Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PWPS BIS-DK-W 120 Rev0 PDF

Caricato da

TomasPavlovicTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PWPS BIS-DK-W 120 Rev0 PDF

Caricato da

TomasPavlovicCopyright:

Formati disponibili

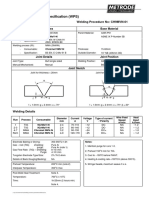

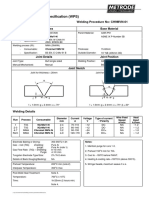

PRELIMINARY WELDING PROCEDURE SPECIFICATION pWPS No.

BIS-DK-W 120

Approval according to:

ISO 15614-1 Revision No. 0

Bilfinger Salamis Date 19.11.2018.

Client:

Client's specification:

ISO 15614-1 Supported by WPQR N/A

Project: N

BIS-DK form number: BIS-DK-F 108 Welding Procedure Qualification Record for SS 316

ISO 15608 ISO 15608

Designation-grade Ceqv. max. Designation-grade Ceqv. max.

Group Group

S335G 1.2 0.43 til S335G 1.2 0.43

Plate-pipe Thickn.range mm Plate-pipe Thickn.range mm

Butt weld t1=35-70mm to Butt weld T2=35-70mm

Fillet weld to Fillet weld

Max. yield strength Pipe diameter range mm Throat thickness mm Other data

- N/A N/A

Joint details and welding sequence (sketch) Tacking Yes No

50° + 10˚ Min. preheat temp. 150 °C

- 5˚

Length 1x25mm mm

No of runs Multi layer

Position PF (uphill)

2-N

Gouging Yes No

1-2 mm 1 Electrode dia. 2,5 / 3,2 mm

2-4 mm Grinding Yes No

Other data

Type Standard Speed mm/min.

Current range

G Gas Run out length

Welding process

T Wire Stringer

P Flux ↓ Run width max. mm

E Electrode EN ISO 2560-A

Run No.

AC

Polarity

↓ Dimension Volt DC Gas L/min.

↓ ↓ Heat

Trademark mm Classification AMP Nozzle Back purge input*

1 111 E FILARC 76S 2,5 E7018G ÷ 20-23 65-80 0,75-0,95 10 - - 1,4-2,4

2 111 E FILARC 76S 3,0 E7018G + 21-23 105-135 1,2-1,55 13 - - 1,5-2,6

3-N 111 E FILARC 76S 3,0 E7018G + 21,5-23 115-135 1,1-1,9 12-16 - - 1,3-2,8

CAP 111 E FILARC 76S 3,0 E7018G + 21,5-23 110-130 1,3-2,0 13-18 - - 1,1-2,3

Special requirements

Preheat 100 °C Interpass temp. max. 150 °C

PWHT: No Yes, see enclosure No.:

Notes - other informations

*Heat input calculated according to EN 1011-1. without Effeciency factor

Date Date Date

19.11.2018.

Contractor's signature Client's or representative's signature Certifying Authority's signature

Bilfinger Salamis UK Ltd, 4 Greenhole Place, Bridge of Don, Aberdeen, AB23 8EU | Tel: +44 1224 246000 | Fax: +44 1224 246100

Potrebbero piacerti anche

- ISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108Documento1 paginaISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108TomasPavlovicNessuna valutazione finora

- ISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108Documento1 paginaISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108TomasPavlovicNessuna valutazione finora

- Metrode - P92 WPS PDFDocumento3 pagineMetrode - P92 WPS PDFXing ChenNessuna valutazione finora

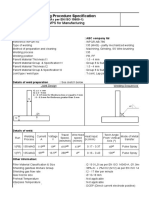

- Welding Procedure Specification (WPS)Documento3 pagineWelding Procedure Specification (WPS)Jignasa ShahNessuna valutazione finora

- S355 To Hardox 450Documento1 paginaS355 To Hardox 450Bien NguyenDuyNessuna valutazione finora

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocumento1 paginaReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNessuna valutazione finora

- S355 To Hardox 450 - Plate 60 MMDocumento1 paginaS355 To Hardox 450 - Plate 60 MMBien NguyenDuyNessuna valutazione finora

- Welding Procedure Specification (WPS) : N.A N.ADocumento1 paginaWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiNessuna valutazione finora

- Wps Repair WorDocumento1 paginaWps Repair WorMajdi JerbiNessuna valutazione finora

- WPS-CR 01-06-15Documento1 paginaWPS-CR 01-06-15majdi jerbiNessuna valutazione finora

- WPS and PQR of DSAW (Helical Welding)Documento9 pagineWPS and PQR of DSAW (Helical Welding)魏利强Nessuna valutazione finora

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocumento3 pagineWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Ornek WPS (ASME IX)Documento1 paginaOrnek WPS (ASME IX)kaynakteknolojiNessuna valutazione finora

- Welding Procedure Specification (WPS)Documento6 pagineWelding Procedure Specification (WPS)Mohamad Marwan HamwiNessuna valutazione finora

- P91 Profile WpsDocumento6 pagineP91 Profile WpsZead Ali Adal100% (2)

- WPS and PQR For SAW (Butt Welding)Documento8 pagineWPS and PQR For SAW (Butt Welding)魏利强Nessuna valutazione finora

- P91 ProfileDocumento6 pagineP91 ProfilesrinivasanNessuna valutazione finora

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Documento2 pagineWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Preliminary Welding Procedure Specification (PWPS)Documento2 paginePreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- Pwps Jo Wps Asme 016 Rev.001Documento2 paginePwps Jo Wps Asme 016 Rev.001Bagandi ManurungNessuna valutazione finora

- WPSDocumento5 pagineWPSParshottam Brahmxatriya100% (1)

- P WPS Smaw Ceym 001 021Documento1 paginaP WPS Smaw Ceym 001 021juan carlos garavitoNessuna valutazione finora

- WPS-Tube To Tube Sheet (SS-SS)Documento2 pagineWPS-Tube To Tube Sheet (SS-SS)suria qaqcNessuna valutazione finora

- A53 WPSDocumento1 paginaA53 WPSNaqqash SajidNessuna valutazione finora

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Documento1 paginaWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Welding Procedure For Plate - WPSDocumento1 paginaWelding Procedure For Plate - WPSCristian ZidarescuNessuna valutazione finora

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocumento6 pagineQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNessuna valutazione finora

- WPS Welding Performance SpecialistDocumento2 pagineWPS Welding Performance SpecialistGobinath GovindarajNessuna valutazione finora

- WPS CR 01-08-09Documento1 paginaWPS CR 01-08-09majdi jerbiNessuna valutazione finora

- Welding Procedure Specification (WPS)Documento2 pagineWelding Procedure Specification (WPS)Petrr RavvNessuna valutazione finora

- Aws b2.1 BMG Base Metal Grouping For Welding Procedure and Performance Qualification 2014Documento2 pagineAws b2.1 BMG Base Metal Grouping For Welding Procedure and Performance Qualification 2014andirahmantanjung100% (1)

- ID Piping 64Documento1 paginaID Piping 64SANUNessuna valutazione finora

- Welding Procedure Specification (WPS)Documento2 pagineWelding Procedure Specification (WPS)Abdulmecit YetisNessuna valutazione finora

- Hfy2 E1890 CPF1WT WLD SPC 0008Documento3 pagineHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNessuna valutazione finora

- 07.3 111 FW ML PF WPS 20mm EngDocumento1 pagina07.3 111 FW ML PF WPS 20mm EngViktorNessuna valutazione finora

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocumento2 pagineNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNessuna valutazione finora

- QW - 482 Welding Procedure Specification (WPS)Documento5 pagineQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNessuna valutazione finora

- Ornek PQR (ASME IX)Documento2 pagineOrnek PQR (ASME IX)kaynakteknolojiNessuna valutazione finora

- Welder Approval CertDocumento1 paginaWelder Approval Certlee.ramsell1Nessuna valutazione finora

- Welding Procedure Specification (WPS) : Page: 1/1Documento5 pagineWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNessuna valutazione finora

- WPS and PQR of GMAWDocumento8 pagineWPS and PQR of GMAW魏利强Nessuna valutazione finora

- PQR Format PDFDocumento2 paginePQR Format PDFHarshit Adwani100% (2)

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Documento2 pagineWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- Welding Procedure Specification (WPS) : Code: Asme-IxDocumento2 pagineWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNessuna valutazione finora

- WPS TTR 01-08-09Documento1 paginaWPS TTR 01-08-09majdi jerbiNessuna valutazione finora

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocumento2 pagineWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNessuna valutazione finora

- Welding Procedure Specification: Material / Joints QualifiedDocumento2 pagineWelding Procedure Specification: Material / Joints QualifiedFernando LlontopNessuna valutazione finora

- WPS-Shell To Shell Joint (CS-CS) .Documento1 paginaWPS-Shell To Shell Joint (CS-CS) .suria qaqcNessuna valutazione finora

- WPS 2 Tube To MembraneDocumento4 pagineWPS 2 Tube To Membraneross anthonyNessuna valutazione finora

- Design of Anchor BoltsDocumento1 paginaDesign of Anchor BoltsdineshNessuna valutazione finora

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- Request For Welding Procedure ApprovalDocumento13 pagineRequest For Welding Procedure ApprovalecsuperalNessuna valutazione finora

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Documento2 paginePreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniNessuna valutazione finora

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocumento2 paginePetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNessuna valutazione finora

- WPS GF170 As 1554.6Documento1 paginaWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Toaz - Info Welding Procedure Specification Format PRDocumento3 pagineToaz - Info Welding Procedure Specification Format PRKarim ZahranNessuna valutazione finora

- Welding Procedure Specification FormatDocumento3 pagineWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Bis-Dk-Rt-1051 - Ip2022-NaDocumento2 pagineBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNessuna valutazione finora

- Bis-Dk-Ut-1109 - 1220-36-Le01Documento3 pagineBis-Dk-Ut-1109 - 1220-36-Le01TomasPavlovicNessuna valutazione finora

- 1200 26 PV 13 API CML Markup and TableDocumento6 pagine1200 26 PV 13 API CML Markup and TableTomasPavlovicNessuna valutazione finora

- Bis-Dk-Rt-1051 - Ip2022-NaDocumento2 pagineBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNessuna valutazione finora

- Bis-Dk-Rt-1049 - Ip2022-CeDocumento2 pagineBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNessuna valutazione finora

- Bis-Dk-Rt-1051 - Ip2022-NaDocumento2 pagineBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNessuna valutazione finora

- Bis-Dk-Rt-1051 - Ip2022-NaDocumento2 pagineBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNessuna valutazione finora

- JSA For Painting and Coating Activities (24-Sep-14)Documento6 pagineJSA For Painting and Coating Activities (24-Sep-14)TomasPavlovic100% (1)

- L1-POL-02 Narcotics Alcohol and Intoxicating Substances Abuse RevDocumento2 pagineL1-POL-02 Narcotics Alcohol and Intoxicating Substances Abuse RevTomasPavlovicNessuna valutazione finora

- Bis-Dk-Ut 1152 - 1200-24-VC01Documento6 pagineBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNessuna valutazione finora

- Bis-Dk-Mt 2107 - Eq 10520337Documento5 pagineBis-Dk-Mt 2107 - Eq 10520337TomasPavlovicNessuna valutazione finora

- Bis-Dk-Ut 1149 - C081-Ip2022-Na-1Documento6 pagineBis-Dk-Ut 1149 - C081-Ip2022-Na-1TomasPavlovicNessuna valutazione finora

- Bis-Dk-Rt-1047 - Ip2022-CeDocumento2 pagineBis-Dk-Rt-1047 - Ip2022-CeTomasPavlovicNessuna valutazione finora

- Games Are Exciting BookDocumento61 pagineGames Are Exciting BookctjazilaNessuna valutazione finora

- Installing Your Smart Thermostat by Yourself: Good To KnowDocumento1 paginaInstalling Your Smart Thermostat by Yourself: Good To KnowTomasPavlovicNessuna valutazione finora

- L5-FMT-086 (Rev 2) Residential Inspection TimesheetDocumento2 pagineL5-FMT-086 (Rev 2) Residential Inspection TimesheetTomasPavlovicNessuna valutazione finora

- JSA For Rope Access Services (24-Sep-14)Documento8 pagineJSA For Rope Access Services (24-Sep-14)TomasPavlovic100% (1)

- L1-POL-01 (Rev 10) QHSSE PolicyDocumento3 pagineL1-POL-01 (Rev 10) QHSSE PolicyTomasPavlovicNessuna valutazione finora

- JSA For Vendor Surveillance Services (04-Jun-14)Documento10 pagineJSA For Vendor Surveillance Services (04-Jun-14)TomasPavlovicNessuna valutazione finora

- L6-TGN-072 (Rev 1) Power SuppliesDocumento10 pagineL6-TGN-072 (Rev 1) Power SuppliesTomasPavlovicNessuna valutazione finora

- L1-POL-03 (Rev 6) Discrimination PolicyDocumento3 pagineL1-POL-03 (Rev 6) Discrimination PolicyTomasPavlovicNessuna valutazione finora

- L6-OGN-113 (Rev 0) Travel SecurityDocumento14 pagineL6-OGN-113 (Rev 0) Travel SecurityTomasPavlovicNessuna valutazione finora

- L6-TGN-070 (Rev 1) TransducersDocumento7 pagineL6-TGN-070 (Rev 1) TransducersTomasPavlovicNessuna valutazione finora

- L6-TGN-096 (Rev 0) Inspection in ManufacturingDocumento6 pagineL6-TGN-096 (Rev 0) Inspection in ManufacturingTomasPavlovicNessuna valutazione finora

- L6-TGN-103 (Rev 1) Pipe (Fluid Conveyance)Documento14 pagineL6-TGN-103 (Rev 1) Pipe (Fluid Conveyance)TomasPavlovicNessuna valutazione finora

- L6-TGN-073 (Rev 1) Electronic Measuring EquipmentDocumento7 pagineL6-TGN-073 (Rev 1) Electronic Measuring EquipmentTomasPavlovicNessuna valutazione finora

- L6-TGN-071 (Rev 1) Bridges and PotentiometersDocumento6 pagineL6-TGN-071 (Rev 1) Bridges and PotentiometersTomasPavlovicNessuna valutazione finora

- L6-TGN-100 (Rev 1) Oil Wells Offshore PlatformsDocumento26 pagineL6-TGN-100 (Rev 1) Oil Wells Offshore PlatformsTomasPavlovicNessuna valutazione finora

- L6-TGN-102 (Rev 1) Types of Test Certificates-ReportsDocumento32 pagineL6-TGN-102 (Rev 1) Types of Test Certificates-ReportsTomasPavlovicNessuna valutazione finora

- L6-TGN-096 (Rev 0) Inspection in ManufacturingDocumento6 pagineL6-TGN-096 (Rev 0) Inspection in ManufacturingTomasPavlovicNessuna valutazione finora

- Antorchas y Consumibles TwecoDocumento164 pagineAntorchas y Consumibles TwecoLeonardo Martínez López100% (1)

- Welded FinDocumento7 pagineWelded FinNatarajan RavisankarNessuna valutazione finora

- Böhler WeldingDocumento32 pagineBöhler WeldingszizaNessuna valutazione finora

- Certificado de Cumplimiento Alambre 0.062Documento2 pagineCertificado de Cumplimiento Alambre 0.062gizaloNessuna valutazione finora

- Pwe (2000) Prac. Weld. Engineer PDFDocumento154 paginePwe (2000) Prac. Weld. Engineer PDFwi100% (1)

- Fatigue TestingDocumento10 pagineFatigue TestingMuhammed SulfeekNessuna valutazione finora

- Svetsaren 2002-2 PDFDocumento55 pagineSvetsaren 2002-2 PDFVijo JoseNessuna valutazione finora

- Shippingworld Shipbuilder Kranendonk Welding Automation 1Documento1 paginaShippingworld Shipbuilder Kranendonk Welding Automation 1Dian Asa UtariNessuna valutazione finora

- VALVESDocumento51 pagineVALVESPalkesh Trivedi100% (2)

- B361-08 Standard Specification For Factory-Made Wrought Aluminum and Aluminum-Alloy Welding FittingsDocumento6 pagineB361-08 Standard Specification For Factory-Made Wrought Aluminum and Aluminum-Alloy Welding FittingsmithileshNessuna valutazione finora

- Description & SpecificationDocumento3 pagineDescription & SpecificationJAY PARIKHNessuna valutazione finora

- Lincoln FC ElectrodesDocumento44 pagineLincoln FC ElectrodeszmcgainNessuna valutazione finora

- 36 504 Welding of High Pressure Temperature Tube and Pipework RevDocumento40 pagine36 504 Welding of High Pressure Temperature Tube and Pipework Revmanojballa100% (1)

- Arc Welding Electrodes Powerpoint PPT PresentationDocumento4 pagineArc Welding Electrodes Powerpoint PPT PresentationramuNessuna valutazione finora

- HR MicrofinishDocumento96 pagineHR MicrofinishSuresh Babu ReddyNessuna valutazione finora

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Documento1 paginaSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNessuna valutazione finora

- CWI TEST FlashcardsDocumento30 pagineCWI TEST FlashcardsLuis Jaramillo100% (3)

- T11M408 I1 Takraf 03910 Vdcme02 P1me01 004Documento42 pagineT11M408 I1 Takraf 03910 Vdcme02 P1me01 004manuelarranoNessuna valutazione finora

- Richard Nakka's Experimental Rocketry SiteDocumento8 pagineRichard Nakka's Experimental Rocketry Siteazrim02Nessuna valutazione finora

- Catalogo FMC - Link Belt - Belt Conveyors IdlersDocumento124 pagineCatalogo FMC - Link Belt - Belt Conveyors IdlersErich Thomas100% (1)

- Welding PPT (New)Documento22 pagineWelding PPT (New)Irfan MehmoodNessuna valutazione finora

- How Do I Set Up My TIG Welder?: Owner's ManualDocumento2 pagineHow Do I Set Up My TIG Welder?: Owner's ManualenricoNessuna valutazione finora

- Norsok M-501 Rev 6 - Painting & CoatingDocumento32 pagineNorsok M-501 Rev 6 - Painting & Coatingbiryets77% (13)

- SAFETY Welding HelmetsDocumento16 pagineSAFETY Welding HelmetsPanneer SelvamNessuna valutazione finora

- Piping CBT Latest Notes 27 Feb 2024Documento26 paginePiping CBT Latest Notes 27 Feb 2024AMALENDU PAULNessuna valutazione finora

- Inspection and Assessment of Damaged Subsea PipelinesDocumento9 pagineInspection and Assessment of Damaged Subsea PipelinesВалерий ГерасимовичNessuna valutazione finora

- MCQ Paper Set 1Documento5 pagineMCQ Paper Set 1ViJay SabHaya0% (1)

- 5.K-7018 (AP) Brochure R3Documento2 pagine5.K-7018 (AP) Brochure R3Sun SunNessuna valutazione finora

- The TLE TVL Framework Overview of SHS TVLDocumento57 pagineThe TLE TVL Framework Overview of SHS TVLmark jason100% (1)

- Part 01 - Review of EN ISO 9606-1Documento26 paginePart 01 - Review of EN ISO 9606-1Turbo Snail RNessuna valutazione finora