Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SMP For Ba Overflow Pump

Caricato da

SonratTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SMP For Ba Overflow Pump

Caricato da

SonratCopyright:

Formati disponibili

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 1 of 14

STANDARD MAINTANENCE PROCEDURE

FOR

BA OVERFLOW PUMP

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 2 of 14

OBJECTIVE

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 3 of 14

The purpose of this work instruction is to explain the procedure for carrying out Overhaul of

BA OVERFLOW PUMP.

1. BA OVERFLOW PUMP

The details of the BA OVERFLOW PUMP are as follows :

Make: Weir Minerals Ltd.; TYPE 8/6 E-AH, Q=305m3/h, H=0.29MPa, 415V, 37 KW, PART

NO.-EAM005M.

DETAILED INSTRUCTION

Sr. Activity Respons

ibility

No.

I Overhaul to be done as per Checklist

1 Before commencing dismantling operations, ensure that the

following tools and tackles are available:

A crane / chain pulley block suitable for handling the weight of pumping

unit.

A selection of ring and open-ended spanners in Metric sizes.

Eyebolts in Metric sizes.

Hardwood and metal packing blocks.

Miscellaneous tools including a set of Allen keys, drills, pin drivers, files

etc.

Extractor / puller for bearing and coupling.

.

After a long service, wear will occur in parts of the pump necessitating the

renewal of the parts. Those most likely to be affected are impeller, Wear

Rings, Bearings, and Sleeves.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 4 of 14

2 Dismantling

1. Before dismantling, make sure the motor is disconnected.

2. The suction and discharge shutoff valves must be closed.

3. The pump casing must have cooled down to ambient temperature.

4. The pump casing must be empty and not under pressure.

5. Detach all auxiliary supply pipe lines.

6. Remove coupling guard.

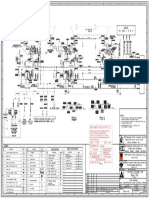

7. Remove coupling half from the pump shaft. Refer fig. no. 1

8. Pull out bearing bracket with discharge cover and complete rotor

(assembled unit).

9. If the pump has been in operation for a long time some parts may be

difficult to remove.

In this case use a penetrating oil or suitable pull-off device.

10.Loosen & remove impeller Lock nut.

11.Remove impeller from pump shaft. Refer fig. no. 2

Fig. no. 1: Dismantling the pump set

Fig. no. 2: Removal of Impeller

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 5 of 14

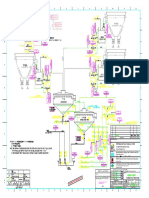

Construction Drawing For BA OVERFLOW PUMP

1 Bearing Assy.

4 Shaft Sleeve

5 Shaft Sleeve O-Ring

6 Frame Plate Liner Stud

7 Seal Ring

8 Frame Plate Liner Insert

9 Impeller

10 Discharge Joint

11 Cover Plate

12 Throat bush

13 Cotter

14 Intake Joint

20 Volute Liner Seal

21 Volute Liner

22 Frame Plate

23 Keeper Plate

29 Packing

30 Shaft Spacer

31 Gland(2 Piece)

32 Gland Bolt-1Nut-1Washer

33 Lantern Restrictor

34 Stuffing Box

35 Impeller O-Ring

36 Gland Clam Bolt

47 Grease Cup

48 Grease Cup Adaptor

50 Neck Ring

53 Expeller Ring

54 Lantern Ring

55 Expeller

56 Shaft O-Ring

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 6 of 14

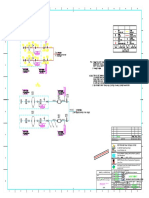

1 SHAFT

3 2 SHAFT KEY

3 LABYRINTH LOCKNUT

4 GREASE NIPPLE

5 GREASE CAP

6 NAMEPLATE IVET

7 NAME PLATE

8 GREASE RETAINER

9 BEARING HOUSING

10 PLUG

11 END COVER

12 BEARING SEAL

13 SHIM SET

14 BEARING

15 END COVER SET SCREW

16 PISTON RING

17 LABYRINTH

Fig. No. 3 : Bearing Assembly.

Dismantling the Bearing Unit

1. Remove bearing covers and gaskets by unscrewing of hex. Bolt. Refer fig.

no. 3

2. Fasten the bearing unit firmly to the bench vice refer fig. no. 4 Strike the

pump shaft end with a soft hammer. Refer fig. no. 4

3. Fasten the shaft (with bearings) to the bench vice and detach bearings

from shaft with a bearing puller. Refer fig. no. 5

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 7 of 14

Note: Always replace the bearings once they have been removed from the

shaft with new ones.

Unnecessary removal of the bearings should be avoided because removal of

the bearing can damage it and cause deterioration of the interference fit.

Except where removal is necessary to give access to the other parts, bearing

should be removed only if they need close inspection. Symptoms, which will

indicate the state of bearing, are the condition of the lubricant, the bearing

running temperature, noise level and vibration during operation.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 8 of 14

4 Examination of Internal Components :

Wearing Rings

The wearing rings have to be replaced when the clearances between the

wearing ring & the impeller & the Discharge cover exceeds three times the

max. Value as shown in the below table or when the reduction of efficiency

of the pump is noticed.

Note: - In MEGA GC wearing ring is not provided.

Original Clearance on the Diameter

Pump Size Casing Side Impeller Side

Maximum Minimum Maximum Minimum

80-200 0.445 0.33 0.445 0.33

New wearing ring clearances are:-

MEGA GC - 0.5 mm on diameter

MEGA - 0.3 mm on diameter

Shaft Sleeves

Replace shaft sleeve if it is grooved or generally worn.

Impeller

a. Inspect the impeller as follows:

i. Examine the impeller for damage.

ii. For corrosive /erosion pitting.

iii. Cavitations pitting.

iv. Bent or cracked vanes, inlet and outlet vane end wear.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 9 of 14

Any of the above may be repaired, or if damage is extensive, impeller may

need replacement.

b. Around the eye, wearing rings protects the impeller. Examine around

the eye at neck portion for grooving in alignment with spindle axis;

slight grooving is acceptable but deep or profuse grooving must be

remedied by machining the impeller by taking a polish cut on wearing

ring. Spare wear rings are supplied with excess outside diameter to

facilitate machining after fitting. The wear rings are shrink fitted on

impeller neck and are screwed.

c. To check wear, around the impeller neck, use precision instruments

such as outside micrometer to accurately measure the outside

diameter. Measurements should be taken at intervals around the

circumference to check the uneven wear. Differences between the

neck OD and the neck ring ID measured will give us the clearance

between the two. Clearance thus obtained should not be more than

150% of maximum designed clearance.

Shaft & keys

Shaft should be checked for the trueness, or any other mechanical

damage and corrosion. If the shaft is not true within 0.1 mm TIR, it

should be replaced / repaired. Examine the shaft keys and key ways.

Remove damaged or worn out keys

Bearings

a. Clean all the components using clean white spirit. Do not use

chlorinated solvents such as trichloroethylene and carbon

tetrachloride because they introduce a corrosion risk when used on

ferrous materials.

b. Visually inspect the bearing. The balls, the inner and outer tracks

must all be free from chipping cracks, abrasions or discoloration.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 10 of 14

c.

1. Check

Vacuumthat

andthe parts

blow outofallthe cage are

cavities firmly fixed

of bearing together.

housing.

d. Visually inspect the bore for any sign of damage. Burrs or any

scratches caused during bearing withdrawal should be carefully

removed by hand application of a fine oilstone, the treatment being

confined to the minimum possible area.

e. Visually inspect Bearing Housing

the outside diameter for signs of fretting, any stains

may be carefully polished off, but abrasion must be kept to the

2. absolute

Set bearing housingthat

minimum vertical on flange.

is required, followed by cleaning.

3. Press in shaft assembly as shown.

4.f. Check

Fasten that

outerbearing

bearingrotates

cover assembly.

freely and smoothly. If there is any doubt

5. regarding

Secure inner bearing cover assembly.

the serviceability of the bearing it should be replaced.

g. If after inspection, the bearing is reusable, completely coat all parts

with rust preventive oil, working it well into the internal parts of the

bearing. Wrap in clean greaseproof paper and store until required for

replacement or refit on to the spindle if needed. In case of immediate

use, coating of rust preventive oil is not necessary.

6. Fit box

Stuffing deflectors

bush at pump side

7. Fit coupling key.

Check

8. Add bore

PVC tapeof to

stuffing box bush and compare with sleeve diameter. If

secure.

9. Place back cover on bench.

"clearance is excessive, the bush should be renewed.

10. Insert the packing / logging ring set into this stuffing box.

Note: While assembling stainless steel component, molybdenum-disulphide

paste

a. should

Before be applied tothoroughly

repacking, prevent galling

clean /stuffing

seizure and

box also to facilitate

gland, packing

easy removal in future.

compartment and shaft protection sleeve.

b. Cut the packing ring to correct length and ends at 45º. Ensure

that the packing rings ends come into contact with one another

on fitment.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 11 of 14

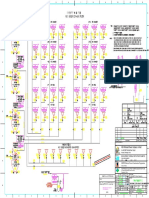

5 Reassembly

11. Coat the fits and screw connections with molykote or

similar before reassembly.

12. Check oil seal & o-rings for its damage; replace if

necessary.

13. All gaskets must be renewed; make sure the new ones

have the same thickness as the old ones.

14. Check the shaft with its spacer sleeve / or shaft protection

sleeve (as applicable) for eccentricity, between centers.

Maximum allowable eccentricity is 0.05mm.

15. Fasten the shaft to the bench vice using soft polish sheets

between the vice clamp jaws to avoid damage. Refer fig. no. A.

16. Heat the bearings in the induction heater about 80-90Deg.C

max. and push it on to the shaft. Fig. no. A Allow the bearings to

cool down. Then tap it lightly against the shoulder using suitable

pipe punch.

17. Fit shaft circlip

Shaft assembly Inner Bearing Cover assembly

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 12 of 14

18. Place back cover on bench.

19.Fasten back cover assembly to bearing housing assembly.

20.Rotate shaft & check for rubbing.

21.Fit impeller key tightly and apply.“Locktite” anti seize compound

to shaft.

22.Tap impeller lightly into place.

23.Tighten impeller nut, holding the shaft steady at coupling end.

24.Check operating gap 0.5-1.5 mm.

25. Lightly grease” O” ring & fit.

6. Possible Faults and Removal

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 13 of 14

REVIEW DATE:-

Faults Cause Removal

Pump fails to Air leaking into suction or gland; Seal the leakage;

discharge any Incorrect direction of pump rotation & impeller worn; Check direction of rotation and replacing impeller;

liquid Suction pipe blocked Removal blockage.

Gland excessively tightened against packing rings; Loosen gland bolts;

Rotating component rubbing on a stationary part; Remove the rubbed parts;

Shaft power Bearing is worn; Replace the bearing;

consumption is Drive belt tension too tight; Adjusting belt;

excessive Flow rate is too large; Modify the pump duty and speed;

Pump speed & ratio too high; Adjusting drive and pump shaft.

Misalignment or unparallel of drive shaft and pump shaft. Adjusting drive and pump shaft.

Lubricants too much or less; Lubricating as requirements;

Bearing is over

Containing impurities in the lubricant; Replace new lubricant;

heating

Bearing worn. Replace new bearing.

Misalignment or unparallel of drive and pump shaft; Adjusting drive and pump shaft;

Shaft is bent; Replacing shaft;

Bearing has Impeller unbalanced due to wear; Remove rubbing and new Impeller;

short life Foreign object entered into the bearing or insufficient Clean the bearing;

lubrication;

Incorrect procedure followed in fitting bearings. Replacing or refitting the bearing.

Packing rings are excessive worn; Replace new packing rings;

Excessive

leakage from Shaft sleeve is worn; Replace shaft sleeve;

stuffing box

Dirty sealing water. Change clean sealing water.

Bearings worn; Replaced by new bearings;

Pump vibrates Impeller unbalanced; Replaced by new impeller;

or is noisy Air entered into suction pipe or blocked; Discharge air and remove block;

Flow rate non-uniform and pump not primed Improve on the pump feeding.

SMP WILL BE REVIEWED IN EVERY SIX MONTH FROM THE DATE OF ISSUE BASED ON

ACTUAL PROBLEM FACED AND SHALL BE UPDATED ACCORDINGLY.

MECHANICAL MAINTANENCE TEAM WILL VISIT THE EQUIPMENT TWICE IN A WEEK & IF

ANY ABNORMALITY NAMELY (VIBRATION, ABNORMAL SOUND, TEMPERATURE RISE, BELT

TIGHTNESS ETC) OF EQUIPMENT IS OBSERVED AND THEN THE SAME WILL BE RECTIFIED

WITHIN PRESCRIBED TIME PERIOD.

DO’s & DONT’s :

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

KMPCL/MAINT/BAOP/01

6 X 600 MW Power Plant

SMP FOR BA OVERFLOW PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 14 of 14

DO’s :

1. Ensure relevant equipment/system PTW is available before starting the work.

2. Ensure relevant equipment/system is electrically isolated before starting the work, if applicable.

3. Ensure relevant air/water valves are fully closed for the equipment/system before starting the work.

4. Provide Danger Boards before starting the work involving dismantling of any equipment/system.

5. Ensure proper follow-up of all statutory requirements & hazard norms.

6. Ensure proper follow-up of all plant practices, existing regulations, prescribed procedures & general

safety prior to carry out any work.

7. While replacing any spares/oil, ensure that the same must be as per OEM recommendation.

8. After overhauling of any equipment, ensure proper preservation of spares/oil.

9. Always use the special tools as recommended by OEM for certain equipments like HCSD Pump.

DONT’s :

1. Don’t start the work without presence of Safety Personnel in case fire / other hazards are involved.

2. Don’t use hammer / heating for removing bearings / gears.

3. Don’t use tools & tackles which are not calibrated / certified by relevant authority.

4. Don’t start the work in Pressure Vessels/Pressure Line/Water Line, unless it is completely de-

pressurised.

5. Don’t start the work, especially at height, without proper PPE’s.

6. Don’t start the work, without presence of skilled personnel/expert.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Potrebbero piacerti anche

- Bah ElevationDocumento1 paginaBah ElevationSonratNessuna valutazione finora

- SMP For Dry Ash UnloaderDocumento8 pagineSMP For Dry Ash UnloaderSonratNessuna valutazione finora

- Bah Side ViewDocumento1 paginaBah Side ViewSonratNessuna valutazione finora

- Control Write Up HCSDDocumento10 pagineControl Write Up HCSDSonratNessuna valutazione finora

- SMP For Vacuum PumpDocumento9 pagineSMP For Vacuum PumpSonratNessuna valutazione finora

- SMP For Sealing Water Pump Multi Stage.Documento13 pagineSMP For Sealing Water Pump Multi Stage.SonratNessuna valutazione finora

- Part List - BEL0800 PDFDocumento1 paginaPart List - BEL0800 PDFSonratNessuna valutazione finora

- SMP For Fluidizing Air BlowerDocumento20 pagineSMP For Fluidizing Air BlowerSonrat100% (1)

- HCSD PDFDocumento1 paginaHCSD PDFSonratNessuna valutazione finora

- Sop For Vent FilterDocumento6 pagineSop For Vent FilterSonratNessuna valutazione finora

- SMP For Supply Water PumpDocumento13 pagineSMP For Supply Water PumpSonratNessuna valutazione finora

- SMP For Slurry PumpDocumento14 pagineSMP For Slurry PumpSonrat100% (1)

- SMP For Agitator (Slurry Sump)Documento9 pagineSMP For Agitator (Slurry Sump)SonratNessuna valutazione finora

- FluidizingDocumento13 pagineFluidizingSonratNessuna valutazione finora

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFDocumento1 paginaBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratNessuna valutazione finora

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFDocumento1 paginaECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratNessuna valutazione finora

- ASH WATER PUMP HOUSE-Model PDFDocumento1 paginaASH WATER PUMP HOUSE-Model PDFSonratNessuna valutazione finora

- FluidizingDocumento13 pagineFluidizingSonratNessuna valutazione finora

- PM For Fly Ash Dry SystemDocumento31 paginePM For Fly Ash Dry SystemSonratNessuna valutazione finora

- StructureDocumento1 paginaStructureSonratNessuna valutazione finora

- Compressor House ModelDocumento1 paginaCompressor House ModelSonratNessuna valutazione finora

- Over Flow Pump Concentrator Buffer Tank ModelDocumento1 paginaOver Flow Pump Concentrator Buffer Tank ModelSonratNessuna valutazione finora

- Water & Slurry BalanceDocumento1 paginaWater & Slurry BalanceSonratNessuna valutazione finora

- ESP-FLD. BLOWER-Model PDFDocumento1 paginaESP-FLD. BLOWER-Model PDFSonratNessuna valutazione finora

- Silo Blower Compressor ModelDocumento1 paginaSilo Blower Compressor ModelSonratNessuna valutazione finora

- Pdi EspDocumento1 paginaPdi EspSonratNessuna valutazione finora

- Silo Unloading ModelDocumento1 paginaSilo Unloading ModelSonratNessuna valutazione finora

- VP To Buffr Hopper-ModelDocumento1 paginaVP To Buffr Hopper-ModelSonratNessuna valutazione finora

- Buffer Hopper & Air Lock Tank-ModelDocumento1 paginaBuffer Hopper & Air Lock Tank-ModelSonratNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Fermentor Scale UpDocumento18 pagineFermentor Scale UpbabuvividNessuna valutazione finora

- Wilo - FA Catalogue - R00Documento12 pagineWilo - FA Catalogue - R00HANIF AKBARNessuna valutazione finora

- Pump PresentationDocumento206 paginePump PresentationMohamed Hamed100% (1)

- Oryza Sativa Manufacturing CorpDocumento99 pagineOryza Sativa Manufacturing CorpAlexander Ibrahim Jr.Nessuna valutazione finora

- Dynatech 4ST Pumps Series Catalog 50 HZDocumento16 pagineDynatech 4ST Pumps Series Catalog 50 HZDYNATECH PUMPS PTE LTDNessuna valutazione finora

- Goulds Pumps: WS - D3 SeriesDocumento4 pagineGoulds Pumps: WS - D3 SeriesBizarre ManeNessuna valutazione finora

- Title Vertical Sump Pumps, CPXV or Ecpj Presenter Ken AuldDocumento25 pagineTitle Vertical Sump Pumps, CPXV or Ecpj Presenter Ken AuldRavi KasaudhanNessuna valutazione finora

- 100 Anze-4vmDocumento1 pagina100 Anze-4vmMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- Chapter - 4Documento37 pagineChapter - 4Barnabas YohannesNessuna valutazione finora

- Principles of Rotating Equipment: Gas InletDocumento15 paginePrinciples of Rotating Equipment: Gas InletAatish ChandrawarNessuna valutazione finora

- Chemical Engineering GATE 1999Documento13 pagineChemical Engineering GATE 1999Anonymous 8pCXXsNessuna valutazione finora

- Design of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFDocumento11 pagineDesign of Impeller Blade by Varying Blades and Type of Blades Using Analytical PDFasrikalyanNessuna valutazione finora

- Ficha Tecnica AURORA PICSA Series 380Documento8 pagineFicha Tecnica AURORA PICSA Series 380Sergio HZNessuna valutazione finora

- QL Series: Vertical, Double-Suction Twin-Volute Turbine PumpsDocumento8 pagineQL Series: Vertical, Double-Suction Twin-Volute Turbine PumpsCarlos RiveraNessuna valutazione finora

- Centrifugal Pumps:: VR Ri Ui U IDocumento31 pagineCentrifugal Pumps:: VR Ri Ui U IValeed Khan100% (1)

- Force Ksb-Omega-Pump Sarcina Pe Flanse PDFDocumento19 pagineForce Ksb-Omega-Pump Sarcina Pe Flanse PDFRusu DimaNessuna valutazione finora

- Centrifugal Pump MathDocumento6 pagineCentrifugal Pump Mathshamiul himelNessuna valutazione finora

- Rotodynamic PumpsDocumento21 pagineRotodynamic PumpsDANIEL ALFONSO SAMPER BRITONessuna valutazione finora

- Intergral TankDocumento5 pagineIntergral Tankprojectssupervision70Nessuna valutazione finora

- Manual Ingersoll RandDocumento18 pagineManual Ingersoll RandJunior Francisco QuijanoNessuna valutazione finora

- Self-Priming Liquid Ring Pumps: With Double Anti-Seize Frontal InsertsDocumento4 pagineSelf-Priming Liquid Ring Pumps: With Double Anti-Seize Frontal Insertscristian villegasNessuna valutazione finora

- Mapua University: 658 Muralla ST., Intramuros, Manila1002, Philippines School of Mechanical and Manufacturing EngineeringDocumento9 pagineMapua University: 658 Muralla ST., Intramuros, Manila1002, Philippines School of Mechanical and Manufacturing EngineeringJazztine Andrei GecoleaNessuna valutazione finora

- ME 310: Fluid Mechanics Laboratory Centrifugal Pump InvestigationDocumento10 pagineME 310: Fluid Mechanics Laboratory Centrifugal Pump InvestigationNaveen KumarNessuna valutazione finora

- Pumps: Tayyab-Ul-Islam 2K17-ESE-22 Muhammad Bilal 2K17-ESE-23 M. Fakhar Hayat 2K17-ESE-24Documento22 paginePumps: Tayyab-Ul-Islam 2K17-ESE-22 Muhammad Bilal 2K17-ESE-23 M. Fakhar Hayat 2K17-ESE-24Tayyab IslamNessuna valutazione finora

- 750-207 OM Profire-M Apr09Documento80 pagine750-207 OM Profire-M Apr09Youssry Elsayed MohamedNessuna valutazione finora

- 150SV Sp-5vomDocumento1 pagina150SV Sp-5vomMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- AgittationMixingPart IDocumento17 pagineAgittationMixingPart IMateo SaloNessuna valutazione finora

- Agitation DevicesDocumento5 pagineAgitation DevicesPassmore DubeNessuna valutazione finora

- JF VerticalFirePumps E00636 (1) Brosur From Vendor BCUDocumento6 pagineJF VerticalFirePumps E00636 (1) Brosur From Vendor BCUyoi_123Nessuna valutazione finora

- 4HH High Head Pump: Highly Efficient Clear Liquid Pump Max. 350 M /hour, Max. 120 MWCDocumento2 pagine4HH High Head Pump: Highly Efficient Clear Liquid Pump Max. 350 M /hour, Max. 120 MWCGonzalez NicolasNessuna valutazione finora