Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

L7042GL - Specification Data PDF

Caricato da

pedro perez MarinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

L7042GL - Specification Data PDF

Caricato da

pedro perez MarinCopyright:

Formati disponibili

L7042GL

VHP Series Gas Engine Extender Series®

®

987 - 1480 BHP (736 - 1104 kWb)

Specifications

Cylinders: V12

Piston Displacement: 7040 cu. in. (115 L)

Bore & Stroke: 9.375” x 8.5” (238 x 216 mm)

Compression Ratio: 10.5:1

Jacket Water System Capacity: 100 gal. (379 L)

Lube Oil Capacity: 190 gal. (719 L)

Starting System: 125 - 150 psi air/gas 24/32V electric

Dry Weight: 21,000 lb. (9525 kg)

Image may not be an accurate

representation of this model

Standard Equipment

AIR CLEANER – Two, 3" dry type filter with hinged rain shield and service EXHAUST OUTLET – Single vertical at rear. Flexible stainless steel connection

indicator. with 8" (203 mm) pipe flange.

BARRING DEVICE – Manual. FLYWHEEL – Approx. WR2 = 155000 lb-in2; with ring gear (208 teeth), machined

to accept two drive adapters: 31.88" (810 mm) pilot bore, 30.25" (768 mm) bolt

BATTERY BOX – Ship loose battery box designed to accommodate two series 31 circle, (12) 0.75"–10 tapped holes; or 28.88" (734 mm) pilot bore, 27.25" (692

12 VDC batteries. Includes power disconnect switch and 20 foot (6.1 m) cable for mm) bolt circle, (12) 0.625"–11 tapped holes and (12) 0.75"–10 tapped holes.

connection to ESM Power Distribution Box.

FLYWHEEL HOUSING – No. 00 SAE.

BEARINGS – Heavy duty, replaceable, precision type.

FUEL SYSTEM – Single 3" ANSI flange fuel inlet connection. Dual natural gas, 4"

BREATHER – Self regulating, closed system. (102 mm) duplex updraft carburetors. Two mounted Fisher 99, 2" (51 mm) gas

CONNECTING RODS – Drop forged steel, rifle drilled. regulators, 43 – 60 psi (296 – 414 kPa) gas inlet pressure required. Prechamber

fuel system and control logic. 10 foot (3 m) harness provided for ESM control of

CONTROL SYSTEM – Waukesha Engine System Manager (ESM) integrates customer supplied fuel shutoff valve.

spark timing control, speed governing, detonation detection, start-stop control,

diagnostic tools, fault logging and engine safeties. Engine Control Unit (ECU) is GOVERNOR – Electric throttle actuator controlled by ESM with throttle position

central brain of the control system and main customer interface. Interface with feedback. Governor tuning is performed using ESP. ESM includes option of a load-

ESM is through 25 foot (7.6 m) harness to local panel, through MODBUS RTU coming feature to improve engine response to step loads.

slave connection RS-485 multidrop hardware, and through the Electronic Service IGNITION SYSTEM – Ignition Power Module (IPM) controlled by ESM, with

Program (ESP). Customer connections are only required to the local panel, fuel spark timing optimized for any speed-load condition. Dual voltage energy levels

valve, and 24V DC power supply. Compatible with Woodward load sharing module. automatically controlled by ESM to maximize spark plug life.

ESM meets Canadian Standards Association Class I, Division 2, Group A, B, C &

D (Canada & US) hazardous location requirements. ESM controlled prechamber INTERCOOLER – Air–to–water.

logic. LEVELING BOLTS

CRANKCASE – Integral crankcase and cylinder frame. Main bearing caps drilled LIFTING EYES – Requires 9.5 ton Working Load Limit (W.L.L.) anchor shackles.

and tapped for temperature sensors. Does not include sensors.

LUBRICATION – Full pressure, gear type pump. Engine mounted full flow lube oil

CRANKSHAFT – Counterweighted, forged steel, seven main bearings, and micro-fiberglass filters with mounted differential pressure gauge. MICROSPIN®

dynamically balanced. bypass filter, engine mounted. Air/gas motor driven prelube pump, requires final

CYLINDERS – Removable bainitic cast iron wet type cylinder liners, chrome piping.

plated on outer diameter. MANIFOLDS – Exhaust, (2) water cooled.

CYLINDER HEADS – Twelve interchangeable. Two hard faced intake and two OIL COOLER – Shell and tube type, with thermostatic temperature controller and

hard faced exhaust valves per cylinder. Hard faced intake and exhaust valve seat pressure regulating valve. Factory mounted.

inserts. Roller valve lifters and hydraulic push rods. Includes prechamber and

related fuel control valves. OIL PAN – Deep sump type. 190 gallon (719 L) capacity including filter and

cooler.

ELECTRONIC SERVICE PROGRAM (ESP) – Microsoft® Windows-based

program provided on CD-ROM for programming and interface to ESM. Includes PAINT – Oilfield orange primer.

E-Help for troubleshooting any ESM faults. Serial harness is provided for PISTONS – Aluminum with floating pin. Oil cooled.

connection of a customer supplied laptop to the ECU RS-232 port.

SHIPPING SKID –For domestic truck or rail.

ENGINE ROTATION – Counterclockwise when facing flywheel.

TURBOCHARGERS – Two, dry type. Wastegate controlled.

ENGINE MONITORING DEVICES – Factory mounted and wired sensors for

lube oil pressure and temperature; intake manifold temperature and pressure; VIBRATION DAMPER – Two, viscous type. Guard included with remote mounted

overspeed; and jacket water temperature; all accessible through ESM®. ESM radiator or no radiator.

continually monitors combustion performance through accelerometers to provide WATER CIRCULATING SYSTEM, AUXILIARY CIRCUIT – Belt driven water

detonation protection. Dual magnetic pick-ups are used for accurate engine speed circulating high capacity pump for intercooler and lube oil cooler. See S6543-38

monitoring. ESM provides predictive spark plug diagnostics as well as advanced performance curve for use with standard 10" diameter crankshaft pulley. Includes

diagnostics of engine and all ESM sensors and logs any faults into non-volatile thermostatic valve.

flash memory. Sensors meet Canadian Standards Association Class 1, Division 2,

Group A, B, C, & D (Canada & US) hazardous location requirements. WATER CIRCULATING SYSTEM, ENGINE JACKET – Belt driven water

circulating pump, cluster type thermostatic temperature regulating valve, full flow

EXHAUST THERMOCOUPLES – 14 K-type thermocouples. One for each bypass type. Flange connections and mating flanges for (2) 4" (102 mm) inlets

individual cylinder and one pre-turbine for each bank and 25 foot (7.6 m) harness. and (1) 5" (127 mm) outlet.

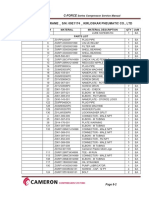

POWER RATINGS: L7042GL VHP Series Gas Engines

Brake Horsepower (kWb Output)

130°F (54°C) I.C. Water Temperature

1200 RPM 1000 RPM 900 RPM 800 RPM

Displ. cu.

Model C.R. Bore & Stroke in. (mm) in. (litres) C I C I C I C I

L7042GL 10.5:1 9.375'' x 8.5'' (238 x 216) 7040 (115) 1480 1626 1233 1355 1110 1219 987 1084

(1104) (1213) (920) (1010) (830) (909) (736) (808)

1200 rpm 1000 rpm

C I C I

Power bhp (kWb) 1480 (1104) 1626 (1213) 1233 (919) 1355 (1010)

BSFC (LHV) Btu/bhp-hr (kJ/kWh) 7157 (10128) 7031 (9948) 7036 (9958) 6759 (9567)

Fuel Consumption Btu/hr x 1000 (kW) 10592 (3106) 11433 (3352) 8675 (2542) 9159 (2684)

NOx g/bhp-hr (mg/nm3 @ 5% O2) 1.50 (607) 1.50 (607) 1.50 (607) 1.50 (607)

Emissions

CO g/bhp-hr (mg/nm3 @ 5% O2) 2.70 (1073) 2.70 (1073) 2.70 (1073) 2.70 (1073)

THC g/bhp-hr (mg/nm3 @ 5% O2) 5.50 (2227) 5.50 (2227) 5.50 (2227) 5.50 (2227)

NMHC g/bhp-hr (mg/nm3 @ 5% O2) 1.00 (405) 1.00 (405) 1.00 (405) 1.00 (405)

Heat to Jacket Water Btu/hr x 1000 (kW) 2834 (830) 3010 (882) 2351 (689) 2400 (703)

Heat to Lube Oil Btu/hr x 1000 (kW) 432 (127) 449 (132) 355 (104) 358 (105)

Balance

Heat

Heat to Intercooler Btu/hr x 1000 (kW) 547 (160) 616 (181) 451 (132) 452 (132)

Heat to Radiation Btu/hr x 1000 (kW) 336 (99) 332 (97) 310 (91) 308 (90)

Total Exhaust Heat Btu/hr x 1000 (kW) 3073 (901) 3370 (988) 2394 (702) 2580 (756)

Induction Air Flow scfm (Nm3/hr) 3699 (5685) 3800 (6110) 3029 (4656) 3045 (4896)

Exhaust

System

Intake/

Exhaust Flow lb/hr (kg/hr) 16050 (7281) 17200 (7802) 13145 (5963) 13825 (6271)

Exhaust Temperature °F (°C) 710 (376) 719 (382) 669 (354) 683 (362)

Typical heat data is shown, however no guarantee is expressed or implied. Consult your Dresser Waukesha Application Engineering Department for system

application assistance.

All natural gas engine ratings are based on a fuel of 900 Btu/ft3 (35.3 MJ/nm3) SLHV, with a 91 WKI®. For conditions or fuels other than standard, consult the

Dresser Waukesha Application Engineering Department.

Data based on standard conditions of 77°F (25°C) ambient temperature, 29.53 inches Hg (100kPa) barometric pressure, 30% relative humidity (0.3 inches HG / 1

kPa water vapor pressure).

Fuel consumption based on ISO3046/1-1995 with a tolerance of +5% for commercial quality natural gas having a 900 BTU/ft3 (35.3 MJ/nm3) SLHV.

Heat data based on fuel consumption +2%.

Heat rejection based on cooling exhaust temperature to 77°F (25°C).

Rating Standard: All models - Ratings are based on ISO 3046/1-1986 with mechanical efficiency of 90% and Tcra (clause 10.1) as specified above limited to

± 10° F (5° C). Ratings are also valid for SAE J1349, BS5514, DIN6271 and AP17B-11C standard atmospheric conditions.

C = ISO Standard Power/Continuous Power Rating: The highest load and speed which can be applied 24 hours per day, seven days per week, 365 days

per year except for normal maintenance. It is permissible to operate the engine at up to 10% overload, or a maximum load indicated by the intermittent

rating, whichever is lower, for two hours in every 24 hour period.

I = Intermittent Service Rating: The highest load and speed that can be applied in variable speed mechanical system application only. Operation at this

rating is limited to a maximum of 3500 hours per year.

Consult your local Waukesha representative for system application assistance. The manufacturer reserves the right to change or modify without notice, the design or

equipment specifications as herein set forth without incurring any obligation either with respect to equipment previously sold or in the process of construction except

where otherwise specifically guaranteed by the manufacturer.

85" 147"

(2159 mm) (3734 mm)

97.83"

(2485 mm)

Dresser, Inc.

Dresser Waukesha

1101 West St. Paul Avenue

Waukesha, WI 53188-4999

T. 262 547 3311

F. 262 549 2795

Bulletin 7005 0710

© 2010 Dresser, Inc. All rights reserved. Waukesha, VHP, ESM, Extender Series, Microspin, and

WKI are trademarks/registered trademarks of Dresser, Inc., Dresser Waukesha www.dresser.com/waukesha

Potrebbero piacerti anche

- Ariel JGKDocumento164 pagineAriel JGKDIEGO YECID MILLAN MENDOZA100% (1)

- Allison MT (B) 600 Series Transmissions Service Manual PDFDocumento56 pagineAllison MT (B) 600 Series Transmissions Service Manual PDFthomas100% (2)

- 2b) Waukesha VHP Mainenance Cosiderations - Hour IntervalsDocumento6 pagine2b) Waukesha VHP Mainenance Cosiderations - Hour IntervalsDibyendu Chakraborty100% (1)

- Waukesha 12 Cyl Extender Parts (Complete)Documento185 pagineWaukesha 12 Cyl Extender Parts (Complete)Stephen Cox94% (17)

- 03 E85 M54 Engine PDFDocumento13 pagine03 E85 M54 Engine PDFlartsim115Nessuna valutazione finora

- Operator'S Manual For Models: JG, Jga, JGM, JGP: Heavy Duty Balanced Opposed CompressorsDocumento70 pagineOperator'S Manual For Models: JG, Jga, JGM, JGP: Heavy Duty Balanced Opposed CompressorsDjebali MouradNessuna valutazione finora

- Waukesha Service Repair Kits 2005Documento205 pagineWaukesha Service Repair Kits 2005Javier Leonidas92% (13)

- Air Intake System - LEBW4969-00 PDFDocumento36 pagineAir Intake System - LEBW4969-00 PDFgustavo caicedoNessuna valutazione finora

- 6388-1 Web PDFDocumento466 pagine6388-1 Web PDFjonathan50% (2)

- Learn Windows PowerShell in A Month of Lunches - Computer ScienceDocumento6 pagineLearn Windows PowerShell in A Month of Lunches - Computer Sciencefofuhuwa25% (4)

- Rod ReversalDocumento21 pagineRod ReversalandresNessuna valutazione finora

- Ariel E. Valves 3.2Documento48 pagineAriel E. Valves 3.2Manuel Liñeiro100% (1)

- VHP Parts BookDocumento19 pagineVHP Parts Bookhuskerchamps100% (6)

- Ariel J. Lubrication System-03 04 04Documento43 pagineAriel J. Lubrication System-03 04 04Manuel LiñeiroNessuna valutazione finora

- Smart ChoicesDocumento32 pagineSmart ChoicesSUN RAVINessuna valutazione finora

- Waukesha L5794GSI SpecDocumento2 pagineWaukesha L5794GSI SpecPaulusIwan100% (3)

- JGR JGJ enDocumento137 pagineJGR JGJ enKarlosant MJ100% (1)

- WGDocumento89 pagineWGagiba100% (1)

- Waukesha Gas Engine SparesDocumento122 pagineWaukesha Gas Engine Sparesakamalapuri388100% (6)

- Dresser-Rand - MANUAL 7SHF162Documento502 pagineDresser-Rand - MANUAL 7SHF162DAVIS VELASQUEZNessuna valutazione finora

- Man Ajax DPC 2802le Om PDFDocumento740 pagineMan Ajax DPC 2802le Om PDFJeff Langley100% (1)

- Cristian Makes and ModelsDocumento54 pagineCristian Makes and ModelsIgnacio Real BuffelliNessuna valutazione finora

- Product Overview-WH FramesDocumento43 pagineProduct Overview-WH FramesArzyman100% (1)

- Force Feed Lubrication Sysytem ImprovementsDocumento8 pagineForce Feed Lubrication Sysytem Improvementsdiego yecid millan mendozaNessuna valutazione finora

- Soccer AllDocumento111 pagineSoccer AllKoall Tchang LindienNessuna valutazione finora

- NUOVO PIGNONE Compressor Spares (2010-37)Documento4 pagineNUOVO PIGNONE Compressor Spares (2010-37)sianas1706Nessuna valutazione finora

- Waukesha V HP Series 4Documento4 pagineWaukesha V HP Series 4rohizatNessuna valutazione finora

- s55 EngineDocumento120 pagines55 Enginepedro perez Marin100% (2)

- 5 PDFDocumento40 pagine5 PDFSantiago Dellacha100% (1)

- Sbindex 6 5 19Documento50 pagineSbindex 6 5 19Sallar Qazi100% (1)

- 6HP26 ZF Transmissions With MechatronicsDocumento66 pagine6HP26 ZF Transmissions With MechatronicsSalman Eid100% (1)

- Ficha Técnica Engine Gas L7042GSI PDFDocumento2 pagineFicha Técnica Engine Gas L7042GSI PDFCamilo Sanchez VanegasNessuna valutazione finora

- Dresser-Rand: Service ManualDocumento1 paginaDresser-Rand: Service ManualTu PhamNessuna valutazione finora

- PM CatalogueDocumento109 paginePM CatalogueCharan KrNessuna valutazione finora

- Waukesha Knock IndexDocumento5 pagineWaukesha Knock IndexAchmad Nizar Zulmi100% (1)

- Wuaukesha EnginesDocumento4 pagineWuaukesha EnginesVirbiirNessuna valutazione finora

- WSHA SB 14-3071 - Engine Vibration and Vibration Level Acceptability Guidelines For Waukesha Gas EngineDocumento4 pagineWSHA SB 14-3071 - Engine Vibration and Vibration Level Acceptability Guidelines For Waukesha Gas EngineCamilo Andres Cardozo Fajardo100% (4)

- Ariel Compressor Bolting Tightening Torque-Reciprocating CompDocumento8 pagineAriel Compressor Bolting Tightening Torque-Reciprocating CompCokro YudhaNessuna valutazione finora

- Waukesha VHP Serie 5Documento45 pagineWaukesha VHP Serie 5dfmolina100% (1)

- Ariel Build Book F-13989 PDFDocumento133 pagineAriel Build Book F-13989 PDFhugoheloNessuna valutazione finora

- Compressor Torque Manual GES089Documento93 pagineCompressor Torque Manual GES089Jeff LNessuna valutazione finora

- Waukesha Gas Engines VHP L7042GLDocumento2 pagineWaukesha Gas Engines VHP L7042GLrohizatNessuna valutazione finora

- Parts List: Frame AssemblyDocumento202 pagineParts List: Frame AssemblylouatiNessuna valutazione finora

- MH62 - 07H1622-07H1628 GEA - ManualDocumento3 pagineMH62 - 07H1622-07H1628 GEA - ManualSAID GUERROUTNessuna valutazione finora

- Technical Manual For Models JGZ and JGU PDFDocumento211 pagineTechnical Manual For Models JGZ and JGU PDFjudarangoca100% (2)

- JGC JGD JGF enDocumento145 pagineJGC JGD JGF enKarlosant MJ100% (2)

- CCIE LabDocumento144 pagineCCIE LabCông SơnNessuna valutazione finora

- Ajax PresentationDocumento34 pagineAjax PresentationJesus lopezNessuna valutazione finora

- Product Catalog 6-25-20Documento62 pagineProduct Catalog 6-25-20ahmed hafezNessuna valutazione finora

- 275GL+ 16V 275GL / GL+ Parts Catalog: Waukesha Gas EnginesDocumento182 pagine275GL+ 16V 275GL / GL+ Parts Catalog: Waukesha Gas EnginesdfmolinaNessuna valutazione finora

- Ariel JGK4 F11982 PartsDocumento19 pagineAriel JGK4 F11982 PartsAnonymous TXOkcdy100% (3)

- Toyota Celica 94-95 & Corolla 93-95 Trouble CodeDocumento2 pagineToyota Celica 94-95 & Corolla 93-95 Trouble CodeKike22Nessuna valutazione finora

- Gas Regulator Maintenance Kits For Waukesha Gas Engines: Product Description Applicable UnitsDocumento2 pagineGas Regulator Maintenance Kits For Waukesha Gas Engines: Product Description Applicable Unitsaras50% (2)

- Technical Spec AgitatorDocumento74 pagineTechnical Spec Agitatornaresh kumarNessuna valutazione finora

- D E F Op InstDocumento85 pagineD E F Op Instwilber100% (2)

- L7042GDocumento2 pagineL7042GRose MarieNessuna valutazione finora

- L7044GSI: VHP Series Four Gas EngineDocumento2 pagineL7044GSI: VHP Series Four Gas EngineferyNessuna valutazione finora

- ABAP Proxy (Complete Developments On SAP-PI &am..Documento7 pagineABAP Proxy (Complete Developments On SAP-PI &am..saranpcNessuna valutazione finora

- Waukesha F11gsi - Valve Clearence - CompressionDocumento2 pagineWaukesha F11gsi - Valve Clearence - Compressionnicol_sg100% (1)

- Ajax Igtb Electronic GovernorDocumento2 pagineAjax Igtb Electronic GovernorAnonymous CD0suI9Nessuna valutazione finora

- Mnit001 Meter Manual PDFDocumento9 pagineMnit001 Meter Manual PDFSergio Andres Rivera JaramilloNessuna valutazione finora

- Compresor Ariel KBU Fase 4Documento211 pagineCompresor Ariel KBU Fase 4Jorge SanchezNessuna valutazione finora

- Catalogo de Partes ARIEL JGC-2Documento84 pagineCatalogo de Partes ARIEL JGC-2diego yecid millan mendozaNessuna valutazione finora

- L7042gsi 7011 0710Documento2 pagineL7042gsi 7011 0710A2 BhaskarNessuna valutazione finora

- L7042GSI: VHP Series Gas Engine Extender SeriesDocumento2 pagineL7042GSI: VHP Series Gas Engine Extender SeriesferyNessuna valutazione finora

- VHP Series Gas Engine Extender Series: 886 - 1547 BHP (660 - 1154 KWB)Documento2 pagineVHP Series Gas Engine Extender Series: 886 - 1547 BHP (660 - 1154 KWB)feryNessuna valutazione finora

- F3514GSI: VHP Series Four Gas EngineDocumento2 pagineF3514GSI: VHP Series Four Gas EngineferyNessuna valutazione finora

- VHP Series Four Gas Engine: Standard EquipmentDocumento2 pagineVHP Series Four Gas Engine: Standard EquipmentferyNessuna valutazione finora

- F3524gsi 7039 0710 PDFDocumento2 pagineF3524gsi 7039 0710 PDFMohamed EssamNessuna valutazione finora

- VHP7104GSI/GSID: VHP Series Four Gas Enginator Generating System Featuring ESM TechnologyDocumento2 pagineVHP7104GSI/GSID: VHP Series Four Gas Enginator Generating System Featuring ESM TechnologyferyNessuna valutazione finora

- 7078 0403 Engine P48GLDDocumento2 pagine7078 0403 Engine P48GLDpedro perez Marin100% (1)

- Ajax Ajax: Arrow Manufactured Replacement PartsDocumento144 pagineAjax Ajax: Arrow Manufactured Replacement Partspedro perez MarinNessuna valutazione finora

- VGF BookDocumento68 pagineVGF BookMudabbir Shan AhmedNessuna valutazione finora

- History of The Reigning Champion: The BMW Boxer EngineDocumento8 pagineHistory of The Reigning Champion: The BMW Boxer Enginepedro perez MarinNessuna valutazione finora

- 3SeriesSaloon Touring2Documento29 pagine3SeriesSaloon Touring2pedro perez MarinNessuna valutazione finora

- Garage FurnitureDocumento16 pagineGarage Furniturepedro perez MarinNessuna valutazione finora

- Garage FurnitureDocumento16 pagineGarage Furniturepedro perez MarinNessuna valutazione finora

- AA283Aircraft and Rocket Propulsion BOOK BJ Cantwell PDFDocumento337 pagineAA283Aircraft and Rocket Propulsion BOOK BJ Cantwell PDFpedro perez MarinNessuna valutazione finora

- B11R Sunsundegui SC7 SpecDocumento1 paginaB11R Sunsundegui SC7 Specpedro perez MarinNessuna valutazione finora

- AA283Aircraft and Rocket Propulsion BOOK BJ Cantwell PDFDocumento337 pagineAA283Aircraft and Rocket Propulsion BOOK BJ Cantwell PDFpedro perez MarinNessuna valutazione finora

- 14 EricCottell NONOX PDFDocumento34 pagine14 EricCottell NONOX PDFpedro perez MarinNessuna valutazione finora

- VHP Parts BookDocumento32 pagineVHP Parts Bookfstaday6624Nessuna valutazione finora

- SatellitecommDocumento2 pagineSatellitecommA. DeviNessuna valutazione finora

- Avinocs MilBusDocumento2 pagineAvinocs MilBussakthisriniNessuna valutazione finora

- Power Supply ExportDocumento513 paginePower Supply ExportAlexandru OrghiciNessuna valutazione finora

- Prof. Arun Kumar Sangaiah-C.V PDFDocumento15 pagineProf. Arun Kumar Sangaiah-C.V PDFIslabudeen MdNessuna valutazione finora

- Pyramid - Adventurous Occupations - Computer Expert (For Gurps 4e)Documento5 paginePyramid - Adventurous Occupations - Computer Expert (For Gurps 4e)answeringthecalNessuna valutazione finora

- AmpliTube 4 User ManualDocumento102 pagineAmpliTube 4 User Manualutenteetico100% (1)

- Virtual InvisibilityDocumento27 pagineVirtual InvisibilityDharmendra SinghNessuna valutazione finora

- Tweet Me, Friend Me, Make Me BuyDocumento7 pagineTweet Me, Friend Me, Make Me BuyBrazil offshore jobsNessuna valutazione finora

- Symantec Data Center Security Server Monitoring Edition and Server Advanced 6.8 Overview GuideDocumento20 pagineSymantec Data Center Security Server Monitoring Edition and Server Advanced 6.8 Overview GuideĐình Khánh BùiNessuna valutazione finora

- P0903, P0915Documento1 paginaP0903, P0915Joanmanel Sola QuintanaNessuna valutazione finora

- Chapter 3 (Methodology) PDFDocumento15 pagineChapter 3 (Methodology) PDFFarid SyazwanNessuna valutazione finora

- Module-5 21ee13Documento11 pagineModule-5 21ee13CHIRAG GOWDANessuna valutazione finora

- 2020-03-04-Manuale-Tecnico-Louça Krupps - Uniko - Wi-Fi-rev03 - ENGDocumento40 pagine2020-03-04-Manuale-Tecnico-Louça Krupps - Uniko - Wi-Fi-rev03 - ENGLuis RolaNessuna valutazione finora

- Student Mark Analysis SystemDocumento20 pagineStudent Mark Analysis SystemSasi S INDIANessuna valutazione finora

- Bharti Airtel PresentationDocumento32 pagineBharti Airtel PresentationNaina ChetwaniNessuna valutazione finora

- Water Pipe Robot With Soft Inflatable ActuatorsDocumento7 pagineWater Pipe Robot With Soft Inflatable ActuatorseyaoNessuna valutazione finora

- Ey Smart ClosingDocumento4 pagineEy Smart ClosingMuhammed JasilNessuna valutazione finora

- Informe de VentasDocumento24 pagineInforme de VentasBlanca Zoraida Mahecha BenitoNessuna valutazione finora

- Bangladesh Railway e Ticket PDFDocumento1 paginaBangladesh Railway e Ticket PDFShanto Mohammad Salah UddinNessuna valutazione finora

- Operation (Short) : FC120 Fire Control Panel (NL)Documento8 pagineOperation (Short) : FC120 Fire Control Panel (NL)Pedro Sanchez RodriguezNessuna valutazione finora

- Customer Master UsermanualDocumento13 pagineCustomer Master UsermanualVeeru ThungaNessuna valutazione finora

- Lab 11 - Private Line Automatic RingdownDocumento5 pagineLab 11 - Private Line Automatic RingdowndjmckcNessuna valutazione finora

- Samsung Eric-Ve-R r1.0Documento43 pagineSamsung Eric-Ve-R r1.0Tintaytoner ZumpangoNessuna valutazione finora