Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

10 OM Decision

Caricato da

andy makmun0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

15 visualizzazioni2 pagineTitolo originale

10 OM Decision-.docx

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

15 visualizzazioni2 pagine10 OM Decision

Caricato da

andy makmunCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

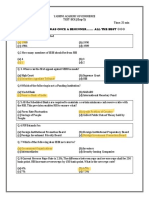

10 OM DECISION

DESIGNING OPERATIONS (CUSTOMIZED OR STANDARDIZED)

DESIGN OF Product Selection The objective of the product decision is to develop

PRODUCTS and implement a product strategy that meets the

demands of the marketplace with a competitive

advantage.

Generating New Changes in product opportunities, the products

Products themselves, product volume, and product mix may

arise due to understanding the customer, economic

change, sociological and demographic change,

technological change, political/legal change, market

practice, professional standards, suppliers, or

distributors.

Product Development A process for determining customer requirements

(customer “wants”) and translating them into

attributes (the “hows”) that each functional area can

understanding and act on (improve a product’s

design, production, maintainability, and use).

MANAGING Quality Standards The totality of features and characteristics of a

QUALITY product that bears on its ability to satisfy customer

quality expectations and how to achieve them

Total Quality Management of an entire organization so that it

Management System excels in all aspects of products and services that

are important to the customer

DESIGN OF Process strategy Organization’s approach to produce a production

PROCESS process with the necessary quality, flexibility, and

cost structure to meet product and volume

requirements.

Process Design Flowchart of production process

Production Technology Recent advances in production technology

Capacity Determine the number of units a facility can

produce to meet optimal utilization and efficiency

LOCATION Factors That Affect Selecting a facility / factory location

Location Decisions

LAYOUT Types of Layout Warehouse layout : Balance low-cost storage with

low-cost material handling. Fixed-position layout :

Move material to the limited storage areas around

the site. Process-oriented layout : Manage varied

material flow for each product. Work-cell layout :

Identify a product family, build teams, and cross-

train team members. Product-oriented layout :

Equalize the task time at each workstation.

HUMAN Labor Planning Staffing policies dealing with employment stability,

RESOURCES work schedules, and work rules

Job Design Tasks that constitute a job for an individual or group

Labor Standards The amount of time required to perform a job or part

of a job

MANAGING OPERATIONS

SUPPLY CHAIN Supply Chain’s Sourcing Strategies (many suppliers, few supliers,

MANAGEMENT Strategic vertical integration, joint ventures, etc.)

Primary supplier selection criteria

Supply Chain Risk and Supplier failure to deliver, Supplier quality failures,

Mitigation Tactics Logistics delays or damage, Natural catastrophes,

etc.

Logistics Management An approach that seeks efficiency of operations

through the integration of all material acquisition,

movement, and storage activities.

Distribution The outbound flow of final products

Management

INVENTORY Raw material / Work-in- How much to order and when to order; how much to

process /Maintenance, keep on hand

repair, and operating

materials / Finished-

goods inventory

SCHEDULE Allocate and prioritize (1) minimize completion time , (2) maximize

demand to available utilization , (3) minimize work-in-process (WIP)

facilities inventory , and (4) minimize customer waiting time

MAINTENANCE Preventive Routine inspections, monitoring, servicing, and

maintenance keeping facilities in good repair

Breakdown Remedial maintenance that occurs when preventive

Maintenance maintenance fails and equipment/facilities must be

repaired on an emergency or priority basis

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Cma Inter GR 1 Financial Accounting Ebook June 2021 OnwardsDocumento358 pagineCma Inter GR 1 Financial Accounting Ebook June 2021 OnwardsSarath KumarNessuna valutazione finora

- 173089Documento22 pagine173089aiabbasi9615100% (1)

- Plasticizers For CPE ElastomersDocumento8 paginePlasticizers For CPE Elastomersbatur42Nessuna valutazione finora

- Role of SpeakerDocumento11 pagineRole of SpeakerSnehil AnandNessuna valutazione finora

- Roasted and Ground Coffee Manufacturing Industry Feasibility StudyDocumento22 pagineRoasted and Ground Coffee Manufacturing Industry Feasibility StudyGhirmaye AbebeNessuna valutazione finora

- WHS Hazard Identification and Incident Reporting ProcedureDocumento6 pagineWHS Hazard Identification and Incident Reporting ProcedureJessica SimsNessuna valutazione finora

- Social Media Engagement and Feedback CycleDocumento10 pagineSocial Media Engagement and Feedback Cyclerichard martinNessuna valutazione finora

- Electric Baseboard StelproDocumento4 pagineElectric Baseboard StelprojrodNessuna valutazione finora

- Webdynpro ResumeDocumento4 pagineWebdynpro ResumeAmarnath ReddyNessuna valutazione finora

- Tutorial 1 Process Heat TransferDocumento4 pagineTutorial 1 Process Heat TransferSuraya JohariNessuna valutazione finora

- STAAD Seismic AnalysisDocumento5 pagineSTAAD Seismic AnalysismabuhamdNessuna valutazione finora

- BBA Lecture NotesDocumento36 pagineBBA Lecture NotesSaqib HanifNessuna valutazione finora

- A Job InterviewDocumento8 pagineA Job Interviewa.rodriguezmarcoNessuna valutazione finora

- HP-exampleDocumento30 pagineHP-exampleAnonymous 105zV1Nessuna valutazione finora

- Gamesa Wind Turbine Element UpgradesDocumento1 paginaGamesa Wind Turbine Element Upgradesstanislav uzunchevNessuna valutazione finora

- Cross-Compilers: / / Running ARM Grub On U-Boot On QemuDocumento5 pagineCross-Compilers: / / Running ARM Grub On U-Boot On QemuSoukous LoverNessuna valutazione finora

- Analyzing Sri Lankan Ceramic IndustryDocumento18 pagineAnalyzing Sri Lankan Ceramic Industryrasithapradeep50% (4)

- C++ & Object Oriented Programming: Dr. Alekha Kumar MishraDocumento23 pagineC++ & Object Oriented Programming: Dr. Alekha Kumar MishraPriyanshu Kumar KeshriNessuna valutazione finora

- J 2022 SCC OnLine SC 864 Tushardubey Symlaweduin 20221015 214803 1 23Documento23 pagineJ 2022 SCC OnLine SC 864 Tushardubey Symlaweduin 20221015 214803 1 23Tushar DubeyNessuna valutazione finora

- DS TEGO Polish Additiv WE 50 e 1112Documento3 pagineDS TEGO Polish Additiv WE 50 e 1112Noelia Gutiérrez CastroNessuna valutazione finora

- Dorma 2012 Price ListDocumento284 pagineDorma 2012 Price ListSecurity Lock DistributorsNessuna valutazione finora

- Report - Fostering The Railway Sector Through The European Green Deal PDFDocumento43 pagineReport - Fostering The Railway Sector Through The European Green Deal PDFÁdámHegyiNessuna valutazione finora

- In The High Court of Delhi at New DelhiDocumento3 pagineIn The High Court of Delhi at New DelhiSundaram OjhaNessuna valutazione finora

- Assignment Mid Nescafe 111173001Documento5 pagineAssignment Mid Nescafe 111173001afnan huqNessuna valutazione finora

- AMC Mining Brochure (A4 LR)Documento2 pagineAMC Mining Brochure (A4 LR)Bandung WestNessuna valutazione finora

- BCK Test Ans (Neha)Documento3 pagineBCK Test Ans (Neha)Neha GargNessuna valutazione finora

- Parts Price ListDocumento5.325 pagineParts Price ListAlva100% (1)

- CreatorsXO JuneDocumento9 pagineCreatorsXO JuneGaurav KarnaniNessuna valutazione finora

- JJDocumento119 pagineJJAnonymous 5k7iGyNessuna valutazione finora

- Exercises Service CostingDocumento2 pagineExercises Service Costingashikin dzulNessuna valutazione finora