Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ms Term Work

Caricato da

RAGHAV VASHICopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ms Term Work

Caricato da

RAGHAV VASHICopyright:

Formati disponibili

MASTER OF ENGINEERING

PRODUCTION ENGINEERING

SUBJECT NAME: MACHINING SCIENCE SEM: I

SUBJECT CODE: 2712802 YEAR: 2017-18

EXPERIMENT NO: 3

Aim: To study Tool Wear.

1. What is ‘Hi-E’ region? The tool life equation for a given operation is VT 0.4 =7. What will be the

change in tool life if speed is cut down to 60%?

2. What is the basic mechanism of cutting tool wear? Explain with sketch progressive tool wear,

diffusion wear and crater wear.

3. Explain the experimental method of determining tool life.

4. Define cutting tool life. State the factors which affect tool life.

5. Describe practical method to find tool life.

EXPERIMENT NO: 4

Aim: To study design of twist drill.

1. Draw and explain geometry of twist drill.

2. Write tool angles for HSS drills for different material.

EXPERIMENT NO: 5

Aim: To study oblique cutting & force Analysis.

1. Explain force relation relationship in oblique cutting

2. Discuss concepts of rake angle measured in different planes for oblique turning operation.

3. Derive and expression for shear angle using Lee & Shaffer’s relationship.

4. State different methods of force measurement and explain any one.

EXPERIMENT NO: 6

Aim: To study grinding forces analysis.

1. Explain criteria for selecting grinding wheel.

2. Explain grinding wheel wear & also Re-sharpening action.

3. What is the mechanics of grinding process? Explain honing and lapping operation

4. Derive an equation to find chip length in grinding.

5. Explain specification of a grinding wheel.

EXPERIMENT NO: 7

Aim: Surface analysis of various manufacturing process.

1. Explain various methods of measuring surface roughness.

2. What is ideal and natural surface roughness? Discuss factors that affect surface quality during

machining of job material.

3. Describe various methods to evaluate surface roughness.

4. Define the following: (i) Roughness (ii) Waviness (iii) Lay (iv) RMS (v) Sampling length. Explain

working principal of Surface roughness meter.

OEP

(Attached two research paper based on topic given below at last of term work)

1. Fabrication and Design evaluation using CAE tools for a 3-axis vertical milling machine for

sculptured surface machining.

2. Finite element analysis and optimization of process parameters involved in single point and multi

point machining process

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Welding Cost Estimator PubDocumento8 pagineWelding Cost Estimator Pubrockufool100% (4)

- L&T Hydrocarbon Wins (Large) EPCC Contract For Petrochemical Fluidized Catalytic Cracking Unit From HRRLDocumento2 pagineL&T Hydrocarbon Wins (Large) EPCC Contract For Petrochemical Fluidized Catalytic Cracking Unit From HRRLRAGHAV VASHINessuna valutazione finora

- Pankaj Mahajan Resume FormatDocumento2 paginePankaj Mahajan Resume FormatRAGHAV VASHINessuna valutazione finora

- Welding Cost Estimator PubDocumento8 pagineWelding Cost Estimator Pubrockufool100% (4)

- #Getreadytojump Winners: S.No Username Character IdDocumento4 pagine#Getreadytojump Winners: S.No Username Character IdRAGHAV VASHINessuna valutazione finora

- MGT 9Documento5 pagineMGT 9RAGHAV VASHINessuna valutazione finora

- Dealer or Wholesaler Plate Affidavit DR 2640 - 0Documento1 paginaDealer or Wholesaler Plate Affidavit DR 2640 - 0RAGHAV VASHINessuna valutazione finora

- C1e 001Documento44 pagineC1e 001Dhananjay KumarNessuna valutazione finora

- Hoj DesaiDocumento1 paginaHoj DesaiRAGHAV VASHINessuna valutazione finora

- Company Profile PDFDocumento10 pagineCompany Profile PDFRAGHAV VASHINessuna valutazione finora

- Tioga Pipe ChartDocumento2 pagineTioga Pipe ChartMahmoud GaberNessuna valutazione finora

- Dummy PDFDocumento1 paginaDummy PDFRAGHAV VASHINessuna valutazione finora

- Applecareplus in TCDocumento7 pagineApplecareplus in TCRAGHAV VASHINessuna valutazione finora

- Computer-Basics - Computer Basics2Documento43 pagineComputer-Basics - Computer Basics2api-216226726Nessuna valutazione finora

- Safari - 04-May-2018 at 6:23 PM PDFDocumento1 paginaSafari - 04-May-2018 at 6:23 PM PDFRAGHAV VASHINessuna valutazione finora

- Computer-Basics - Computer Basics2Documento43 pagineComputer-Basics - Computer Basics2api-216226726Nessuna valutazione finora

- Dummy PDFDocumento1 paginaDummy PDFRAGHAV VASHINessuna valutazione finora

- Einstein II DGSDocumento24 pagineEinstein II DGSAsghar Ali100% (1)

- Lecture-9 SIMS NDTDocumento61 pagineLecture-9 SIMS NDTKo Lin Lin KoNessuna valutazione finora

- Dummy PDFDocumento1 paginaDummy PDFRAGHAV VASHINessuna valutazione finora

- Pubg Mobile India Series 2020 Competition Rules: (Version 1.0, 2020)Documento41 paginePubg Mobile India Series 2020 Competition Rules: (Version 1.0, 2020)ShubhamNessuna valutazione finora

- Pom Question BankDocumento1 paginaPom Question BankRAGHAV VASHINessuna valutazione finora

- Company Profile PDFDocumento10 pagineCompany Profile PDFRAGHAV VASHINessuna valutazione finora

- Pom Question BankDocumento1 paginaPom Question BankRAGHAV VASHINessuna valutazione finora

- Government Jobs Updates 2019: TH THDocumento9 pagineGovernment Jobs Updates 2019: TH THVishnu BoopathiNessuna valutazione finora

- Government Jobs Updates 2019: TH THDocumento9 pagineGovernment Jobs Updates 2019: TH THVishnu BoopathiNessuna valutazione finora

- TTTTDocumento3 pagineTTTTRAGHAV VASHINessuna valutazione finora

- Radiographic TestingDocumento47 pagineRadiographic TestingsmrndrdasNessuna valutazione finora

- Government Jobs Updates 2019: TH THDocumento9 pagineGovernment Jobs Updates 2019: TH THVishnu BoopathiNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Ductwork Myth BusterDocumento3 pagineDuctwork Myth BustermbowmanjaxNessuna valutazione finora

- PPC Porcelain Solid Core Post Insulators and Operating RodsDocumento23 paginePPC Porcelain Solid Core Post Insulators and Operating RodsCHRISTIANNessuna valutazione finora

- Sustainable Production of Acrolein: Investigation of Solid Acid-Base Catalysts For Gas-Phase Dehydration of GlycerolDocumento7 pagineSustainable Production of Acrolein: Investigation of Solid Acid-Base Catalysts For Gas-Phase Dehydration of GlycerolnayarapradoNessuna valutazione finora

- Instructors' Solutions For Mathematical Methods For Physics and Engineering by RileyDocumento512 pagineInstructors' Solutions For Mathematical Methods For Physics and Engineering by Rileyastrowiz8813% (8)

- Charpy Impact Test - STP 1072Documento219 pagineCharpy Impact Test - STP 1072biancogallazzi100% (3)

- Robotic CafeDocumento13 pagineRobotic CafeRana SaqlainNessuna valutazione finora

- 117BH - Ceramic Science and Technology PDFDocumento8 pagine117BH - Ceramic Science and Technology PDFvenkiscribd444Nessuna valutazione finora

- Microsoft Office 2003Documento41 pagineMicrosoft Office 2003Jas RockNessuna valutazione finora

- OpenSolver ChangeLogDocumento24 pagineOpenSolver ChangeLogSantaCruzStoreroomNessuna valutazione finora

- S8 PDFDocumento184 pagineS8 PDFsrdsosonpurNessuna valutazione finora

- Case/Duct System (Automobile)Documento7 pagineCase/Duct System (Automobile)Tran xuan ThuyNessuna valutazione finora

- OMN-FAC-411 - Piping General RequirementsDocumento38 pagineOMN-FAC-411 - Piping General RequirementsvinodNessuna valutazione finora

- Broadcast BillDocumento22 pagineBroadcast BillLidwin SoundariaNessuna valutazione finora

- Titus Slot DiffuserDocumento4 pagineTitus Slot Diffuservico1982Nessuna valutazione finora

- Buckling Considerations in Pile Design: October 2005Documento9 pagineBuckling Considerations in Pile Design: October 2005shashank sharmaNessuna valutazione finora

- Smart Soot Blower SystemDocumento8 pagineSmart Soot Blower SystemidigitiNessuna valutazione finora

- Barriere Levante IndustrielleDocumento2 pagineBarriere Levante IndustrielleAlekso GjakovskiNessuna valutazione finora

- DefluoridationDocumento13 pagineDefluoridationSuha Yechwad100% (1)

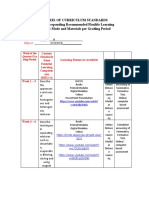

- Matrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodDocumento2 pagineMatrix of Curriculum Standards With Corresponding Recommended Flexible Learning Delivery Mode and Materials Per Grading PeriodNora HerreraNessuna valutazione finora

- Market Consumer Perception Mahindra ThesisDocumento95 pagineMarket Consumer Perception Mahindra ThesisHarmeet singh100% (1)

- Breakwater Vertical BarriersDocumento10 pagineBreakwater Vertical BarriersAlbert PranataNessuna valutazione finora

- Belden 9463 PDFDocumento3 pagineBelden 9463 PDFtr0184Nessuna valutazione finora

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Documento5 pagineData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Sample Letters To DEPDocumento7 pagineSample Letters To DEPSJLibraryNessuna valutazione finora

- Electric Companies in AfghanistanDocumento8 pagineElectric Companies in AfghanistanRichie Vemon100% (1)

- Stainless Steel Wire Mesh and Wire ClothDocumento3 pagineStainless Steel Wire Mesh and Wire ClothStela LjevarNessuna valutazione finora

- Intel® System Identification UtilityDocumento2 pagineIntel® System Identification UtilityPatel NikhilNessuna valutazione finora

- Ponds and Aerated LagoonsDocumento24 paginePonds and Aerated LagoonsGabriella AngNessuna valutazione finora

- Rajasthan Heritage Digital Case Study MinDocumento4 pagineRajasthan Heritage Digital Case Study MinSaket Singh TomarNessuna valutazione finora

- SSA 716 StudentGuide 20150211Documento551 pagineSSA 716 StudentGuide 20150211Ashok Kumaresan100% (1)