Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vikta102 Ecl Modbus Opc

Caricato da

Tobias AngererCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vikta102 Ecl Modbus Opc

Caricato da

Tobias AngererCopyright:

Formati disponibili

ECL MODBUS OPC

Instructions

DH-SMT/DK VI.KT.A1.02 © Danfoss 09/2006

Instructions ECL MODBUS OPC

Table of Contents

1. Introduction 3

1.1 Prior to installation ......................................................................................................................................................................................................................4

2. How to install the program 4

3. Navigation in the Configurator 5

4. How to get started 5

4.1 Network scan.................................................................................................................................................................................................................................6

4.2 Device scan ....................................................................................................................................................................................................................................7

4.3 Device and tag names ...............................................................................................................................................................................................................8

4.4 Conversions ...................................................................................................................................................................................................................................8

4.5 Third party products ..................................................................................................................................................................................................................9

5. Installation and technical information 9

6. Troubleshooting 10

VI.KT.A1.02 © Danfoss 09/2006 DH-SMT/DK

Instructions ECL MODBUS OPC

1. Introduction

This instruction covers the ECL MODBUS OPC, i.e. the ECL MODBUS Configurator and the ECL MODBUS OPC Server.

The ECL MODBUS OPC Server uses the OPC Data Access Specification version 2.0.

The ECL MODBUS OPC Configurator and Server can communicate with ECL Comfort controllers with ECA 71 module. The

communication takes place by means of Windows COM ports, e.g. COM1. The Server can use multiple COM ports to support

multiple networks.

The ECL MODBUS OPC Configurator and Server are in the following referred to as Configurator and Server. The Configurator is

used for the setup of the Server. Setup changes will not take effect until the Server has been restarted.

The Configurator is an online tool that can scan a network for ECL Comfort devices and their parameters. Devices, groups and

parameters can also be added manually.

The network scan searches a network for installed ECL Comfort devices. The search is done from address 1 to address 247. The

network scan can only add new devices – existing devices will NOT be deleted.

The device scan retrieves the parameter list from the selected ECL Comfort controller. The parameters are placed in a hierarchical

structure depending on the ECL Comfort application. The device scan can only add new folders and parameters – existing

folders and parameters will NOT be deleted.

This help file is written for ECL MODBUS OPC version 1.1

It is recommended to make a backup of the OPC database before modifications are carried out.

Third party SCADA system:

OPC Client Connected via

Danfoss MODBUS

OPC server

TCP/IP, USB or

RS-232 to

RS-485 (MODBUS)

ECL Comfort

M-Bus connection

Heat meter

DH-SMT/DK VI.KT.A1.02 © Danfoss 09/2006 3

Instructions ECL MODBUS OPC

1.1 Prior to installation

Min. PC requirements

• Intel Pentium or equivalent processor

• Windows 2000®, Windows NT or Windows XP

• 128 MB RAM

• 500 MB free hard disk space

References

Type Description Code No. (Parts list No.)

ECA 71 MODBUS communication module 087B1126

Documentation available on http://heating.danfoss.com:

Instructions, ECA 71 protocol (087R9775, English)

Instructions, ECA 71 / 72 installation and user guide (087R9769, English)

Cables

The required cables will depend on the used equipment. Consult the MODBUS RS-485 converter documentation for further

details.

Please do also consult the ECA 71 instructions for details about the network layout and connection.

MODBUS RS-485 Converters

The MODBUS network uses a 2-wire RS-485 interface. This interface is typically not part of a standard PC, and it is therefore

necessary to connect a MODBUS RS-485 converter.

Basically there are 4 groups of converters:

• RS-232 ↔ RS-485

• USB ↔ RS-485

• TCP/IP ↔ RS-485

• Expansion module, e.g. PCI ↔ RS-485

Common requirements for all converters are that they have to be capable of running MODBUS RS-485, the desired

communication setting (baud rate, parity etc.) and must offer a Windows COM (Virtual COM) port interface to the Configurator

and Server.

The MODBUS standardspecifies line termination and polarization. It is an advantage if this is built into the converter. It is

recommended to use isolated converters (and repeaters) to increase robustness.

For specific details, please consult the specifications

• Modbus Application Protocol V1.1a.

• MODBUS over Serial Line, Specification & Implementation guide V1.0

both of which can be found on http://www.modbus.org/

Achievable performance will depend on the chosen converter.

2. How to install the program

Run the Setup.exe file on the PC onto which the OPC Server and Configurator must be installed. Follow the installation wizard.

The next step is to read the section on “How to get started”.

4 VI.KT.A1.02 © Danfoss 09/2006 DH-SMT/DK

Instructions ECL MODBUS OPC

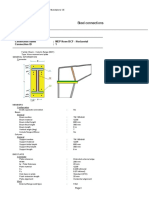

3. Navigation in the Configurator

The Configurator resembles the Windows Explorer, with a left-hand side for level/item navigation and a right-hand side with

details for the selected level/item.

In the Configurator new ports, devices, groups and parameters can be added with a right-click of the mouse or by means of the

menu item ‘Edit’ ↔ ‘New’.

The illustration shows the hierarchical structure (as known from the Windows Explorer) with the newly created folders ‘NewPort’,

‘NewDevice’, ‘NewFolder’ and ‘NewDataItem’.

4. How to get started

After installation it is necessary to configure the database or select an already existing (valid) database. The database

configuration must be carried out with the Configurator.

An existing database can be selected by opening the database and closing the Configurator. When this is carried out, the

Configurator will ask whether the new database should be used for the Server.

For the configuration of a new database, the following steps must must be carried out for each network:

1. Run the Configurator (located in the start menu, ‘Programs’ ↔ ‘District Heating’ ↔ ‘ECL MODBUS OPC Server’ ↔

’Configurator’)

2. Add/select a port by specifying the COM port and the serial settings

3. Scan the network or add devices manually

4. Scan each device or add groups and parameters/tags manually

5. Close the Configurator

DH-SMT/DK VI.KT.A1.02 © Danfoss 09/2006 5

Instructions ECL MODBUS OPC

The database is configured and the Server has the parameters/tags which an OPC client can use.

If the network is updated or expanded, e.g. new controllers are added or application cards changed, it is recommended to follow

the steps above for an update of the database configuration.

4.1 Network scan

The network scan is used to search the network for new devices. Third party products are not supported by this function, and

must be added manually.

The network scan can be activated in the port window. Before the scan, the correct communication parameters must be set.

The network scan takes approximately 1 – 5 minute to complete.

6 VI.KT.A1.02 © Danfoss 09/2006 DH-SMT/DK

Instructions ECL MODBUS OPC

4.2 Device scan

Device scan is used for finding the groups and parameters of a device. Whenever a device has been replaced, the application

changed etc., this function should be used. Third party products are not supported by this function, and must be added

manually.

The device scan can be activated in the device window – after the network scan. Before a scan, a device must be selected.

The device scan takes approximately 1 – 5 minute to complete.

The device scan can only be used for ECL type devices.

If a device is re-scanned, the old folders should be deleted.

The button ‘Fill Conversions’ must be used before a scan if the database does not contain the necessary scales. It adds/repairs

the necessary default conversions items.

DH-SMT/DK VI.KT.A1.02 © Danfoss 09/2006 7

Instructions ECL MODBUS OPC

4.3 Device and tag names

Device and tag names are generated automatically. The names will therefore be the same from scan to scan if nothing is

changed (version of Configurator, ECA 71, ECL Comfort, or Application).

Whenever possible, the automatically generated names should be used, as this will reduce overall system setup modifications.

Description field can be changed if desired.

4.4 Conversions

All values can be converted (scaled) by the OPC Server.

To add/modify a conversion:

1. ‘Add/Modify’ a conversion in the Conversions folder.

2. For the parameters that require conversion, select ‘Use conversion’ in the parameter dialog and then select the appropriate

conversion

Default conversions ‘ECL Scale x’ is a conversion which is equal to 10x, e.g. ‘ECL Scale -1’ is equal to 10-1 (division by 10).

‘ECL Scale Schedule’ is used for all schedule values. As default the conversion will divide the values by 100, i.e. 8:00 is 8 and 8:30

is 8,3 (not 800 and 830). The conversion can be changed if this representation is not desired.

8 VI.KT.A1.02 © Danfoss 09/2006 DH-SMT/DK

Instructions ECL MODBUS OPC

4.5 Third party products

Third party products, such as general inputs/outputs, which support the standard MODBUS RTU interface can manually be

added with the Configurator.

New devices, groups and parameters can be added by a right-click of the mouse or the menu item ‘Edit’ → ‘New’.

Note that any third party products must use the same communication settings as the rest of the network (baud rate, parity etc.).

5. Installation and technical information

The installation includes the files ‘PNU & GROUP numbers parameter list.txt’ and ‘search list.txt’. These files are used during a

device scan and are not to be modified.

Cache function

The ‘Cache’ folder contains cached device scan results. When a new application type is scanned, a cache file is generated. If an

application type is known, the cached file will be used, thus eliminating a complete device scan. This will speed up the process.

The cache function can be enabled/disabled by creating/deleting the ‘Cache’ folder.

Scan timeout

The network scan timeout parameter can, if necessary, be changed by adding a DWORD value with the name ScanTimeout to the

registration database key.

HKEY_CURRENT_USER\Software\Danfoss A/S\ECL Modbus OPC Configurator\Options

The default value is 250 ms.

(The device scan uses the device read timeout).

Default database

The installation includes a default database named ECL_ModbusOPCConfigurator.mdb.

Database compatibility

Databases from ECL MODBUS OPC version 1.0 are usable after the ‘Fill Conversions’ function has run.

Databases from Demo Iconics MODBUS OPC are not compatible.

DH-SMT/DK VI.KT.A1.02 © Danfoss 09/2006 9

Instructions ECL MODBUS OPC

6. Troubleshooting

Fault Cause Solution

No database Installation not complete • Uninstall and reinstall the program

Alternative

• Create a new database with ‘File’

→ ’New’

• Or open an existing database with

‘File’ → ‘Open’

When the program is closed, choose

‘Yes’ to set the new database as the

current one.

Network scan does not find any False communication port and/or • Check that the COM port setting is

devices settings correct.

• Check that the cable/network is

connected correctly

• Check that cable termination and

polarization is correct

Device scan does not find all Not fully supported module • Manually insert the missing

parameters parameters

• Update the Configurator if possible

Low server performance Invalid devices and/or parameters. • Remove invalid devices (that do

To high update rate requested. not exist in the network)

Low performing converters/repeaters

• Remove invalid parameters (that

do not exist in the device)

• Change the requested update rate

to a more reasonable value

• Check that converters and

repeaters are correctly installed

and have the needed performance

• Converters that run over other

media (e.g. the internet) can

introduce delays

VI.KT.A1.02 © Danfoss 09/2006 DH-SMT/DK

Potrebbero piacerti anche

- ARM-Based Microcontroller Multitasking Projects: Using the FreeRTOS Multitasking KernelDa EverandARM-Based Microcontroller Multitasking Projects: Using the FreeRTOS Multitasking KernelValutazione: 5 su 5 stelle5/5 (1)

- Networked Control System: Fundamentals and ApplicationsDa EverandNetworked Control System: Fundamentals and ApplicationsNessuna valutazione finora

- Advantech Webaccess Device Driver Guide Wago 750 Ethernet Tcp/Ip ModbusDocumento46 pagineAdvantech Webaccess Device Driver Guide Wago 750 Ethernet Tcp/Ip ModbusMohamed ElbanadiNessuna valutazione finora

- Eio0000000064 03Documento95 pagineEio0000000064 03BlakeNessuna valutazione finora

- AN0009v04-UC20-WL2000 ModbusTCP Master Implementation in Node-REDDocumento32 pagineAN0009v04-UC20-WL2000 ModbusTCP Master Implementation in Node-REDJirawat JumpathongNessuna valutazione finora

- ION7650 Third Party Protocols (70002-0248-06)Documento31 pagineION7650 Third Party Protocols (70002-0248-06)Edwin IxtinNessuna valutazione finora

- Quantum CPU Operating System: Upgrade and Update ProcedureDocumento52 pagineQuantum CPU Operating System: Upgrade and Update ProcedureIrfan AshrafNessuna valutazione finora

- BA - KOSTAL Interface Description MODBUS TCP - SunSpec - HybridDocumento26 pagineBA - KOSTAL Interface Description MODBUS TCP - SunSpec - HybridJan RittelNessuna valutazione finora

- Profinet Design 8062 v114 Dec14Documento34 pagineProfinet Design 8062 v114 Dec14ParamNessuna valutazione finora

- Modbus Messaging Implementation Guide V1 0aDocumento46 pagineModbus Messaging Implementation Guide V1 0acontrolsoftNessuna valutazione finora

- Modbus Register Lists - PCME Wet Stack SystemsDocumento14 pagineModbus Register Lists - PCME Wet Stack SystemsRafael Porcelles BonilhaNessuna valutazione finora

- ASSIGNMENT 1 (Embd&IOmT)Documento9 pagineASSIGNMENT 1 (Embd&IOmT)rakesh.jNessuna valutazione finora

- Modbus Messaging Implementation Guide V1 0bDocumento46 pagineModbus Messaging Implementation Guide V1 0bGiles HarperNessuna valutazione finora

- Manual Ixarc Ocd emDocumento25 pagineManual Ixarc Ocd emT BagNessuna valutazione finora

- EDP System and Baseboard ManualDocumento35 pagineEDP System and Baseboard ManualVishal ThakurNessuna valutazione finora

- QSG0007-UR20-Modbus Understanding Coils and RegisterDocumento20 pagineQSG0007-UR20-Modbus Understanding Coils and RegisterUiliansNessuna valutazione finora

- Anybus Modbus-TCP/RTU Gateway: User ManualDocumento22 pagineAnybus Modbus-TCP/RTU Gateway: User Manualyana sopian hidayatNessuna valutazione finora

- Modbus Application Protocol V1 1b3Documento50 pagineModbus Application Protocol V1 1b3doce12Nessuna valutazione finora

- Modbus and ION Technology: Technical NoteDocumento19 pagineModbus and ION Technology: Technical NoteJohn SumagüeNessuna valutazione finora

- User Manual: Gateway / Bridge Canopen To Modbus TCP ClientDocumento12 pagineUser Manual: Gateway / Bridge Canopen To Modbus TCP ClientkoboNessuna valutazione finora

- PN624325 01 - USB RS485 Converter - ManualDocumento14 paginePN624325 01 - USB RS485 Converter - ManualOmar HajjiNessuna valutazione finora

- Modbus Application Protocol SpecificationDocumento45 pagineModbus Application Protocol SpecificationVictor FirmesNessuna valutazione finora

- Modbus Application Protocol V1 1aDocumento51 pagineModbus Application Protocol V1 1aGabriel FuchsNessuna valutazione finora

- Archivos y Apuntes ModbusDocumento35 pagineArchivos y Apuntes ModbusDiego Alejandro Gallardo IbarraNessuna valutazione finora

- Serial - Ethernet ModuleDocumento22 pagineSerial - Ethernet ModuleJAC 91Nessuna valutazione finora

- CP1L-EL - EM Modbus TCP Client Socket Services PDFDocumento7 pagineCP1L-EL - EM Modbus TCP Client Socket Services PDFfaspNessuna valutazione finora

- User Manual: J1939 / Modbus TCP Slave - ConverterDocumento29 pagineUser Manual: J1939 / Modbus TCP Slave - ConverterMohamed KhaldiNessuna valutazione finora

- IOSrv MBENETDocumento42 pagineIOSrv MBENETIrwan PambudiNessuna valutazione finora

- Lab ManualDocumento82 pagineLab ManualSafa MNessuna valutazione finora

- Ambit Cable Modem: User's GuideDocumento42 pagineAmbit Cable Modem: User's GuideJohn PerkinsonNessuna valutazione finora

- User Guide MK IVModbus 01Documento31 pagineUser Guide MK IVModbus 01Evgeny TumalevNessuna valutazione finora

- CANOpen and CoDeSys PBF Part 1 - Basic FunctionsDocumento15 pagineCANOpen and CoDeSys PBF Part 1 - Basic FunctionsgiusssyNessuna valutazione finora

- Vacon NX OPTCI Modbus TCP Board User Manual DPD00900A UKDocumento32 pagineVacon NX OPTCI Modbus TCP Board User Manual DPD00900A UKKiran AcharNessuna valutazione finora

- D027B OmronDocumento141 pagineD027B OmronirfanWPKNessuna valutazione finora

- Motion Control Solution For New PLC-based Standard Development Platform For VLT Instrument Control SystemsDocumento12 pagineMotion Control Solution For New PLC-based Standard Development Platform For VLT Instrument Control SystemsMinh Nhut LuuNessuna valutazione finora

- Modbus 通信協定01Documento10 pagineModbus 通信協定01wenyuan.chenNessuna valutazione finora

- Modbus Messaging On Tcp/Ip Implementation Guide V1.0bDocumento46 pagineModbus Messaging On Tcp/Ip Implementation Guide V1.0bBruno SilvaNessuna valutazione finora

- Open Modbus TCP SpecificationsDocumento24 pagineOpen Modbus TCP SpecificationsAssia IaqbalNessuna valutazione finora

- Canopen Network Quick Start Guide On Premium and Micro PLCS: February 2005 EngDocumento22 pagineCanopen Network Quick Start Guide On Premium and Micro PLCS: February 2005 EngJames GeorgeNessuna valutazione finora

- Ecu Can Analyser Global Guide 2p0p0Documento11 pagineEcu Can Analyser Global Guide 2p0p0fghNessuna valutazione finora

- UC 7112 LX Plus User Guide 2 0 0Documento19 pagineUC 7112 LX Plus User Guide 2 0 0markelovfyodorNessuna valutazione finora

- Open Modbus/Tcp Specification: Release 1.0, 29 March 1999Documento23 pagineOpen Modbus/Tcp Specification: Release 1.0, 29 March 1999adsad12345Nessuna valutazione finora

- Modbus FAQ: Home Products Tutorial Directory Glossary ContribDocumento10 pagineModbus FAQ: Home Products Tutorial Directory Glossary Contribindra lukmanNessuna valutazione finora

- Comunicaciones UnitronicsDocumento47 pagineComunicaciones UnitronicsUcayaliAlDiaNessuna valutazione finora

- E777 Modbus Master Software Development GuideDocumento43 pagineE777 Modbus Master Software Development GuideRubén MontalvanNessuna valutazione finora

- TC2716en-Ed01 Information On Modem Configuration With OXE Multitech Modem RemovalDocumento5 pagineTC2716en-Ed01 Information On Modem Configuration With OXE Multitech Modem RemovalAsnake TegenawNessuna valutazione finora

- AV EoC Web Manual 6027,8Documento12 pagineAV EoC Web Manual 6027,8Andres Alberto ParraNessuna valutazione finora

- Art85140 CAN Via UDPDocumento13 pagineArt85140 CAN Via UDPgeronimo montiNessuna valutazione finora

- Inter Controller CAN Converter Global GuideDocumento8 pagineInter Controller CAN Converter Global GuideMuhammad Shoaib HussainNessuna valutazione finora

- Using Matlab With Canoe: 2017-03-09 Application Note An-Ind-1-007Documento14 pagineUsing Matlab With Canoe: 2017-03-09 Application Note An-Ind-1-007Raul BachmannNessuna valutazione finora

- Ambit U10c018Documento32 pagineAmbit U10c018shaikh_piscesNessuna valutazione finora

- Lubmon Connect: Remote InterfaceDocumento44 pagineLubmon Connect: Remote InterfaceRicardo RoquettiNessuna valutazione finora

- MbenetDocumento42 pagineMbenetWendy AbadNessuna valutazione finora

- AbsoluteEncoders OCD IndustrialEthernet TCP IP Manual Modbus DataContentDocumento26 pagineAbsoluteEncoders OCD IndustrialEthernet TCP IP Manual Modbus DataContentVoicu StaneseNessuna valutazione finora

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosDa EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosValutazione: 5 su 5 stelle5/5 (1)

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksDa EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksNessuna valutazione finora

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDa EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNessuna valutazione finora

- Curriculum VitaeDocumento4 pagineCurriculum VitaeShams TabrezNessuna valutazione finora

- 12671/nilagiri SF Exp Sleeper Class (SL)Documento2 pagine12671/nilagiri SF Exp Sleeper Class (SL)em emmNessuna valutazione finora

- Research Study On Engineered Wood Laminated Veneer Lumber (LVL), Glue-Laminated Timber (Glulam) and Cross-Laminated Timber (CLT)Documento9 pagineResearch Study On Engineered Wood Laminated Veneer Lumber (LVL), Glue-Laminated Timber (Glulam) and Cross-Laminated Timber (CLT)Ahmad MahyuddinNessuna valutazione finora

- Acado ManualDocumento118 pagineAcado ManualFrancisco Manuel Arrabal CamposNessuna valutazione finora

- Acti 9 Complete PDFDocumento408 pagineActi 9 Complete PDFmimIX00% (1)

- Tekcien PDFDocumento171 pagineTekcien PDFASOCIACION ATECUBO100% (1)

- Unit Plan Final Assessment Rubrics PDFDocumento2 pagineUnit Plan Final Assessment Rubrics PDFapi-282198214Nessuna valutazione finora

- EasyPower v. Operation Technology ComplaintDocumento10 pagineEasyPower v. Operation Technology ComplaintKenan FarrellNessuna valutazione finora

- Fiber SM MM Pigtails DatasheetDocumento2 pagineFiber SM MM Pigtails DatasheetS BanerjeeNessuna valutazione finora

- RAM Connection Standalone CE ReportDocumento4 pagineRAM Connection Standalone CE ReportThanh ViệtNessuna valutazione finora

- 2023 Online ASCP Batch 3 Class ScheduleDocumento1 pagina2023 Online ASCP Batch 3 Class ScheduleLhalline el CalaminosNessuna valutazione finora

- Arm ShowDocumento38 pagineArm Showselva33Nessuna valutazione finora

- D785T007Documento11 pagineD785T007LLNessuna valutazione finora

- 2009 Hack - Lu Slides WM6 RootkitDocumento59 pagine2009 Hack - Lu Slides WM6 RootkitchepimancaNessuna valutazione finora

- Remote Control Using Infrared With Message RecordingDocumento107 pagineRemote Control Using Infrared With Message RecordingBASEER AHMADNessuna valutazione finora

- MCM Oil Tools: Chokes and Control PanelsDocumento4 pagineMCM Oil Tools: Chokes and Control PanelsCARLOS SANCHEZNessuna valutazione finora

- Orme 8 2018Documento60 pagineOrme 8 2018sureshmechanical86Nessuna valutazione finora

- AIC - Selection - 2015 PDFDocumento7 pagineAIC - Selection - 2015 PDFSlimane SlimaneNessuna valutazione finora

- Cooler Instruction (Shargh)Documento39 pagineCooler Instruction (Shargh)hamid hoorshad100% (2)

- Corporate Responsibility: Using Our Expertise To Build A Stronger and Safer SocietyDocumento52 pagineCorporate Responsibility: Using Our Expertise To Build A Stronger and Safer SocietyHuening KaiNessuna valutazione finora

- Generator Hipot TestingDocumento30 pagineGenerator Hipot TestingBalu MNessuna valutazione finora

- Technical Catalogue: June JuneDocumento9 pagineTechnical Catalogue: June JunehaggNessuna valutazione finora

- MGT One Minute Manager SummaryDocumento5 pagineMGT One Minute Manager SummaryJitendra SinghNessuna valutazione finora

- SreenplayDocumento3 pagineSreenplayyyrwt bhiNessuna valutazione finora

- Lightworks v14.0.0 Quick Start GuideDocumento38 pagineLightworks v14.0.0 Quick Start GuideSrL3onNessuna valutazione finora

- Material Short Text Alter Sap CodeDocumento16 pagineMaterial Short Text Alter Sap CodeHafiz SaraswalaNessuna valutazione finora

- Practice Exam 2Documento4 paginePractice Exam 2Clariza Mae PerniaNessuna valutazione finora

- Para List GSM BSC 6900Documento5.604 paginePara List GSM BSC 6900hassanNessuna valutazione finora

- Bit Error Rate FOR BPSKDocumento4 pagineBit Error Rate FOR BPSKjameelahmadNessuna valutazione finora

- Fisher 3582 Control ValveDocumento48 pagineFisher 3582 Control ValveJaime Andres Villegas MansillaNessuna valutazione finora