Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

60 M.bow String Girder-10411-7-R

Caricato da

kesharinareshDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

60 M.bow String Girder-10411-7-R

Caricato da

kesharinareshCopyright:

Formati disponibili

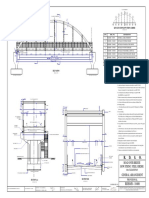

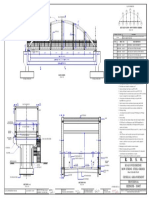

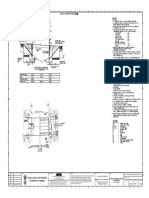

OF EJ

OF EJ

OF BOTTOM

A

LONG. BEAM

BOTTOM LONG. BEAM

250 600

B

1550 12 @100 C/C 12 @100 C/C 12 @100 C/C

10 @200 C/C

KERB (TYP.)

10 @200 C/C

450

RCC CRASH

C C BARRIER

D D

BOTTOM CROSS

OF ALIGNMENT

BEAM

12000

7500

6 - 16

EXPANSION JOINT

POCKET FOR

450

1550

OF EDGE BEAM

600 250

300

B

300

POCKET FOR EXPANSION JOINT

700 TOP REINFORCEMENT

RC DETAILS OF DECK SLAB

A

BOTTOM REINFORCEMENT

NUMERATION OF DECK SLAB - PLAN OF ALIGNMENT SCALE 1:50

SCALE 1:50 12 - 12

25 mm GAP SHALL BE PROVIDED

12 @100 C/C LONGITUDINALLY @ 5000 C/C

OF ALIGNMENT 2- 10 12 @100 C/C 10 @150 C/C

2.5 % SLOPE 2.5 % SLOPE

150 150 12000 150 150 10 @ 150

1500 450 7500 450 1500

100 DIA. PVC PIPE 10 @150 C/C

AT 5000 C/C (TYP.) 70 THK. CONCRETE PRECAST 12 @100 C/C

65 THK. WEARING COAT (TYP.)

PANEL TO BE USED IN LIEU OF

200 THK. SHUTTERING. 70 THK. GALVANIZED

DECK SLAB FOLDED SHEET MAY ALSO BE USED. SECTION B-B

SCALE 1:25

2.5 % SLOPE 2.5 % SLOPE 12 @100 C/C

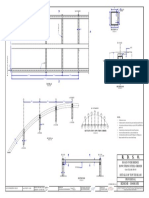

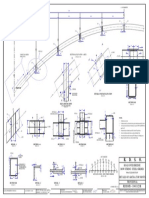

3 - 16 M.S FLAT WELDED

300 TO ISMC 100 NOTE:

70 THK. CONCRETE 10 @150 C/C

PRECAST PANEL 1. All dimensions are in mm.

MS WELD MESH 2. No dimensions shall be scaled from this drawing, only written dimension shall be followed.

WELDED TO FLAT

BOTTOM CROSS BEAM 3. All steel plates used in fabrication of this bridge are of grade Fe 490B. Only ISMB 600 is of

DRAIN PIPE @ 5000 C/C SECTION A-A BOTTOM LONG. BEAM ISMC 100

SCALE 1:50 grade Fe 410C.

300

4. All material shall pass test/analysis prescribed by relevant IS specifications.

5. All steel work fabrication shall be done in accordance with Indian Codes.

10 @150 C/C

50 50

300

6. All workshop fabrication shall be done using SAW (Submerged Arc Welding) process.

175 175

OF EJ 12 @100 C/C 12 @100 C/C 7. Splicing of members shall be done as shown in detailed drawings.

1850

POCKET FOR

EXPANSION JOINT 50 X 10 THK MS. PLATE 3 - 16 SECTION D-D

R. D. S. O.

500

3mm PLATE COLLAR, 25mm WIDE

300

(SCALE 1:10)

60 10

WEARING COAT NB 65 (MEDIUM) PIPE RAIL

R250 RCC CRASH

300 12 THK. BASE PLATE CUT TO SHAPE

BARRIER

E E

CONCRETE 120 X 120 X 16 THK. BASE PLATE

ROAD OVER BRIDGE

250

50 NB

150

100 DIA. PVC 115

300

DECK SLAB 16 THK. BASE PLATE OVER

PIPE @ 5000 C/C 12 THK. M.S PLATE MS RAIL

R50

EPOXY RESIN MORTAR

50 X 10 THK. MS PLATE BOW STRING STEEL GIRDER

125

70 THK. CONCRETE 4 Nos.12 DIA. GALVANIZED BENT TO SHAPE

120

60

50

MS BOLTS COMPLETE WITH

PRECAST PANEL

52 60m CLEAR SPAN

100

NUTS AND WASHERS 60

325

20

4 Nos. 10 DIA.

200 THK 175

MS ROD 48 LONG 13.5 DIA. HOLE FOR 12 DIA. MS BOLT

65 THK

WEARING COAT

CONCRETE SLAB WELDED TO BOLT

PIPE RAILING

DETAILS OF CONCRETE DECK SLAB

CRASH BARRIER 175

BOTTOM LONG. BEAM

NUMERATION DETAILS DETAILS OF HANDRAILS

PROVISIONAL

150

250

SECTION C-C OF CRASH BARRIER SECTION E-E

SCALE 1:25 SCALE 1:20

ON CRASH BARRIER

SCALE 1:10 SCALE 1:5

DETAILS OF HAND RAIL (PAPER SIZE A1)

(SCALE 1:15)

RDSO/B - 10411/7/R

DRAWN BY: M/S Abhinav Associates DESIGNED BY: SCRUTINIZED & CHECKED BY: APPROVED BY:

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

CALCULATION REGISTER NO. DD/2014/20 AutoCAD FILE NO.: B-10411 OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

CHECKED BY: V. K. PANDEY (SSE) VIVEK KUMAR (XEN/NCR/B&S/RDSO) SRIJAN TRIPATHI (DBS /SB-I) A. K. DADARYA (EDBS) OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

Potrebbero piacerti anche

- 30 M Bow String Girder-10409-7rDocumento1 pagina30 M Bow String Girder-10409-7rprejithNessuna valutazione finora

- 60 M.bow String Girder-10411-4-RDocumento1 pagina60 M.bow String Girder-10411-4-RkesharinareshNessuna valutazione finora

- 42 M Bow String Girder-10408-7-R PDFDocumento1 pagina42 M Bow String Girder-10408-7-R PDFPhanindra MajetiNessuna valutazione finora

- 60 M.bow String Girder-10411-5-RDocumento1 pagina60 M.bow String Girder-10411-5-RkesharinareshNessuna valutazione finora

- RDSO B 11754 4R1 (Mod)Documento1 paginaRDSO B 11754 4R1 (Mod)shibnath lahiriNessuna valutazione finora

- Drawings For Culvert at 293+538 PDFDocumento3 pagineDrawings For Culvert at 293+538 PDFSurya GowthamNessuna valutazione finora

- 60 M.bow String Girder-10411-RDocumento1 pagina60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- 60 M.bow String Girder 10411 3 RDocumento1 pagina60 M.bow String Girder 10411 3 RkesharinareshNessuna valutazione finora

- 60 M.bow String Girder-10411-8-R1Documento1 pagina60 M.bow String Girder-10411-8-R1kesharinaresh100% (1)

- Proposed Arch Bridge On Lower Lake of Bhopal: A Case StudyDocumento3 pagineProposed Arch Bridge On Lower Lake of Bhopal: A Case StudyInnovative Research PublicationsNessuna valutazione finora

- 42m BowStringDocumento1 pagina42m BowStringsorowareNessuna valutazione finora

- DrawingsStrutures PKG V PDFDocumento67 pagineDrawingsStrutures PKG V PDFMandeep Singh100% (1)

- Master List of Drawings Nov 2019Documento67 pagineMaster List of Drawings Nov 2019Kanhaiya Lal YadavNessuna valutazione finora

- 60 M.bow String Girder 10411 1 RDocumento1 pagina60 M.bow String Girder 10411 1 RkesharinareshNessuna valutazione finora

- 36m BowString PDFDocumento1 pagina36m BowString PDFD SRINIVAS100% (1)

- 42 M Bow String Girder-10408-5-R PDFDocumento1 pagina42 M Bow String Girder-10408-5-R PDFPhanindra MajetiNessuna valutazione finora

- JMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27Documento1 paginaJMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27RVNLPKG6B VBL-GTLM100% (1)

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocumento4 pagineHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarNessuna valutazione finora

- Major BR - No.607 OHE Mast - V1 - SSE-BR-DRG-6 - P16Documento1 paginaMajor BR - No.607 OHE Mast - V1 - SSE-BR-DRG-6 - P16dipakNessuna valutazione finora

- 48m BowStringDocumento1 pagina48m BowStringgoutammand100% (2)

- M Bow String Girder-10409-9Documento1 paginaM Bow String Girder-10409-9prejithNessuna valutazione finora

- Modified LVUP DrawingsDocumento1 paginaModified LVUP DrawingsAldrinNessuna valutazione finora

- 54 M.bow String Girder-10410-9Documento1 pagina54 M.bow String Girder-10410-9SANJEEV VERMANessuna valutazione finora

- RDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDDocumento1 paginaRDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDSrikanth Patel DspNessuna valutazione finora

- Drawing Title: Employer Project Design Consultant: HouseDocumento5 pagineDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalNessuna valutazione finora

- R. D. S. O.: Rdso/b - 10408/6Documento1 paginaR. D. S. O.: Rdso/b - 10408/6MUTHU PANDINessuna valutazione finora

- 36m BowString PDFDocumento1 pagina36m BowString PDFgoutammand67% (3)

- PCC Breast Wall 11-05-2021-ModelDocumento1 paginaPCC Breast Wall 11-05-2021-ModelEr navneet jassiNessuna valutazione finora

- Drawing 15m GirderDocumento4 pagineDrawing 15m GirderShaileshRastogiNessuna valutazione finora

- 42 M Bow String Girder-10408-1-RDocumento1 pagina42 M Bow String Girder-10408-1-RPhanindra MajetiNessuna valutazione finora

- C/S of Staircase (SCALE-1:25) : Pradeep YadavDocumento1 paginaC/S of Staircase (SCALE-1:25) : Pradeep YadavRVNLPKG6B VBL-GTLM100% (1)

- Shimla Bypass Cable Stayed Bridge BOQDocumento11 pagineShimla Bypass Cable Stayed Bridge BOQShaileshRastogi100% (1)

- 42 M Bow String Girder-10408-3-R PDFDocumento1 pagina42 M Bow String Girder-10408-3-R PDFPhanindra MajetiNessuna valutazione finora

- Design of PSC Box 45.0 M Span PDFDocumento89 pagineDesign of PSC Box 45.0 M Span PDFsiddharth yadavNessuna valutazione finora

- 42 M Bow String Girder-10408-2-R PDFDocumento1 pagina42 M Bow String Girder-10408-2-R PDFPhanindra MajetiNessuna valutazione finora

- M Bow String Girder-10408-9-R PDFDocumento1 paginaM Bow String Girder-10408-9-R PDFPhanindra MajetiNessuna valutazione finora

- 42 M Bow String Girder-10408-8-R1 PDFDocumento1 pagina42 M Bow String Girder-10408-8-R1 PDFPhanindra MajetiNessuna valutazione finora

- Rdso B-11753 5R1Documento1 paginaRdso B-11753 5R1shibnath lahiriNessuna valutazione finora

- Chinyalisaur Bridge Presentation 12.03.12Documento17 pagineChinyalisaur Bridge Presentation 12.03.12rims26Nessuna valutazione finora

- Girder ErrectionDocumento16 pagineGirder ErrectionSujeet DubeyNessuna valutazione finora

- Appendix B3 GAD Major BridgeDocumento6 pagineAppendix B3 GAD Major BridgeMAULIK RAVALNessuna valutazione finora

- Thulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Documento4 pagineThulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Himal KafleNessuna valutazione finora

- IRC 6-2017 Ammendment (Nov-17)Documento9 pagineIRC 6-2017 Ammendment (Nov-17)avisek_basuNessuna valutazione finora

- 60 M.bow String Girder 10411 2 RDocumento1 pagina60 M.bow String Girder 10411 2 Rkesharinaresh100% (1)

- 9 Sacrificial - Shuttering-1 by RMDocumento18 pagine9 Sacrificial - Shuttering-1 by RMASHISANessuna valutazione finora

- Elevation Section A A: RDSO/B-10423/2R R0Documento1 paginaElevation Section A A: RDSO/B-10423/2R R0Srikanth Patel DspNessuna valutazione finora

- Bridge PDFDocumento57 pagineBridge PDFudaynarayanaNessuna valutazione finora

- B6 Preparation of Bridge GAD BKK 220322Documento43 pagineB6 Preparation of Bridge GAD BKK 220322Ali_nauman429458Nessuna valutazione finora

- Alok Panday Design & Construction of SuperstructureDocumento57 pagineAlok Panday Design & Construction of SuperstructureBalakumaran GunasekaranNessuna valutazione finora

- Cost Estimate - Package 1Documento78 pagineCost Estimate - Package 1dheeraj sehgalNessuna valutazione finora

- North Western Railway: Sr. Den (Co) /JP CBE....... JPDocumento1 paginaNorth Western Railway: Sr. Den (Co) /JP CBE....... JPEr Navneet JassiNessuna valutazione finora

- Drainage Spout & Crash Barrier Detail PDFDocumento1 paginaDrainage Spout & Crash Barrier Detail PDFshshank guptaNessuna valutazione finora

- Drawings of Crash Barrier PDFDocumento1 paginaDrawings of Crash Barrier PDFRajesh100% (1)

- R. D. S. O.: Rdso/b - 10408/7Documento1 paginaR. D. S. O.: Rdso/b - 10408/7MUTHU PANDINessuna valutazione finora

- All RDSO Bow String Girder of Span 60-72 MDocumento9 pagineAll RDSO Bow String Girder of Span 60-72 MAjay Sinha60% (5)

- 225KL - 18M-Blank-1Documento1 pagina225KL - 18M-Blank-1Tarun SinghalNessuna valutazione finora

- Column & Axis Plan: Conc BLK Wall (By Others)Documento1 paginaColumn & Axis Plan: Conc BLK Wall (By Others)WaleedAL-suheelyDNessuna valutazione finora

- Cold Formed Steel PoultryDocumento17 pagineCold Formed Steel PoultryWaleedAL-suheelyDNessuna valutazione finora

- Solapur Divn MapDocumento1 paginaSolapur Divn MapsanjayisdonNessuna valutazione finora

- Jr. Calle O1: Plaza de ArmasDocumento1 paginaJr. Calle O1: Plaza de ArmasJhon AtalayaNessuna valutazione finora

- Rdso Bow String Girder-10411-9Documento1 paginaRdso Bow String Girder-10411-9a Rawat100% (1)

- 60 M.bow String Girder-10411-8-R1Documento1 pagina60 M.bow String Girder-10411-8-R1kesharinaresh100% (1)

- 60 M.bow String Girder-10411-RDocumento1 pagina60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- Construction of Road Over Bridge in Manduadih Yard 31.08.17Documento21 pagineConstruction of Road Over Bridge in Manduadih Yard 31.08.17kesharinaresh100% (1)

- Rdso Bow String Girder-10411-9Documento1 paginaRdso Bow String Girder-10411-9a Rawat100% (1)

- 60 M.bow String Girder-10411-8-R1Documento1 pagina60 M.bow String Girder-10411-8-R1kesharinaresh100% (1)

- Sample Work Exp. Hetauda Dudaura Bridge - 2074-075.Documento1 paginaSample Work Exp. Hetauda Dudaura Bridge - 2074-075.kesharinareshNessuna valutazione finora

- 60 M.bow String Girder 10411 1 RDocumento1 pagina60 M.bow String Girder 10411 1 RkesharinareshNessuna valutazione finora

- 60 M.bow String Girder 10411 3 RDocumento1 pagina60 M.bow String Girder 10411 3 RkesharinareshNessuna valutazione finora

- Checklist Rob WR PDFDocumento7 pagineChecklist Rob WR PDFkesharinareshNessuna valutazione finora

- 60 M.bow String Girder 10411 2 RDocumento1 pagina60 M.bow String Girder 10411 2 Rkesharinaresh100% (1)

- Design Calculation 246 MT FIX REVDocumento8 pagineDesign Calculation 246 MT FIX REVkesharinareshNessuna valutazione finora

- Dudaura Bridge ContractDocumento3 pagineDudaura Bridge ContractkesharinareshNessuna valutazione finora

- Checklist Rob WR PDFDocumento7 pagineChecklist Rob WR PDFkesharinareshNessuna valutazione finora

- Waterway - Hydrograph Calculations - Jan 2015Documento17 pagineWaterway - Hydrograph Calculations - Jan 2015kesharinareshNessuna valutazione finora

- Design Calculation 246 MT SG (L) REVDocumento8 pagineDesign Calculation 246 MT SG (L) REVkesharinareshNessuna valutazione finora

- Loi 04Documento1 paginaLoi 04kesharinareshNessuna valutazione finora

- Scope of WorkDocumento24 pagineScope of WorkkesharinareshNessuna valutazione finora

- Geotechnical Final For WebDocumento193 pagineGeotechnical Final For Webkesharinaresh100% (1)

- Power Point - Load Calculations On Railway Bridges - Lecture 070619Documento17 paginePower Point - Load Calculations On Railway Bridges - Lecture 070619kesharinaresh50% (2)

- Geotechnical Investigations For BridgesDocumento45 pagineGeotechnical Investigations For BridgeskesharinareshNessuna valutazione finora

- EPC ContractsDocumento36 pagineEPC Contractskesharinaresh50% (2)

- Cable Coordinates PSC CompositeDocumento4 pagineCable Coordinates PSC CompositekesharinareshNessuna valutazione finora

- Conferencia DR Dariusz AltermanDocumento10 pagineConferencia DR Dariusz AltermanEliana Ríos BustosNessuna valutazione finora

- Basic of HVACDocumento17 pagineBasic of HVACRajesh PuppalaNessuna valutazione finora

- Operasional, Troubleshooting Dan MaintenanceDocumento15 pagineOperasional, Troubleshooting Dan MaintenanceMiftahudin yamharNessuna valutazione finora

- Submission: Document No Received Date Review Date NotesDocumento1 paginaSubmission: Document No Received Date Review Date NotesMahmoud AbbassNessuna valutazione finora

- Design Guide Structural Brick Veneer Wscpa PDFDocumento62 pagineDesign Guide Structural Brick Veneer Wscpa PDFMadhusudan ShewalkarNessuna valutazione finora

- Cec 103 Workshop Technology 1 FT ExamDocumento7 pagineCec 103 Workshop Technology 1 FT ExamIsrael Adegboyega100% (1)

- Construction Notes: CASE-1Documento1 paginaConstruction Notes: CASE-1Cyril AleaNessuna valutazione finora

- Wind TechnicquesDocumento19 pagineWind TechnicquesCeciliaNessuna valutazione finora

- Rock Wool Glass WoolDocumento3 pagineRock Wool Glass WoolPrasanna IndrajithNessuna valutazione finora

- Work Description Unit (M.H./UNIT) Qty Duration MANPOWER (Man) LOW Average High Hrs Low Form Works InstallationDocumento43 pagineWork Description Unit (M.H./UNIT) Qty Duration MANPOWER (Man) LOW Average High Hrs Low Form Works InstallationJoseph ValenciaNessuna valutazione finora

- 4 Kerja TanahDocumento116 pagine4 Kerja Tanahنور أزلينNessuna valutazione finora

- Quick Reference GuideDocumento2 pagineQuick Reference Guideapi-279886039Nessuna valutazione finora

- MS For Ductwork SystemDocumento19 pagineMS For Ductwork SystemTruong Quoc Bao100% (1)

- Architectural Design (Finals)Documento3 pagineArchitectural Design (Finals)Myka MivelNessuna valutazione finora

- Lennox MS8C-MS8H Mini-Split SystemsDocumento4 pagineLennox MS8C-MS8H Mini-Split Systemsjcpa1000Nessuna valutazione finora

- Roof Water Proofing SystemDocumento10 pagineRoof Water Proofing Systemkranthi kumarNessuna valutazione finora

- Project Engineer OIC - Chief, Construction Section (Dcdeo) (Dcdeo) District Engineer (Dcdeo) Jocelyn C. Magnaye Robert L. Mamaril Richard A. RagasaDocumento1 paginaProject Engineer OIC - Chief, Construction Section (Dcdeo) (Dcdeo) District Engineer (Dcdeo) Jocelyn C. Magnaye Robert L. Mamaril Richard A. RagasaMark James CalumpangNessuna valutazione finora

- Architectural: Building Envelope SolutionsDocumento294 pagineArchitectural: Building Envelope SolutionsGabriel FlorianNessuna valutazione finora

- ADocumento234 pagineAAdrian HurmuzacheNessuna valutazione finora

- Richmond East Primary Care Centre 10551 Shellbridge Way, Suites 90 & 95 Richmond, BCDocumento611 pagineRichmond East Primary Care Centre 10551 Shellbridge Way, Suites 90 & 95 Richmond, BCPaola GonzalezNessuna valutazione finora

- Brochure Console Units - MIHP09-18 1Documento2 pagineBrochure Console Units - MIHP09-18 1alogentleNessuna valutazione finora

- Utilization Factor PDFDocumento4 pagineUtilization Factor PDFMuraryspotty33% (3)

- LOD Explained - Relation With Design Phases and Building Designs InfographicDocumento1 paginaLOD Explained - Relation With Design Phases and Building Designs InfographicMohammed ElSegaeyNessuna valutazione finora

- Column ReportDocumento24 pagineColumn Reportmsiddiq1Nessuna valutazione finora

- 1.2 Advantages Types of Pre StressingDocumento11 pagine1.2 Advantages Types of Pre StressingcatiexpertNessuna valutazione finora

- Preca Catalog Read ViewDocumento16 paginePreca Catalog Read ViewAanchal AroraNessuna valutazione finora

- Temple DesignDocumento3 pagineTemple Designraju_420034520Nessuna valutazione finora

- Hydraulic Calculations Fire Protectionxlsx PDF FreeDocumento12 pagineHydraulic Calculations Fire Protectionxlsx PDF Free8benitez suiteNessuna valutazione finora

- Aqua Snap®Documento96 pagineAqua Snap®Jonh RiberosNessuna valutazione finora

- Design Slab, Beam, Girder, Column & Footings of A 90ft X 60ftDocumento37 pagineDesign Slab, Beam, Girder, Column & Footings of A 90ft X 60ftSabah Qureshi83% (23)