Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bulletin 947541 PDF

Caricato da

Rolando Rodriguez0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni2 pagineTitolo originale

bulletin_947541.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni2 pagineBulletin 947541 PDF

Caricato da

Rolando RodriguezCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

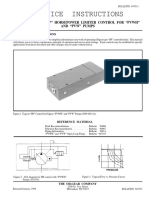

BULLETIN 947541

"P-1NN" PRESSURE COMPENSATOR CONTROL

(with 4-way pilot control valve)

Operation for a typical pump driven clockwise

(right hand) is described. Cut-a-way diagrams

are a representation of typical pumps with this

control. Actual coupling of control to pump

control pin and swashblock varies from pump

type to pump type. But, functionally, the

swashblock (and resultant delivery) is posi-

tioned by two opposite (acting) control pis-

tons (although, in some cases, the [two] pis-

tons may actually be a single [one] piece.

See individual control parts drawings for ac-

tual configuration and location of part assem-

blies, orifices, connections and ports.

I. PRINCIPLE OF OPERA-

TION

A. STARTING (See Figure 1 & 2)

The bias control piston spring positions the

control and connected pump swashblock so

the pump will deliver maximum volume to

raise pressure in the system.

B. RAISING PRESSURE

Pump delivery (and resultant pressure) is fed

back to the control through Port "OP1" (in

some cases, an orifice may be installed in this

port). The four-way pilot control valve is

held in the "open" position by a pilot con-

trol valve spring. Flow (and resultant pres-

sure) is transmitted through the pilot control

valve spool to the area behind the bias con-

trol piston and through orifice Port OP2.

Therefore, pressure acting on either end of

the pilot control valve is equal, the spool is

balanced and held in the open position by the

pilot control valve spring. Flow (and result-

ant pressure) is also transmitted through Port

OP3 and Port OP4 to the adjustable con-

trol relief (unloading) valve which blocks

further flow in the control (and pressure trans-

mittal).

(Continued on page 2)

Figures 1 & 2. Raising Pump Pressure (5V-12125-L sh. 1).

THE OILGEAR COMPANY

2300 So. 51st. Street

Issued Sept., 2000 Milwaukee, WI 53219 BULLETIN 947541

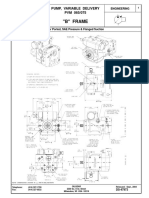

C. PRESSURE COMPENSATING,

pump unloading.(See Figures 3

and 4).

When pressure on the cone shaped relief valve

plunger exceeds the presetting of the relief

valve (set by turning in or out the relief valve

screw which sets the tension or force, of the

relief valve spring) the cone shaped plunger

moves off it's seat and allows flow through

the valve, through drain line to pump case and

case drain. Now, pressure is no longer acting

on the spring end of the pilot control valve

spool. Due to orifice in Port OP2, there is

still pressure on the other end of the pilot con-

trol valve spool. This differential pressure

forces the pilot control valve spool to shift and

compress the pilot control valve spring. The

pilot control valve spool now allows pump de-

livery (and resultant pressure) to flow to the

unloading control piston. The pilot control

valve spool simultaneously drains the fluid

from behind the bias control piston.

The control piston now moves the control pin

and shifts the swashblock to a position to- PILOT CONTROL 4-WAY

VALVE SPOOL

wards neutral where the pump (is unloaded)

delivers "just enough" volume to maintain

(make-up for component slip losses or leak-

age) system pressure as regulated by the ad-

justable control relief valve.

D. HOLDING PRESSURE (See Fig

ures 1 and 2).

If the system pressure drops below preset com-

pensating pressure (in the event of increased

leakage of system components and/or open-

ing of system valves etc.), the control relief

valve conical plunger seats (stopping flow to

drain), pressure (and force) on pilot control

valve spool is (again) balanced, pilot control

valve spring returns spool to original position

(as shown in figures 1 and 2), swashblock po-

sition shifts, and pump is "stroked" for in-

creased (towards full) delivery until the con-

trol relief valve preset pressure is reached

again.

II. ORIFICE FUNCTIONS

Orifice Decreasing Orifice Diameter will

No. Result In:(Increasing Diameter

will Do the Opposite) Figures 3 & 4 Compensating Pump Delivery (5V-12125-L sh. 2).

OP1 Overall slowing of control response *

OP2 Do not change size of orifice**

OP3 Do not change - increased stability

OP4 Do not change - increased stability

OP5 Slowing of "off stroke" time ##

OP6 Increased unstability #

OP14 Slowing down of "on stroke" time.

Do not go smaller than 0.060"

* Orifice not used (standard)

** If this orifice becomes plugged, the control will

hold pump on minimum stroke. Be sure orifice

is not plugged.

# Plugged on "PVK" pumps

## Not used on "PVG" Pumps

BULLETIN 947541 Page 2 LITHO IN USA

Potrebbero piacerti anche

- Oilgear Handwheel Controls Service InstructionsDocumento4 pagineOilgear Handwheel Controls Service InstructionsRolando RodriguezNessuna valutazione finora

- Service Instructions: Oilgear Type "HP" Horsepower Limiter Control For "PVWH" and "PVW" PumpsDocumento4 pagineService Instructions: Oilgear Type "HP" Horsepower Limiter Control For "PVWH" and "PVW" PumpsRolando RodriguezNessuna valutazione finora

- Service Instructions: Oilgear Type "CH" High-Low Compensator Control For "PVWH" and "PVW" PumpsDocumento4 pagineService Instructions: Oilgear Type "CH" High-Low Compensator Control For "PVWH" and "PVW" PumpsRolando RodriguezNessuna valutazione finora

- Lega PVWHDocumento4 pagineLega PVWHJorge MendozaNessuna valutazione finora

- Service InstructionsDocumento4 pagineService InstructionsRolando RodriguezNessuna valutazione finora

- "B" Frame: Pump, Variable Delivery PVM 065/075Documento7 pagine"B" Frame: Pump, Variable Delivery PVM 065/075Rolando RodriguezNessuna valutazione finora

- Service Instructions: Oilgear Type "MN" and "MS" Lever Controls For "PVWH" and "PVW" PumpsDocumento4 pagineService Instructions: Oilgear Type "MN" and "MS" Lever Controls For "PVWH" and "PVW" PumpsRolando RodriguezNessuna valutazione finora

- Service Instructions: Oilgear Type "HF" Horsepower Limiter W/Load Sensor Controls For "PVWH" and "PVW" PumpsDocumento4 pagineService Instructions: Oilgear Type "HF" Horsepower Limiter W/Load Sensor Controls For "PVWH" and "PVW" PumpsRolando RodriguezNessuna valutazione finora

- "B" Frame: Pump, Variable Delivery PVM 025, 034 & 046Documento7 pagine"B" Frame: Pump, Variable Delivery PVM 025, 034 & 046Rolando RodriguezNessuna valutazione finora

- Tobul CatalogDocumento44 pagineTobul CatalogSanjeev VermaNessuna valutazione finora

- Oilgear Type "PVM" Pumps - 011/-014/-022/-025/-034/-046/ - 064/-065/-075/-076/-098/-130 Service InstructionsDocumento64 pagineOilgear Type "PVM" Pumps - 011/-014/-022/-025/-034/-046/ - 064/-065/-075/-076/-098/-130 Service InstructionsRolando RodriguezNessuna valutazione finora

- PVK PDFDocumento12 paginePVK PDFNicole SmithNessuna valutazione finora

- Pump Reference PDFDocumento2 paginePump Reference PDFRolando RodriguezNessuna valutazione finora

- Pump AdaptersDocumento21 paginePump AdaptersRolando RodriguezNessuna valutazione finora

- Tobul CatalogDocumento44 pagineTobul CatalogSanjeev VermaNessuna valutazione finora

- Mount CatalogDocumento20 pagineMount CatalogRolando RodriguezNessuna valutazione finora

- Features: How To OrderDocumento8 pagineFeatures: How To OrderRolando RodriguezNessuna valutazione finora

- Electric Motor Information: Dimensions For AC MotorsDocumento21 pagineElectric Motor Information: Dimensions For AC MotorsRolando RodriguezNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Venus in MulaDocumento2 pagineVenus in MulaGovind BallabhNessuna valutazione finora

- PERSONS Finals Reviewer Chi 0809Documento153 paginePERSONS Finals Reviewer Chi 0809Erika Angela GalceranNessuna valutazione finora

- Test Report OD63mm PN12.5 PE100Documento6 pagineTest Report OD63mm PN12.5 PE100Im ChinithNessuna valutazione finora

- Quality Control Plan Static EquipmentDocumento1 paginaQuality Control Plan Static EquipmentdhasdjNessuna valutazione finora

- Cellular Basis of HeredityDocumento12 pagineCellular Basis of HeredityLadyvirdi CarbonellNessuna valutazione finora

- Auditor General Insurance Regulation Dec 2011Documento23 pagineAuditor General Insurance Regulation Dec 2011Omar Ha-RedeyeNessuna valutazione finora

- A. Kumar Aswamy Job Offer LetterDocumento1 paginaA. Kumar Aswamy Job Offer LetterHimanshu PatelNessuna valutazione finora

- EO On Ban of Fireworks (Integrated)Documento2 pagineEO On Ban of Fireworks (Integrated)Mario Roldan Jr.Nessuna valutazione finora

- Roadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostDocumento4 pagineRoadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostJanel Castillo Balbiran33% (3)

- The Secret of The House WTDocumento22 pagineThe Secret of The House WTPetr -50% (2)

- Biology (Paper I)Documento6 pagineBiology (Paper I)AH 78Nessuna valutazione finora

- Human Capital FormationDocumento9 pagineHuman Capital Formationtannu singh67% (6)

- TS4-F - Fire SafetyDocumento2 pagineTS4-F - Fire SafetyDominic SantiagoNessuna valutazione finora

- Business Startup Practical Plan PDFDocumento70 pagineBusiness Startup Practical Plan PDFShaji Viswanathan. Mcom, MBA (U.K)Nessuna valutazione finora

- Fundamentals of Fast SwimmingDocumento9 pagineFundamentals of Fast SwimmingTorcay Ulucay100% (1)

- Abstract - Tropen Tag 2011 PDFDocumento634 pagineAbstract - Tropen Tag 2011 PDFzmoghesNessuna valutazione finora

- Heat Exchanger Sodium SilicateDocumento2 pagineHeat Exchanger Sodium SilicateChristopher BrownNessuna valutazione finora

- 10059-DC-K-01-A Design BasisDocumento34 pagine10059-DC-K-01-A Design BasisAnonymous RvIgDUNessuna valutazione finora

- Chemical and Physical Properties of Refined Petroleum ProductsDocumento36 pagineChemical and Physical Properties of Refined Petroleum Productskanakarao1Nessuna valutazione finora

- Forest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundDocumento4 pagineForest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundAnonymous 6iFFjEpzYjNessuna valutazione finora

- Practice of Epidemiology Performance of Floating Absolute RisksDocumento4 paginePractice of Epidemiology Performance of Floating Absolute RisksShreyaswi M KarthikNessuna valutazione finora

- ME JBP 70A Pen Dissolved Oxygen Meter PDFDocumento1 paginaME JBP 70A Pen Dissolved Oxygen Meter PDFpiknikmonsterNessuna valutazione finora

- Merit of RatingDocumento1 paginaMerit of RatingRaidasNessuna valutazione finora

- ERS M22 PC4 FerryDocumento2 pagineERS M22 PC4 FerryouakgoodNessuna valutazione finora

- Manual Masina de Spalat Slim SamsungDocumento1.020 pagineManual Masina de Spalat Slim SamsungPerfectreviewNessuna valutazione finora

- Piping Material Classes GuideDocumento98 paginePiping Material Classes GuideLuis Pottozen VillanuevaNessuna valutazione finora

- Aging and Elderly IQDocumento2 pagineAging and Elderly IQ317537891Nessuna valutazione finora

- Grade Eleven Test 2019 Social StudiesDocumento6 pagineGrade Eleven Test 2019 Social StudiesClair VickerieNessuna valutazione finora

- Simple Syrup I.PDocumento38 pagineSimple Syrup I.PHimanshi SharmaNessuna valutazione finora