhat Is Wrong With Scientology - Healing - Rathbun, Mark 'Marty'anon_123915842100% (1)

- Iso 9001Documento15 pagineIso 9001Andro Ignacio100% (1)

- AS9104 Process Flowcharts PDFDocumento36 pagineAS9104 Process Flowcharts PDFCarlos Macedo100% (1)

- Turtle Diagram For AuditDocumento5 pagineTurtle Diagram For AuditSelvaraj Simiyon100% (3)

- ISO 9001-2015 Presentation - PPSXDocumento25 pagineISO 9001-2015 Presentation - PPSXrasimc9475Nessuna valutazione finora

- Brainwashing in Scientology's Rehabilitation Project Force (RPF) by Dr. Stephen KentDocumento33 pagineBrainwashing in Scientology's Rehabilitation Project Force (RPF) by Dr. Stephen KentThe Department of Official Information100% (1)

- Process Audit Plan ScheduleDocumento4 pagineProcess Audit Plan ScheduleTravisNessuna valutazione finora

- Form - Supplier Quality Survey - Rev 0Documento3 pagineForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNessuna valutazione finora

- Iso SampleDocumento14 pagineIso Samplemritunjay100% (2)

- Continuous ImprovementDocumento88 pagineContinuous Improvementkgkganesh8116Nessuna valutazione finora

- Handbook For Group Auditing PDFDocumento5 pagineHandbook For Group Auditing PDFCristiano Manzzini100% (1)

- Supplier Incident Analysis: Claim NoDocumento10 pagineSupplier Incident Analysis: Claim Nonitin pendharkarNessuna valutazione finora

- Requirement For Iso 9001 2015Documento3 pagineRequirement For Iso 9001 2015Anonymous r2EiqSrBNessuna valutazione finora

- C4 Turtle Diagram Process Design ProcessDocumento1 paginaC4 Turtle Diagram Process Design Processcao thanh quocNessuna valutazione finora

- Aphorisms and Advert From 8-80Documento29 pagineAphorisms and Advert From 8-80selfdevNessuna valutazione finora

- Scientology by WakefieldDocumento202 pagineScientology by WakefieldMauser91100% (1)

- Questions and Answers ISO 9001Documento27 pagineQuestions and Answers ISO 9001مختار حنفىNessuna valutazione finora

- Iso 9000 2015Documento15 pagineIso 9000 2015Vasudevan GovindarajNessuna valutazione finora

- Understanding, Knowledge, and Awareness of ISO 9001:2015: November 4, 2019Documento103 pagineUnderstanding, Knowledge, and Awareness of ISO 9001:2015: November 4, 2019Hisar SimanjuntakNessuna valutazione finora

- Paradise IATF IA Presentation PDFDocumento211 pagineParadise IATF IA Presentation PDFSameer SaxenaNessuna valutazione finora

- Corrective Action: Organization Details JustificationDocumento1 paginaCorrective Action: Organization Details JustificationaezacsNessuna valutazione finora

- IATF 16949 Trainers Guide SampleDocumento8 pagineIATF 16949 Trainers Guide SampleTuan Anh67% (3)

- Advanced Quality ManualDocumento17 pagineAdvanced Quality ManualalexrferreiraNessuna valutazione finora

- HCOB, Field Staff Member Repair & Revitalization LiDocumento14 pagineHCOB, Field Staff Member Repair & Revitalization LiFlibberdygibberNessuna valutazione finora

- ISO 9001 2015 Foundation Training PPT - DeltaDocumento242 pagineISO 9001 2015 Foundation Training PPT - Deltaziad shifa100% (1)

- Scientology: Report of The Board of Inquiry Into Scientology, Victoria, Australia - 1965Documento204 pagineScientology: Report of The Board of Inquiry Into Scientology, Victoria, Australia - 1965sirjsslutNessuna valutazione finora

- ISO 9001 Key Process Turtle TemplateDocumento1 paginaISO 9001 Key Process Turtle TemplateShirleyNessuna valutazione finora

- Tokyo PresentationDocumento109 pagineTokyo PresentationMoti Ben-ZurNessuna valutazione finora

- Internal Audit Process Flow ChartDocumento1 paginaInternal Audit Process Flow ChartAgus KurniawanNessuna valutazione finora

- Audit SkillsDocumento36 pagineAudit SkillsSudhagarNessuna valutazione finora

- CQI-IRCA LA Online Exam Guide5Documento8 pagineCQI-IRCA LA Online Exam Guide5shams aliNessuna valutazione finora

- Auditor Observation Form MASTERDocumento7 pagineAuditor Observation Form MASTERGavin JordanNessuna valutazione finora

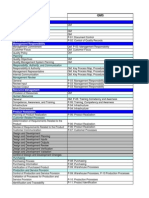

- IATF 16949-2016 Quick Reference GuideDocumento12 pagineIATF 16949-2016 Quick Reference Guidevenkatesh vajarapuNessuna valutazione finora

- Quality Audit Handbook PDFDocumento59 pagineQuality Audit Handbook PDFmadmaxjune17557Nessuna valutazione finora

- Supplier Audit Check SheetDocumento33 pagineSupplier Audit Check SheetMotive PostNessuna valutazione finora

- 2019-AIAG Catalog PDFDocumento80 pagine2019-AIAG Catalog PDFgeocastellaNessuna valutazione finora

- AWS MSP Partner Program Validation ChecklistDocumento32 pagineAWS MSP Partner Program Validation Checklistsai kiran100% (1)

- 8D Problem SolvingDocumento7 pagine8D Problem SolvingLokesh Narasimhaiah100% (1)

- Form - Nonconforming Part DispositionDocumento1 paginaForm - Nonconforming Part DispositionSelvaraj SimiyonNessuna valutazione finora

- Customer Complaints Management PDFDocumento9 pagineCustomer Complaints Management PDFShrawan JhaNessuna valutazione finora

- Downs and Adrian - Interview, Focus Group InterviewDocumento9 pagineDowns and Adrian - Interview, Focus Group InterviewDana Stanescu0% (1)

- NIST SP 800-171r1Documento125 pagineNIST SP 800-171r1Fabio MartinezNessuna valutazione finora

- SIPOC: A Six Sigma Tool Helping On ISO 9000 Quality Management SystemsDocumento10 pagineSIPOC: A Six Sigma Tool Helping On ISO 9000 Quality Management SystemsYogesh ChavanNessuna valutazione finora

- How To Create An Process Flowchart: White PaperDocumento5 pagineHow To Create An Process Flowchart: White Papermardirad0% (1)

- Context & Interested Party Analysis RIODocumento7 pagineContext & Interested Party Analysis RIOMuhamad HaykalNessuna valutazione finora

- Audit MatrixDocumento4 pagineAudit MatrixramschellamNessuna valutazione finora

- Audit Sampling ManualDocumento16 pagineAudit Sampling Manualవెంకటరమణయ్య మాలెపాటిNessuna valutazione finora

- ISO 9001-2008 Internal Audit ChecklistDocumento43 pagineISO 9001-2008 Internal Audit Checklistshinto LawrenceNessuna valutazione finora

- IRCA Application RequirementsDocumento58 pagineIRCA Application RequirementsLuis Gustavo PachecoNessuna valutazione finora

- IATF - International Automotive Task ForceDocumento10 pagineIATF - International Automotive Task ForceBeli NovareseNessuna valutazione finora

- ISO 9001-2015 Process Audit ChecklistDocumento17 pagineISO 9001-2015 Process Audit ChecklistKevin Hogwood100% (2)

- Integrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodDa EverandIntegrated Management Systems: QMS, EMS, OHSMS, FSMS including Aerospace, Service, Semiconductor/Electronics, Automotive, and FoodNessuna valutazione finora

- ISSAI 4000 - Compliance AuditDocumento31 pagineISSAI 4000 - Compliance AuditDedi PramonoNessuna valutazione finora

- Rp2-Iso9001 2015Documento38 pagineRp2-Iso9001 2015Zia MalikNessuna valutazione finora

- Lead Auditor ISO 9001Documento3 pagineLead Auditor ISO 9001Agung Nugroho0% (1)

- Section 4Documento3 pagineSection 4fuazNessuna valutazione finora

- SMETA Best Practice GuidanceDocumento39 pagineSMETA Best Practice GuidanceMohamad Samsul Hadi100% (2)

- Manufacturing Supplier Quality Engineer in Nashua NH Resume Daniel DudkaDocumento2 pagineManufacturing Supplier Quality Engineer in Nashua NH Resume Daniel DudkaDaniel DudkaNessuna valutazione finora

- 6 Iatf 16949 Certification Cheat SheetDocumento5 pagine6 Iatf 16949 Certification Cheat Sheet88No1FanNessuna valutazione finora

- Motorola Quality ManualDocumento12 pagineMotorola Quality ManualHaroon MukhtarNessuna valutazione finora

- Quality Assurance Process A Complete Guide - 2020 EditionDa EverandQuality Assurance Process A Complete Guide - 2020 EditionNessuna valutazione finora

- Understanding Iso 9000 Understanding Iso 9000 Quality Management System QDocumento24 pagineUnderstanding Iso 9000 Understanding Iso 9000 Quality Management System QManikandan100% (2)

- Building Quality StrategyDocumento18 pagineBuilding Quality Strategyjuancar2_88Nessuna valutazione finora

- DCC and QMS Coordinator - HandoutDocumento17 pagineDCC and QMS Coordinator - HandoutRaymond PalisocNessuna valutazione finora

- 6BWSHR Working With Machines A2 Poster EnglishDocumento1 pagina6BWSHR Working With Machines A2 Poster EnglishKhuda BukshNessuna valutazione finora

- Management System Auditing by David HoyleDocumento35 pagineManagement System Auditing by David HoylesonicefuNessuna valutazione finora

- IATF Additional Requirement LocationsDocumento6 pagineIATF Additional Requirement LocationsSudhagar50% (2)

- V and VDocumento11 pagineV and Vdakshina656087Nessuna valutazione finora

- 27 Feb 2019 - Auditor TrainingDocumento30 pagine27 Feb 2019 - Auditor TrainingbojaNessuna valutazione finora

- Process Approach A Complete Guide - 2019 EditionDa EverandProcess Approach A Complete Guide - 2019 EditionNessuna valutazione finora

- Standard Inspection Procedure A Complete Guide - 2020 EditionDa EverandStandard Inspection Procedure A Complete Guide - 2020 EditionNessuna valutazione finora

- Cost Of Poor Quality A Complete Guide - 2021 EditionDa EverandCost Of Poor Quality A Complete Guide - 2021 EditionNessuna valutazione finora

- FCA Reminder LetterDocumento1 paginaFCA Reminder LetterSelvaraj SimiyonNessuna valutazione finora

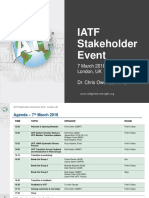

- Iatf Stakeholder Event: IATF Transition Survey Feedback Niall Kealey (SMMT Oversight)Documento19 pagineIatf Stakeholder Event: IATF Transition Survey Feedback Niall Kealey (SMMT Oversight)Selvaraj SimiyonNessuna valutazione finora

- Ford Letter Reporting of IATF 16949 Transition Audit StatusDocumento1 paginaFord Letter Reporting of IATF 16949 Transition Audit StatusSelvaraj SimiyonNessuna valutazione finora

- 3X3 ISO 9001 2015 - RequirementsDocumento42 pagine3X3 ISO 9001 2015 - RequirementsSelvaraj SimiyonNessuna valutazione finora

- IATF 16949 Systematic Review Team Process and Progress: Russ Hopkins Ford Motor CompanyDocumento4 pagineIATF 16949 Systematic Review Team Process and Progress: Russ Hopkins Ford Motor CompanySelvaraj SimiyonNessuna valutazione finora

- BMW Group. Transition Update and Current StatusDocumento4 pagineBMW Group. Transition Update and Current StatusSelvaraj SimiyonNessuna valutazione finora

- Iatf Stakeholder Event: 7 March 2018 London, UK Dr. Chris Owen (SMMT)Documento5 pagineIatf Stakeholder Event: 7 March 2018 London, UK Dr. Chris Owen (SMMT)Selvaraj SimiyonNessuna valutazione finora

- Iatf Stakeholder Conference: 13 September 2017 Oberursel, Germany Norbert Haß (VDA QMC)Documento6 pagineIatf Stakeholder Conference: 13 September 2017 Oberursel, Germany Norbert Haß (VDA QMC)Selvaraj SimiyonNessuna valutazione finora

- 04 - IATF Stakeholder Conference 2017 - Bachir Benrahal - FINALDocumento15 pagine04 - IATF Stakeholder Conference 2017 - Bachir Benrahal - FINALSelvaraj SimiyonNessuna valutazione finora

- Iatf Stakeholder Conference: 13 September 2017 Oberursel, Germany Dale Hammer (IAOB)Documento3 pagineIatf Stakeholder Conference: 13 September 2017 Oberursel, Germany Dale Hammer (IAOB)Selvaraj SimiyonNessuna valutazione finora

- Form - CAR LogDocumento49 pagineForm - CAR LogSelvaraj SimiyonNessuna valutazione finora

- 02 - IATF Stakeholder Conference 2017 - James Bruin - FINALDocumento15 pagine02 - IATF Stakeholder Conference 2017 - James Bruin - FINALSelvaraj SimiyonNessuna valutazione finora

- Form - Requisition FormDocumento1 paginaForm - Requisition FormSelvaraj SimiyonNessuna valutazione finora

- List Your Processes Here: Enter Full Name of CAR Form Here Enter Abbreviated Name of Your CAR Form HereDocumento4 pagineList Your Processes Here: Enter Full Name of CAR Form Here Enter Abbreviated Name of Your CAR Form HereSelvaraj SimiyonNessuna valutazione finora

- Form - Design Control FormDocumento4 pagineForm - Design Control FormSelvaraj SimiyonNessuna valutazione finora

- Revision 2: International Automotive Task ForceDocumento21 pagineRevision 2: International Automotive Task ForceSelvaraj SimiyonNessuna valutazione finora

- Thehopeof Man: Another New Book From Ron!Documento8 pagineThehopeof Man: Another New Book From Ron!Andreas GroßNessuna valutazione finora

- David Miscavige Interview With Ted KoppelDocumento28 pagineDavid Miscavige Interview With Ted KoppelClassIVauditorNessuna valutazione finora

- Ivy 01Documento36 pagineIvy 01Clif Cunningham100% (1)

- Certification Bodies and Auditors Requirements Version 2.1Documento12 pagineCertification Bodies and Auditors Requirements Version 2.1PT KPMNessuna valutazione finora

- The Auditor 47 1969 MinusDocumento11 pagineThe Auditor 47 1969 MinusAndreas GroßNessuna valutazione finora

- Jbptunikompp GDL Basukirahm 25649 1 01 Int SDocumento44 pagineJbptunikompp GDL Basukirahm 25649 1 01 Int SCecep Kurnia SastradiprajaNessuna valutazione finora

- PSA 230 (RED) "Audit Documentation": (Effectivity Date: December 15, 2009)Documento20 paginePSA 230 (RED) "Audit Documentation": (Effectivity Date: December 15, 2009)Christine NicoleNessuna valutazione finora

- E2HSMS IA Checklist - Excel FormatDocumento8 pagineE2HSMS IA Checklist - Excel FormatDen PamplonaNessuna valutazione finora

- Performing Preliminary Engagement ActivitiesDocumento9 paginePerforming Preliminary Engagement ActivitiesMarnelli CatalanNessuna valutazione finora

- PEFC Requirements For Certification Bodies Operating Forest Management Certification (PEFC ST 1004:201x) - Enquiry DraftDocumento21 paginePEFC Requirements For Certification Bodies Operating Forest Management Certification (PEFC ST 1004:201x) - Enquiry DraftPEFC InternationalNessuna valutazione finora