Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pellets Friability

Caricato da

raju narayana padalaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pellets Friability

Caricato da

raju narayana padalaCopyright:

Formati disponibili

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/286902355

Evaluation of pellet friability

Article · January 2009

CITATIONS READS

2 2,041

3 authors, including:

Katerina Kubova Dvorackova

University of Veterinary and Pharmaceutical Sciences Brno

57 PUBLICATIONS 291 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Architecture of Correlated Disorder at the Interface of Porous Organic-Inorganic Hybrids: Interactions, Structures, and Dynamics at Atomic Resolution. View project

All content following this page was uploaded by Katerina Kubova Dvorackova on 11 January 2016.

The user has requested enhancement of the downloaded file.

Farmacie 1-09 17.2.2009 9:29 Str. 9

PŮVODNÍ PRÁCE

Evaluation of pellet friability

GRYCZOVÁ E., DVOŘÁČKOVÁ K., RABIŠKOVÁ M.

University of Veterinary and Pharmaceutical Brno, Faculty of Pharmacy, Department of Pharmaceutics

Sciences, Czech Republic

Received 4 November 2008 / Accepted 1 December 2008

SUMMARY

Evaluation of pellet friability

Pellet friability and hardness are important particle characteristics as they predict pellet behavior

during technological processes such as film coating, filling into hard gelatin capsules or

compressing into tablets. At present no methods for testing of these pellet properties are present in

pharmacopoeias and various methods adapted from tablet evaluation are used. A number of methods

and different equipment are used to determine pellet friability. These methods in addition differ also

in the testing conditions. Therefore pellets of different hardness and composition were chosen on

purpose for this experiment to show the influence of method variables on the friability of brittle and

hard pellets prepared by different techniques. Pellet friability was tested in the same equipment

under different conditions, but always with the equal amount of sample and equal total number of

revolutions. All the samples exhibited also similar residue moisture content. As different friability

values were obtained for the same sample under different testing conditions it is necessary to pay

attention to the method used and its parameters. This experiment indicates that pellet friability is

influenced not only by pellet composition but also by the technique of their manufacture.

Key words: pellets – hardness – friability – methods of evaluation – testing conditions

Čes. a slov. Farm., 2009; 58, 9–13

SOUHRN

Hodnocení oděru pelet

Pevnost a oděr jsou důležitými vlastnostmi pelet, protože umožňují předpovídat jejich chování

v průběhu technologických procesů, např. při filmovém obalování, plnění do tvrdých želatinových

tobolek nebo při lisování do tablet. V současné době lékopisy neuvádějí žádné metody k testování

uvedených vlastností u pelet a v praxi se používají metody odvozené z metod doporučených pro

hodnocení tablet. Ke stanovení oděru pelet slouží různé přístroje a aplikuje se řada metod, které se

navíc liší i podmínkami testů. Pro vyhodnocení vlivu rozdílných podmínek metody na hodnoty odě-

ru pelet se pro tento experiment vybraly pelety různé pevnosti a složení, připravené několika tech-

nologiemi. Oděr pelet se testoval vždy ve stejném zařízení za odlišných podmínek, zkoušené množ-

ství vzorků a celkový počet otáček však zůstávaly konstantní. Všechny vzorky měly také podobný

obsah vlhkosti. Vzhledem k tomu, že se hodnoty oděru u téhož vzorku často významně lišily, je bez-

podmínečně důležité u zvolené metody dodržovat vždy stejné podmínky k dosažení reprodukova-

telných a srovnatelných výsledků. Experiment naznačil, že oděr pelet je ovlivněn nejen jejich slo-

žením ale také způsobem výroby.

Klíčová slova: pelety – pevnost – oděr – metody hodnocení – podmínky testování

Čes. a slov. Farm., 2009; 58, 9–13 Má

Address for correspondence:

doc. PharmDr. Miloslava Rabišková, CSc.

Ústav technologie léků FaF VFU

Palackého 1–3, 612 42 Brno

e-mail: rabiskovam@vfu.cz

ČESKÁ A SLOVENSKÁ FARMACIE, 2009, 58, č. 1 9

Farmacie 1-09 17.2.2009 9:29 Str. 10

Introduction Another group of tests is based on the use of a Turbula

blender 13, 14) or horizontal shakers 15, 16). All these

Pellets are small spherical particles used for oral described methods work in closed systems. Thus the

application; their diameter for pharmaceutical purposes attrition remains in the apparatus and can get into a

lies usually in the range of 0.5–2.0 mm. As contact with the surface of pellets.

multiparticulates, i.e. higher number of particulate drug As friability testing apparatus should simulate the

units in one dose, they exhibit several advantages conditions the product will be exposed to in the

comparing to single unit dosage forms such as tablets. In production process later on, e.g. during coating or drying

pharmacotherapy, they offer the drug delivery processes in fluid bed devices an open system would be

independent on the stomach emptying, a reduction of more appropriate as the attrition is removed immediately

gastrointestinal tract irritation and minimizing of side from the tested system 17, 18).

effects. Flexibility in dosage form design, possible Friability is characterized as the weight loss of a

combination of several drugs in one dose, improved sample (%) 17), the mean pellet diameter reduction (%)

19, 20)

stability and easy coating due to pellet spherical shape or the difference in areas under the curve of pellet

belong among their advantages in technology. Therefore size distribution before and after the friability testing 21).

pellets are very often used for controlled drug release Limit value of pellet friability should correspond to

preparations, i.e. they undergo subsequent processes their intended use 21), for instance for pellets proposed for

such as coating, filling into hard gelatin capsules or subsequent coating value lower than 1.7% is

compressing into tablets. Thus their mechanical recommended 22).

properties especially pellet hardness and friability are In this experimental study pellet hardness and

very important parameters. In fluid bed film coating the friability were tested, and the influence of pellet

friability of pellet cores can significantly influence the composition, preparation process and variables of

coating quality. A high amount of attrition of the core friability test on pellet mechanical properties was

material during the coating procedure could modify drug observed.

release behavior due to the incorporation of small

particles into the film coating 1). For this and above

mentioned reasons mechanical pellet properties should EXPERIMENTAL

be evaluated using appropriate well defined methods.

Pellet hardness is usually measured using tablet

strength testers equipped with a cell for pellet evaluation. Materials

However it is significantly dependent on pellet diameter,

composition and manufacturing process 2). Hardness is In this experiment, pellets of different composition

characterized as a resistance against the crushing under prepared using various pelletization techniques were

defined conditions. It is measured in a tester consisting chosen (Table 1). Freely soluble diltiazem hydrochloride

of two clips the sample is inserted in. The clips are (DHCl, kindly donated by Zentiva, Czech Republic) or

moving against each other and the force when the sample sparingly soluble diclofenac sodium (DNa, Amoli

breaks is registered 3). Hardness is determined either in Organics, Mumbai, India) were used as model drugs.

Newtons or kilograms: 1N = 9.81 kg. Microcrystalline cellulose (MCC, Avicel® PH 101,

To compare the hardness of tablets differing in shape Mingtai Chemical Co., Ltd., Taiwan), lactose

there exist formulas describing their diameter and monohydrate (Cerapharm, Vienna, Austria) and

thickness 4). Similar formula can be used also for pellets: povidone (PVP, Kollidon® 25, BASF, Germany) were

excipients, and Celphere® (Asahi Kasei Kogyo, Japan)

were used as inactive cores. All substances were of

δf(s) = 0.4 × 2F pharmaceutical grade (Ph.Bs. 2005; Ph. Eur. IV); other

π×r materials used for pellet evaluation were of analytical

purity.

δf(s) is the tensile strength, F is the crushing force, r is

the pellet diameter. The unit of δf(s) is Pascal5, 6. Pellet preparation

Pellet friability can be determined by a number of

different methods using various equipments. Widely Pellets were prepared either by a layering technique or

used are rotating drums like friability testing apparatus by an agglomeration in a Rotoprocessor (Multiprocessor

for tablets, e.g. Erweka 7, 8) or Roche 9–12) Friabilator. Due MP 1, Aeromatic Fielder, Switzerland). For layering,

to the electrostatic charge and low weight of pellets MCC inactive cores Celphere® (CP 305) or lactose/MCC

providing insufficient mechanical stress during these cores prepared in our laboratory were used as starters.

tests, their stainless steel variation and the addition of Lactose/MCC cores were prepared as follows: 350 g of

glass or steel balls are used. However the friability MCC and 650 g of lactose were mixed for 5 min in a

conditions among these methods differ significantly, for Stephan mixer (UMC 5, Germany). One kilogram of

instance the number of balls from 10 11) to 200 7, 12), their powder blend was loaded into the inner bowl of the

material, i.e. glass 7, 9–12) or steel 8), the amount of pellets Rotoprocessor and water was sprayed into the container

5 g 9, 11) or 10 g 7, 8, 10, 12), testing time from 3 8) to 10 7, 10, 12) at the optimal, experimentally determined rate 23). Once

minutes, and rotating speed of 10 8), 25 12) or 36 9) rpm. all the water was sprayed, spheronization was performed

10 ČESKÁ A SLOVENSKÁ FARMACIE, 2009, 58, č. 1

Farmacie 1-09 17.2.2009 9:29 Str. 11

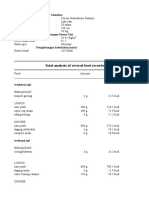

Table 1. Composition of the samples, pellet preparation and size

Sample Composition (%) Technology used for preparation Pellet size(mm)

DHCla) DNab) MCCc) LMd) PVPe)

1 48.5 – 48.5 – 3.0 layering of DHCl on MCC cores 0.5–0.8

2 55.0 – 35.0 10.0 – rotoagglomeration 0.8–1.0

3 48.5 – 17.0 31.6 2.9 layering of DHCl on LM/ MCC cores 0.8–1.0

4 – – 100.0 – – Celphere® 0.5–0.71

5 – 10.0 35.0 55.0 – rotoagglomeration 0.8–1.0

6 – – 35.0 65.0 – rotoagglomeration 0.8–1.0

a)

diltiazem hydrochloride, b) diclofenac sodium, c) microcrystalline cellulose, d) lactose monohydrate, e) povidone

Table 2. Variables in friability measurements

Number of glass balls Rotation time Rotation speed Total number Definition

(min) (rpm) of rotations of friability (mm)

200 10 20

100 10 20

10 10 20 200 < 0.25

100 5.5 36

10 5.5 36

for 2 min. After completion of the pellet formation, the Ltd., Balzers, Liechtenstein) and observed under the

pellets were dried at 50 °C by lifting the inner wall of microscope operating at 5.0 kV.

Rotoprocessor. Required pellet size fractions, i.e. 0.5–0.8 The hardness of used starters and prepared pellets was

mm and 0.8–1.0 mm, were separated on sieves of tested on the C 50 Tablet Hardness Tester (Engineering

appropriate apertures. To prepare the active pellets of Systems, England) equipped with a C5 cell for pellet

samples 1 and 3, concentrated solution (i.e. 50% w/w) of evaluation. The hardness of ten randomly selected

DHCl in purified water with PVP was sprayed onto the particles of each sample was evaluated.

smaller starters surface in a fluid bed unit equipped with For friability testing, 10 g of dust free particles (pellets

a Wurster column (Multiprocessor MP 1, Aeromatic or starters) were precisely weighed, put into the

Fielder, Switzerland) until the theoretical drug amount friabilator Roche (type TAR 10, Erweka, Germany) with

reached 50% of the pellet weight. Pellets were dried in stainless steel drum along with 200, 100 or 10 pieces of

the same equipment and stored in plastic bags at room 4 mm glass beads, respectively, and rotated for 10 or 5.5

temperature for further evaluation. The other pellet minutes at 20 or 36 rpm. The experimental conditions are

samples, i.e. samples 2 and 5 were prepared in a described in Table 2. Particles smaller than 0.25 mm

Rotoprocessor by wetting and spheronizing the were regarded as the attrition. The friability was

homogenized powder mixture (Table 1) as described expressed as a percentage of the weight loss after

above. Purified water was used as the wetting agent. agitation. The measurement was repeated three times.

Celphere® (CP 507) produced commercially were used

as sample 4 for mechanical pellet properties comparison.

Pellet properties evaluation RESULTS AND DISCUSSION

Particle size and size distribution of both, starters and

prepared pellets, were determined by a sieve analysis for Pellets of different composition, size and hardness

each sample. The set of stainless steel sieves with (Table 1) were chosen on purpose for this experiment to

apertures in the range of 0.5–1.0 mm and a sieve shaker show the influence of method variables on the friability

(type AS 200, Retsch, Germany) were used. Particles of brittle and hard pellets prepared by different

smaller than 0.5 mm were considered as a dust and techniques. Pellet friability was tested in the same

particles bigger than 1.0 mm (for sample 1 bigger than equipment (Roche Friabilator) under different conditions

0.8 mm) as agglomerates and were excluded from the (Table 2), but always with the equal amount of sample

total yield. Selected pellet fractions were used for further (10 g) and equal total number of revolutions (200). All

evaluation. the samples exhibited similar residue moisture content

The particle shape and internal structure were (1.41–2.59%). Table 3 indicates hardness and friability

examined using a JEOL JSM-6700F scanning electron of pellet samples.

microscope (JEOL Ltd., Japan). Samples were mounted It is obvious that with increasing pellet hardness

on a cylindrical stub using a double-sided sticky tape. friability values of samples decrease despite of the

The samples were coated with an approx. 70 nm thick friability test conditions (Table 3). When tensile strengths

gold layer in a SCD 030 sputter coater (Balzers Union of samples are compared the lowest values, i.e. 0.26 MPa

ČESKÁ A SLOVENSKÁ FARMACIE, 2009, 58, č. 1 11

Farmacie 1-09 17.2.2009 9:29 Str. 12

Table 3. Hardness and friabilities of prepared pellets

Sample Pellet Calculated Friability (%)

hardness tensile strength

(N) (MPa) 200/10/20* 100/10/20 10/10/20 100/5.5/36 10/5.5/36

1 0.87 ± 0.33 0.26 3.16 ± 0.30 1.56 ± 0.19 0.50 ± 0.15 1.85 ± 0.11 0.71 ± 0.15

2 1.67 ± 0.59 0.26 2.62 ± 0.04 1.49 ± 0.06 0.35 ± 0.02 1.64 ± 0.03 0.47 ± 0.02

3 2.84 ± 0.36 0.45 1.91 ± 0.08 0.82 ± 0.07 0.29 ± 0.01 1.04 ± 0.07 0.29 ± 0.02

4 3.41 ± 1.08 1.19 0.38 ± 0.07 0.24 ± 0.08 0.19 ± 0.07 0.26 ± 0.04 0.24 ± 0.07

5 3.61 ± 0.69 0.57 0.26 ± 0.06 0.22 ± 0.06 0.14 ± 0.04 0.24 ± 0.05 0.19 ± 0.03

6 4.89 ± 0.54 0.77 0.18 ± 0.01 0.09 ± 0.04 0.07 ± 0.03 0.17 ± 0.03 0.13 ± 0.05

*

number of glass beads/rotation time (min)/rotation speed (rpm)

were noticed for pellet samples 1 and 2 with low hardness Figure 1 and Figure 2). Furthermore when the inactive

values. Equal tensile strength to break pellets is probably cores are compared, better mechanical properties were

given by the predominant properties of DHCl either in obtained for active pellets with LM/MCC cores than

pellets (sample 2: 55%) or in the active layer (sample pellets started with only MCC cores (pellet hardness of

1 : 88%). The highest tensile strength (1.19 MPa) was 2.84 vs. 0.87 N, calculated tensile strength of 0.45 MPa

calculated for MCC starters Celphere® that are generally vs. 0.26 MPa, and friabilities 0.29–1.91% vs.

considered as very hard. Other tensile strength values 0.50–3.16%). This can be explained by different cores

corresponded to the increasing pellet hardness and solubility and wettability. While MCC cores are insoluble

decreasing pellet friability. Pellets prepared using the in water, which was used as wetting agent for the

drug layering technique generally showed higher layering, LM/ MCC cores were partly soluble due to high

sensitivity to friability conditions than pellets produced lactose content (65%). For successful drug solution

by a rotoagglomeration (samples 1 and 3, Table 3, layering process it is necessary to wet properly the solid

surface of the starter. Only under these conditions,

droplets of the drug solution could spread all over the

solid surface and create a continuous drug layer. As LM/

MCC cores are partly soluble in water, one might

presume their surface is better wetted by the drug solution

making the layering process more effective and the drug

layer adhering more tightly to the core surface. The

consequence indicates higher pellet hardness and lower

pellet friability. This theory was supported by SEM

images of layered pellets (Figure 3) and also photos of

pellets after the friability test (Figure 2). The left part of

Figure 3 (sample 1) shows clearly defined drug layer on

MCC starter surface while on the right side of this picture

(sample 3) drug layer and starter surface are not well

distinguishable. On Figure 2a, the core surface without

Fig. 1. Sensitivity of different pellet samples to variable active layer is clearly visible (sample 1) indicating thus

conditions of friability tests that drug layer is not binding tightly to the starter’s core.

a b c

Fig. 2. Sample 1 (a), sample 3 (b) and sample 6 (c) after friability test under condition 200/10/20 (magnification 25×)

12 ČESKÁ A SLOVENSKÁ FARMACIE, 2009, 58, č. 1

Farmacie 1-09 17.2.2009 9:29 Str. 13

A B

Fig. 3. The cross-section of the layered pellet (left) containing the MCC and LM/ MCC (right) as observed under the scanning

electron microscope (magnification 500×)

3. Chalabala, M. et al.: Technologie léků. Praha: Galén

This feature is less obvious on Figure 2b (sample 3)

1997, 408 s.

signalizing better active layer to core sticking. On the 4. Davies, P.: Oral solid dosage forms. In: Gibson, M.:

other hand the surface of a sample prepared by Pharmaceutical preformulation and formulation.

rotoagglomeration (Figure 2c) remains almost untouched Englewood: IHS® Health Group 2001; 379–458.

after agitation under comparable conditions showing thus 5. Santos, H. et al.: Eur. J. Pharm. Sci., 2004; 21, 271–281.

high resistence against a friction. 6. Santos, H. et al.: Int. J. Pharm., 2005; 295(1–2), 15–27.

Pellets obtained by an agglomeration process in a 7. Baert, L., Fanara, D., Remon, J. P., Massart, D.:

J. Pharm. Pharmacol., 1992; 44, 676–678.

Rotoprocessor containing lower drug amount (sample 5) 8. Wan, L. S. C., Jeyalaban, T.: Chem. Pharm. Bull., 1985;

or drug free pellets (sample 6) showed the highest 33, 5449.

hardness values (3.61 N and 4.89 N) and the lowest 9. Eerikainen, S.: Int. J. Pharm. 1991; 77, 89–106.

friability (0.14–0.26% and 0.07–0.18%, respectively). 10. Bainchini, R., Bruni, G., Gazzaniga, A., Vecchio, C.:

These values were comparable to those obtained for Drug Dev. Ind. Pharm., 1992; 18, 1485–1503.

sample 4, i.e. commercially produced starters Celphere® 11. Hellen, L., Yliruusi, J., Merkku, P., Kristoffersson,

E.: Int. J. Pharm., 1993; 96, 197–204.

considered as mechanically highly resistant.

12. Mesiha, M. S., Valles, J.: Drug Dev. Ind. Pharm., 1993;

Since limit values for pellet friability were published in 19, 943–959.

the literature, i.e. less than 1.7% 22), it is necessary to pay 13. De Doeuff, E., Vanhoeve, M., Gayor, A. T., Becourt,

attention to the method used and its parameters. As shown P.: Proc. Int. Conf. Pharm. Tech. (APGI), 1992; 6, 207.

in our experiment, different friability values of one sample 14. Bataille, B., Rahman, L., Jakob, M.: Pharm. Acta.

can be obtained indicating either satisfactory or Helv., 1991; 66, 233–236.

unsatisfactory friability values. Especially brittle pellets are 15. Körber, U., Moest, T.: Acta Pharm. Technol., 1990; 36,

33.

very sensitive to the variables of friability method used.

16. Lindner, H., Kleinebudde, P.: J. Pharm. Pharmacol.,

1994; 46, 2–7.

This experimental work has been supported by IGA VFU 17. Schulz, P., Kleinebudde, P.: Pharm. Ind., 1995; 57 (4),

Project No 136/2008/FaF and the pharmaceutical company 323–328.

Zentiva a.s. Praha, Czech Republic. 18. Thoma, K., Gröning, R., Zimmer, T.: Acta Pharm.

Technol., 1986; 32, 137.

19. Heng, P.W.S., Koo, O.M.Y. : Pharm. Research, 2001; 18,

480–487.

REFERENCES 20. Noché, C. et al.: Pharm. Tech. Eur., 1994; 6, 39–46.

21. Airaksinen, S. et al.: Pharm. Ind., 2000; 62, 999–1002.

22. Vertommen J., Kinget R.: Drug Dev. Ind. Pharm., 1997;

23, 39–46.

1. Ghebre-Selassie, I.: In: Ghebre-Selassie (ed.): 23. Vetchý, D., Rabišková, M.: Int. J. Pharm., 2002; 242,

Pharmaceutical Pelletization Technology. New York: 353–356.

Marcel Dekker Inc. 1989; 261–265.

2. Podzceck, F., Almeida, S. M.: Eur. J. Pharm. Sci., 2002;

16, 209–214.

ČESKÁ A SLOVENSKÁ FARMACIE, 2009, 58, č. 1 13

View publication stats

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Dispensing Pharmacy MCQSDocumento25 pagineDispensing Pharmacy MCQSraju narayana padala100% (1)

- Process Validation of Liquid Orals: 1 Sarika KadamDocumento19 pagineProcess Validation of Liquid Orals: 1 Sarika Kadamraju narayana padalaNessuna valutazione finora

- 8 Ba Be FdaDocumento36 pagine8 Ba Be Fdaraju narayana padalaNessuna valutazione finora

- Scaleup of Oral Extended-Release Dosage Forms: Pharmaceutical Research December 1993Documento7 pagineScaleup of Oral Extended-Release Dosage Forms: Pharmaceutical Research December 1993raju narayana padalaNessuna valutazione finora

- Pilot Plant Review1Documento10 paginePilot Plant Review1raju narayana padalaNessuna valutazione finora

- Fishspoilage 2015Documento26 pagineFishspoilage 2015raju narayana padalaNessuna valutazione finora

- Acyclovir Uv MethodDocumento5 pagineAcyclovir Uv Methodraju narayana padalaNessuna valutazione finora

- Hydro Gel Classification Properties Preparation and Technical FeaturesDocumento9 pagineHydro Gel Classification Properties Preparation and Technical Featuresraju narayana padalaNessuna valutazione finora

- Formulation Development and Evaluation of Sustained Release Tablets of AceclofenacDocumento128 pagineFormulation Development and Evaluation of Sustained Release Tablets of Aceclofenacraju narayana padala0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 756S PDFDocumento248 pagine756S PDFShahzad FidaNessuna valutazione finora

- Case Diagnosis For RomanDocumento4 pagineCase Diagnosis For RomanChris Marie JuntillaNessuna valutazione finora

- Fermentation Media: Agustin Krisna WardaniDocumento27 pagineFermentation Media: Agustin Krisna WardaniYosiaNessuna valutazione finora

- Afico Pipe InsulaionDocumento4 pagineAfico Pipe InsulaionProcurement AlamcoNessuna valutazione finora

- Plumber (General) - II R1 07jan2016 PDFDocumento18 paginePlumber (General) - II R1 07jan2016 PDFykchandanNessuna valutazione finora

- Case Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenDocumento7 pagineCase Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenTrishani NahaNessuna valutazione finora

- GCU 0103 Computer PlatformsDocumento5 pagineGCU 0103 Computer PlatformsArani NavaratnarajahNessuna valutazione finora

- Peseshet - The First Female Physician - (International Journal of Gynecology & Obstetrics, Vol. 32, Issue 3) (1990)Documento1 paginaPeseshet - The First Female Physician - (International Journal of Gynecology & Obstetrics, Vol. 32, Issue 3) (1990)Kelly DIOGONessuna valutazione finora

- LIST OF REGISTERED DRUGS As of December 2012: DR No Generic Brand Strength Form CompanyDocumento2 pagineLIST OF REGISTERED DRUGS As of December 2012: DR No Generic Brand Strength Form CompanyBenjamin TantiansuNessuna valutazione finora

- Chapter 23Documento9 pagineChapter 23Trixie Myr AndoyNessuna valutazione finora

- Application of Knowledge QuestionsDocumento16 pagineApplication of Knowledge QuestionsElllie TattersNessuna valutazione finora

- Writing The Motherland From The DiasporaDocumento23 pagineWriting The Motherland From The DiasporaIfeoluwa Watson100% (1)

- 8582d Soldering Station English User GuideDocumento9 pagine8582d Soldering Station English User Guide1valdasNessuna valutazione finora

- Diabetes Mellitus Nursing Care PlanDocumento7 pagineDiabetes Mellitus Nursing Care PlanjamieboyRN91% (32)

- Tugas Gizi Caesar Nurhadiono RDocumento2 pagineTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoNessuna valutazione finora

- Ciac - HW Brochure Seer 16Documento2 pagineCiac - HW Brochure Seer 16Tatiana DiazNessuna valutazione finora

- Sim Medium 2 (English)Documento2 pagineSim Medium 2 (English)TheLobitoNessuna valutazione finora

- Wax Depilation ManualDocumento17 pagineWax Depilation ManualAmit Sharma100% (1)

- Io (Jupiter Moon)Documento2 pagineIo (Jupiter Moon)FatimaNessuna valutazione finora

- CV Ilham AP 2022 CniDocumento1 paginaCV Ilham AP 2022 CniAzuan SyahrilNessuna valutazione finora

- Aircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management EngineerDocumento46 pagineAircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management Engineerchouchou chamaNessuna valutazione finora

- Linkage 2 Lab ReportDocumento25 pagineLinkage 2 Lab Reportapi-25176084883% (6)

- School: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabDocumento3 pagineSchool: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabNanette Morado0% (1)

- Voca-Book (This Must Be The Place)Documento13 pagineVoca-Book (This Must Be The Place)Анастасия ВознесенскаяNessuna valutazione finora

- Retropharyngeal Abscess (RPA)Documento15 pagineRetropharyngeal Abscess (RPA)Amri AshshiddieqNessuna valutazione finora

- Final Plant Diversity Lab ReportDocumento6 pagineFinal Plant Diversity Lab Reportapi-508660724Nessuna valutazione finora

- Nepal Health Research CouncilDocumento15 pagineNepal Health Research Councilnabin hamalNessuna valutazione finora

- PACKET 1 - Exercises and ActivitiesDocumento7 paginePACKET 1 - Exercises and ActivitiesPrantsir Pernes100% (2)

- Diagnostic Test 12Documento3 pagineDiagnostic Test 12Honorato BugayongNessuna valutazione finora

- Learners ' Health and Safety Practices and Their Academic PerformanceDocumento10 pagineLearners ' Health and Safety Practices and Their Academic PerformanceHira SaddozaiNessuna valutazione finora