Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Capacitance

Caricato da

Mark CaliwagCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Capacitance

Caricato da

Mark CaliwagCopyright:

Formati disponibili

FUEL QUANTITY INDICATING SYSTEMS

FAR Part 91 requires a fuel gauge indicating the quantity of fuel in each tank. These gauges, or systems, may be as

simple as a wire attached to a cork float. The amount of wire protruding from the cap indicates the amount of fuel in

the tank.

MECHANICAL INDICATORS

Other direct-reading fuel quantity indicators move a pointer across the dial by magnetic coupling. A float rides on

the top of the fuel which, through a bevel gear, rotates a horseshoe-shaped permanent magnet inside the indicator

housing. A pointer attached to a small permanent magnet and mounted on a pivot is separated from the horseshoe

magnet by an aluminum alloy diaphragm. The permanent magnet is coupled to the horseshoe magnet by the

magnetic fields. The pointer will move around the dial to indicate the level of fuel in the tank.

DIRECT CURRENT ELECTRICAL INDICATORS

In most cases, a direct connection between the float and the indicator is not possible. A DC electrical indicator

solves this problem. It converts mechanical motion of the float into a varying direct current. This current then drives

a mechanical indicator or is converted to a digital readout.

CAPACITANCE FUEL QUANTITY SYSTEMS

Many modern aircraft use a capacitance-type fuel quantity measuring system that factors in fuel density, as well as

volume.

This is an electronic system that measures the capacitance of the probe, or probes, that serve as the tank sender units.

A capacitor is a device that can store an electrical charge.

The probes in a capacitance fuel quantity indicating system consist of two concentric metal tubes that serve as the

plates of the capacitor

These probes extend from the top to the bottom of the tank. When the tank is empty, the plates are separated by air

that has a dielectric constant of one. When the tank is full, the dielectric is fuel that has a constant of approximately

two.

The probes also take into account the density of the fuel.

While the difference is negligible on small airplanes powered by avgas, it can be significant on large airplanes

powered by kerosene. Fuel density can change due to variations in temperature or due to substitution of a different

grade of jet fuel. The capacitive probes sense this because denser fuel has a higher dielectric constant, which

increases the measured fuel quantity at a given volume.

Since a capacitive fuel sensor measures the mass of the fuel, some compensation is required if the desired indication

is to be in gallons. To accomplish this, a compensator is built into the bottom of one of the tank units.

To provide accurate indications, the compensator should be calibrated for the grade of fuel normally used in the

aircraft.

Capacitive fuel systems can be tailored for tanks of all sizes and shapes. Another advantage is that all the probes in

the aircraft can be connected so the system that integrates their output to show the total amount of fuel on board

Troubleshooting a capacitance-type fuel-quantity indicating system is quite simple. Following the appropriate

instructions, connect a test unit into the system.

The testing unit may also provide a technician with the capability to calibrate the system following troubleshooting

and/or repairs.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Aps 3200 TrainingDocumento740 pagineAps 3200 TrainingBosanac Sasa100% (9)

- Certification Flight Standards Doc Oeb Supporting Documents TGL TGL26 Section 2 REV10Documento11 pagineCertification Flight Standards Doc Oeb Supporting Documents TGL TGL26 Section 2 REV10Mark CaliwagNessuna valutazione finora

- PabingDocumento6 paginePabingMark CaliwagNessuna valutazione finora

- HardDocumento2 pagineHardMark CaliwagNessuna valutazione finora

- Certification Flight Standards Doc Oeb Supporting Documents TGL TGL26 Section 2 REV10Documento11 pagineCertification Flight Standards Doc Oeb Supporting Documents TGL TGL26 Section 2 REV10Mark CaliwagNessuna valutazione finora

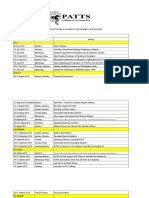

- PLP Calendar of Activities 1Documento9 paginePLP Calendar of Activities 1Mark CaliwagNessuna valutazione finora

- HardDocumento2 pagineHardMark CaliwagNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Evolution of Campus Switching: Marketing Presentation Marketing PresentationDocumento35 pagineEvolution of Campus Switching: Marketing Presentation Marketing PresentationRosal Mark JovenNessuna valutazione finora

- DLL in Health 7 3rd QuarterDocumento2 pagineDLL in Health 7 3rd QuarterJuna Lyn Hermida ArellonNessuna valutazione finora

- Translations Telugu To English A ClassifDocumento111 pagineTranslations Telugu To English A ClassifGummadi Vijaya KumarNessuna valutazione finora

- Sidomuncul20190313064235169 1 PDFDocumento298 pagineSidomuncul20190313064235169 1 PDFDian AnnisaNessuna valutazione finora

- Necromunda CatalogDocumento35 pagineNecromunda Catalogzafnequin8494100% (1)

- Matrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014Documento19 pagineMatrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014navigareeNessuna valutazione finora

- Adsorption ExperimentDocumento5 pagineAdsorption ExperimentNauman KhalidNessuna valutazione finora

- Fall 3050 SyllabusDocumento6 pagineFall 3050 Syllabustaher91Nessuna valutazione finora

- OM Part B - Rev1Documento45 pagineOM Part B - Rev1Redouane BelaassiriNessuna valutazione finora

- Department of Education: Republic of The PhilippinesDocumento1 paginaDepartment of Education: Republic of The PhilippinesKlaribelle VillaceranNessuna valutazione finora

- Science Grade 10 (Exam Prep)Documento6 pagineScience Grade 10 (Exam Prep)Venice Solver100% (3)

- Ep Docx Sca SMSC - V2Documento45 pagineEp Docx Sca SMSC - V290007Nessuna valutazione finora

- Philpost RRDocumento6 paginePhilpost RRGene AbotNessuna valutazione finora

- 5 24077 Rev2 PDFDocumento3 pagine5 24077 Rev2 PDFJavier GarcíaNessuna valutazione finora

- (QII-L2) Decorate and Present Pastry ProductsDocumento30 pagine(QII-L2) Decorate and Present Pastry ProductsLD 07100% (1)

- L5T-112 Manual - 2007 - Issue 1.1 PDFDocumento16 pagineL5T-112 Manual - 2007 - Issue 1.1 PDFfluidaimaginacionNessuna valutazione finora

- International Business ManagementDocumento3 pagineInternational Business Managementkalaiselvi_velusamyNessuna valutazione finora

- King Saud UniversityDocumento10 pagineKing Saud UniversitypganoelNessuna valutazione finora

- Upadhyayaetal TrueliqtrigcurveDocumento14 pagineUpadhyayaetal TrueliqtrigcurveVetriselvan ArumugamNessuna valutazione finora

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDocumento16 pagineBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- p7000 Series PDFDocumento592 paginep7000 Series PDFtony445Nessuna valutazione finora

- EvolutionCombatMedic 2022Documento17 pagineEvolutionCombatMedic 2022smith.kevin1420344100% (1)

- Pds Hempel's Maestro Water Borne Primer 28830 En-GbDocumento2 paginePds Hempel's Maestro Water Borne Primer 28830 En-GbKalaiyazhagan ElangeeranNessuna valutazione finora

- Rwamagana s5 Mathematics CoreDocumento4 pagineRwamagana s5 Mathematics Coreevariste.ndungutse1493Nessuna valutazione finora

- Model DPR & Application Form For Integrated RAS PDFDocumento17 pagineModel DPR & Application Form For Integrated RAS PDFAnbu BalaNessuna valutazione finora

- Net Pert: Cable QualifierDocumento4 pagineNet Pert: Cable QualifierAndrés Felipe Fandiño MNessuna valutazione finora

- NHL DB Rulebook ENGLISHDocumento6 pagineNHL DB Rulebook ENGLISHAdhika WidyaparagaNessuna valutazione finora

- Jordan CVDocumento2 pagineJordan CVJordan Ryan SomnerNessuna valutazione finora

- Leibniz, Gottfried Wilhelm - Strickland, Lloyd - Leibniz's Monadology - A New Translation and Guide-Edinburgh University Press (2014)Documento327 pagineLeibniz, Gottfried Wilhelm - Strickland, Lloyd - Leibniz's Monadology - A New Translation and Guide-Edinburgh University Press (2014)Gigla Gonashvili100% (1)

- Subject: PSCP (15-10-19) : Syllabus ContentDocumento4 pagineSubject: PSCP (15-10-19) : Syllabus ContentNikunjBhattNessuna valutazione finora