Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Section 15 Non Destrictive Testing

Caricato da

S GoudaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Section 15 Non Destrictive Testing

Caricato da

S GoudaCopyright:

Formati disponibili

~Unsa.L aA!};Jn.

I:Jsau-uoN

SI uO!};Jas

uO!};JadsUI ~u!Pla M. S SIM.

TWI

rllfll. _ THE WELDING INSTITUTE

Non-Destructive Testing:

NDT or Non Destructive Testing may be used as a means to evaluate the quality of a

component by assessing its internal and/or external integrity, but without destroying it.

There are many methods of NDT some of which require a very high level of skill both in

application and analysis and therefore NDT operators for these methods require a high

degree of training and experience to apply them successfully.

The four principle methods ofNDT used are: .

1) Penetrant testing

2) Magneticparticle testing

3) Ultrasonictesting

4) Radiographic testing

A welding inspector should have a general working knowledge of all these NDT

methods, their applications, advantages and disadvantages.

NDT operators are examined to establish their level of skill, which is dependant on their

knowledge and experience, in the same way as welders and welding inspectors are

examined and tested to establish their level of skill.

Various examination schemes exist for this purpose throughout the world. In the UK the

CSWIP and PCN examination schemes are those that are recognised most widely.

A good NDT operator has both knowledge and experience, however some of the above

techniques are more reliant on these factors than others.

Welding Inspection of Steels WIS 5 15.1 TWI WORLD CENTRE FOR

Section 15 Non-Destructive Testing MATERIALS JOINING

Rev 09-09-06 Copyright © 2006 TWl Ltd mOl TECHNOLOGY

TWI

V/l!JI. _ THE WELDING INSTITUTE

Penetrant Testing

Basic Procedure

1) The component must be thoroughly cleaned and have a smooth surface finish

2) Penetrant is applied and allowed to dwell for a specified time. (Contact time)

3) Once the dwell or contact time has elapsed, the excess penetrant is removed by

wiping with a clean lint free cloth, fmally wiped with a soft paper towel moistened

with liquid solvent. (Solvent wipe)

4) The developer is then applied, and any penetrant that has been drawn into any

defect by capillary action will be now be drawn out by reverse capillary action

5) A close inspection is made to observe any indications (bleed out) in the developer

6) Post cleaning and protection

Method (Colour contrast, solvent removable)

1) Apply Penetrant 2) Clean then apply Developer 3) Result

,r

Advantage Disadvantages

1) Low operator skill level 1) Careful surface preparation

2) Used on non-ferromagnetic 2) Surface breaking flaws only

3) Low cost 3) Not used on porous material

4) Simple, cheap and easy to interpret 4) No permanent record

5) Portability 5) Hazardous chemicals

Welding Inspection of Steels WIS 5 15.2

Section 15 Non-Destructive Testing

TWI WORLD CENTRE FOR

MATERIALS JOINING

Rev 09-09-06 Copyright © 2006 TWI Ltd VOl TECHNOLOGY

TWI

V/lDI. _ THE WELDING INSTITUTE

Magnetic Particle Testing

Basic Procedure

1) Test method for the detection of surface and sub-surface defects in ferromagnetic

materials

2) Magnetic field induced in component.

(Permanent magnet, electromagnet (Y6 Yoke) or current flow (prods)

3) Defects disrupt the magnetic flux

4) Defects revealed by applying ferromagnetic particles.

(Background contrast paint may be required)

Method

1) Apply contrast paint 2) Apply magnet & ink 3) Result

Advantage Disadvantages

1) Pre-cleaning not as critical as with DPI 1) Ferromagnetic materials only

2) Will detect some sub-surface defects 2) Demagnetisation may be

required

3) Relatively low cost 3) Direct current flow may

produce Arc strikes

4) Simple equipment 4) No permanent record

5) Possible to inspect through thin coatings 5) Required to test in 2 directions

Welding Inspection of Steels WIS 5 15.3

Section 15 Non-Destructive Testing

TWI WORLD CENTRE FOR

MATERIALS JOINING

Rev 09-09-06 Copyright © 2006 TWI Ltd VOl TECHNOLOGY

TWI

VIlOI. _ THE WELDING INSTITUTE

Ultrasonic Testing

Basic Procedure

1) Component must be thoroughly cleaned; this may involve light grinding to remove

any spatter, pitting etc in order to obtain a smooth surface

2) Couplant is then applied to the test surface. (water, oil, grease etc.)

This enables the ultrasound to be transmitted fTom the probe into the component

under test

3) A range of angled probes are used to examine the weld root region and fusion faces.

(Ultrasound must strike the fusion faces or any discontinuities present in the weld at

90° in order to obtain the best reflection of ultrasound back to the probe for display

on the cathode ray tube)

Method

1) Apply Couplant 2) Apply sound wave 3) Result

Signal rebound from the

lack of sidewall fusion

Portable

Able

Advantage

No

Can major

Ferrous &with

to detect

easily instant

and

safety

detect

Non results

sizeofsub-surface

-requirements

lack

ferrous sidewall

alloys defects

fusion3)

4)

5)

1)

2) Disadvantages

1) High operator skill level

Difficult to interpret

Requires calibration

No pennanent record.

(Unless automated)

Not easily applied to complex

geometry

WeJding Inspection ofSteeJs WIS 5 15.4

Section 15 Non-Destructive Testing TWI WORLD CENTRE FOR

MATERIALS JOINING

Rev 09-09-06 Copyright © 2006 TWI Ltd VOl TECHNOLOGY

TWI

V/lOL THE WELDING INSTITUTE

Radiographic Testing

Basic Procedure

1) X or Gamma radiation is imposed upon a test object

2) Radiation is transmitted in varying degrees dependant upon the density of the

material through which it is travelling

3) Variations in transmission detected by photographic film, or fluorescent screens.

(Film placed between lead screens then placed inside a cassette)

4) An IQI (image quality indicator) should always be placed on top of the

specimen to record the sensitivity of the radiograph

Method

i

a) Load film cassette b) Exposure to radiation c) Developed graph

Radioactivesource -

Devel0d]

graph ,~ >I \=

'~

• •

I

Permanent

Most record

Detectsmaterials

internal can be tested

flaws 1)

2)

3)

Advantage

1)

Disadvantages

Skilled interpretation required

Access to both sides required

Sensitive to defect orientation

(possible to miss planar flaws)

4) Gives a direct image of flaws 4) Health hazard

5) Fluoroscopy can give real time imaging 5) High capital cost

Welding Inspection of Steels WIS 5 15.5

Section 15 Non-Destructive Testing TWI WORLD CENTRE FOR

MATERIALS JOINING

Rev 09-09-06 Copyright © 2006 TWI Ltd mOl TECHNOLOGY

TWI

roOI. _ THE WELDING INSTITUTE

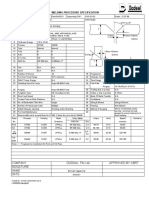

Summary of Non Destructive Testing:

tested.

Yokes.

All

Wet

and Colour

Permanent

materials

materials.

& Dry

X-ray

Un-favoured

grained

magnets Low

No

All

small can

sidewall

can Gamma

lack

Permanent

be

Advantages

Surface/Sub

sources

inks.

Application

Portable

for

structured

and be

fusion

of

tested

Disadvantages

straight

more

Requires

straight

surfaces

A wide

No

High

Relatively

safety

non

Simple

Can

Gamma cost of

with

large

operator

diameter,

porous

assess defects

sidewall

record

surface

instant

easily

Extremely skill

current

safety

Difficult

Surface

variety

Cannot

Highly

Fe may

permanent

process of

find

messy

calibration

flaws

be

toof

requirements

low

equipment

ray fusion**

results

flaws

results

level

lack

requirements

tested

interpret

generally

magnetic

operator

clean

De-magnetise costmaterials

only

record

metals

the

skill

after

material

or

penetration

is very technique

line of Can cause arc strikes using

identify

material

inlevel

pipe

portable only

use

Discipline

Welds/Castings.

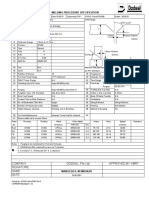

** To identify planar or 2 dimensional defects such as lack of side wall fusion, or cracks

etc, the orientation of the radiation beam must be in line with the orientation of the defect

as shown below, hence if the radiation source is at the centre of the weld then no

indication of lack of side wall fusion may be shown on the radiograph.

Lack of

sidewall fusion

Film

Radiation beam

Welding Inspection of Steels WIS 5 15.6 TWI WORLD CENTRE FOR

Section 15 Non-Destructive Testing MATERIALS JOINING

Rev 09-09-06 Copyright © 2006 TWI Ltd VOl TECHNOLOGY

TWI

VDOI. _ THE WELDING INSTITUTE

WIS 5 Section 15 Exercises:

1) List 5 advantages and 5 disadvantages of each NDT discipline?

Discipline 345 Advantages12354

Disadvantages

2) Briefly state the major limitation of the Radiographic NDT process in terms

of the orientation and practical observation of internal planar imperfections?

3) Complete the basic procedure for the Penetrant testinf! method of NDT?

1. The component must be thorou2hlv cleaned with a smooth surface finish

2. --------------------------

3. -------------------------

4.

5. --------------------------

6.

Welding Inspection of Steels WIS 5 15.7

Section 15 Non-Destructive Testing

TWI WORLD CENTRE FOR

MATERIALS JOINING

Rev 09-09-06 Copyright © 2006 TWI Ltd rzlOI TECHNOLOGY

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Air Cooler-Example 8-2Documento3 pagineAir Cooler-Example 8-2citramuaraNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Iec 60287-1-1Documento44 pagineIec 60287-1-1Jose Giraldo100% (1)

- Astm A350 LF2Documento1 paginaAstm A350 LF2anjangandak2932100% (1)

- Sub Grade PropertiesDocumento76 pagineSub Grade PropertiesSivakumar M100% (4)

- API 570 Course Notes - JoshiDocumento173 pagineAPI 570 Course Notes - JoshiPrabhakar Kattula100% (3)

- Weldability of Materials - Aluminium Alloys - Job Knowledge 21Documento3 pagineWeldability of Materials - Aluminium Alloys - Job Knowledge 21brijesh kinkhabNessuna valutazione finora

- CCH 70-3 InglésDocumento81 pagineCCH 70-3 InglésDavid Andres Cañas SuarezNessuna valutazione finora

- PP34. Rev.1xlsDocumento1 paginaPP34. Rev.1xlsS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento2 pagineWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- PP34. Rev.1xlsDocumento1 paginaPP34. Rev.1xlsS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento2 pagineWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento2 pagineWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Documento2 pagineWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Documento2 pagineWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Documento1 paginaWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaNessuna valutazione finora

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocumento1 paginaWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNessuna valutazione finora

- Nanofibers and Their Applications in Tissue Engineering: Rajesh Vasita Dhirendra S KattiDocumento16 pagineNanofibers and Their Applications in Tissue Engineering: Rajesh Vasita Dhirendra S KattiAlex John Denoga AbandoNessuna valutazione finora

- 3.failures Resulting From Static LoadingDocumento32 pagine3.failures Resulting From Static LoadingRainaMohanSaiNessuna valutazione finora

- Quantum DevicesDocumento132 pagineQuantum DevicesAritra LahiriNessuna valutazione finora

- Wireless Transmission of Electrical PowerDocumento25 pagineWireless Transmission of Electrical PowerMk Enterprise JamuriaNessuna valutazione finora

- Construction and Building Materials: Laila Aouba, Cécile Bories, Marie Coutand, Bernard Perrin, Hervé LemercierDocumento7 pagineConstruction and Building Materials: Laila Aouba, Cécile Bories, Marie Coutand, Bernard Perrin, Hervé LemercierDaniela Sierra UpeguiNessuna valutazione finora

- Lab Report Alternating CurrentDocumento4 pagineLab Report Alternating Currentalinaathirah04Nessuna valutazione finora

- 02112015000000B - Boehler FOX EV 70 - CeDocumento1 pagina02112015000000B - Boehler FOX EV 70 - CeOPAZOSCNessuna valutazione finora

- Rotation Reciprocation or CombinationDocumento30 pagineRotation Reciprocation or CombinationvanillalavenderNessuna valutazione finora

- Piper AlphaDocumento18 paginePiper AlphaSKataNessuna valutazione finora

- Experiment 1 - Sem2Documento7 pagineExperiment 1 - Sem2MUHAMMAD SYUKRI FITRI BIN MOHAMAD RAZALINessuna valutazione finora

- XE SampleDocumento31 pagineXE SampleJerome HarinaNessuna valutazione finora

- X-Ray DiffractionDocumento30 pagineX-Ray DiffractionMerve Ayvaz KöroğluNessuna valutazione finora

- Heat Transfer in Bioreactor: Manam Walait Lecturer FLS, UCP LahoreDocumento8 pagineHeat Transfer in Bioreactor: Manam Walait Lecturer FLS, UCP LahoreJawadNessuna valutazione finora

- Fracture Mechanics of Concrete PDFDocumento159 pagineFracture Mechanics of Concrete PDFChetan PatilNessuna valutazione finora

- 1 s2.0 S1566119923001659 MainDocumento8 pagine1 s2.0 S1566119923001659 MainMatias AlonsoNessuna valutazione finora

- Anisotropy of Additively Manufactured 18ni 300 Maraging Steel - 2020 - ProcediaDocumento11 pagineAnisotropy of Additively Manufactured 18ni 300 Maraging Steel - 2020 - ProcediaajayvgNessuna valutazione finora

- Soil Mechanics PP 2013Documento4 pagineSoil Mechanics PP 2013Zack FengNessuna valutazione finora

- Aislamiento Termico-Broch Cryogel ZDocumento2 pagineAislamiento Termico-Broch Cryogel ZJavier Caamaño VillafañeNessuna valutazione finora

- Exercícios Resolvidos - Cap. 08 (Pares) - Equilíbrio Físico (Propriedades de Soluções) - Princípios de Química - AtkinsDocumento39 pagineExercícios Resolvidos - Cap. 08 (Pares) - Equilíbrio Físico (Propriedades de Soluções) - Princípios de Química - AtkinsCristiane MauadNessuna valutazione finora

- A Review Paper On Photovoltaic TextilesDocumento13 pagineA Review Paper On Photovoltaic TextilesShradha Shinde DongreNessuna valutazione finora

- Class Xii Physics Study Material 2023-24Documento323 pagineClass Xii Physics Study Material 2023-24IRONRISHINessuna valutazione finora

- PLAXIS 2D CE V20.00 Tutorial Lesson 08Documento19 paginePLAXIS 2D CE V20.00 Tutorial Lesson 08Safwat El RoubyNessuna valutazione finora

- 5M MTC - Aj420Documento7 pagine5M MTC - Aj420Paing Soe LinNessuna valutazione finora