Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ultra AARR (Alkali-Aggregate Reaction Resistant)

Caricato da

Salman GhiasCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ultra AARR (Alkali-Aggregate Reaction Resistant)

Caricato da

Salman GhiasCopyright:

Formati disponibili

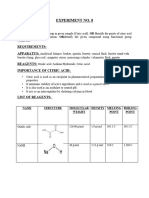

ULTRA AARR

Alkali-Aggregate Reaction Resistant

Adhesives,

Description Benefits

Admixture

ULTRA AARR is lithium nitrate base Minimizes deleterious For higher alkali content in cement this

admixture used to control alkali-slica admixture can be used at the weight 2%

Grouts & expansions in concrete due

reaction (ASR) in high alkali by weight of cement.

Anchors, to ASR

concrete, produced when using

reactive aggregates.

Increases durability and life Mixing patterns

Concrete span of the concrete Initial trials should be done with normal

Repairs,

structure concrete. After initial trials, minor

Alkali –Silica Reaction (ASR) is a modifications to the overall mixture may

chemicals reaction which occurs Allows use to locally be made as needed to optimize

Protecting when the alkali hydroxides present in available aggregate. performance.

Coatings,

the pore solution of the concrete react Compatible with

with certain forms of reactive silica More efficient use of mixing water will

appropriate pozzolans and improve mix cohesion. 470

Industrial present in the aggregates to form an other Ultra Admixtures

Flooring, CI/: u2

alkali silica gel. This gel itself is

harmless, but the presence of

Easy to use. Storage

Ultra AARR has a minimum shelf life of 1

Surface moisture it swells and generates o o

year while stored at 2 -50 C.

Treatments tensile stresses in the concrete,

eventually causing the concrete to Properties Freezing point: Approximately -3°C

crack. The main source of alkalis Appearance: Brown liquid

(sodium and potassium) in fresh Cautions

concrete is Portland cement. Specific gravity: Typically 1.170 at Health and safety

25°C

Ultra AARR is non-hazardous. However,

Chloride content: Nil to BS 5075 it should not be swallowed or allowed to

come into contact With skin and eyes.

How it works Air entrainment: Typically less

When lithium nitrate is than 3% additional air is entrained Gloves and goggles should be used.

at normal dosages. Splashes on the skin should be removed

added to the concrete

with water. In case of contact with eyes

in sufficient quantity, Alkali content: Nil rinse immediately with plenty of water

the alkali silica gel and seek medical advice.

Equivalent/liter of admixture. A

along with the sodium, fact If swallowed seek medical attention

potassium and calcium sheet on this subject is available. immediately - do not induce vomiting.

ions also contains

lithium ions. This gel For further information consult the

Material Safety Data Sheet available for

contains lithium ions this product.

Packing

does not have a Ultra AARR is available in (210 Ltr)

tendency to swell and drum, or bulk supply in tank size is Cleaning and Disposal

available. Cleaning and disposal Spillages of Ultra

expand in the presence AARR should be absorbed onto sand,

of moisture and hence earth or vermiculite and transferred to

prevent the concrete suitable containers. Remaining material

Typical dosage should be rinsed down with large

from cracking. The standard dosage of Ultra quantities of water.

ASTM Standards. AARR depends on the alkali

Compile with ASTM content of the cement used. Add

0.8 to 1.8% by weight of cement

Standard C-289, C227, depending upon the alkali contents

C1260 & C1293 in the cement.

Ultra Chemicals, LLC. USA

2153 North Westwood,Main Blvd, Poplar Bluff, MO 63901. Phone 573-778-3367 Fax 573-778-3376

info@ultra-chemicals.com, www.ultra-chemicals.com

Potrebbero piacerti anche

- Barrafer ADocumento2 pagineBarrafer ADoby YuniardiNessuna valutazione finora

- Agentes AntiescalaDocumento7 pagineAgentes AntiescalaFabian ArboledaNessuna valutazione finora

- Company Profile Publication Water Treat DC3Documento13 pagineCompany Profile Publication Water Treat DC3tito rahmanNessuna valutazione finora

- SILDRIL System Engineering GuidelinesDocumento7 pagineSILDRIL System Engineering GuidelinesAhmer AkhlaqueNessuna valutazione finora

- SLE123 - Sample Quiz 04 QuestionsDocumento17 pagineSLE123 - Sample Quiz 04 QuestionsNinaNessuna valutazione finora

- 83120-On The Dynamics of The Friction CoefficientDocumento7 pagine83120-On The Dynamics of The Friction CoefficientVitor JardimNessuna valutazione finora

- Fosroc Data Sheet 350 DISDocumento2 pagineFosroc Data Sheet 350 DISKUNAL SHAHNessuna valutazione finora

- Auramix 400Documento2 pagineAuramix 400manish lakhanpal50% (2)

- Calgon Filtrasorb 100Documento2 pagineCalgon Filtrasorb 100PT Deltapuro IndonesiaNessuna valutazione finora

- Ds Filtra10015 Ein E1Documento2 pagineDs Filtra10015 Ein E1edywahonoNessuna valutazione finora

- Auramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyDocumento2 pagineAuramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyABHI MITRANessuna valutazione finora

- Fosroc Auramix 300 AdmixtureDocumento2 pagineFosroc Auramix 300 Admixture892513822950% (2)

- Diaoxy Hi-Build Amine Cured EpoxyDocumento4 pagineDiaoxy Hi-Build Amine Cured Epoxybublooo123Nessuna valutazione finora

- Auramix 350 DIS: High Range Water Reducing and Retarding Type Admixture For Wide Range of Concrete GradeDocumento2 pagineAuramix 350 DIS: High Range Water Reducing and Retarding Type Admixture For Wide Range of Concrete GradeABHI MITRANessuna valutazione finora

- Auramix 300: Advanced Low Viscosity Retarding Super-Plasticiser, Based On Polycarboxylic TechnologyDocumento2 pagineAuramix 300: Advanced Low Viscosity Retarding Super-Plasticiser, Based On Polycarboxylic TechnologyHasan al MahmudNessuna valutazione finora

- Auramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic TechnologyDocumento2 pagineAuramix 400: Advanced Low Viscosity High Performance Superplasticiser, Based On Polycarboxylic Technologymalaya tripathy100% (1)

- Auramix 600 BFLDocumento2 pagineAuramix 600 BFLpeashNessuna valutazione finora

- DuraproofDocumento2 pagineDuraproofM HAFEEZ RAJANessuna valutazione finora

- Auramix 300 BFLDocumento2 pagineAuramix 300 BFLpeashNessuna valutazione finora

- 1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)Documento4 pagine1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)bublooo123Nessuna valutazione finora

- TDS Auramix 300 IndiaDocumento2 pagineTDS Auramix 300 IndiaDipNessuna valutazione finora

- Auramix 400 BFLDocumento2 pagineAuramix 400 BFLpeashNessuna valutazione finora

- Auramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeDocumento2 pagineAuramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeVipin Kumar Parashar100% (1)

- Ex 8Documento6 pagineEx 8raffia mahakNessuna valutazione finora

- Auramix 400: Advanced Low Viscosity High Performance Super-Plasticiser, Based On Polycarboxylic TechnologyDocumento2 pagineAuramix 400: Advanced Low Viscosity High Performance Super-Plasticiser, Based On Polycarboxylic TechnologyAnonymous XVEucVMsENessuna valutazione finora

- 11 Fibre Ropes PDFDocumento12 pagine11 Fibre Ropes PDFThomas KamongNessuna valutazione finora

- CHAPTER 2 AnachemDocumento5 pagineCHAPTER 2 AnachemrhymeNessuna valutazione finora

- Polymer Support FluidDocumento2 paginePolymer Support FluidhamsarajshettyNessuna valutazione finora

- Auramix 400Documento2 pagineAuramix 400Srinivash 4423Nessuna valutazione finora

- Product Data Sheet: 24K Carbon TowDocumento1 paginaProduct Data Sheet: 24K Carbon TowsaadnaumanNessuna valutazione finora

- TDS Auramix 400 IndiaDocumento2 pagineTDS Auramix 400 IndiaAnu K PeterNessuna valutazione finora

- Uv Curable Acrylic CoatDocumento10 pagineUv Curable Acrylic Coatxx100% (1)

- Acumer™: Scale Inhibitor and DispersantDocumento3 pagineAcumer™: Scale Inhibitor and DispersantAndreia Frassini100% (1)

- TP 245Documento4 pagineTP 245Mercy OrjiNessuna valutazione finora

- Alkali-Free Powder AcceleratorDocumento2 pagineAlkali-Free Powder AcceleratorVietpapayaNessuna valutazione finora

- Acumer 200Documento2 pagineAcumer 200abdoelandhakimNessuna valutazione finora

- Renderoc LA55Documento2 pagineRenderoc LA55Mansoor AliNessuna valutazione finora

- Kaolite LI Monolithics Up To 2600°F (1427°C) : Datasheet Code US: 3-14-103 SDS: 103 / 153Documento3 pagineKaolite LI Monolithics Up To 2600°F (1427°C) : Datasheet Code US: 3-14-103 SDS: 103 / 153luisNessuna valutazione finora

- Module 1 Unit 2Documento2 pagineModule 1 Unit 2ARRIANE CYREL CAMACHONessuna valutazione finora

- PPCJ ArticleDocumento2 paginePPCJ Articlenc5r8fkp6zNessuna valutazione finora

- Carboglas 1601 SG PDSDocumento5 pagineCarboglas 1601 SG PDSWifi wpa wepNessuna valutazione finora

- Auracast 100 BFLDocumento2 pagineAuracast 100 BFLpeashNessuna valutazione finora

- Steamate NA0880Documento2 pagineSteamate NA0880Taufik TajudinNessuna valutazione finora

- ACEcare 30KCDocumento1 paginaACEcare 30KCtopguitarNessuna valutazione finora

- Zerust AxxaVisHST-10Documento2 pagineZerust AxxaVisHST-10ccorp0089Nessuna valutazione finora

- CHEM LEC - Laboratory SuppliesDocumento5 pagineCHEM LEC - Laboratory Suppliescherrycayari13Nessuna valutazione finora

- Tds Aqualoc Tp350Documento1 paginaTds Aqualoc Tp350Vikram ManeNessuna valutazione finora

- Auramix 300Documento2 pagineAuramix 300Raja RamarNessuna valutazione finora

- Itric CID: Product BulletinDocumento2 pagineItric CID: Product BulletinHung Can DinhNessuna valutazione finora

- Auramix 500Documento2 pagineAuramix 500ritesh100% (1)

- 100M ReaxDocumento1 pagina100M ReaxNagy AliNessuna valutazione finora

- Rrrrrnaa EF PDFDocumento1 paginaRrrrrnaa EF PDFHYDRAGUARDPLUS ANTIMICROBIAL NANO COATINGNessuna valutazione finora

- Vecom 0503 RustremoverDocumento1 paginaVecom 0503 RustremoverSPYRONessuna valutazione finora

- Rapid Identification of Alkali Silica Reaction Products in ConcreteDocumento3 pagineRapid Identification of Alkali Silica Reaction Products in ConcreteEvert RiveraNessuna valutazione finora

- Biblio 14 December 2021Documento6 pagineBiblio 14 December 2021bedghiou djohraNessuna valutazione finora

- The Salt Pill™: Product Data Sheet (PDS)Documento1 paginaThe Salt Pill™: Product Data Sheet (PDS)Iqbal batchaNessuna valutazione finora

- Ac-Corroguard: Inhibitor Solution For Reinforcement BarDocumento1 paginaAc-Corroguard: Inhibitor Solution For Reinforcement BarbhagwatpatilNessuna valutazione finora

- DSM Chemical Guide 2007 03.qDocumento17 pagineDSM Chemical Guide 2007 03.qABHISEK BHATTACHARYANessuna valutazione finora

- EMULSION TECHNICAL DATA SHEET (7 Revised 1212)Documento1 paginaEMULSION TECHNICAL DATA SHEET (7 Revised 1212)kabiru isahNessuna valutazione finora

- Lapox AR-101: Technical Data Sheet - Polymers BusinessDocumento2 pagineLapox AR-101: Technical Data Sheet - Polymers Businesssriatul2006Nessuna valutazione finora

- EffiKlean SI PDS (Global)Documento1 paginaEffiKlean SI PDS (Global)Steam WaterNessuna valutazione finora

- Cap1B. IGCSE Practice Exam QuestionsDocumento5 pagineCap1B. IGCSE Practice Exam QuestionsJavier R. TrigosoNessuna valutazione finora

- AMMAN Is Hiring!Documento1 paginaAMMAN Is Hiring!Mine 77Nessuna valutazione finora

- Montie Carlo S O S of La Itice Models For CromoleculesDocumento52 pagineMontie Carlo S O S of La Itice Models For CromoleculespovNessuna valutazione finora

- Contructed Wetlands PDFDocumento30 pagineContructed Wetlands PDFJose Romero Puentes100% (1)

- Literature ReviewDocumento26 pagineLiterature ReviewMark Geoshua GodoyNessuna valutazione finora

- Myritol® 318Documento4 pagineMyritol® 318hadjer djemiliNessuna valutazione finora

- Cambridge International AS & A Level: PHYSICS 9702/42Documento24 pagineCambridge International AS & A Level: PHYSICS 9702/42Gulnur KenzheevaNessuna valutazione finora

- USP2024... Acepromazine Maleate TabletsDocumento1 paginaUSP2024... Acepromazine Maleate TabletsNeeraj SinghNessuna valutazione finora

- Low Temp Separation Unit PDFDocumento2 pagineLow Temp Separation Unit PDFMaribel Apaza MamaniNessuna valutazione finora

- Investigation On Barail Formation Coals of Upper Assam With Reference of Coal Bed Methane (CBM)Documento6 pagineInvestigation On Barail Formation Coals of Upper Assam With Reference of Coal Bed Methane (CBM)Prasun BanikNessuna valutazione finora

- Nitration of Methyl Benzoate (Organic Chemistry)Documento6 pagineNitration of Methyl Benzoate (Organic Chemistry)Run Xiang Ang100% (2)

- Introduction To Flow Cytometry May 10 PDFDocumento7 pagineIntroduction To Flow Cytometry May 10 PDFSilviaGonzalezSierraNessuna valutazione finora

- Articol 18Documento6 pagineArticol 18RaulNessuna valutazione finora

- D 422 - 63 R98 - Rdqymi02m1i5oa - PDFDocumento8 pagineD 422 - 63 R98 - Rdqymi02m1i5oa - PDFEnmanuel Cruz0% (1)

- IMG - 0531 EE PreBoard Exam 12bDocumento1 paginaIMG - 0531 EE PreBoard Exam 12blet ramNessuna valutazione finora

- Acs Langmuir 7b01682Documento10 pagineAcs Langmuir 7b01682harry mahfuzanNessuna valutazione finora

- Magna 55 BrazingDocumento2 pagineMagna 55 BrazingLee Chong EeNessuna valutazione finora

- Experiment 2 Optical and Radiation Pyrometry Lab ReportDocumento15 pagineExperiment 2 Optical and Radiation Pyrometry Lab ReportWardah SaqibNessuna valutazione finora

- Em SyllabusDocumento6 pagineEm SyllabusSuresh BalamNessuna valutazione finora

- Arena-Flow Software For Sand Core EngineeringDocumento71 pagineArena-Flow Software For Sand Core Engineeringpatrones. valerio cNessuna valutazione finora

- Experiment No. 1 Properties and Detection of CarbonDocumento3 pagineExperiment No. 1 Properties and Detection of CarbonWea Gene AzaresNessuna valutazione finora

- Choice and Analysis of The Launcher Interface Optimal Solution For AnDocumento5 pagineChoice and Analysis of The Launcher Interface Optimal Solution For AnAntonio Pérez AlonsoNessuna valutazione finora

- Stas ReviewDocumento35 pagineStas Reviewchristine manaloNessuna valutazione finora

- Module 3 and 4 Physical ScienceDocumento11 pagineModule 3 and 4 Physical ScienceBlake DoomedNessuna valutazione finora

- Final Exam Review ProblemsDocumento8 pagineFinal Exam Review ProblemsIrina StefaniaNessuna valutazione finora

- Quantitative Estimation of Amino Acids by NinhydrinDocumento4 pagineQuantitative Estimation of Amino Acids by Ninhydrinbhuvana_eee0% (1)

- LAS SHS PhySci MELC 7 Q2 Week-3Documento10 pagineLAS SHS PhySci MELC 7 Q2 Week-3Nini VillezaNessuna valutazione finora

- Phys 1111 SygsuDocumento4 paginePhys 1111 SygsuLeporeNessuna valutazione finora