Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Polymer Characterization Technical Poster PDF

Caricato da

MariaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Polymer Characterization Technical Poster PDF

Caricato da

MariaCopyright:

Formati disponibili

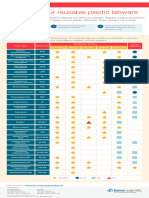

Polymer Characterization

LDPE Polyethylene low density HDPE Polyethylene high density ABS Acrylonitrile-butadiene-styrene SAN Styrene-acrylonitrile copolymer EVA Polyethylene co-vinyl acetate PVA Polyvinyl acetate PerkinElmer Solutions for Polymer Characterization

Tg(ºC): -130 to 100 Cp (J/g*K): 1,8 to 3,4 Tg(ºC): -130 to 100 Cp (J/g*K): 1,8 to 3,4 Tg(ºC): 110 to 125 CpJ/(g*K): 1,25 to 1,7 Tg(ºC): 95 to 110 CpJ/(g*K): 1,2 Tg(ºC): -45 to 20 CpJ/(g*K): 2,3 Tg(ºC): 25 to 35 CpJ/(g*K): -

Tm(ºC): 100 to 120 DHf (J/g): - Tm(ºC): 130 to 140 DHf (J/g): 293 Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): 30 to 100 DHf (J/g): 10 to 100 Tm(ºC): - DHf (J/g): -

Td(ºC): 490 to 500 Td(ºC): 490 to 500 Td(ºC): 420 Td(ºC): 420 Td(ºC): 480 Td(ºC): -

PP Polypropylene PS Polystyrene PMMA Polymethylmethacrylate PBMA Polybuthylmethacrylate CA Cellulose acetate EP Epoxy resin Molecular Spectroscopy FTIR Differential Scanning Calorimetry

Tg(ºC): -20 to -5 CpJ/(g*K): 1,8 Tg(ºC): 90 to 110 Cp (J/g*K): 1,8 to 3,4 Tg(ºC): 85 to 100 CpJ/(g*K): 1,45 to 1,5 Tg(ºC): 15 to 25 CpJ/(g*K): - Tg(ºC): 45 to 60 CpJ/(g*K): - Tg(ºC): 50 to 200 CpJ/(g*K): 1,6 to 2,1 Identify and quantitate organic molecules and compounds, Glass transition & melting temperatures, crystallinity, heat of

Understand chemical & physical composition of laminates & fusion, reaction rates, specific heat & heat capacity, curing,

Tm(ºC): 165 to 175 DHf (J/g): 207 Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - adhesives , Troubleshoot chemical origin of occlusions Identify safety & stability studies

Td(ºC): 450 Td(ºC): 445 Td(ºC): 360 to 390 Td(ºC): - Td(ºC): - Td(ºC): 400 to 450 orientation of molecules

Mechanical Analysis

Modulus, stiffness, damping, crystalline, alpha and beta

transitions, glass transition & melting temperatures

PET Polyethylene terephthalate PBT Polybutylene terephthalate PTFE Polytetrafluoroethylene POM Polyoxymethylene UP Polyester resin PF Phenol formaldehyde resin

Tg(ºC): 70 to 80 CpJ/(g*K): 1,05 to 1,2 Tg(ºC): 45 to 65 Cp (J/g*K): 1,3 Tg(ºC): 120 to 130 CpJ/(g*K): 1 Tg(ºC): -75 to -60 CpJ/(g*K): 1,5 Tg(ºC): 60 to 170 CpJ/(g*K): 1,2 to 2,3 Tg(ºC): 70 to 210 CpJ/(g*K): 1,2

Tm(ºC): 245 to 265 DHf (J/g): 140 Tm(ºC): 220 to 230 DHf (J/g): 142 Tm(ºC): 320 to 330 DHf (J/g): 82 Tm(ºC): 140 to 175 DHf (J/g): 190 Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): -

Td(ºC): 425 to 440 Td(ºC): 410 Td(ºC): 580 Td(ºC): 400 Td(ºC): 340 to 480 Td(ºC): 450 to 480

Hyphenated Techniques Thermogravimetry

Identify and quantitate evolved gases in resins and compounds Wt % Additive & bi-product losses, Wt % Fillers & Ash,

Decarboxylation, Pyrolization, Decomposition and Stability

studies

Polymer Properties and Classification

PVC Polyvinylchloride PVC-P Polyvinylchloride plasticizer PEEK Polyether ether ketone PES Polyethersulfone PUR Polyurethane PDMS Polydimethylsiloxane THERMOPLASTIC

Tg(ºC): 65 to 85 CpJ/(g*K): 0,8 to 1,2 Tg(ºC): -50 to 80 CpJ/(g*K): 0,8 to 0,9 Tg(ºC): 145 to 155 CpJ/(g*K): - Tg(ºC): 220 to 230 CpJ/(g*K): 1,3 to 1,40 Tg(ºC): 10 to 180 CpJ/(g*K): 1,7 to 2,1 Tg(ºC): -130 to -120 CpJ/(g*K): 1,3 to 1,5 A polymer that becomes moldable above a specific temperature and solidifies upon

Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): 335 to 345 DHf (J/g): 130 Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): -50 to -40 DHf (J/g): 35 cooling, in a reversible process.

Td(ºC): 290 to 460 Td(ºC): 290 to 460 Td(ºC): 600 Td(ºC): 580 to 590 Td(ºC): 240 to 350 Td(ºC): 530

Are made of polymers linked by intermolecular interactions or van der Waals forces,

forming long linear or branched structures.

The polymer can take two different types of structures, amorphous (characterized by the

glass transition) or crystalline structures (characterized by the melting point) , being

possible the existence of both structures in the same thermoplastic material

THERMOSETTING

A polymer that irreversibly becomes rigid when heated in a irreversible process.

PVF Polyvinylfluoride PCL Polycaprolactone PSU Polysulfone PPS Polyphenylene sulfide BR Butadiene Rubber SBR Styrene-butadiene rubber Are made by polymers joined together by chemical bonds, acquiring a highly crosslinked

polymer structure responsible for the high mechanical and physical strength, on the other

Tg(ºC): 30 to 45 CpJ/(g*K): 1 to 1,8 Tg(ºC): -60 CpJ/(g*K): - Tg(ºC): 185 to 195 CpJ/(g*K): 1,35 Tg(ºC): 80 to 90 CpJ/(g*K): Tg(ºC): -95 to -85 CpJ/(g*K): 1,7 to 2,0 Tg(ºC): -55 to -35 CpJ/(g*K): 1,85 to 2,0 hand is this highly crosslinked structure which provides a poor elasticity.

Tm(ºC): 190 to 200 DHf (J/g): 164 Tm(ºC): 60 DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): 275 to 290 DHf (J/g): 80 Tm(ºC): 110 to 130 DHf (J/g): - Tm(ºC): -20 DHf (J/g): 170

Td(ºC): 430 to 445 Td(ºC): - Td(ºC): 530 Td(ºC): 510 to 550 Td(ºC): 350 to 370 Td(ºC): 435 to 455 Thermosets are completely amorphous and have no melting properties, and their

properties are governed by its glass transition temperature.

ELASTOMER

A polymer with viscoelasticity and very weak inter-molecular forces, generally having low

Young's modulus and high failure strain compared with other materials

Depending on the distribution and degree of the chemical bonds of the polymers,

elastomeric materials can have properties or characteristics similar to thermosets or

thermoplastic

PA6 Polyamide 6 PA66 Polyamide 66 EVOH Ethylene vinyl alcohol PVOH Polyvinylalcohol NBR Acrylonitrile-butadiene rubber CR Chloroprene rubber Elastomers are amorphous polymers with properties governed by its glass transition

temperature that are below 0ºC.

Tg(ºC): 40 to 60 CpJ/(g*K): 1,6 to 1,7 Tg(ºC): 50 to 60 CpJ/(g*K): 1,9 Tg(ºC): 50 to 70 CpJ/(g*K): - Tg(ºC): 80 to 90 CpJ/(g*K): 1,55 Tg(ºC): -40 to 5 CpJ/(g*K): 1,95 Tg(ºC): -50 to -30 CpJ/(g*K): -

Tm(ºC): 210 to 220 DHf (J/g): 190 Tm(ºC): 240 to 265 DHf (J/g): 185 Tm(ºC): 150 to 190 DHf (J/g): - Tm(ºC): 220 to 260 DHf (J/g): 156 Tm(ºC): - DHf (J/g): 485 Tm(ºC): 40 to 70 DHf (J/g): 1 to 10 -

Td(ºC): 435 Td(ºC): 450 Td(ºC): - Td(ºC): 260 to 320 Td(ºC): 450 Td(ºC): 380 to 460 Tg is the range of temperatures over glass transition occurs.

Tg Glass transition is the reversible transition in amorphous region of a material from a hard and

relatively brittle "glassy" state into a molten or rubber-like state.

Tm is the range of temperatures over melting occurs.

Tm Melting is the physical process that results in the phase transition of a substance from a solid to a

liquid.

Td is the range of temperatures over decomposition occurs.

Td Thermal decomposition is a process of extensive chemical species change caused by heat.

PA12 Polyamide 12 PA610 Polyamide 6/10 PC Polycarbonate PAM Polyacrylamide NR Natural rubber EPDM Ethylene-propylene-diene rubber DHf DHf is the is the change of enthalpy resulting from providing energy, typically heat, to a specific

quantity of the substance to change its state from a solid to a liquid at constant pressure

Tg(ºC): 40 to 50 CpJ/(g*K): 1,1 to 1,25 Tg(ºC): 40 to 70 CpJ/(g*K): 1,6 Tg(ºC): 140 to 150 CpJ/(g*K): 1,2 to 1,5 Tg(ºC): 160 to 170 CpJ/(g*K): - Tg(ºC): 95 to 110 CpJ/(g*K): 1,2 Tg(ºC): 95 to 110 CpJ/(g*K): 1,2

Cp is a measurable physical quantity equal to the ratio of the heat added to (or removed from) an

Tm(ºC): 170 to 180 DHf (J/g): 95 Tm(ºC): 210 to 230 DHf (J/g): 117 to 127 Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Tm(ºC): - DHf (J/g): - Cp object to the resulting temperature change.

Td(ºC): 465 Td(ºC): 450 to 465 Td(ºC): 480 Td(ºC): - Td(ºC): 420 Td(ºC): 420

PerkinElmer, Inc., 940 Winter Street, Waltham, MA USA (800) 762-4000 or (+1) 203 925-4602 www.perkinelmer.com

Potrebbero piacerti anche

- Thermal Properties and Applications of Common PolymersDocumento1 paginaThermal Properties and Applications of Common PolymersJatin DarveNessuna valutazione finora

- Technical Spec Sheet for 107679 POLYBATCH ABVT 22 SCDocumento1 paginaTechnical Spec Sheet for 107679 POLYBATCH ABVT 22 SCShahid AslamNessuna valutazione finora

- C'POL-331 chemical resistant resin dataDocumento2 pagineC'POL-331 chemical resistant resin dataSAURABH MODINessuna valutazione finora

- Epofine 404 - Finehard 2404Documento3 pagineEpofine 404 - Finehard 2404Karishma PrabhuNessuna valutazione finora

- Ultra-stable all-solid-state sodium metal batteries enabled by perfluoropolyether-based electrolytesDocumento39 pagineUltra-stable all-solid-state sodium metal batteries enabled by perfluoropolyether-based electrolytesG WynnNessuna valutazione finora

- Compatibility Tables for Common O-Ring MaterialsDocumento53 pagineCompatibility Tables for Common O-Ring MaterialsAhmed DhanaNessuna valutazione finora

- Polyesters: Corporate Training and PlanningDocumento46 paginePolyesters: Corporate Training and Planningharsh salunkheNessuna valutazione finora

- Paratherm MR BulletinDocumento1 paginaParatherm MR Bulletinkman548Nessuna valutazione finora

- Hydrocarbon Detector TubeDocumento2 pagineHydrocarbon Detector TubeGreenXheaVNessuna valutazione finora

- 4662022Documento40 pagine4662022sterlingNessuna valutazione finora

- Chemical Compatibility Guide: First Choice When Quality CountsDocumento28 pagineChemical Compatibility Guide: First Choice When Quality CountsYavuz SolmazNessuna valutazione finora

- Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, CalicutDocumento38 pagineEvaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicutjohn paul.jaisonNessuna valutazione finora

- FUELSDocumento2 pagineFUELSMaria SarwatNessuna valutazione finora

- CORROSION RESISTANCE Durco 2 PDFDocumento8 pagineCORROSION RESISTANCE Durco 2 PDFJUAN ANTONIO HERNANDEZ SOSANessuna valutazione finora

- Blends of Poly (Ethylene Terephthalate) and Poly (Butylene Terephthalate)Documento9 pagineBlends of Poly (Ethylene Terephthalate) and Poly (Butylene Terephthalate)NÄndo PelÄezNessuna valutazione finora

- How To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesDocumento11 pagineHow To Choose Permanent Magnet Materials: 5. Grade and Magnetic PropertiesdNessuna valutazione finora

- Antti Vuori ANPSG2001Documento29 pagineAntti Vuori ANPSG2001Eduardo MagallonNessuna valutazione finora

- THERMAL PROPERTIES OF POLYMER (Update)Documento38 pagineTHERMAL PROPERTIES OF POLYMER (Update)Vĩ Lê QuangNessuna valutazione finora

- Key Products : The Steak !!!Documento88 pagineKey Products : The Steak !!!stevenNessuna valutazione finora

- Jeffamine T 403 Us 2 08Documento2 pagineJeffamine T 403 Us 2 08shirshendu gopeNessuna valutazione finora

- Therminol® 55 Heat Transfer Fluid - TDS - Eastman Chemical CompanyDocumento3 pagineTherminol® 55 Heat Transfer Fluid - TDS - Eastman Chemical CompanyDhvanit JoshiNessuna valutazione finora

- Bab 7 5 Characterization 02 ThermoanalisisDocumento39 pagineBab 7 5 Characterization 02 ThermoanalisisPutrik AgustinaNessuna valutazione finora

- Synthesis and Solubilities of 3 9 Dipyrolidino 2 4 8 10 Tetraoxa 3 9 Diphosphaspiro 5 5 Undecane 3 9 Dioxide in Selected SolventsDocumento7 pagineSynthesis and Solubilities of 3 9 Dipyrolidino 2 4 8 10 Tetraoxa 3 9 Diphosphaspiro 5 5 Undecane 3 9 Dioxide in Selected SolventsoksanaNessuna valutazione finora

- ChemGuide 8677 PDocumento32 pagineChemGuide 8677 PPiok Piere TenengNessuna valutazione finora

- Thermal Analysis TechniquesDocumento34 pagineThermal Analysis TechniquesMujahid AmeenNessuna valutazione finora

- Solid State Polymerization Its Action On Thermal and Rheological Properties of PETPC Reactive BlendsDocumento7 pagineSolid State Polymerization Its Action On Thermal and Rheological Properties of PETPC Reactive Blends何恭彥Nessuna valutazione finora

- Non-Storage / Special Protection / Storage Sprinklers: General InformationDocumento7 pagineNon-Storage / Special Protection / Storage Sprinklers: General InformationsakurageassNessuna valutazione finora

- 3 2536 14 3 2016 Ijcs PDFDocumento7 pagine3 2536 14 3 2016 Ijcs PDFrsr ecNessuna valutazione finora

- Gasket Corrosion Resistance Guide Page-1Documento1 paginaGasket Corrosion Resistance Guide Page-1KiranNessuna valutazione finora

- Gasket Corrosion Guide Page 1Documento1 paginaGasket Corrosion Guide Page 1KiranNessuna valutazione finora

- Bikiaris 1996Documento6 pagineBikiaris 1996Sy Nguyen VietNessuna valutazione finora

- Polym DSC&TGA 2022Documento23 paginePolym DSC&TGA 2022Priyashi ChoudharyNessuna valutazione finora

- (283.15 To 353.15) K at Pressures Up To 25 MP A: PGT Measurements and Eos Predictions of Glycol Ethers FromDocumento6 pagine(283.15 To 353.15) K at Pressures Up To 25 MP A: PGT Measurements and Eos Predictions of Glycol Ethers FromCarlos FerreraNessuna valutazione finora

- Thermal Behavior of Polymers PDFDocumento9 pagineThermal Behavior of Polymers PDFjraman24Nessuna valutazione finora

- Stamm Synthetic PolymersDocumento31 pagineStamm Synthetic PolymersGLUSITANIO, DIANA YSABELA JOHANA T.Nessuna valutazione finora

- ANS 002 Determination of Cristallinity of PET by DSCDocumento2 pagineANS 002 Determination of Cristallinity of PET by DSCTiwiNessuna valutazione finora

- PETDocumento52 paginePETAkash YadavNessuna valutazione finora

- Crude Oil Assay SlateDocumento2 pagineCrude Oil Assay Slatemahmoudmaklad100% (1)

- Poster Expo Quim I A 2008Documento1 paginaPoster Expo Quim I A 2008Steven ObrienNessuna valutazione finora

- Bioalcohols Bioethers - 2021 - EngDocumento47 pagineBioalcohols Bioethers - 2021 - EngCarlos francisco PerézNessuna valutazione finora

- Biomasa Macro-1Documento16 pagineBiomasa Macro-1Carlos Ubillas AlcaldeNessuna valutazione finora

- Materials Characterization Part1 PDFDocumento194 pagineMaterials Characterization Part1 PDFA1234 AJEF100% (1)

- TPR Temperature Switch: Series TPR High Accuracy Nema 4X & Ip 65 UL, CSA and CE Approved Compact, Economical DesignDocumento4 pagineTPR Temperature Switch: Series TPR High Accuracy Nema 4X & Ip 65 UL, CSA and CE Approved Compact, Economical DesignargaNessuna valutazione finora

- Resume PipDocumento3 pagineResume PipYuuSachiNessuna valutazione finora

- Kinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderDocumento6 pagineKinetic and Thermodynamic Study of Methanolysis of Poly (Ethylene Terephthalate) Waste PowderMaria ElaineNessuna valutazione finora

- Thermo Scientific Sterilizing Your Reusable Plastic Labware PosterDocumento1 paginaThermo Scientific Sterilizing Your Reusable Plastic Labware PosterSütő László BalázsNessuna valutazione finora

- Thermodynamic Properties of Polybutyleneglycol Adipate : (Received 27 July 1982)Documento6 pagineThermodynamic Properties of Polybutyleneglycol Adipate : (Received 27 July 1982)Syachnia RaniNessuna valutazione finora

- TI Polymer Periodic TableDocumento1 paginaTI Polymer Periodic TableandreslfortesNessuna valutazione finora

- Marking requirements for electrical equipment used in explosive gas atmospheresDocumento1 paginaMarking requirements for electrical equipment used in explosive gas atmospheresBinhvvNessuna valutazione finora

- Relevant Details of AminesDocumento2 pagineRelevant Details of AminesdbothejuNessuna valutazione finora

- Analisis AnalisisDocumento33 pagineAnalisis AnalisisNadiannafi NuhriNessuna valutazione finora

- Annealing of Polymers, Alloys, Composites), Part 3, 2020-1Documento3 pagineAnnealing of Polymers, Alloys, Composites), Part 3, 2020-1Laura GarcíaNessuna valutazione finora

- An M145 Thermal Degradation TG-FTIR enDocumento3 pagineAn M145 Thermal Degradation TG-FTIR enzhenyu zhangNessuna valutazione finora

- Catalysts: Active Site of O and Its Improvement Mechanism Over Ce-Ti Catalyst For NH - SCR ReactionDocumento14 pagineCatalysts: Active Site of O and Its Improvement Mechanism Over Ce-Ti Catalyst For NH - SCR ReactionJosé BarrosNessuna valutazione finora

- 01-DSC Method PDFDocumento24 pagine01-DSC Method PDFDanNessuna valutazione finora

- Experiment No. 4 Heat of CombustionDocumento4 pagineExperiment No. 4 Heat of CombustionjohannNessuna valutazione finora

- Polymer properties comparisonDocumento2 paginePolymer properties comparisonitsmeNessuna valutazione finora

- Gel Electrophoresis of ProteinsDa EverandGel Electrophoresis of ProteinsMichael J DunnNessuna valutazione finora

- Handbook of Heating, Ventilating and Air ConditioningDa EverandHandbook of Heating, Ventilating and Air ConditioningValutazione: 4 su 5 stelle4/5 (6)

- KTS - Sarao.bakus Temple of Eternal FiireDocumento176 pagineKTS - Sarao.bakus Temple of Eternal FiireK.T.S. SaraoNessuna valutazione finora

- Hart Fuller Debate: Hart Fuller Debate Is One of The Most Interesting Academic Debates of All Times That Took Place inDocumento1 paginaHart Fuller Debate: Hart Fuller Debate Is One of The Most Interesting Academic Debates of All Times That Took Place inAmishaNessuna valutazione finora

- Parameters Governing Predicted and Actual RQD Estimation - FINAL - PUBLISHED - VERSIONDocumento14 pagineParameters Governing Predicted and Actual RQD Estimation - FINAL - PUBLISHED - VERSIONKristian Murfitt100% (1)

- F588 PDFDocumento8 pagineF588 PDFOscar Gutiérrez-JuncoNessuna valutazione finora

- Fundamentals of VolleyballDocumento2 pagineFundamentals of VolleyballLawrence CezarNessuna valutazione finora

- Finite Element Simplified Fatigue AnalysisDocumento4 pagineFinite Element Simplified Fatigue AnalysisJin Hwan KimNessuna valutazione finora

- Turkey ImportDocumento14 pagineTurkey ImportMani 1Nessuna valutazione finora

- Lab Journal 4 14032023 104921amDocumento8 pagineLab Journal 4 14032023 104921amHammad MashwaniNessuna valutazione finora

- Difference Between AerospaceDocumento2 pagineDifference Between AerospaceSyawalMaulanaNessuna valutazione finora

- Ebook Scientific InstrumentsDocumento9 pagineEbook Scientific InstrumentsPavans LuckyNessuna valutazione finora

- SAFETY AND LOSS PREVENTION FOR CHEMICAL PROCESS FACILITIESDocumento13 pagineSAFETY AND LOSS PREVENTION FOR CHEMICAL PROCESS FACILITIESKinosraj KumaranNessuna valutazione finora

- Shop Math PDFDocumento29 pagineShop Math PDFKen LeeNessuna valutazione finora

- MACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Documento2.231 pagineMACRO XII Subhash Dey All Chapters PPTs (Teaching Made Easier)Vatsal HarkarNessuna valutazione finora

- Warhammer 40k Kroot VehiclesDocumento2 pagineWarhammer 40k Kroot VehiclesJoseph RobinsonNessuna valutazione finora

- Material Safety Data Sheet - MSDS: Section 1. Chemical Product and Company IdentificationDocumento5 pagineMaterial Safety Data Sheet - MSDS: Section 1. Chemical Product and Company IdentificationPubcrawlNessuna valutazione finora

- Practice: Circles and ArcsDocumento2 paginePractice: Circles and ArcsTIANA ARILENessuna valutazione finora

- South African Flora GlossaryDocumento47 pagineSouth African Flora Glossarymr.bryceNessuna valutazione finora

- 322439480MVR Single Page Single Page Booklet - OPTDocumento12 pagine322439480MVR Single Page Single Page Booklet - OPTlarry vargas bautistaNessuna valutazione finora

- Chemical reactions and structuresDocumento22 pagineChemical reactions and structuresStormy StudiosNessuna valutazione finora

- Hyundai Elevator Manual Helmon 2000 InstructionDocumento27 pagineHyundai Elevator Manual Helmon 2000 InstructionReynold Suarez100% (1)

- Operation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationDocumento6 pagineOperation & Maintenance Manual For Bolted Steel Tanks: Complete InstallationIrvansyah RazadinNessuna valutazione finora

- Dokumen - Tips - Astm A535 9 Percent NickelDocumento5 pagineDokumen - Tips - Astm A535 9 Percent NickelJeovanne CabralNessuna valutazione finora

- Gold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, IndonesiaDocumento10 pagineGold Grade of Epithermal Gold Ore at Lamuntet, Brang Rea, West Sumbawa District, West Nusa Tenggara Province, Indonesiasukri arjunaNessuna valutazione finora

- Self-Balancing Two-Wheeler Using GyroscopeDocumento33 pagineSelf-Balancing Two-Wheeler Using Gyroscopemilan mottaNessuna valutazione finora

- 7H17-28 Clearances and Wear Limits PDFDocumento3 pagine7H17-28 Clearances and Wear Limits PDFDimitris K100% (1)

- JMJ Marist Brothers Notre Dame of Marbel University Integrated Basic Education Department City of Koronadal, South CotabatoDocumento13 pagineJMJ Marist Brothers Notre Dame of Marbel University Integrated Basic Education Department City of Koronadal, South CotabatoNestor Gerotape DiosanaNessuna valutazione finora

- Overview of Pathophysiology of Hypoxemia and HypoxiaDocumento15 pagineOverview of Pathophysiology of Hypoxemia and HypoxiaMARY ANN CAGATANNessuna valutazione finora

- Proceedings of National Conference on Landslides held in LudhianaDocumento8 pagineProceedings of National Conference on Landslides held in LudhianaAniket PawarNessuna valutazione finora

- CORRELATION AND LINEAR REGRESSIONDocumento9 pagineCORRELATION AND LINEAR REGRESSIONSANKET GANDHINessuna valutazione finora

- The Blue Hotel PDFDocumento22 pagineThe Blue Hotel PDFGabriel OvidorNessuna valutazione finora