Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Low Pressure Water Heating Boilers (Under 800,000 BTUHR Output)

Caricato da

gabrielCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Low Pressure Water Heating Boilers (Under 800,000 BTUHR Output)

Caricato da

gabrielCopyright:

Formati disponibili

**************************************************************************

USACE / NAVFAC / AFCESA / NASA UFGS-23 52 43.00 20 (July 2006)

------------------------------

Preparing Activity: NAVFAC Superseding

UFGS-23 52 43.00 20 (April 2006)

UNIFIED FACILITIES GUIDE SPECIFICATIONS

References are in agreement with UMRL dated 9 October 2006

Revised throughout - changes not indicated by CHG tags

**************************************************************************

SECTION TABLE OF CONTENTS

DIVISION 23 - HEATING, VENTILATING, AND AIR CONDITIONING

SECTION 23 52 43.00 20

LOW PRESSURE WATER HEATING BOILERS (UNDER 800,000 BTU/HR OUTPUT)

07/06

PART 1 GENERAL

1.1 REFERENCES

1.2 RELATED REQUIREMENTS

1.3 DESIGN REQUIREMENTS

1.3.1 Detail Drawings

1.3.2 Water Analysis

1.4 SAFETY STANDARDS

1.5 SUBMITTALS

1.6 SUSTAINABLE DESIGN REQUIREMENTS

1.6.1 Local/Regional Materials

1.6.2 Environmental Data

PART 2 PRODUCTS

2.1 BOILERS

2.2 BURNERS AND CONTROL EQUIPMENT

2.2.1 Atmospheric-Type Gas Burner

2.2.2 Gas-Fired Power Burner

2.2.3 Oil-Fired Power Burner

2.2.4 Oil-Fired Power Burner

2.2.5 Gas and Light Oil-Fired Power Burner

2.3 BOILER TRIM AND CONTROL EQUIPMENT

2.3.1 Emergency Disconnect Switch

2.3.2 Relief Valves

2.3.3 Pressure and Altitude Gage or Combination Pressure/Altitude Gage

2.3.4 Thermometer

2.3.5 Drain Tapping

2.3.6 Make-up Water Station

2.3.6.1 Pressure Reducing Station

2.3.6.2 Backflow Preventers

2.3.7 Feedwater Treatment Feeder

2.3.8 Combustion Regulator

2.3.9 Air Vent Valve

SECTION 23 52 43.00 20 Page 1

2.3.10 High Temperature Limit Switch

2.3.11 Low Water Pressure Control

2.3.12 Low Water Level Cutoff Switch

2.3.13 Boiler Safety Control Circuits

2.3.14 Indicating Lights

2.3.15 Alarm Bell

2.3.16 Post-Combustion Purge

2.3.17 Draft

2.3.18 Stack, Breeching, and Supports

2.3.19 Hot Water Coils

2.3.20 Stack Thermometer

2.4 ELECTRIC MOTORS

PART 3 EXECUTION

3.1 EQUIPMENT INSTALLATION

3.2 EQUIPMENT FOUNDATIONS

3.3 BOILER CLEANING

3.4 FIELD QUALITY CONTROL

3.4.1 Operational Tests

3.4.1.1 Preliminary Operational Test

3.4.1.2 Acceptance Operational Test and Inspection

3.5 WASTE MANAGEMENT

3.6 SCHEDULE

-- End of Section Table of Contents --

SECTION 23 52 43.00 20 Page 2

**************************************************************************

USACE / NAVFAC / AFCESA / NASA UFGS-23 52 43.00 20 (July 2006)

------------------------------

Preparing Activity: NAVFAC Superseding

UFGS-23 52 43.00 20 (April 2006)

UNIFIED FACILITIES GUIDE SPECIFICATIONS

References are in agreement with UMRL dated 9 October 2006

Revised throughout - changes not indicated by CHG tags

**************************************************************************

SECTION 23 52 43.00 20

LOW PRESSURE WATER HEATING BOILERS (UNDER 800,000 BTU/HR OUTPUT)

07/06

**************************************************************************

NOTE: This guide specification covers the

requirements for low pressure hot water heating

boilers under 235 kilowatt 800,000 BTU/hr output.

Comments and suggestions on this guide specification

are welcome and should be directed to the technical

proponent of the specification. A listing of

technical proponents, including their organization

designation and telephone number, is on the Internet.

Recommended changes to a UFGS should be submitted as

a Criteria Change Request (CCR).

Use of electronic communication is encouraged.

Brackets are used in the text to indicate designer

choices or locations where text must be supplied by

the designer.

**************************************************************************

PART 1 GENERAL

1.1 REFERENCES

**************************************************************************

NOTE: Issue (date) of references included in

project specifications need not be more current than

provided by the latest guide specification. Use of

SpecsIntact automated reference checking is

recommended for projects based on older guide

specifications.

**************************************************************************

The publications listed below form a part of this specification to the

extent referenced. The publications are referred to within the text by the

basic designation only.

SECTION 23 52 43.00 20 Page 3

AMERICAN NATIONAL STANDARDS INSTITUTE (ANSI)

ANSI Z21.13 (2001; A 2002) Gas-Fired Low-Pressure

Steam and Hot Water Boilers

ANSI Z83.3 (1971; R 1995) Gas Utilization Equipment

in Large Boilers

ASME INTERNATIONAL (ASME)

ASME BPVC SEC IV (2001) Boiler and Pressure Vessel Code;

Section IV, Recommended Rules for the Care

and Operation of Heating Boilers

ASME CSD-1 (2002) Control and Safety Devices for

Automatically Fired Boilers

ASTM INTERNATIONAL (ASTM)

ASTM A 53 (1999b) Pipe, Steel, Black and Hot-Dipped,

Zinc-Coated, Welded and Seamless

ASTM C 59/C 59M2 (1980) Mineral Fiber Blanket Insulation

and Blanket-Type Pipe Insulation

(Metal-Mesh Covered) (Industrial Type)

ASTM E 2129 (2001; R 2003) Data Collection for

Sustainability Assessment of Building

Products

NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATION (NEMA)

NEMA MG 1 (2003; R 2004) Motors and Generators

NATIONAL FIRE PROTECTION ASSOCIATION (NFPA)

NFPA 211 (2003) Chimneys, Fireplaces, Vents, and

Solid Fuel-Burning Appliances

U.S. DEPARTMENT OF DEFENSE (DOD)

MIL-B-18796 (Rev F; Notice 1) Burners, Single: Oil,

Gas, and Gas-Oil Combination for Packaged

Boilers (320,001 to 125,000,000 BTU/HR

Thermal Output Capacity)

MIL-B-18797 (Rev G; Notice 1) Burners, Single: Light

Oil, Gas, and Light Oil-Gas Combination

for Packaged Heating Boilers (up to

320,000 BTU/HR Thermal Output Capacity)

MIL-B-18897 (Rev F) Boilers, Steam and Hot Water,

Watertube (Straight Bare and Finned Tube),

Cast Iron and Firebox, Packaged Type

(40,000 to 35,000,000 BTU/HR Thermal

Output Capacity)

MIL-F-18113 (Rev E; Notice 1) Feeders, Boiler Water

Treatment, By-Pass and Compound Receiver

SECTION 23 52 43.00 20 Page 4

Types

U.S. ENVIRONMENTAL PROTECTION AGENCY (EPA)

Energy Star (1992; R 2006) Energy Star Energy

Efficiency Labeling System

UNDERWRITERS LABORATORIES (UL)

UL 726 (1995; Rev thru Jan 2001) Oil-Fired Boiler

Assemblies

UL 795 (1999) Commercial-Industrial Gas Heating

Equipment

1.2 RELATED REQUIREMENTS

Section 23 03 00.00 20 BASIC MECHANICAL MATERIALS AND METHODS, applies to

this section, with the additions and modifications specified herein.

1.3 DESIGN REQUIREMENTS

**************************************************************************

NOTE: Insert boiler output capacity or indicate in

boiler schedule. Select boiler design working

pressure, operating pressure, operating temperature,

and return water temperature and indicate in boiler

schedule on drawings.

**************************************************************************

**************************************************************************

NOTE: Use Energy Star option for boilers less than

88 kW300,000 BTU/hr and FEMP option for boilers 88 kW

300,000 BTU/hr or greater.

**************************************************************************

Boiler shall be suitable for installation in the space shown with ample

room for opening doors and cleaning and removal and replacement of tubes.

Boiler shall have an output of [_____] kW BTU/hr with an efficiency not

less than that recommended by [Energy Star][FEMP]. Boiler shall be

designed, tested, and installed in accordance with ASME BPVC SEC IV and

ASME CSD-1. Paint boiler in accordance with manufacturer's

recommendations. Boiler design working pressure shall be [207 kPa (gage)]

[30 psig] [_____]. Boiler operating pressure shall be [83 kPa (gage)] [12

psig] [_____]. Boiler operating temperature shall be [82 degrees C] [180

degrees F] [_____]. Boiler return water temperature shall be [71 degrees C]

[160 degrees C] [_____]. Provide a thermostatically controlled three-way

mixing valve on boiler suitable for operating conditions of the boiler.

1.3.1 Detail Drawings

Submit fuel train and wiring diagram

1.3.2 Water Analysis

Provide test reports of water analysis.

SECTION 23 52 43.00 20 Page 5

1.4 SAFETY STANDARDS

Hot water boilers, burners and supplementary control devices, safety

interlocks, or limit controls required under this specification, shall meet

requirements of the following standards as applicable:

a. Oil-Fired Units: UL 726.

b. Gas-Fired Units: ANSI Z83.3, ANSI Z21.13 or UL 795.

c. Combination Gas- and Oil-Fired Units: UL 726, ANSI Z83.3,

ANSI Z21.13 or UL 795.

d. All Units: ASME BPVC SEC IV and ASME CSD-1.

Controls not covered by the above shall have a UL label, UL listing mark,

or shall be listed in the Factory Mutual Approval Guide.

1.5 SUBMITTALS

**************************************************************************

NOTE: Submittals must be limited to those necessary

for adequate quality control. The importance of an

item in the project should be one of the primary

factors in determining if a submittal for the item

should be required.

A “G” following a submittal item indicates that the

submittal requires Government approval. Some

submittals are already marked with a “G”. Only

delete an existing “G” if the submittal item is not

complex and can be reviewed through the Contractor’s

Quality Control system. Only add a “G” if the

submittal is sufficiently important or complex in

context of the project.

For submittals requiring Government approval on Army

projects, a code of up to three characters within

the submittal tags may be used following the "G"

designation to indicate the approving authority.

Codes for Army projects using the Resident

Management System (RMS) are: "AE" for

Architect-Engineer; "DO" for District Office

(Engineering Division or other organization in the

District Office); "AO" for Area Office; "RO" for

Resident Office; and "PO" for Project Office. Codes

following the "G" typically are not used for Navy

projects.

Submittal items not designated with a "G" are

considered as being for information only for Army

projects and for Contractor Quality Control approval

for Navy projects.

**************************************************************************

Government approval is required for submittals with a "G" designation;

submittals not having a "G" designation are [for Contractor Quality Control

approval.][for information only. When used, a designation following the

"G" designation identifies the office that will review the submittal for

SECTION 23 52 43.00 20 Page 6

the Government.] The following shall be submitted in accordance with

Section 01 33 00 SUBMITTAL PROCEDURES:

**************************************************************************

NOTE: Include the following paragraph for

SOUTHNAVFACENGCOM projects.

**************************************************************************

[ Submittals for this Section shall be delivered to the Contracting Officer,

who shall forward two complete sets of copies to the Commanding Officer,

Southern Division, Naval Facilities Engineering Command, Code 16B, for

review and approval.]

SD-02 Shop Drawings

Fuel train

Wiring diagram

SD-03 Product Data

Boilers: power output, thermal efficiency, ASME certification,

allowable working pressure, model number, documentation for

Energy Star qualifications or meeting FEMP requirements

Boiler trim and control equipment

Burners and control equipment

Stack, breeching, and supports

[ Local/Regional Materials

Documentation indicating distance between manufacturing facility

and the project site. Indicate distance of raw material origin

from the project site. Indicate relative dollar value of

local/regional materials to total dollar value of products

included in project.]

[ Environmental Data]

SD-06 Test Reports

Operational tests

Water analysis

SD-07 Certificates

Boilers

Burners and control equipment

Boiler trim and control equipment

Boilers

Boiler trim and control equipment

SECTION 23 52 43.00 20 Page 7

Burners and control equipment

Boiler manufacturer's certificate of boiler performance

including evidence that the burners provided shall be a make,

model, and type certified and approved by the manufacturer of the

boiler being provided.

SD-08 Manufacturer's Instructions

Boilers

Feedwater treatment feeder

SD-10 Operation and Maintenance Data

Boilers, Data Package 4

Submit in accordance with Section 01 78 23 OPERATION AND

MAINTENANCE DATA.

SD-11 Closeout Submittals

Posted operating instructions for heating water boilers

1.6 SUSTAINABLE DESIGN REQUIREMENTS

1.6.1 Local/Regional Materials

**************************************************************************

NOTE: Using local materials can help minimize

transportation impacts, including fossil fuel

consumption, air pollution, and labor.

**************************************************************************

Use materials or products extracted, harvested, or recovered, as well as

manufactured, within a [500][_____] mile [800][_____] kilometer radius from

the project site, if available from a minimum of three sources.

1.6.2 Environmental Data

**************************************************************************

NOTE: ASTM E 2129 provides for detailed

documentation of the sustainability aspects of

products used in the project. This level of detail

may be useful to the Contractor, Government,

building occupants, or the public in assessing the

sustainability of these products.

**************************************************************************

[Submit Table 1 of ASTM E 2129 for the following products: [_____].]

PART 2 PRODUCTS

2.1 BOILERS

**************************************************************************

NOTE: Select boiler type and style required. The

Energy Policy Act of 2005 requires new buildings to

use 30 percent less energy than the ASHRAE 90.1

SECTION 23 52 43.00 20 Page 8

level. Efficient heating equipment and components

contribute to the following LEED credits: EA

Prerequisite 2; EA1.

**************************************************************************

**************************************************************************

NOTE: Efficiency of 85 percent for boilers less than

88 kW 300,000 Btuh is per Energy Star requirements;

87 percent is an option that is readily available

for these boilers.

**************************************************************************

MIL-B-18897. Provide hot water heating boiler complete with firing

equipment, combustion chamber, insulation with steel jacket, safety and

operating controls, integral electrical wiring and other appurtenances, to

make the boiler a complete, self-contained, fully-automatic unit, ready for

service upon completion of utility connections. [Boilers less than 88 kW

300,000 Btuh shall have an Annual Fuel Utilization Efficiency (AFUE) of at

least [85][87] percent.] [Gas fired boilers greater than 88 kW 300,000 Btuh

output shall have a steady state combustion efficiency of at least 80

percent when fired at the maximum and minimum capacities which are provided

and allowed by the controls.] [Oil fired boilers greater than 88 kW

300,000 Btuh output shall have a steady state combustion efficiency of at

least 83 percent when fired at the maximum and minimum rated capacities

which are provided and allowed by the controls.]

2.2 BURNERS AND CONTROL EQUIPMENT

**************************************************************************

NOTE: Indicate fuel trains on the drawings.

Conform to the requirements of ASME CSD-1 and

MIL-B-18796. See MIL-B-18796 for guidelines for

selection of a combustion control systems.

**************************************************************************

[2.2.1 Atmospheric-Type Gas Burner

Atmospheric-type gas burner (under 117 kW 400,000 BTU/hr input). ANSI Z21.13.

Automatic recycling burner. ON-OFF type combustion control system.

[Interrupted] [Intermittent] pilot type ignition system, and pilot shall be

electrode-ignited natural gas type. Design burner and combustion control

equipment for firing natural gas having a specific gravity of [0.6] [_____]

and a heating value of approximately [37,300 kJ per cubic meter] [1000 BTU

per cubic foot] and be an integral part of the boiler. Burner controls and

safety equipment shall conform to applicable requirements of ANSI Z21.13,

including complete gas shut-off and pilot gas. Gas pressure available:

[_____ Pa inches of water gage] [_____ kPa (gage) psig].

][2.2.2 Gas-Fired Power Burner

Gas-fired power burner (over 117 kW 400,000 BTU/hr input). MIL-B-18796.

Interrupted pilot type ignition system, and pilot shall be the

electrode-ignited natural gas type. Design burner and combustion control

equipment for firing natural gas having a specific gravity of [0.6] [_____]

and a heating value of approximately [37,300 kJ per cubic meter] [1000 BTU

per cubic foot] [____] and be an integral part of the boiler. Burner

controls and safety equipment shall conform to applicable requirements of

MIL-B-18796. Mount controls; including operating switches, indicating

lights, gages, alarms, motor starters, fuses, and circuit elements of

SECTION 23 52 43.00 20 Page 9

control systems on a single control panel or cabinet designed for separate

mounting not on the burner in accordance with MIL-B-18796. The combustion

control system shall be the [on/off] [high-low-off] [positioning]

[metering] type. Locate flame scanner such that testing and cleaning of

scanner can be accomplished without disassembly of burner. Provide fuel

train as indicated. Gas pressure available: [_____ Pa inches of water

gage] [_____ kPa (gage) psig].

][2.2.3 Oil-Fired Power Burner

Oil-fired power burner (under 117 kW 400,000 BTU/hr input). MIL-B-18797.

Direct electric-spark-ignited type ignition system. Burner controls and

safety equipment shall conform to applicable requirements of MIL-B-18797.

The combustion control system shall be the [on/off] [high-low-off]

[positioning] [metering] type.

][2.2.4 Oil-Fired Power Burner

Oil-fired power burner (over 117 kW 400,000 BTU/hr input). MIL-B-18796.

Pressure-atomizing type burner. Direct electric-spark-ignited type

ignition system. Design burner and combustion control equipment for firing

commercial grade number 2 fuel oil and be an integral part of the boiler.

Burner controls and safety equipment shall conform to applicable

requirements of MIL-B-18796. The combustion control system shall be the

[on/off] [high-low-off] [positioning] [metering] type. Mount controls;

including operating switches, indicating lights, gages, alarms, motor

starters, fuses, and circuit elements of control systems on a single

control panel or cabinet designed for separate mounting not on the burner

in accordance with MIL-B-18796. Locate flame scanner such that testing and

cleaning of scanner can be accomplished without disassembly of burner.

Provide fuel train as indicated.

][2.2.5 Gas and Light Oil-Fired Power Burner

Gas and light oil-fired power burner (over 117 kW 400,000 BTU/hr Input).

MIL-B-18796. The combustion control system shall be the [on/off]

[high-low-off] [positioning] [metering] type. Pressure-atomizing type oil

burner. Interrupted-pilot type ignition system, and pilot be

electrode-ignited natural gas type, except that the oil burner be direct

electric-spark-ignited. Design burner and combustion control equipment for

firing commercial grade number 2 fuel oil and natural gas having a specific

gravity of [0.6] [_____] and a heating value of approximately [37,300 kJ

per cubic meter] [1000 BTU per cubic foot] [_____] and be an integral part

of boiler. Burner controls and safety equipment shall conform to

applicable requirements of MIL-B-18796. Mount controls; including

operating switches, indicating lights, gages, alarms, motor starters,

fuses, and circuit elements of control systems on a single control panel or

cabinet designed for separate mounting not on the burner in accordance with

MIL-B-18796. Locate flame scanner such that testing and cleaning of

scanner can be accomplished without disassembly of burner. Provide fuel

train as indicated. Gas pressure available: [_____ Pa inches of water

gage] [_____ kPa (gage) psig].

]2.3 BOILER TRIM AND CONTROL EQUIPMENT

**************************************************************************

NOTE: Include MIL-B-18796 if power burner with

input exceeding 117 kW 400,000 BTU/hr is required.

**************************************************************************

SECTION 23 52 43.00 20 Page 10

Provide in accordance with MIL-B-18897 [and MIL-B-18796] and additional

requirements specified below.

2.3.1 Emergency Disconnect Switch

**************************************************************************

NOTE: Indicate location of emergency disconnect

switch on drawings. Insert emergency switch

amperage required.

**************************************************************************

Provide and locate on wall outside boiler room entrance or just inside

door, when boiler room door is on building exterior to allow rapid and

complete shutdown of the boiler in the event of an emergency. Emergency

switch shall be a [_____]-amp. fuse-type safety switch. Switch shall be

red and furnished with a label indicating function of switch.

2.3.2 Relief Valves

Provide relieving capacity for the full output of boiler installed.

Relief-valve piping shall conform to ASTM A 53, schedule 40 steel pipe and

be piped full-size [to a floor drain] [to 150 mm 6 inches above floor].

2.3.3 Pressure and Altitude Gage or Combination Pressure/Altitude Gage

MIL-B-18897. Provide one located on supply water piping and one on return

water piping.

2.3.4 Thermometer

Provide thermometer with a scale equivalent to 1.5 times outlet water

temperature. Provide one located on supply water piping and one on return

water piping.

2.3.5 Drain Tapping

Provide drain valve and piping [to a floor drain] [to 150 mm 6 inches above

floor].

2.3.6 Make-up Water Station

2.3.6.1 Pressure Reducing Station

**************************************************************************

NOTE: Select operating pressure required.

**************************************************************************

Provide a water pressure-reducing valve and relief valve, or a combination

of the two in the makeup water line to the boiler to maintain a water

pressure of [83 kPa (gage)] [12 psig] [_____] in the hot water system.

Provide a 20 mm 3/4 inch globe valve by-pass around this valve.

2.3.6.2 Backflow Preventers

Section 22 00 00 PLUMBING SYSTEMS. Locate upstream of by-pass.

SECTION 23 52 43.00 20 Page 11

2.3.7 Feedwater Treatment Feeder

Provide in accordance with MIL-F-18113, Type II - Shot-Type Feeder (manual,

intermittent feed), Style A - for use with pressures up to 1379 kPa (gage)

200 psig maximum.

2.3.8 Combustion Regulator

Provide adjustable temperature, thermostatic immersion type that shall

limit boiler water temperature to a maximum of 121 degrees C 250 degrees F.

Control shall actuate burner through an electric relay system to maintain

boiler water temperature within normal prescribed limits at loads within

rated capacity of boiler.

2.3.9 Air Vent Valve

Provide with screwed connection, stainless steel disk, and stainless steel

seats to vent entrapped air.

2.3.10 High Temperature Limit Switch

**************************************************************************

NOTE: Specify alarm and indicating lights if input

exceeds 117 kW 400,000 BTU/hr.

**************************************************************************

Provide immersible aquastat type with a temperature setting above that of

the combustion regulator and below that of the lowest relief valve setting.

Aquastat shall function to cause a safety shutdown by closing fuel

valves[,] [and] shutting down burner equipment [, activating a red

indicating light, and sounding an alarm] in the event that boiler water

temperature rises to the high temperature limit setting. A safety shutdown

due to high temperature shall require manual reset before operation can

resume and prevent recycling of burner equipment.

2.3.11 Low Water Pressure Control

**************************************************************************

NOTE: Specify alarm and indicating lights if input

exceeds 117 kW 400,000 BTU/hr. Select operating

pressure required.

**************************************************************************

Provide mercury switch type. Control shall have a main scale, adjusting

screws at the top of the case, and have an internal or external bellows.

Control shall be the type which will open an electric circuit on a drop in

pressure below a set minimum. Control shall be set and installed to cause

a safety shutdown by closing fuel valves[,] [and] shutting down burner

equipment [, activating a red indicating light, and sounding an alarm] in

the event that water pressure in the system drops below [83 kPa (gage)] [12

psig] [_____]. A safety shutdown due to low water pressure shall require

manual reset before operation can resume and prevent recycling of burner

equipment.

2.3.12 Low Water Level Cutoff Switch

**************************************************************************

NOTE: Specify alarm and indicating lights if input

exceeds 117 kW 400,000 BTU/hr.

SECTION 23 52 43.00 20 Page 12

**************************************************************************

Provide float actuated type. Low water level cutoff shall cause a safety

shutdown by closing fuel valves[,] [and] shutting down burner equipment [,

activating a red indicating light, and sounding an alarm] in the event that

water level drops below the lowest safe permissible water level established

by the boiler manufacturer and ASME BPVC SEC IV. A safety shutdown due to

low water shall require manual reset before operation can resume and

prevent recycling of burner equipment.

2.3.13 Boiler Safety Control Circuits

**************************************************************************

NOTE: Include draft fan if power burner is

specified.

**************************************************************************

Provide boiler safety control circuits, including control circuits for

burner [and draft fan], shall be single-phase, two-wire one-side grounded,

and not over 120 volts. Provide safety control switching in ungrounded

conductors. Provide overcurrent protection. In addition to circuit

grounds, ground metal parts which do not carry current to a grounding

conductor.

2.3.14 Indicating Lights

**************************************************************************

NOTE: Delete entire paragraph if boiler input does

not exceed 117 kW 400,000 BTU/hr. Include draft fan

if power burner is specified.

**************************************************************************

Provide indicating lights as follows. Each safety interlock requiring a

manual reset shall have an individually-labeled indicating light.

Non-recycling controls/interlocks shall have the reset located on

control/interlock itself. Indicating lights shall have colors as follows

in lieu of those required by MIL-B-18796:

a. Amber: Ignition on

b. Green: Main fuel safety shut-off valves open

c. Red (One for Each): Safety lockout, flame failure, low water

pressure, low water level, and high temperature

[d. Blue: Draft]

2.3.15 Alarm Bell

**************************************************************************

NOTE: Delete entire paragraph if boiler input does

not exceed 117 kW 400,000 BTU/hr.

**************************************************************************

Provide alarm bell not less than 100 mm 4 inches in diameter, electrically

operated, with a manual disconnect switch. Disconnect switch shall be type

and wired so that switching off alarm following a safety shutdown will not

prevent alarm from sounding again upon recurrence of a subsequent safety

shutdown condition.

SECTION 23 52 43.00 20 Page 13

2.3.16 Post-Combustion Purge

**************************************************************************

NOTE: Delete entire paragraph if atmospheric burner

is specified.

**************************************************************************

Provide controls and wiring necessary to ensure operation of draft fan for

a period of not less than 15 seconds or of sufficient duration to provide

four complete air changes in the boiler combustion chamber (whichever is

greater) following shutdown of burner upon satisfaction of heat demand.

Upon completion of post-combustion purge period, draft fan shall

automatically shutdown until next restart.

2.3.17 Draft

Comply with boiler manufacturer's recommendations.

2.3.18 Stack, Breeching, and Supports

**************************************************************************

NOTE: NFPA 211, Type B vent can only be used with

an atmospheric burner.

**************************************************************************

[Provide boiler stack constructed of sheet steel having a thickness of not

less than 2.47 mm 0.0972 inches with welded joints. Insulate stack located

inside the building with 38 mm 1 1/2 inches of mineral wool conforming to

applicable requirements of ASTM C 59/C 59M2, Class II - for use up to 649

degrees C 1200 degrees F. Insulation shall receive a finish coat of

finishing cement not less than 19 mm 3/4 inch thick, trowelled to a smooth

finish. Provide stack supports, umbrella collar and cap, and flue

transition piece. Stack diameter and height shall be in accordance with

manufacturer's recommendations and conform to NFPA 211.]

[NFPA 211, [Type B - gas] [Type L - oil and gas/oil], prefabricated

multi-wall type, flashed to the roof, and complete with rain cap. Stack

diameter and height shall be in accordance with manufacturer's

recommendations and conform to NFPA 211.]

2.3.19 Hot Water Coils

**************************************************************************

NOTE: Delete entire paragraph unless hot water

coils are required to instantaneously heat domestic

water.

**************************************************************************

Provide coils capable of heaing [_____] L/s GPM of water with [_____]

degreeCF rise conforming to MIL-B-18897.

2.3.20 Stack Thermometer

Provide flue gas thermometer with scale calibrated from 66 to 399 degrees C

150 to 750 degrees F and mounted in flue gas outlet.

SECTION 23 52 43.00 20 Page 14

2.4 ELECTRIC MOTORS

Electric motors shall meet requirements of NEMA MG 1. Motors less than 3/4

kW 1 hp shall meet NEMA High Efficiency requirements. Motors 3/4 kW 1 hp

and larger shall meet NEMA Premium Efficiency requirements. Motors which

are an integral part of the packaged boiler system shall be the highest

efficiency available by the manufacturer of the packaged boiler. Motors

shall be variable speed.

PART 3 EXECUTION

3.1 EQUIPMENT INSTALLATION

Install equipment in accordance with manufacturer's installation

instructions. Grout equipment mounted on concrete foundations before

installing piping. Install piping in such a manner as not to place a

strain on equipment. Do not bolt flanged joints tight unless they match.

Grade, anchor, guide, and support piping without low pockets. Feedwater

treatment feeders shall be mounted so that the top of the feeder is no

higher than 1219 mm 48 inches above the finished floor.

3.2 EQUIPMENT FOUNDATIONS

Locate equipment foundations as indicated, designed, and made of sufficient

size and weight to preclude shifting of equipment under operating

conditions or under abnormal conditions that could be imposed upon the

equipment. Foundations shall meet requirements of the equipment

manufacturer. Concrete and grout shall conform to Section 03 30 00.00 20

CAST-IN-PLACE CONCRETE.

3.3 BOILER CLEANING

Before being placed in service, boiler shall be boiled out for a period of

24 hours at a pressure not exceeding 83 kPa (gage) 12 psig. Solution to be

used in the boiler for the boiling out process shall consist of two pounds

of trisodium phosphate per 379 liters 100 gallons of water. Upon

completion of boiling out, flush out boiler with potable water, drain, and

charge with chemically treated water. Protect boiler and appurtenances

against internal corrosion until testing is completed and boiler is

accepted. Professional services are required for cleaning/treatment

process.

3.4 FIELD QUALITY CONTROL

Perform and furnish everything required for inspections and tests as

specified herein to demonstrate that boiler and auxiliary equipment, as

installed, are in compliance with contract requirements. Start-up and

operate the system. During this time, clean strainers until no further

accumulation of foreign material occurs. Exercise care to minimize loss of

water when strainers are cleaned. Adjust safety and automatic control

instruments as necessary to place them in proper operation and sequence.

Test instrumentation shall be calibrated and have full scale readings from

1.5 to 2 times test values. Coordinate installation and tests with

commissioning as specified in Section [01 91 00][_____] COMMISSIONING.

3.4.1 Operational Tests

Operate each boiler and appurtenances prior to final testing and insure

that necessary adjustments have been made. Provide testing equipment

SECTION 23 52 43.00 20 Page 15

required to perform tests. During this testing period, provide operating

instructions and training to persons tasked with operation of the boiler.

Tests shall be accomplished with both fuels on dual fuel units and include

the following:

3.4.1.1 Preliminary Operational Test

Operate the boilers continuously for a period of at least 8 hours to

demonstrate proper operability of the combustion control, flame safeguard

control, and safety interlocks.

3.4.1.2 Acceptance Operational Test and Inspection

**************************************************************************

NOTE: Insert the appropriate Engineering Field

Division.

**************************************************************************

Conduct a preliminary operational test prior to requesting an acceptance

operational test and inspection by a [_____] Division, Naval Facilities

Engineering Command Boiler inspector. The Contracting Officer, upon

receipt of the notice from the Contractor, shall request the boiler be

inspected by [_____] Division Naval Facilities Engineering Command.

Fifteen days advance notice is required for scheduling inspector to conduct

acceptance operational test and inspection.

3.5 WASTE MANAGEMENT

**************************************************************************

NOTE: Diverting waste from the landfill contributes

to the following LEED credit: MR2. Coordinate with

Section 01572 CONSTRUCTION AND DEMOLITION WASTE

MANAGEMENT.

**************************************************************************

Separate waste in accordance with the Waste Management Plan. Close and

seal tightly all partly used adhesives and solvents; store protected in a

well-ventilated, fire-safe area at moderate temperature.

3.6 SCHEDULE

Some metric measurements in this section are based on mathematical

conversion of inch-pound measurements, and not on metric measurements

commonly agreed on by the manufacturers or other parties. The inch-pound

and metric measurements shown are as follows:

Products Inch-Pound Metric

a. Alarm Bell

Diameter = 4 inches = 100 mm

b. Stack Thermometer

Scale Range = 150-750 degrees F = 66-399 degrees C

-- End of Section --

SECTION 23 52 43.00 20 Page 16

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Edmond Paris - The Secret History of Jesuits (1975)Documento197 pagineEdmond Paris - The Secret History of Jesuits (1975)adrian_pirlea89% (9)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Maintenance and Operations of Ventilation SystemsDocumento74 pagineMaintenance and Operations of Ventilation SystemsgabrielNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Ufc 3-430-08n Central Heating Plants (16 January 2004)Documento230 pagineUfc 3-430-08n Central Heating Plants (16 January 2004)Bob VinesNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- VentilationDocumento92 pagineVentilationRobert Nixon100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- DOE Fundamentals Handbook, Electrical Science, Volume 1 of 4Documento166 pagineDOE Fundamentals Handbook, Electrical Science, Volume 1 of 4Bob VinesNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Edmond Paris - The Secret History of Jesuits (1975)Documento197 pagineEdmond Paris - The Secret History of Jesuits (1975)adrian_pirlea89% (9)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Hummer H1-Service ManualDocumento1.203 pagineHummer H1-Service Manualpakiturbo2papeles100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Dept. EEE-2Documento118 pagineDept. EEE-2RENGANATHAN PNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Valves, Piping, and Equipment in Valve ManholesDocumento31 pagineValves, Piping, and Equipment in Valve ManholesgabrielNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Fundamentals Handbook, Electrical Science Vol 3 (DOE 1992)Documento126 pagineFundamentals Handbook, Electrical Science Vol 3 (DOE 1992)Anonymous N0VcjC1ZoNessuna valutazione finora

- Heat Distribution Systems in Concrete TrenchesDocumento34 pagineHeat Distribution Systems in Concrete TrenchesgabrielNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Energy Recovery SystemsDocumento20 pagineEnergy Recovery SystemsgabrielNessuna valutazione finora

- Doe Fundamentals Handbook - Electrical Science PDFDocumento142 pagineDoe Fundamentals Handbook - Electrical Science PDFmiveyNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Expedient Repair of Utility Systems ManualDocumento49 pagineExpedient Repair of Utility Systems ManualgabrielNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Heating and Cooling Distribution SystemsDocumento143 pagineHeating and Cooling Distribution SystemsMuhammad ade hotmanNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Forced Hot Water Heating Systems Using Water and Steam Heat ExchangersDocumento47 pagineForced Hot Water Heating Systems Using Water and Steam Heat ExchangersgabrielNessuna valutazione finora

- DOE Engineering Symbols-HandbookDocumento96 pagineDOE Engineering Symbols-Handbookapi-3717958Nessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Ufc 3-440-04n Solar Heating of Buildings and Domestic Hot Water (16 January 2004)Documento167 pagineUfc 3-440-04n Solar Heating of Buildings and Domestic Hot Water (16 January 2004)Bob VinesNessuna valutazione finora

- Water-Loop and Ground-Loop Heat Pump SystemsDocumento67 pagineWater-Loop and Ground-Loop Heat Pump SystemsgabrielNessuna valutazione finora

- Engineering Drawing Handbook PDFDocumento120 pagineEngineering Drawing Handbook PDFRobert Nixon100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ElsafeDocumento324 pagineElsafenavinchopra1986Nessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Thermal Insulation For Mechanical SystemsDocumento63 pagineThermal Insulation For Mechanical SystemsgabrielNessuna valutazione finora

- Aboveground Heat Distribution System PDFDocumento27 pagineAboveground Heat Distribution System PDFGabriel GabrielNessuna valutazione finora

- Water and Steam Heating - Oil, Gas or Both - Up To 20 MBTUHDocumento77 pagineWater and Steam Heating - Oil, Gas or Both - Up To 20 MBTUHgabrielNessuna valutazione finora

- Exterior Underground Steam Distribution SystemDocumento46 pagineExterior Underground Steam Distribution SystemgabrielNessuna valutazione finora

- Central Steam Boiler Plants PDFDocumento134 pagineCentral Steam Boiler Plants PDFGabriel GabrielNessuna valutazione finora

- Ufc 3-540-04n Diesel Electric Generating Plants (16 January 2004)Documento104 pagineUfc 3-540-04n Diesel Electric Generating Plants (16 January 2004)Bob VinesNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Pre-Engineered Underground Heat Distribution SystemDocumento46 paginePre-Engineered Underground Heat Distribution SystemgabrielNessuna valutazione finora

- Architects-Engineers Guide To Energy Conservation in Existing Buildings - Volume 1 PDFDocumento63 pagineArchitects-Engineers Guide To Energy Conservation in Existing Buildings - Volume 1 PDFGabriel GabrielNessuna valutazione finora

- Central Refrigeration Equipment For Air Conditioning PDFDocumento50 pagineCentral Refrigeration Equipment For Air Conditioning PDFGabriel GabrielNessuna valutazione finora

- Spma001a ADCDocumento59 pagineSpma001a ADCHelder NascimentoNessuna valutazione finora

- TLMCL03 Training Manual v2Documento182 pagineTLMCL03 Training Manual v2Shankar Narayanan50% (2)

- Attachment 4 UDOT Standard Specification 02056Documento7 pagineAttachment 4 UDOT Standard Specification 02056snake2Nessuna valutazione finora

- Thetford Marine Catalog North America 2021 Low Res PDFDocumento84 pagineThetford Marine Catalog North America 2021 Low Res PDFJulio LemosNessuna valutazione finora

- Testing of Concrete Masonry: Laboratory Experiment NoDocumento10 pagineTesting of Concrete Masonry: Laboratory Experiment NokeishasantiagoNessuna valutazione finora

- Cim Provider GR Manual ElxDocumento13 pagineCim Provider GR Manual ElxIlnomeCompletosNessuna valutazione finora

- 10-Unit Commercial BuildingDocumento5 pagine10-Unit Commercial BuildingJeremy BuelbaNessuna valutazione finora

- Yacht Design - Interior Design - Naval ArchitectureDocumento15 pagineYacht Design - Interior Design - Naval ArchitectureVirginia MarkovicNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Understanding CairoDocumento143 pagineUnderstanding Cairomarinum7Nessuna valutazione finora

- Ccna4 Practica 7 ResueltoDocumento7 pagineCcna4 Practica 7 ResueltoJake EspinoNessuna valutazione finora

- Mitsubishi Q TCPDocumento17 pagineMitsubishi Q TCPSrinivasan RamachandranNessuna valutazione finora

- Critical Structures Construction Issues: Self Study CourseDocumento43 pagineCritical Structures Construction Issues: Self Study CourseEliNessuna valutazione finora

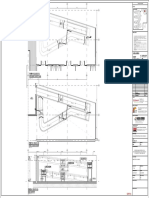

- VT-706 Ramp Detail - Ramp A1Documento1 paginaVT-706 Ramp Detail - Ramp A1Modular Design TeamNessuna valutazione finora

- Archivematica: Using Micro-Services and Open-Source Software To Deliver A Comprehensive Digital Curation SolutionDocumento5 pagineArchivematica: Using Micro-Services and Open-Source Software To Deliver A Comprehensive Digital Curation SolutiondejanbogNessuna valutazione finora

- As 2118.5-2008 Automatic Fire Sprinkler Systems Home Fire Sprinkler SystemsDocumento9 pagineAs 2118.5-2008 Automatic Fire Sprinkler Systems Home Fire Sprinkler SystemsSAI Global - APAC0% (1)

- Ev Do Wikipedia SummaryDocumento5 pagineEv Do Wikipedia Summarymau_mmx5738Nessuna valutazione finora

- Laboratory Report No 1Documento4 pagineLaboratory Report No 1Lonie ReyesNessuna valutazione finora

- DATA SHEET Cfip Phoenix Etsi Ds en v1 13Documento6 pagineDATA SHEET Cfip Phoenix Etsi Ds en v1 13juanyuyinNessuna valutazione finora

- Guardhouse 1-2Documento2 pagineGuardhouse 1-2dawitgggNessuna valutazione finora

- Places To Visit in KharkivDocumento9 paginePlaces To Visit in KharkivIvanka ShumykNessuna valutazione finora

- Online BookStore ReportDocumento48 pagineOnline BookStore Reportpathami50% (12)

- 1st - 3rd Floor PlanDocumento1 pagina1st - 3rd Floor PlanHardik sarvaiyaNessuna valutazione finora

- Rev.5 m2 Arch Full SetDocumento184 pagineRev.5 m2 Arch Full SetJose TorresNessuna valutazione finora

- Ceiling Swirl Diffusers With Perforated Face Plate: Type DCSDocumento31 pagineCeiling Swirl Diffusers With Perforated Face Plate: Type DCSSreehari Raju KalidindiNessuna valutazione finora

- AS-400 All in OneDocumento157 pagineAS-400 All in OneRameshBabuMuthireddy100% (1)

- GSM Call FlowDocumento2 pagineGSM Call Flownagendra_badamNessuna valutazione finora

- Aircrete Blocks Technical ManualDocumento95 pagineAircrete Blocks Technical Manualpseudosil100% (3)

- Checklist For Waterproofing - TerraceDocumento1 paginaChecklist For Waterproofing - Terraceyash shahNessuna valutazione finora

- TerrariumsDocumento29 pagineTerrariumsAmruta Patil25% (4)

- Slip Form ConstructionDocumento6 pagineSlip Form ConstructionKomal KhatriNessuna valutazione finora