Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Novaguard

Caricato da

Manuel DueñasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Novaguard

Caricato da

Manuel DueñasCopyright:

Formati disponibili

PRODUCT DATA SHEET November 22, 2018 (Revision of November 9, 2018)

NOVAGUARD™ 840

DESCRIPTION

Two-component, solvent-free, amine-cured novolac phenolic epoxy coating

PRINCIPAL CHARACTERISTICS

• Suitable for heavy H2S wastewater environments

• Suitable for use on primed steel or direct to concrete/masonry

• Good visibility due to light color

• Glossy and smooth appearance

• Reduced explosion risk and fire hazard

• Suitable for storage of unleaded gasolines

• Good chemical resistance against a wide range of chemicals and solvents

• A clear version is available for application of glass mats repair systems or application of chopped glass fibers

• Excellent resistance to crude oil up to 120°C (250°F)

• Can be applied by heavy-duty, single-feed, airless spray equipment (60:1)

• Meets the requirements of EI 1541 2.2 (coating systems for aviation fuel storage tanks and pipes)

• Meets NSF/ANSI Standard 61 for potable water when applied and used as described on http://info.nsf.org/

COLOR AND GLOSS LEVEL

• Green, cream, clear

• Gloss

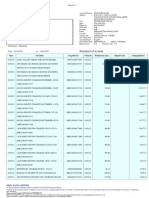

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 1.3 kg/l (10.8 lb/US gal)

Volume solids 100%

VOC (Supplied) Directive 1999/13/EC, SED: max. 106.0 g/kg

max. 142.0 g/l (approx. 1.2 lb/US gal)

EPA Method 24: 73.0 g/ltr (0.6 lb/USgal)

Recommended dry film thickness 300 - 600 µm (12.0 - 24.0 mils) depending on system

Theoretical spreading rate 3.3 m²/l for 300 µm (134 ft²/US gal for 12.0 mils)

Dry to touch 6 hours

Overcoating Interval Minimum: 24 hours

Maximum: 2 months

Full cure after 5 days

Ref. 7468 Page 1/6

PRODUCT DATA SHEET November 22, 2018 (Revision of November 9, 2018)

NOVAGUARD™ 840

Data for mixed product

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Carbon steel

• Steel; blast cleaned to a minimum of SSPC-SP10 or ISO-SA2½ , blasting profile 50 – 125 µm (5.0 mils) (2.0 – 5.0 mils)

• Steel with suitable primer (NOVAGUARD 260 or PHENGUARD 930) must be dry and free from any contamination

Concrete

• Remove grease, oil and other penetrating contaminants according to ASTM D4258

• Abrade the surface per ASTM D4259 to remove all chalk and surface glaze or laitance. Achieve surface profile - ICRI CSP

3 to 5

• NOVAGUARD 840 with PPG 884 Additive or AMERCOAT 114A may be used as a pit filler for certain applications. Check

with PPG Technical Service for guidance on chemical resistance

• Maximum recommended moisture transmission rate is 3 lbs / 1,000 ft2 / 24 hours by moisture transmission test (ASTM

F1869, calcium chloride test or by ASTM D4263, plastic sheet test)

• Moisture content should not exceed 4% (ASTM D4944, Calcuim Carbide Gas method)

Substrate temperature and application conditions

• Substrate temperature during application and curing should be above 5°C (41°F)

• Substrate temperature during application and curing should be at least 3°C (5°F) above dew point

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 80:20 (4:1)

• The temperature of the mixed base and hardener should preferably be at least 20°C (68°F)

• At lower temperature, the viscosity will be too high for spray application

• No thinner should be added

• For recommended application instructions, see working procedure

Induction time

None

Ref. 7468 Page 2/6

PRODUCT DATA SHEET November 22, 2018 (Revision of November 9, 2018)

NOVAGUARD™ 840

Pot life

1 hour at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Airless spray

• Use heavy-duty, single-feed, airless spray equipment, preferably 60:1 pump ratio and suitable high-pressure hoses/in-

line heating or insulated hoses may be necessary to avoid cooling down of paint in hoses at low air temperature

• Length of hoses should be as short as possible

Recommended thinner

No thinner should be added

Nozzle orifice

Approx. 0.53 mm (0.021 in)

Nozzle pressure

At 20°C (68°F) paint temperature min. 28.0 MPa (approx. 280 bar; 4061 p.s.i.). At 30°C (86°F) min. 22.0 MPa (approx. 220 bar;

3191 p.s.i.)

Brush/roller

• Brush: for stripe coating and spot repair only

Recommended thinner

No thinner should be added

Cleaning solvent

THINNER 90-53 or THINNER 90-83

Notes:

- Paint inside the spraying equipment must be removed before the pot life has been expired

- All application equipment must be cleaned immediately after use

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

300 µm (12.0 mils) 3.3 m²/l (134 ft²/US gal)

600 µm (24.0 mils) 1.7 m²/l (67 ft²/US gal)

Note: Maximum DFT when brushing: 150 µm (6.0 mils)

Ref. 7468 Page 3/6

PRODUCT DATA SHEET November 22, 2018 (Revision of November 9, 2018)

NOVAGUARD™ 840

Measuring wet film thickness

• A difference is often obtained between the measured apparent WFT and the real applied WFT. This is due to the

thixotropy and the surface tension of the paint, which retards the release of air, trapped in the paint film for some time

• Recommendation is to apply a WFT, which is equal to the specified DFT plus 60 µm (2.4 mils)

Measuring dry film thickness

• Because of low initial hardness the DFT cannot be measured within some days, due to the penetration of the measuring

device into the soft paint film

• The DFT should be measured using a calibration foil of known thickness placed in between the coating and the

measuring device

Overcoating interval for DFT up to 300 µm (12.0 mils)

Overcoating with... Interval 5°C (41°F) 10°C (50°F) 20°C (68°F) 30°C (86°F)

itself Minimum 3.5 days 36 hours 24 hours 16 hours

Maximum 3 months 3 months 2 months 1 month

Note: Surface should be dry and free from any contamination

Curing time for DFT up to 300 µm (12.0 mils)

Substrate temperature Dry to handle Minimum cure time for purely Minimum cure time for all

aliphatic petroleum product other chemicals

(see note)

5°C (41°F) 60 hours 10 days 15 days

10°C (50°F) 30 hours 5 days 7 days

20°C (68°F) 16 hours 60 hours 5 days

30°C (86°F) 10 hours 36 hours 3 days

40°C (104°F) 6 hours 18 hours 48 hours

Notes:

- Gasoline or gasoline/alcohol blends are not included in purely aliphatic petroleum products, please contact your PPG representative

for further details

- Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and 1434)

Pot life (at application viscosity)

Mixed product temperature Pot life

10°C (50°F) 2 hours

20°C (68°F) 1 hour

30°C (86°F) 45 minutes

Note: Due to exothermic reaction, temperature during and after mixing may increase

Ref. 7468 Page 4/6

PRODUCT DATA SHEET November 22, 2018 (Revision of November 9, 2018)

NOVAGUARD™ 840

Product Qualifications

• Qualified for ANSI/NSF Standard 61 (potable water). For NSF application instructions, please visit the following website:

http://www.nsf.org/certified-products-systems/

SAFETY PRECAUTIONS

• For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

• Although this is a solvent-free paint, care should be taken to avoid inhalation of spray mist, as well as contact between the

wet paint and exposed skin or eyes

• Ventilation should be provided in confined spaces to maintain good visibility

• If workers are exposed to concentrations above the exposure limit, they must use appropriate personal protective

equipment (PPE).

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

• CONVERSION TABLES INFORMATION SHEET 1410

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY INDICATIONS INFORMATION SHEET 1430

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

• CLEANING OF STEEL AND REMOVAL OF RUST INFORMATION SHEET 1490

• SPECIFICATION FOR MINERAL ABRASIVES INFORMATION SHEET 1491

• RELATIVE HUMIDITY – SUBSTRATE TEMPERATURE – AIR TEMPERATURE INFORMATION SHEET 1650

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the

rightful claim of any third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER

STATUTE OR ARISING OTHERWISE IN LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE,

ARE DISCLAIMED BY PPG. Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the

applicable shelf life of the product, or one year from the date of the delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar

Buyer from recovery under this warranty.

Ref. 7468 Page 5/6

PRODUCT DATA SHEET November 22, 2018 (Revision of November 9, 2018)

NOVAGUARD™ 840

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon

laboratory tests that PPG believes to be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or

suggestions relating to the use of the PPG product, whether in technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own

particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and

application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or the contents of this information (unless there are written agreements

stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This sheet supersedes all previous versions and it is the

Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

The PPG logo, and all other PPG marks are property of the PPG group of companies. All other third-party marks are property of their respective owners.

Ref. 7468 Page 6/6

Potrebbero piacerti anche

- PPG PDS Amercoat 450HDocumento6 paginePPG PDS Amercoat 450HsanguripNessuna valutazione finora

- Amercoat 450H PDSDocumento7 pagineAmercoat 450H PDSNnamdi AmadiNessuna valutazione finora

- PPG AT450 TopcoatDocumento6 paginePPG AT450 TopcoatelgusNessuna valutazione finora

- Amercoat 68hsvocDocumento6 pagineAmercoat 68hsvocVijay KumarNessuna valutazione finora

- Amershield Voc Clear Coat ResinDocumento6 pagineAmershield Voc Clear Coat ResinOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Amercoat 68hs - Ingles 2015Documento6 pagineAmercoat 68hs - Ingles 2015Peter CallánNessuna valutazione finora

- Megaseal TFDocumento6 pagineMegaseal TFSatish VishnubhotlaNessuna valutazione finora

- en-US 7743Documento5 pagineen-US 7743Jose Manuel Guizado SolisNessuna valutazione finora

- Sigmacover 280 (Primer) For HDG SurfaceDocumento6 pagineSigmacover 280 (Primer) For HDG SurfaceRauf AliyevNessuna valutazione finora

- Sigmafast 210 Ral 5011Documento5 pagineSigmafast 210 Ral 5011alexis garciaNessuna valutazione finora

- en-US 6832Documento5 pagineen-US 6832ROGER ENRIQUE JARA ALFARONessuna valutazione finora

- Sigmazinc™ 102 HS: Product Data SheetDocumento4 pagineSigmazinc™ 102 HS: Product Data Sheetyogeshkumar121998Nessuna valutazione finora

- External - PDSDocumento10 pagineExternal - PDSfaisalfaiNessuna valutazione finora

- Amercoat 450SDocumento4 pagineAmercoat 450SVijay KumarNessuna valutazione finora

- Sigmashield 880Documento6 pagineSigmashield 880Vijay KumarNessuna valutazione finora

- PPG AT370 PrimerDocumento4 paginePPG AT370 PrimerelgusNessuna valutazione finora

- Amer Coat 383 Sigma Fast TdsDocumento5 pagineAmer Coat 383 Sigma Fast TdsVINAY SARDANessuna valutazione finora

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetDocumento5 pagineSigmashield™ 880 / Amerlock® 880: Product Data Sheetjaime San Martin PulgarNessuna valutazione finora

- Sigmafast™ 278 / Amercoat® 278: Product Data SheetDocumento5 pagineSigmafast™ 278 / Amercoat® 278: Product Data SheetStuart LemonNessuna valutazione finora

- Nu-Klad™ SL: Product Data SheetDocumento4 pagineNu-Klad™ SL: Product Data SheetJefry SandyNessuna valutazione finora

- Amercoat® 71 TC: Product Data SheetDocumento5 pagineAmercoat® 71 TC: Product Data SheetNizar BouchaalaNessuna valutazione finora

- Sigmadur™ 188: Product Data SheetDocumento5 pagineSigmadur™ 188: Product Data SheetkaleshNessuna valutazione finora

- Sigmacover 850 Sigmashield 880 HSDocumento6 pagineSigmacover 850 Sigmashield 880 HSshahrimanNessuna valutazione finora

- en-US 6823Documento5 pagineen-US 6823JagdishNessuna valutazione finora

- Sigmacover™ 620: Product Data SheetDocumento5 pagineSigmacover™ 620: Product Data SheetAnonymous fvO1W3100% (1)

- Sigmacover 350 AluDocumento6 pagineSigmacover 350 AluRauf AliyevNessuna valutazione finora

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetDocumento5 pagineSigmashield™ 880 / Amerlock® 880: Product Data SheetIchsan RosidinNessuna valutazione finora

- Nova Guard 260 - InternalDocumento6 pagineNova Guard 260 - InternalfaisalfaiNessuna valutazione finora

- Sigmafast 278Documento6 pagineSigmafast 278stolemkd3Nessuna valutazione finora

- Sigmafast 278Documento5 pagineSigmafast 278kaleshNessuna valutazione finora

- Sigmacover™ 620: Product Data SheetDocumento5 pagineSigmacover™ 620: Product Data SheetMahmoud TahaNessuna valutazione finora

- Sigmacover 350Documento7 pagineSigmacover 350karim hassanNessuna valutazione finora

- Sigmacover 620Documento5 pagineSigmacover 620praveenpatel.pp7143Nessuna valutazione finora

- Sigmafast™ 210: Product Data SheetDocumento5 pagineSigmafast™ 210: Product Data SheetJurgen En Mari BeckenbauerNessuna valutazione finora

- Amercoat 78HBDocumento6 pagineAmercoat 78HBVijay KumarNessuna valutazione finora

- Amercoat 71TCDocumento5 pagineAmercoat 71TCVijay KumarNessuna valutazione finora

- HT Sigmacover 720Documento6 pagineHT Sigmacover 720Saul AntayhuaNessuna valutazione finora

- Sigmacover™ 300: Product Data SheetDocumento6 pagineSigmacover™ 300: Product Data SheetinnovativekarthiNessuna valutazione finora

- Amercoat 68HSDocumento7 pagineAmercoat 68HSVijay KumarNessuna valutazione finora

- Sigmacover™ 380: Product Data SheetDocumento5 pagineSigmacover™ 380: Product Data SheetGibbs PerNessuna valutazione finora

- SigmaCover-300 DataDocumento7 pagineSigmaCover-300 DataFaisal FaizNessuna valutazione finora

- SIgmaguard 720Documento7 pagineSIgmaguard 720Khan ZamanNessuna valutazione finora

- Amercoat 450 XDocumento5 pagineAmercoat 450 XStephen Francis BothelloNessuna valutazione finora

- en-US 7466Documento5 pagineen-US 7466RizckyAdhiprasetyoNessuna valutazione finora

- PPG Hi-Temp™ 1027 HDDocumento5 paginePPG Hi-Temp™ 1027 HDMarleo MorenoNessuna valutazione finora

- Amerlock 400BFDocumento6 pagineAmerlock 400BFVijay KumarNessuna valutazione finora

- Sigmacover™ 410/sigmacover™ 410 LT: Product Data SheetDocumento5 pagineSigmacover™ 410/sigmacover™ 410 LT: Product Data SheetNaveedMalikNessuna valutazione finora

- Sigmacover™ 410/sigmacover™ 410 LT: Product Data SheetDocumento5 pagineSigmacover™ 410/sigmacover™ 410 LT: Product Data SheetNaveedMalikNessuna valutazione finora

- Sigmazinc 109hs PDFDocumento5 pagineSigmazinc 109hs PDFAneesh Lie A YoungNessuna valutazione finora

- Sigmadur™ 540: Product Data SheetDocumento5 pagineSigmadur™ 540: Product Data SheetStuart LemonNessuna valutazione finora

- Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data SheetDocumento4 pagineSigmaline™ 780 / Phenguard™ Subsea 780: Product Data SheetscottNessuna valutazione finora

- Amercoat 68 HsDocumento7 pagineAmercoat 68 HsdharamgurnaniNessuna valutazione finora

- Sigma Cover 256Documento5 pagineSigma Cover 256Trịnh Minh KhoaNessuna valutazione finora

- Sigmacover 380 Data SheetDocumento5 pagineSigmacover 380 Data SheetcloudNessuna valutazione finora

- Amerlock 400Documento7 pagineAmerlock 400Satish VishnubhotlaNessuna valutazione finora

- Sigmacover-456 Technical Data SheetDocumento6 pagineSigmacover-456 Technical Data SheetGurdeep Sungh AroraNessuna valutazione finora

- en-US 8208Documento5 pagineen-US 8208Ha SonNessuna valutazione finora

- Sigmacover™ 456: Product Data SheetDocumento6 pagineSigmacover™ 456: Product Data SheetscottNessuna valutazione finora

- Amerlock 400 Sigmacover 400Documento6 pagineAmerlock 400 Sigmacover 400Vijay KumarNessuna valutazione finora

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlDa EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNessuna valutazione finora

- Civil Appeal 14 of 2015Documento21 pagineCivil Appeal 14 of 2015JamesNessuna valutazione finora

- Bank Officer's Handbook of Commercial Banking Law 5thDocumento363 pagineBank Officer's Handbook of Commercial Banking Law 5thCody Morgan100% (5)

- Philippines Supreme Court Rules Surviving Brother May Seek Declaration of Deceased Brother's Null MarriageDocumento9 paginePhilippines Supreme Court Rules Surviving Brother May Seek Declaration of Deceased Brother's Null MarriageMarvin CeledioNessuna valutazione finora

- How To File Motionin in New JerseyDocumento11 pagineHow To File Motionin in New Jerseyrajinusa100% (1)

- Title Pages 1. 2: 22167 Sexuality, Gender and The Law STUDENT ID: 201604269Documento21 pagineTitle Pages 1. 2: 22167 Sexuality, Gender and The Law STUDENT ID: 201604269Joey WongNessuna valutazione finora

- G.R. No. 152295 Montesclaros vs. COMELECDocumento2 pagineG.R. No. 152295 Montesclaros vs. COMELECRia N. HipolitoNessuna valutazione finora

- PI200 User Guide 230 V 50 HZDocumento26 paginePI200 User Guide 230 V 50 HZEsneider Rodriguez BravoNessuna valutazione finora

- Affirmative Action in India: Ensuring Equality and Social JusticeDocumento11 pagineAffirmative Action in India: Ensuring Equality and Social JusticeDeepa MoondraNessuna valutazione finora

- A Critical Look at Tanzani's Development Vision 2025Documento4 pagineA Critical Look at Tanzani's Development Vision 2025Haron KombeNessuna valutazione finora

- Mormugao Port (Adoptation of Rules) Regulations, 1964Documento2 pagineMormugao Port (Adoptation of Rules) Regulations, 1964Latest Laws TeamNessuna valutazione finora

- Al Nokhitha Fund Prospectus Sep2010 Tcm9-8959Documento27 pagineAl Nokhitha Fund Prospectus Sep2010 Tcm9-8959wesamNessuna valutazione finora

- 10-Cisa It Audit - BCP and DRPDocumento27 pagine10-Cisa It Audit - BCP and DRPHamza NaeemNessuna valutazione finora

- APPLICATION FORM FOR Short Service Commission ExecutiveDocumento1 paginaAPPLICATION FORM FOR Short Service Commission Executivemandhotra87Nessuna valutazione finora

- AFN 132 Homework 1Documento3 pagineAFN 132 Homework 1devhan12Nessuna valutazione finora

- For Session DTD 5th Sep by CA Alok Garg PDFDocumento46 pagineFor Session DTD 5th Sep by CA Alok Garg PDFLakshmi Narayana Murthy KapavarapuNessuna valutazione finora

- NdpsDocumento22 pagineNdpsRaviKumar VeluriNessuna valutazione finora

- v2.6 CCURE Simplex Integration RN 8200-1191-99A0Documento5 paginev2.6 CCURE Simplex Integration RN 8200-1191-99A0Rafael RojasNessuna valutazione finora

- Akmal - Assignment On Thinking SkillsDocumento9 pagineAkmal - Assignment On Thinking SkillsChew Cheng HaiNessuna valutazione finora

- Recorte Apis 1Documento35 pagineRecorte Apis 1ENZO SEBASTIAN GARCIA ANDRADENessuna valutazione finora

- Bangladesh Merchant Shipping Act 2020Documento249 pagineBangladesh Merchant Shipping Act 2020Sundar SundaramNessuna valutazione finora

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocumento4 pagineStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceSiraj PNessuna valutazione finora

- Pi SC4000 17-06 enDocumento1 paginaPi SC4000 17-06 enAlexandre RogerNessuna valutazione finora

- Salcon Berhad PDFDocumento9 pagineSalcon Berhad PDFRachmatt RossNessuna valutazione finora

- Love Is AliveDocumento3 pagineLove Is Alivesteven harrisNessuna valutazione finora

- BOA Firm ListDocumento48 pagineBOA Firm ListHtet Aung LinNessuna valutazione finora

- T1 B24 Various Interrogation Reports FDR - 4-12-95 FBI Investigation - Murad 579Documento18 pagineT1 B24 Various Interrogation Reports FDR - 4-12-95 FBI Investigation - Murad 5799/11 Document Archive100% (1)

- ACT-Act No. 3110 (Reconstitution of Judicial Records)Documento10 pagineACT-Act No. 3110 (Reconstitution of Judicial Records)xteriyakixNessuna valutazione finora

- Camper ApplicationDocumento4 pagineCamper ApplicationClaire WilkinsNessuna valutazione finora

- ASEAN Integration Opens Philippines to Regional Economic GrowthDocumento40 pagineASEAN Integration Opens Philippines to Regional Economic GrowthTESDA Korea-Phil. Information Technology Training CenterNessuna valutazione finora

- Public Disorders: Art. 153 Revised Penal Code. Tumults and Other Disturbances of Public OrderDocumento5 paginePublic Disorders: Art. 153 Revised Penal Code. Tumults and Other Disturbances of Public Orderjeysonmacaraig100% (2)