Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

T 30

Caricato da

Renny DevassyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

T 30

Caricato da

Renny DevassyCopyright:

Formati disponibili

M ARYLAND METRI C S

P.O.Box 261 Owings Mills, MD 21117 USA

(410)358-3130 (800)638-1830 Faxes: (410)358-3142 (800)872-9329

http://mdmetric.com techinfo@mdmetric.com

TECHNICAL INFORMATION and DATA

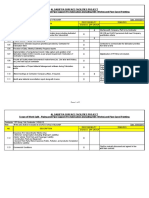

Stainless steel grades

Chemical composition

Chemical composition, mass content %1)

Group Grade C Si Mn P S Cr Mo7) Ni Cu Notes

A1 0,12 1,0 6,5 0,200 0,15–0,35 16–19 0,7 5–10 1,75–2,25 2) 8) 13)

A2 0,1 1,0 2,0 0,050 0,03 15–20 – 8–19 4 6) 9) 12)

Austenitic A3 0,08 1,0 2,0 0,045 0,03 17–19 – 9–12 1 3 ) 4) 8 )

A4 0,08 1,0 2,0 0,045 0,03 16–18,5 2–3 10–15 1 5) 12)

A5 0,08 1,0 2,0 0,045 0,03 16–18,5 2–3 10,5–14 1 3 ) 4) 5 )

C1 0,09–0,15 1,0 1,0 0,050 0,03 11,5–14 – 1 – 5)

Martensitic C3 0,17–0,25 1,0 1,0 0,040 0,03 16–18 – 1,5–2,5 –

C4 0,08–0,15 1,0 1,5 0,060 0,15–0,35 12–14 0,6 1 – 2 ) 5)

Ferritic F1 0,12 1,0 1,0 0,040 0,03 15–18 – 1 – 6) 10) 11)

Austenitic- 0,03 1,7 1,5 – – 18–19 2–2,7 4,5–5 – N = 0,07

Ferritic FA14)

0,03 1,0 2,0 – – 21–23 2,5–3 5–5,5 –

N = 0,14

01) Values are maximum unless otherwise indicated.

02) Sulphur may be replaced by selenium.

03) Must contain titanium > 5 x C up to 0,8% maximum for stabilization, or4).

04) Must contain niobium (columbium) and/or tantalum > 10 x C up to 1% maximum for stabilization, or3).

05) At the option of the manufacturer the carbon content may be higher where required to obtain the specified mechanical

properties at larger diameters, but shall not exceed 0,12% for austenitic steels.

06) Molybdenum may also be present at the option of the manufacturer.

07) If for some applications a maximum molybdenum content is essential, this must be stated.

08) If the nickel content is below 8%, the minimum manganese content must be 5%.

09) If the chromium content is below 17%, the minimum nickel content should be 12%.

10) May contain titanium > 5 x C up to 0,8% maximum.

11) May contain niobium (columbium) and/or tantalum > 10 x C up to 1,0% maximum.

12) For austenitic stainless steels having a maximum carbon content of 0,03%, nitrogen may be present to a maximum

of 0,22%.

13) There is no minimum limit to the copper content providing that the nickel content is greater than 8%.

14) For information only, will most probably be included in the future.

Corrosion resistance

Resistance Loss of material Loss of material Comments

group g/m2 h in mm per year

completely resistant

0 max. 0,1 max. 0,11

sufficiently resistant

1 > 0,1–1,0 > 0,11–1,1

less resistant

2 > 1,0–10,0 > 1,1–11,0

not resistant

3 > 10,0 > 11,0

X Risk of pitting even in resistance group 0

The data listed are based on laboratory tests. If parts are intended for a critical application, they should be tested in a practice oriented

experiment (consult an expert if necessary).

If there is a risk of inter-granular corrosion (mainly in chlorine bearing environments) use titanium or niobium stabilized

steels (grade A3 or A5) or low carbon stainless steels (grade A2L or A4L). For details see ISO 3506 or consult an expert.

T 30 copyright 1998 Maryland Metrics All rights reserved

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- WPS Alloy 625 Strip With Flux EST 236Documento1 paginaWPS Alloy 625 Strip With Flux EST 236Renny DevassyNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 1250 kVA Genset Specifications PDFDocumento8 pagine1250 kVA Genset Specifications PDFRenny DevassyNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Responsibility Matrix For Shop Piping WorksDocumento5 pagineResponsibility Matrix For Shop Piping WorksRenny DevassyNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Price List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevDocumento67 paginePrice List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevRenny DevassyNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- OGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Documento14 pagineOGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Renny DevassyNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Soudokay Strip Cladding - PrincipesDocumento31 pagineSoudokay Strip Cladding - PrincipesRenny DevassyNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Weldingguide ENGDocumento518 pagineWeldingguide ENGBoris Kozjan0% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Cummins C900D5 Diesel Generator Data Sheet PDFDocumento3 pagineCummins C900D5 Diesel Generator Data Sheet PDFpurushmicroNessuna valutazione finora

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Lincoln Strip Cladding Presentation April 2011Documento26 pagineLincoln Strip Cladding Presentation April 2011Renny DevassyNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- 0400GF Amerlock 400 GF PDS PDFDocumento4 pagine0400GF Amerlock 400 GF PDS PDFRenny DevassyNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 0400GF Amerlock 400 GF PDSDocumento4 pagine0400GF Amerlock 400 GF PDSRenny DevassyNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Tubular Products From Special MetalsDocumento26 pagineTubular Products From Special Metalskaveh-bahiraeeNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- HEMI Cryo Brochure 6 PageDocumento6 pagineHEMI Cryo Brochure 6 PageRenny DevassyNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Garnet IDocumento3 pagineGarnet IRenny DevassyNessuna valutazione finora

- Tubular Products From Special MetalsDocumento26 pagineTubular Products From Special Metalskaveh-bahiraeeNessuna valutazione finora

- Tubular Products From Special MetalsDocumento26 pagineTubular Products From Special Metalskaveh-bahiraeeNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Ratnamani - Manufacturing RangeDocumento2 pagineRatnamani - Manufacturing RangeRenny DevassyNessuna valutazione finora

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- 1250 kVA Genset SpecificationsDocumento8 pagine1250 kVA Genset SpecificationsRenny DevassyNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- 888DFHD - 1000kva. Fuel ConsumptionDocumento3 pagine888DFHD - 1000kva. Fuel ConsumptionRenny DevassyNessuna valutazione finora

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- FILTRACIONDocumento14 pagineFILTRACIONantoniojaviermaciasNessuna valutazione finora

- Cummins C900D5 Diesel Generator Data Sheet PDFDocumento3 pagineCummins C900D5 Diesel Generator Data Sheet PDFpurushmicroNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Inspection Certificate EN 10204 PDFDocumento0 pagineInspection Certificate EN 10204 PDFkronos39zeusNessuna valutazione finora

- Friction Factor Formulas For CheresourcesDocumento4 pagineFriction Factor Formulas For CheresourcesHarjasa AdhiNessuna valutazione finora

- T 71 UDocumento1 paginaT 71 URenny DevassyNessuna valutazione finora

- Compressible Cake Constant Pressure ProfileDocumento9 pagineCompressible Cake Constant Pressure ProfileClarence AG YueNessuna valutazione finora

- P091 067 UmDocumento208 pagineP091 067 UmBojan MarkovićNessuna valutazione finora

- Ips e PR 850 PDFDocumento73 pagineIps e PR 850 PDFdeyanshu7Nessuna valutazione finora

- 1.diesel Engine AssemblyDocumento22 pagine1.diesel Engine Assemblypepenapao1217Nessuna valutazione finora

- Case Study 5 - Enhanced ERDDocumento4 pagineCase Study 5 - Enhanced ERDMarcos Jeremy0% (1)

- GA-I (H) D 1000 Series ROBOTDocumento1 paginaGA-I (H) D 1000 Series ROBOTmfarrukhkNessuna valutazione finora

- Non Traditional MachiningDocumento17 pagineNon Traditional MachiningLeo Dev WinsNessuna valutazione finora

- Gardner Denver S.R.L. Spare Parts Price List Gds 10Documento140 pagineGardner Denver S.R.L. Spare Parts Price List Gds 10Tina Manousi100% (2)

- Dead LoadsDocumento1 paginaDead LoadsShokry AlkissyNessuna valutazione finora

- Ref Qty Part # Part Description UsageDocumento2 pagineRef Qty Part # Part Description UsageJusaNadaNessuna valutazione finora

- Deltascope FMP10 Isoscope FMP10 Dualscope FMP20: Operators ManualDocumento152 pagineDeltascope FMP10 Isoscope FMP10 Dualscope FMP20: Operators ManualMarcelino Navarrete EvaristoNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- ID FanDocumento49 pagineID Fansomyaranjan das50% (2)

- SH5002-7J S EnuDocumento304 pagineSH5002-7J S Enu19848096Nessuna valutazione finora

- HBN PVC Free Alternatives ChartDocumento24 pagineHBN PVC Free Alternatives ChartaggibudimanNessuna valutazione finora

- Power Transformer ENUDocumento32 paginePower Transformer ENUDaniel RizzoNessuna valutazione finora

- Computer Architecture and Parallel Processing by Kai Hwang PDFDocumento6 pagineComputer Architecture and Parallel Processing by Kai Hwang PDFApoorva ursNessuna valutazione finora

- Mbackpaper 18Documento6 pagineMbackpaper 18Aakash PathakNessuna valutazione finora

- 555 - 00028 Material Review Board Process Flow and Visual Managment1Documento14 pagine555 - 00028 Material Review Board Process Flow and Visual Managment1Samsung Joseph0% (1)

- XFABDocumento44 pagineXFABJulinNessuna valutazione finora

- 7 Longest Bridges in The WorldDocumento15 pagine7 Longest Bridges in The WorldWai Lana ButlerNessuna valutazione finora

- 036 Siga-UmDocumento6 pagine036 Siga-UmzezohomeNessuna valutazione finora

- Con-E-Co Manual de PartesDocumento198 pagineCon-E-Co Manual de PartesBogar Pineda100% (1)

- Operators Manual: TEC-B-0002 REV0 1/09Documento117 pagineOperators Manual: TEC-B-0002 REV0 1/09Clay MorrisNessuna valutazione finora

- Response - Records - Phase 2Documento31 pagineResponse - Records - Phase 2Bob MackinNessuna valutazione finora

- 014 A5.2 Floor FinishesDocumento1 pagina014 A5.2 Floor FinishesqgfytzvqabzqrxyilmNessuna valutazione finora

- Using Oracle Database Vault With Oracle Database 12c - D86597GC10 - 1080544 - USDocumento3 pagineUsing Oracle Database Vault With Oracle Database 12c - D86597GC10 - 1080544 - USJinendraabhi0% (1)

- Weinig Rondamat 960 PDFDocumento16 pagineWeinig Rondamat 960 PDFCimpean AlexandruNessuna valutazione finora

- Cable Calculations Worked ExamplesDocumento676 pagineCable Calculations Worked Examplesagan sitompul100% (1)

- Five Masterworks by Louis Sauer - 9103559 PDFDocumento64 pagineFive Masterworks by Louis Sauer - 9103559 PDFAntonello Martinez GianfredaNessuna valutazione finora

- Get TRDocDocumento185 pagineGet TRDockfrisch1229Nessuna valutazione finora

- Francis and Kaplan Reaction TurbinesDocumento5 pagineFrancis and Kaplan Reaction TurbinesfahadNessuna valutazione finora