Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Positive Isolation Summary

Caricato da

Can YıldırımCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Positive Isolation Summary

Caricato da

Can YıldırımCopyright:

Formati disponibili

Column A Column B Column C Column D

On line maintenance of equipment (e.g. On line maintenance of

Design Pressure / Vessel entry (Note pump / compressor / heat exchanger / valves / instruments (e.g. Valving to install positive

Fluid

Rating 4,5) filter / other equipment with spare or control valves, PSVs with isolation (Note 3,6)

with bypass) spare or with bypass)

Class A

· Fluids handled above AIT or 315°C

· H2 rich gases (>30%)

· Acute toxicity Fluid cat 1, 2 & 3 (H330, H331 - inhalation) Any Positive Isolation Positive Isolation Double Block and Bleed Double Block and Bleed

· Self-reactive substances and mixtures (peroxides)

· STOT (Specific Target Organ Toxicant - single exposure

cat 1 H370)

Class B

ANSI <=300 Positive Isolation Positive Isolation Single Block and Bleed Single Block and Bleed

· Carcinogenic / Mutagenic 1A e 1B (H340/H350)

· Flammable gases cat 1 (H220)

· Flammable liquids cat 1 (H224) ANSI >=600 Positive Isolation Positive Isolation Double Block and Bleed Double Block and Bleed

Class C

· Flammable gases cat 2 (H221)

· Flammable liquids cat 2 & 3 (H225/H226)

· Oxydizing gases cat 1 (H270) ANSI <=600 Positive Isolation Positive Isolation Single Block and Bleed Single Block and Bleed

· Oxidizing Liquids cat 1, 2 & 3 (H271/H272)

· Steam

· Unstable explosives or explosive of Divisions 1.1, 1.2, 1.3,

1.4 and 1.5

· Acute toxicity fluids cat 1,2 & 3 (H300, H310, H301, H311 -

contact / ingestion)

· Skin corrosive cat 1 (H314)

· Acute toxicity fluids cat 4 (H302/H304/H312/H332) ANSI >=900 Positive Isolation Positive Isolation Double Block and Bleed Double Block and Bleed

· Skin irritant cat 2 (H315)

· Nitrogen (asphyxiants)

· Eye damage and irritation cat 1 & 2 (H318/319)

Class D (non-classified fluids)

ANSI <=300 Positive Isolation Single Block and Bleed Single Block and Bleed Single Block and Bleed

· Service Water

· Potable Water

· Firewater

ANSI 600 Positive Isolation Double Block and Bleed Double Block and Bleed Single Block and Bleed

· Injection Water

· Instrument air

· Plant air

ANSI >=900 Positive Isolation Double Block and Bleed Double Block and Bleed Double Block and Bleed

· Other not classified materials.

NOTES

1. The size of lines to be isolated and duration of work (e.g. longer than one shift) may necessitate a higher category of isolation.

2. The distance between block valves shall be minimized. Appropriately rated ball, plug or gate valves are considered effective as block valves for isolation. Butterfly valves may be used for isolation in

some circumstances provided they are appropriately specified for the service. Globe or needle valves shall only be relied upon to provide isolation of equipment for maintenance where these valves are

infrequently operated, e.g. level bridle vents/drains.

3. In case Positive Isolation cannot be achieved, a risk assessment shall be undertaken to confirm safe execution of maintenance activities by valved isolation or need of additional measures to be

implemented.

4. For RTJ flanges and lined vessels (requiring frequent nozzle inspection), spools shall be used instead of blinds.

5. Where the vessel forms part of a process train it is acceptable to provide positive isolation at the train boundary limits.

6. Battery limits configurations includes always positive isolation (see battery limit arrangement inside typical P&IDs n. BD0928-0000-50-004). Provide the required valving to install positive isolation on

the battery limit side valve.

7. Double bleeds valves must be installed for the services with ANSI pressure rating >= 900

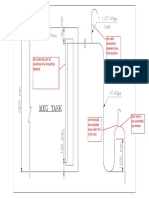

POSITIVE ISOLATION TYPICAL

Valves arrangements shown in figure 1, 2 and 3 needed to make possible the safe achievement of Positive Isolation defined in Table.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Rosemount Temperature Surface Sensors: Product Description ConsiderationsDocumento10 pagineRosemount Temperature Surface Sensors: Product Description ConsiderationshamedNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Dielectric Constants List enDocumento8 pagineDielectric Constants List engadgil_vikrantNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Applied Thermal EngineeringDocumento6 pagineApplied Thermal EngineeringSabeeh FaruquiNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Piping Specification BreaksDocumento6 paginePiping Specification BreaksvijeyimusNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Ansi b36.10 Pipe SizeDocumento9 pagineAnsi b36.10 Pipe SizeSpoonful BurnsideNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Magnetrol 961Documento8 pagineMagnetrol 961Andres LeonNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Ejector Modeling in HYSYSDocumento10 pagineEjector Modeling in HYSYSBruce Eng100% (3)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Chimney Trays PDFDocumento4 pagineChimney Trays PDFcvolkan1100% (4)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- CLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFDocumento1 paginaCLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFCan YıldırımNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- DM TankDocumento2 pagineDM TankCan YıldırımNessuna valutazione finora

- Purging Air From Piping and Vessels in Hydrocarbon ServiceDocumento7 paginePurging Air From Piping and Vessels in Hydrocarbon ServiceCan YıldırımNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Overflow Line PDFDocumento1 paginaOverflow Line PDFCan YıldırımNessuna valutazione finora

- E-Leak TestingDocumento3 pagineE-Leak TestingItziar MinondoNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- DM TankDocumento2 pagineDM TankCan YıldırımNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- L-17 (SS) (Iac) ( (Ee) Nptel)Documento9 pagineL-17 (SS) (Iac) ( (Ee) Nptel)Chandra ShekarNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Tank Overflow (Commented) PDFDocumento1 paginaTank Overflow (Commented) PDFCan YıldırımNessuna valutazione finora

- Protect Centrifugal Pumps From Low Flows PDFDocumento12 pagineProtect Centrifugal Pumps From Low Flows PDFicingrockNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Guidelines For Operation of Minimum Flow Control ValvesDocumento10 pagineGuidelines For Operation of Minimum Flow Control ValvesDawid DobrzańskiNessuna valutazione finora

- Air LeakageDocumento2 pagineAir LeakageanurudhNessuna valutazione finora

- Reactor Design Guide1Documento27 pagineReactor Design Guide1Chau MaiNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- SRV PopDocumento8 pagineSRV PopradenmuhaiminNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Air Cooled Condenser DesignDocumento5 pagineAir Cooled Condenser Designamin shiranNessuna valutazione finora

- Ansi b36.10 Pipe SizeDocumento9 pagineAnsi b36.10 Pipe SizeSpoonful BurnsideNessuna valutazione finora

- Kod SizingDocumento2 pagineKod SizingCan YıldırımNessuna valutazione finora

- Iterative Methods For Looped Network Pipeline Calculation: To Cite This VersionDocumento49 pagineIterative Methods For Looped Network Pipeline Calculation: To Cite This VersionCan YıldırımNessuna valutazione finora

- Material Safety Data Sheet: English - USA/OSHA HvgoDocumento9 pagineMaterial Safety Data Sheet: English - USA/OSHA Hvgocvolkan1Nessuna valutazione finora

- (Distillation) - Separation Tower Design (Daniel.R.Lewin)Documento22 pagine(Distillation) - Separation Tower Design (Daniel.R.Lewin)sankeduNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- AIChEOptimumDsn2004 For InfoDocumento38 pagineAIChEOptimumDsn2004 For InfoCan YıldırımNessuna valutazione finora

- Thermophysical Properties of Fluids. II. Methane, Ethane, Propane, Lsobutane and N-ButaneDocumento222 pagineThermophysical Properties of Fluids. II. Methane, Ethane, Propane, Lsobutane and N-ButaneCan YıldırımNessuna valutazione finora

- P Radiator Valves en PDFDocumento16 pagineP Radiator Valves en PDFpolitoNessuna valutazione finora

- Technical Service Bulletin: Commissioning Procedure For HydracapDocumento10 pagineTechnical Service Bulletin: Commissioning Procedure For HydracapValesh MonisNessuna valutazione finora

- Activity Number 2Documento9 pagineActivity Number 2Mariella SingsonNessuna valutazione finora

- TE - Mech - RAC - Chapter 5 - Thermodyn Propertis of Moist AirDocumento48 pagineTE - Mech - RAC - Chapter 5 - Thermodyn Propertis of Moist AirAkshay ChandoleNessuna valutazione finora

- General Chemistry Ii: A. Paint Thinner and OilDocumento3 pagineGeneral Chemistry Ii: A. Paint Thinner and OilCherry A. BallesterosNessuna valutazione finora

- Visual Ingredients Simple Facial WashDocumento1 paginaVisual Ingredients Simple Facial WashArgo MuríantoNessuna valutazione finora

- Mark Scheme (Results) Summer 2010: IGCSE Chemistry (4335) Paper 1FDocumento16 pagineMark Scheme (Results) Summer 2010: IGCSE Chemistry (4335) Paper 1FCoolman PoonNessuna valutazione finora

- FINAL LCCP Handbook v2.1 With Appendix - JAN 2015Documento67 pagineFINAL LCCP Handbook v2.1 With Appendix - JAN 2015Sean CrossNessuna valutazione finora

- tmp327F TMPDocumento228 paginetmp327F TMPFrontiersNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- TM-4143 Slide Metoda EOR (Week IX)Documento51 pagineTM-4143 Slide Metoda EOR (Week IX)AwabNessuna valutazione finora

- ASTM GradesDocumento4 pagineASTM GradesSaurabh MundheNessuna valutazione finora

- DiopenDocumento4 pagineDiopenademar john ZamoraNessuna valutazione finora

- Design of Micro Piles For Slope StabilizationDocumento70 pagineDesign of Micro Piles For Slope StabilizationedguortNessuna valutazione finora

- Wear of Coated and Uncoated Carbides in Turning Tool SteelDocumento6 pagineWear of Coated and Uncoated Carbides in Turning Tool Steelking9sunNessuna valutazione finora

- Voluntary Specification For Self Adhering Flashing Used For Installation of Exterior Wall Fenestration Products (AAMA711-05)Documento17 pagineVoluntary Specification For Self Adhering Flashing Used For Installation of Exterior Wall Fenestration Products (AAMA711-05)Mauricio Riquelme100% (2)

- SCES3083 Topic 5 FluidDocumento44 pagineSCES3083 Topic 5 Fluid胡佳玲Nessuna valutazione finora

- What Is A Performance CurveDocumento8 pagineWhat Is A Performance CurveRanjit PaulNessuna valutazione finora

- Free EnergyDocumento17 pagineFree EnergyDolih GozaliNessuna valutazione finora

- GED Chemistry Note1 (Atoms, Molecules and Their Properties)Documento6 pagineGED Chemistry Note1 (Atoms, Molecules and Their Properties)Shahadat Hussain Parvez100% (2)

- Promax - Property Packages Selection GuideDocumento2 paginePromax - Property Packages Selection GuidedumpmejunkmailsNessuna valutazione finora

- Physics11 WorkEnergy PDFDocumento143 paginePhysics11 WorkEnergy PDFKeith Ryan LapizarNessuna valutazione finora

- Francis Preston Venable-A Short History of ChemistryDocumento184 pagineFrancis Preston Venable-A Short History of Chemistrynareshraichura100% (1)

- Lecture 2 - Origin of Elements, ClassificationDocumento24 pagineLecture 2 - Origin of Elements, ClassificationMihatsu TakiNessuna valutazione finora

- Chem Is Try Lab 2019Documento8 pagineChem Is Try Lab 2019leah phoNessuna valutazione finora

- Glinka Problems in General Chemistry MirDocumento290 pagineGlinka Problems in General Chemistry MirMaurizio D'IppolitoNessuna valutazione finora

- GenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Documento22 pagineGenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Junelle Ramos Aquino100% (1)

- N-Containing Secondary CompoundsDocumento16 pagineN-Containing Secondary CompoundsNasiha el KarimaNessuna valutazione finora

- Proses Manufaktur - Fundamental of Metal FormingDocumento35 pagineProses Manufaktur - Fundamental of Metal FormingAnatolium IrgrandeNessuna valutazione finora

- SM1F03NSK SinopowerDocumento11 pagineSM1F03NSK SinopowerleandroNessuna valutazione finora

- SCDL ProjectDocumento139 pagineSCDL ProjectChetan Shitole67% (6)