Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TABLE OF CONTENTS of Penstock

Caricato da

Madhav BaralTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TABLE OF CONTENTS of Penstock

Caricato da

Madhav BaralCopyright:

Formati disponibili

PENSTOCK PIPE (H.

M WORKS)

Mai – Beni (H.E.P) 9.51MW

TABLE OF CONTENTS

CHAPTER 1 INSPECTION ON RECEIPT MATERIALS

1.1 Visual inspection

1.1.1 Inspect Physical Damage for all incoming materials.

1.1.2 Check the dimensions Labelling in specified manner.

1.1.3 Inspect sample Test accordingly to their Certified WPS

1.2 Points to be Record and check the materials

1.2.1 Date of Receipt

1.2.2 Name of product, Heat no, control no, Assigned by

manufacture.

1.2.3 Check the Quality and Grade of Materials against documents.

CHAPTER 2 FABRICATION (IN PROCESS)

2.1 Processes

2.1.1 Cutting (with Dimension Inspection)

2.1.2 Forming or Bending

2.1.3 Maching

2.1.4 Welding (Examine according to certified electrode and

welder).

2.1.5 Final Assembly

CHAPTER 3 QUALITY CONTROL INSPECTION PROGRAM FOR FABRICATION

3.1 Dimension Inspection Record

3.2 Welding Inspection Record

3.2.1 NDT Examine Technique

3.2.2 Detection of surface Flaws.

a.) Visuals inspection.

b.) Magnetic particle inspection.

c.) Fluorescent Dye Penetrant Inspection

3.2.3 Detection of internals Flaws

a.) X-Radiography.

b.) Ultrasonic Testing

c.) Eddy current Testing

3.3 Prepare Quality assurance plan (QAP) with certified AWS

3.4 Inspection of Ovality.

3.5 Water filling and Pressure Test.

CHAPTER 4 QUALITY CONTROL INSPECTION PROGRAM FOR PAINTING

4.1 Painting Process

4.2 Sand Blasting of Pipe.

4.3 Surface Preparation

4.3.1 Cleaning

4.3.2 Rust Removal

4.4 Priming

4.5 Finishing Coating

CHAPTER 5 EXECUTION AND INSTALLATION AT SITE

5.1 Methods and Procedure of execution of pipe.

PENSTOCK PIPE (H.M WORKS)

Mai – Beni (H.E.P) 9.51MW

5.1.1 Perform the safety plan accordingly of H.M works

5.1.2 Monitor Status

5.1.2.1 Pipe Monitoring

5.1.2.2 Tools monitoring

5.1.2.3 Process monitoring

5.1.2.4 Job monitoring

5.1.3 Welding examine with certified WPS

5.1.3.1 Follow the NDT Technique Against QAP (BIS)

5.1.4 Debugging the R.L and slope level of Excavation.

CHAPTER 6 DOCUMENTATION

6.1 Summary of QAP with IS (AWS) certified.

6.2 Personnel Evaluation of penstock Inspection.

6.3 Frequency Inspection

6.4 Conclusion of penstock Inspection Record.

Potrebbero piacerti anche

- Handbook of Quality Integrated Circuit ManufacturingDa EverandHandbook of Quality Integrated Circuit ManufacturingValutazione: 5 su 5 stelle5/5 (1)

- 2003 CPA Phys-Mech Manual Revised 10-13-03Documento78 pagine2003 CPA Phys-Mech Manual Revised 10-13-03Rubén Eduardo Galindo CarmonaNessuna valutazione finora

- Boxt Field Quality PlanDocumento86 pagineBoxt Field Quality PlanHariom GuptaNessuna valutazione finora

- Materials and welding rules for inland shipsDocumento212 pagineMaterials and welding rules for inland shipsNavalPRO Ingeniería NavalNessuna valutazione finora

- Dubai Lab Accreditation Requirements for Geotech TestsDocumento12 pagineDubai Lab Accreditation Requirements for Geotech TestsdangdaNessuna valutazione finora

- 216-NR Consolidated 2020-07Documento263 pagine216-NR Consolidated 2020-07Dinar OjakNessuna valutazione finora

- 5.ITP For Excavation and Back FillingDocumento19 pagine5.ITP For Excavation and Back FillingDaniel Sinaga100% (5)

- ITP MEKANIKAL SEAMLESS PIPE MILL PROJECTpraktis (Contruction Phase)Documento98 pagineITP MEKANIKAL SEAMLESS PIPE MILL PROJECTpraktis (Contruction Phase)ariefNessuna valutazione finora

- Field Civil Inspection & Test PlanDocumento9 pagineField Civil Inspection & Test PlanChristian Albert Sinaga RumajarNessuna valutazione finora

- Itp Civil WorkDocumento9 pagineItp Civil WorkChristian Albert Sinaga RumajarNessuna valutazione finora

- Screening Criteria Rev 2018 (1) (1) - 1560840206Documento2 pagineScreening Criteria Rev 2018 (1) (1) - 1560840206santoshNessuna valutazione finora

- Boiler Erection Procedure and ChecklistDocumento19 pagineBoiler Erection Procedure and ChecklistMountadsuli Febrialam80% (5)

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022Documento2 pagineBatch Test Certificate: Page 1 of 2 Form No: F/QC/012/1 3 Rev: 05 /2022gauravNessuna valutazione finora

- Pages From ASME - B31 - 3 - UnlockedDocumento8 paginePages From ASME - B31 - 3 - UnlockedJose Juan GasparNessuna valutazione finora

- JLL Quality Test Reports & Checklists - CivilDocumento55 pagineJLL Quality Test Reports & Checklists - CivilN.PrabhuNessuna valutazione finora

- 2008 - Experimental Assesment On Corrosion Under Insulation (CUI)Documento56 pagine2008 - Experimental Assesment On Corrosion Under Insulation (CUI)Ronnie Johan IswandyNessuna valutazione finora

- Batch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022Documento2 pagineBatch Test Certificate: Page 1 of 2 Form No: F/QC/011/1 4 Rev: 05 /2022gauravNessuna valutazione finora

- Material TestingDocumento302 pagineMaterial Testingabdsattar1701Nessuna valutazione finora

- Visual Inspection of Sterile Products: Best Practices DocumentDocumento77 pagineVisual Inspection of Sterile Products: Best Practices Documentjay patelNessuna valutazione finora

- Visual Inspection of Sterile Products Best PracticesDocumento77 pagineVisual Inspection of Sterile Products Best PracticesValfar RoblesNessuna valutazione finora

- Quality Control Procedure SampleDocumento12 pagineQuality Control Procedure Samplepocharquitecturaromania92% (50)

- RCC Manula Control CalidadDocumento76 pagineRCC Manula Control CalidadvscavelliNessuna valutazione finora

- ITP Piping-PMLSB Fire WaterDocumento22 pagineITP Piping-PMLSB Fire Watermohd as shahiddin jafriNessuna valutazione finora

- Requerimientos de CalidadDocumento12 pagineRequerimientos de CalidadEfrain PerezNessuna valutazione finora

- Dimensional Inspection ProcedureDocumento3 pagineDimensional Inspection ProcedureWalter Unabia Rendon100% (5)

- Mil STD 331dDocumento291 pagineMil STD 331dNicolasSuchNessuna valutazione finora

- Construction of A Bridge WBSDocumento1 paginaConstruction of A Bridge WBSMark Robin MalabedNessuna valutazione finora

- Soft Brown Abstract Playful Online Shop Site GraphDocumento1 paginaSoft Brown Abstract Playful Online Shop Site GraphMark Robin MalabedNessuna valutazione finora

- Scope of Test and Inspection For Insulating WorkDocumento5 pagineScope of Test and Inspection For Insulating WorkDineshNessuna valutazione finora

- NR 216 - 2005Documento236 pagineNR 216 - 2005Marcos Verissimo Juca de PaulaNessuna valutazione finora

- Materials and Qualification Procedures For Ships Book D November 2023Documento47 pagineMaterials and Qualification Procedures For Ships Book D November 2023david limNessuna valutazione finora

- Quality Assurance Project Plan (Qapp) FOR Storage Tank Program (STP) SamplingDocumento149 pagineQuality Assurance Project Plan (Qapp) FOR Storage Tank Program (STP) SamplingCrisNessuna valutazione finora

- Cone Penetration Testing GuideDocumento332 pagineCone Penetration Testing GuideRenaud Martin-EnglishNessuna valutazione finora

- CPT en Practica Geotecnica - Lunne, Robertson, PowellDocumento332 pagineCPT en Practica Geotecnica - Lunne, Robertson, PowellEloy Jiménez OntiverosNessuna valutazione finora

- D3276-00 Standard Guide For Painting Inspectors (Metal Substrates)Documento14 pagineD3276-00 Standard Guide For Painting Inspectors (Metal Substrates)kyeong cheol leeNessuna valutazione finora

- Ultrasonic Exam Procedure for Welds & ConnectionsDocumento17 pagineUltrasonic Exam Procedure for Welds & ConnectionsMohanadNessuna valutazione finora

- AbstractDocumento5 pagineAbstractcity cyberNessuna valutazione finora

- Pressure Vessel ITP Rev 0Documento21 paginePressure Vessel ITP Rev 0Ahmad HasnanNessuna valutazione finora

- NATO Quality Assurance RequirementsDocumento19 pagineNATO Quality Assurance RequirementsBahadır HarmancıNessuna valutazione finora

- Phased Array Ultrasonic Testing ProcedureDocumento21 paginePhased Array Ultrasonic Testing ProcedureKarrar TalibNessuna valutazione finora

- LR - Construction Monitoring Procedure PDFDocumento30 pagineLR - Construction Monitoring Procedure PDFYong KimNessuna valutazione finora

- Batch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019Documento2 pagineBatch Test Certificate: Form No: F/QC/012/11 Rev: 10 /2019அன்புடன் அஸ்வின்Nessuna valutazione finora

- Quality Control ProcedureDocumento12 pagineQuality Control ProcedureZiya Ahmed100% (6)

- Effects of Indoor Air Quality On The Occupant's Health and Productivity in An Office BuildingDocumento52 pagineEffects of Indoor Air Quality On The Occupant's Health and Productivity in An Office BuildingDicky HidayatNessuna valutazione finora

- Mock Exercise Instructions For Fabricators of Steel BuildingsDocumento8 pagineMock Exercise Instructions For Fabricators of Steel BuildingscarlosNessuna valutazione finora

- 01 Quality Control ManualDocumento100 pagine01 Quality Control Manualbandhakam bandhakamNessuna valutazione finora

- Nilex HDPE Installation Manual PDFDocumento19 pagineNilex HDPE Installation Manual PDFĐặng Thịnh NguyễnNessuna valutazione finora

- Product Manual 13422Documento5 pagineProduct Manual 13422North EastNessuna valutazione finora

- Mass Flow Metering Delivery Procedure For BunkeringDocumento22 pagineMass Flow Metering Delivery Procedure For Bunkeringmanuelsantos2007Nessuna valutazione finora

- QA/QC Requirements for Engineering, Procurement, Construction and Commissioning of Gas Train 5Documento91 pagineQA/QC Requirements for Engineering, Procurement, Construction and Commissioning of Gas Train 5faisal jasimNessuna valutazione finora

- C. Manufactured: 2. Handling and Storage of MaterialsDocumento1 paginaC. Manufactured: 2. Handling and Storage of MaterialsCiv PaesNessuna valutazione finora

- NDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Documento20 pagineNDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Md Abu Hanif RajuNessuna valutazione finora

- Working ITPDocumento4 pagineWorking ITPStephen BoodooNessuna valutazione finora

- Halat Amar Land Port Electrical Installation MethodDocumento22 pagineHalat Amar Land Port Electrical Installation MethodWaleed SalihNessuna valutazione finora

- LNG-80-100937-RA-6065-00023-0000 HT PipingDocumento7 pagineLNG-80-100937-RA-6065-00023-0000 HT PipingMohammad AftabNessuna valutazione finora

- Method Statement Horizontal Directional DrillingDocumento59 pagineMethod Statement Horizontal Directional DrillingNaser Mahamid100% (1)

- Content List 3Documento13 pagineContent List 3NisaNessuna valutazione finora

- Laboratory Handbook: BSM Cold RecyclingDocumento11 pagineLaboratory Handbook: BSM Cold RecyclingAliNessuna valutazione finora

- Packing, Storage and IdentificationDocumento2 paginePacking, Storage and IdentificationMadhav BaralNessuna valutazione finora

- Measurement and Payment: 1. Demobilization From The SiteDocumento2 pagineMeasurement and Payment: 1. Demobilization From The SiteMadhav BaralNessuna valutazione finora

- 1.1 Detailed Requirements For Guide Frame: GeneralDocumento2 pagine1.1 Detailed Requirements For Guide Frame: GeneralMadhav BaralNessuna valutazione finora

- 2.1.1. Longitudinal Stress Developed Due Pipe Displacement Restrain by StiffenersDocumento1 pagina2.1.1. Longitudinal Stress Developed Due Pipe Displacement Restrain by StiffenersMadhav BaralNessuna valutazione finora

- Turbine runner design requirementsDocumento1 paginaTurbine runner design requirementsMadhav BaralNessuna valutazione finora

- Asian Hydropower Company Pvt. LTD.: Headrace Pipe 2.5 6.650 Stiffeners (Height 100 MM) 2.5 6.650Documento2 pagineAsian Hydropower Company Pvt. LTD.: Headrace Pipe 2.5 6.650 Stiffeners (Height 100 MM) 2.5 6.650Madhav BaralNessuna valutazione finora

- Pressure RiseDocumento1 paginaPressure RiseMadhav BaralNessuna valutazione finora

- Procedure For Complaints and Claims For DamageDocumento2 pagineProcedure For Complaints and Claims For DamageMadhav BaralNessuna valutazione finora

- Standards and Regulations: TurbineDocumento1 paginaStandards and Regulations: TurbineMadhav BaralNessuna valutazione finora

- NDT Testing Methods for WeldsDocumento1 paginaNDT Testing Methods for WeldsMadhav BaralNessuna valutazione finora

- 2.1.1. Longitudinal Stress Developed Due Pipe Displacement Restrain by StiffenersDocumento4 pagine2.1.1. Longitudinal Stress Developed Due Pipe Displacement Restrain by StiffenersMadhav BaralNessuna valutazione finora

- Tech NDocumento1 paginaTech NMadhav BaralNessuna valutazione finora

- Payment DetailDocumento1 paginaPayment DetailMadhav BaralNessuna valutazione finora

- HAB-VAB - Mai BeniDocumento2 pagineHAB-VAB - Mai BeniMadhav BaralNessuna valutazione finora

- Pa IgnouDocumento19 paginePa IgnousudiptarimsNessuna valutazione finora

- Bifurcation Design PDFDocumento51 pagineBifurcation Design PDFMadhav BaralNessuna valutazione finora

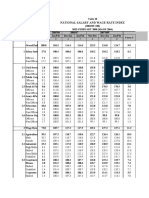

- National Salary and Wage Rate Index TrendsDocumento4 pagineNational Salary and Wage Rate Index TrendsMadhav BaralNessuna valutazione finora

- Weekly Target For EM DivisionDocumento1 paginaWeekly Target For EM DivisionMadhav BaralNessuna valutazione finora

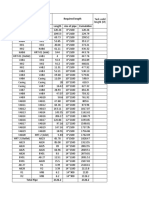

- New Microsoft Excel WorksheetDocumento4 pagineNew Microsoft Excel WorksheetMadhav BaralNessuna valutazione finora

- 386 1282 1 PB PDFDocumento5 pagine386 1282 1 PB PDFAhmedNessuna valutazione finora

- Payment DetailDocumento1 paginaPayment DetailMadhav BaralNessuna valutazione finora

- TABLE OF CONTENTS of PenstockDocumento2 pagineTABLE OF CONTENTS of PenstockMadhav BaralNessuna valutazione finora

- Sdaf PDFDocumento1 paginaSdaf PDFMadhav BaralNessuna valutazione finora

- Root Gap RequirementDocumento12 pagineRoot Gap RequirementMadhav BaralNessuna valutazione finora

- Meeting AgendaDocumento1 paginaMeeting AgendaMohammad Rafiq IzzatNessuna valutazione finora

- DsadaDocumento1 paginaDsadaMadhav BaralNessuna valutazione finora

- Payment DetailDocumento1 paginaPayment DetailMadhav BaralNessuna valutazione finora

- Result Open Competition Adv. No. 08-2075-76 & 09-2075-76-1 PDFDocumento2 pagineResult Open Competition Adv. No. 08-2075-76 & 09-2075-76-1 PDFPrabin BhandariNessuna valutazione finora

- DsadaDocumento1 paginaDsadaMadhav BaralNessuna valutazione finora

- Iso 9606-3Documento30 pagineIso 9606-3Aleksandar StojanovicNessuna valutazione finora

- Additive Manufacturing and Sand Casting Foundries in NigeriaDocumento9 pagineAdditive Manufacturing and Sand Casting Foundries in NigeriaNurudeen Adekunle RajiNessuna valutazione finora

- 1 8159-51CrV4Documento2 pagine1 8159-51CrV4black_absynthNessuna valutazione finora

- Bohler Fox N Ev 50-1Documento1 paginaBohler Fox N Ev 50-1Kara WhiteNessuna valutazione finora

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDocumento1 paginaAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkNessuna valutazione finora

- Tritech Water Poramax Brochures 8 en SingleDocumento5 pagineTritech Water Poramax Brochures 8 en SingleWendyNessuna valutazione finora

- Bangalore Aircraft FacilitiesDocumento2 pagineBangalore Aircraft FacilitiesAmit YadavNessuna valutazione finora

- GANESH Precision GT-1340 Geared-Head Engine Lathe: 13" Swing Over Bedways, 40" Center DistanceDocumento3 pagineGANESH Precision GT-1340 Geared-Head Engine Lathe: 13" Swing Over Bedways, 40" Center DistancemattnificentNessuna valutazione finora

- High-strength sack kraft paperDocumento2 pagineHigh-strength sack kraft paperDaniel GoffNessuna valutazione finora

- Introduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415Documento24 pagineIntroduction To Manufacturing Systems Design and Analysis: Spring 2019 Isye 415VaikunthtendulkarNessuna valutazione finora

- MERV rating chart for air filter efficiencyDocumento1 paginaMERV rating chart for air filter efficiencyfrancisco_mateoNessuna valutazione finora

- 07 Catalytic Cracking PDFDocumento37 pagine07 Catalytic Cracking PDFjeedanNessuna valutazione finora

- Engine Block Cleaning ProcedureDocumento7 pagineEngine Block Cleaning ProcedureKamal PakdamanNessuna valutazione finora

- Papermaking 2017Documento7 paginePapermaking 2017quizizz section4Nessuna valutazione finora

- Ihp Report 2.0Documento15 pagineIhp Report 2.0Vishwajeet SatputeNessuna valutazione finora

- Manufacturing Process-IIDocumento620 pagineManufacturing Process-IIPOKemon PokemonNessuna valutazione finora

- Slitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)Documento3 pagineSlitter Knives (Top/Bottom Slitter Knives) 裁切專用刀具-分條圓刀 (上/下圓刀)smartcad60Nessuna valutazione finora

- Cost Produksi /ukuran (Fob) : Revisi Harga Log TGL 28 Jan 2015 Meeting Direksi Di Wtu Banjarmasin USD 13500Documento63 pagineCost Produksi /ukuran (Fob) : Revisi Harga Log TGL 28 Jan 2015 Meeting Direksi Di Wtu Banjarmasin USD 13500Aris SusantoNessuna valutazione finora

- Ge Ge752 User Manual 15 20Documento6 pagineGe Ge752 User Manual 15 20RICHARDNessuna valutazione finora

- Pipe Components PDFDocumento179 paginePipe Components PDFmatevzartacNessuna valutazione finora

- 31CrMo23 Data SheetDocumento2 pagine31CrMo23 Data SheetOrnella MancinelliNessuna valutazione finora

- Palu Mallet KrisbowDocumento1 paginaPalu Mallet Krisbowhamidin_syarifNessuna valutazione finora

- 17-4PH Technical DataDocumento7 pagine17-4PH Technical DataKir VinNessuna valutazione finora

- Blast Furnace Presentation Ver1Documento39 pagineBlast Furnace Presentation Ver1abhijit kumarNessuna valutazione finora

- NORD-Painting CodeDocumento3 pagineNORD-Painting CodeubabNessuna valutazione finora

- Sand Casting of Metals: Elizabeth MertenDocumento13 pagineSand Casting of Metals: Elizabeth Mertentanu rd100% (1)

- 1 - DRV Ind Vol 73 4Documento9 pagine1 - DRV Ind Vol 73 4toz66Nessuna valutazione finora

- Paint - WikipediaDocumento15 paginePaint - Wikipediadeafrh4Nessuna valutazione finora

- NSSCC SpecDocumento12 pagineNSSCC SpecganeshNessuna valutazione finora

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocumento1 paginaAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNessuna valutazione finora

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDa EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeValutazione: 4.5 su 5 stelle4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDa EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesValutazione: 5 su 5 stelle5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDa EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNessuna valutazione finora

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDa EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsValutazione: 4 su 5 stelle4/5 (146)

- Coating and Drying Defects: Troubleshooting Operating ProblemsDa EverandCoating and Drying Defects: Troubleshooting Operating ProblemsValutazione: 5 su 5 stelle5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeDa EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeValutazione: 5 su 5 stelle5/5 (1)

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Guidelines for Implementing Process Safety ManagementDa EverandGuidelines for Implementing Process Safety ManagementNessuna valutazione finora

- The Periodic Table: A Very Short IntroductionDa EverandThe Periodic Table: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeDa EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction in the Science of Everyday LifeValutazione: 4 su 5 stelle4/5 (9)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableDa EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableValutazione: 3.5 su 5 stelle3.5/5 (22)

- Napoleon's Buttons: 17 Molecules That Changed HistoryDa EverandNapoleon's Buttons: 17 Molecules That Changed HistoryValutazione: 4 su 5 stelle4/5 (25)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDa EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsValutazione: 5 su 5 stelle5/5 (3)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilDa EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilValutazione: 5 su 5 stelle5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingDa EverandIt's Elemental: The Hidden Chemistry in EverythingValutazione: 4 su 5 stelle4/5 (10)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDa EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNessuna valutazione finora

- Chemical Process Safety: Learning from Case HistoriesDa EverandChemical Process Safety: Learning from Case HistoriesValutazione: 4 su 5 stelle4/5 (14)

- The Cyanide Canary: A True Story of InjusticeDa EverandThe Cyanide Canary: A True Story of InjusticeValutazione: 4 su 5 stelle4/5 (51)

- Rules of Thumb for Maintenance and Reliability EngineersDa EverandRules of Thumb for Maintenance and Reliability EngineersValutazione: 4.5 su 5 stelle4.5/5 (12)

- Incidents That Define Process SafetyDa EverandIncidents That Define Process SafetyNessuna valutazione finora

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDa EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksValutazione: 5 su 5 stelle5/5 (1)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeDa EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeValutazione: 4 su 5 stelle4/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDa EverandChemistry for Breakfast: The Amazing Science of Everyday LifeValutazione: 4.5 su 5 stelle4.5/5 (90)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDa EverandChemistry for Breakfast: The Amazing Science of Everyday LifeValutazione: 4.5 su 5 stelle4.5/5 (14)

- Guidelines for Asset Integrity ManagementDa EverandGuidelines for Asset Integrity ManagementValutazione: 5 su 5 stelle5/5 (1)

- Safety Fundamentals and Best Practices in Construction IndustryDa EverandSafety Fundamentals and Best Practices in Construction IndustryNessuna valutazione finora

- The Rights of Nature: A Legal Revolution That Could Save the WorldDa EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldValutazione: 5 su 5 stelle5/5 (1)