Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)

Caricato da

Alam MD SazidTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)

Caricato da

Alam MD SazidCopyright:

Formati disponibili

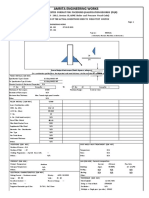

Welding Procedure Specification

(WPS) SWCC

LIMAK/SAWAED

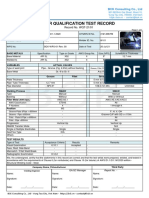

WPS No: WPS-JR1 Revision:00 Date:01/11/2019 Client: Limak

PQR No:01 Revision:00 Date: Third Party Agency:

Code: API 1104 Welding Process(es): SMAW Company: Sawaed Engineering

Page:01 Type(s): MANUAL Project: Jubail Riyadh Water Transmission

System (Stations)

Materials: -API-5L-PSL-1-L245-X52 or X60

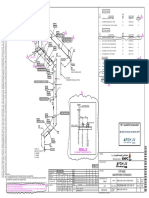

JOINTS (QW-402) POST WELD HEAT TREATMENT (QW-407)

Holding Temperature Range: (ASME BPVC SEC VIII DIV 1-Nonmandatory Appendix R)

Joint Design: Single V Groove

Backing: Yes / No--No Holding Time :N/A

Backing Material (Type): N/A Heating Rate:

No fusing Metal Cooling Rate:

Base Metal

Weld Metal PWHT Chart:N/A

Nonmetallic

Root Opening:2-4mm Root Face:1.5-2.5 mm GAS: (QW-408) (ASME SEC IIC SFA-5.32)

Groove Angle:30-35 Degree Radius (J-U): Percent Composition:

Back Gouging: N/A Gas(es): Mixture: flow rate:

BASE METAL: (QW-403) Shielding N/A N/A N/A

N/A N/A N/A

P No.- 01 Trailing:

Group No.- 02 Backing: N/A N/A N/A

Thick. Range :4.8mm-19m

ELECTRICAL CHARACTERISTICS: (QW-409)

Base Metal: (QW-451.1) Current AC or DC: AC Polarity: DCEP

Amps .(Range):

Pipe Dia. Range: >12.75mm

Volt .(Range):

Chemical Analysis: -0.21% max Tungsten Electrode Size and Type: (ASME SEC IIC SFA-5.12)

Mode of Metal Transfer for GMAW: (ASME SEC IIC SFA-5.18)

FILLER METAL: (QW-404) Electrode Wire Feed Speed Range:

Spec.No.(SFA):5.5 (ASME SEC IIC) AWS NO.(Class): (ASME SEC IIC) Heat input Allowance:

F-No: (Table QW-432)-04 A-No: (Table QW-442)- 01

Size of Filler Metals: Root 2.4-3.2mm Weld Metals: Deposited Thickness WELDING TECHNIQUE: (QW-410)

Hot/Fill/Cap- 4.0-5.0mm

Electrode-Flux(Class): Groove: (Table QW-451.1) Stringer/Weave Bead: Strings/Weaves

Brand Name: Fillet: N/A Orifice or Gas Cup Size: N/A

Consumable Insert:N/A Initial & Interpass cleaning : Brushing/Grinding

Method of Back Gouging: N/A

POSITIONS: (QW-405) Oscillation:N/A

Position of Groove: Contact Tube to Word Distance:N/A

Welding Progressions:5G Up Hill /Down Hill--Downhill Multiple or Single Pass (per side): Multiple

Position(S) of Fillet: N/A Multiple or Single Electrodes: Multiple

PREHEAT (QW-406) Travel Speed (Range): Ref. Table 1

Preheat Temp.Min: 15 Degree Centigrade

Peening:N/A

(ASME BPVC SEC VIII DIV 1-Nonmandatory Appendix R)

Inter Pass Temp.Max: 150 Degree Centigrade Other:N/A

Preheat Maintenance:

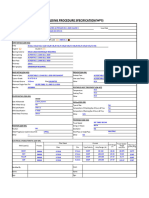

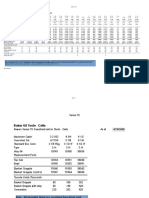

WELDING PROCEDURE: TABLE-01

Joint Details

Filler Metal Current (ASME SEC IIC)

Heat Input Travel Speed

Pass Process

(kj/mm) (mm/min)

Class Dia Polarity Volt AMP 30º-35

ROOT PASS SMAW E6010 2.4.-3.2 DCEP 26-28 85-95 2 (±0.5)

HOT PASS SMAW E7018 4.0-5.0 DCEP 21-24 85-115

FILL PASS SMAW E7018 4.0-5.0 DCEP 21-24 115-140

FILL PASS SMAW E7018 4.0-5.0 DCEP 21-24 115-140

CAP PASS SMAW E7010 4.0-5.0 DCEP 27-29 110-125 2 (±0.5)

RUN SEQUENCE WELD PROGRESSION-DOWNHILL FOR ALL PASSSES

1.Fit Up 2.Welding*/Cleaning 3.Visual Inspection 4.NDT (RT, UT, PT, MT) ** 2 (±0.5)

*: Distortion Control Shall be Consider. ** As Per Quality specs and Documents (QCP)

2 (±05).

Prepared By: Checked &Approved By: Contractor: LIMAK Client: JACOB/SWCC

Sawaed Engineering Sawaed Engineering

Date: Date: Date: Date:

Sign: Sign: Sign: Sign:

Potrebbero piacerti anche

- Manual Joints (QW - 402) : Page 1 of 12Documento12 pagineManual Joints (QW - 402) : Page 1 of 12miteshpatel191Nessuna valutazione finora

- Welding Proposed Pwps For Our Jubail WorkDocumento2 pagineWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPSDocumento6 pagineWPSYASH BARDHAN SinghNessuna valutazione finora

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Documento3 pagineAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNessuna valutazione finora

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Documento2 pagineWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNessuna valutazione finora

- WPSDocumento2 pagineWPSAlam MD Sazid100% (1)

- Joints (Qw-402) DetailsDocumento3 pagineJoints (Qw-402) DetailsNaqqash SajidNessuna valutazione finora

- Wps Pip Gtaw - ArabianDocumento1 paginaWps Pip Gtaw - ArabianIshack MohammedNessuna valutazione finora

- PWPS WPS CAP 039 PQR 035Documento15 paginePWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNessuna valutazione finora

- TopCoreBelco 101 FCDocumento9 pagineTopCoreBelco 101 FCCesar ArellanoNessuna valutazione finora

- WPS Pipe 08'' SHD 40 SMAW REV02Documento2 pagineWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNessuna valutazione finora

- P. WpsDocumento14 pagineP. WpsIsmiArdyNessuna valutazione finora

- Pipeline Weld Joint & Ragiograph Film Numbering SystemDocumento9 paginePipeline Weld Joint & Ragiograph Film Numbering Systemgst ajah100% (2)

- Welding Procedure Qualification Record: Shipyard LogoDocumento4 pagineWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- WOPQ Form English1Documento2 pagineWOPQ Form English1oaperuchenaNessuna valutazione finora

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 pagineASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNessuna valutazione finora

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocumento3 pagineIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNessuna valutazione finora

- WQT Aws D1.1Documento1 paginaWQT Aws D1.1Ali HammoudaNessuna valutazione finora

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Documento2 pagineWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNessuna valutazione finora

- WPS PQR PDFDocumento23 pagineWPS PQR PDFAhmad Daniel100% (1)

- Editable AWS D1.1 WPSDocumento2 pagineEditable AWS D1.1 WPSSheik Mohamed100% (1)

- Alishar SP 2Documento84 pagineAlishar SP 2Alam MD SazidNessuna valutazione finora

- Wps Mma PipeDocumento2 pagineWps Mma PipeDimitris NikouNessuna valutazione finora

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocumento3 pagineDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNessuna valutazione finora

- RTCC Manual WPS Approval WE-WPS-001Documento7 pagineRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNessuna valutazione finora

- Form Wps JBL09-2011Documento2 pagineForm Wps JBL09-2011fawad aliNessuna valutazione finora

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 pagineCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNessuna valutazione finora

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocumento31 pagineALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNessuna valutazione finora

- PQR Editable SampleDocumento2 paginePQR Editable SampleKoya ThangalNessuna valutazione finora

- WPS - Smaw - 2Documento6 pagineWPS - Smaw - 2Harkesh RajputNessuna valutazione finora

- 03 WPS CS 1Documento3 pagine03 WPS CS 1mohammadNessuna valutazione finora

- Mechanical Test 1Documento21 pagineMechanical Test 1Manoranjan sharmaNessuna valutazione finora

- Weld Summary ReportDocumento80 pagineWeld Summary ReportBinu SulochananNessuna valutazione finora

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocumento3 pagineVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNessuna valutazione finora

- Wps Aws d1.1 NEWDocumento2 pagineWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- d1.1 Fcaw Unlimited Test Plate ConfigurationDocumento77 pagined1.1 Fcaw Unlimited Test Plate ConfigurationJuan Martinez100% (1)

- PQR WPQ Witness Report LatestDocumento1 paginaPQR WPQ Witness Report LatestSatish KeskarNessuna valutazione finora

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Documento4 pagineProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNessuna valutazione finora

- Welding Parameters Control PipelineDocumento1 paginaWelding Parameters Control PipelinemusheerNessuna valutazione finora

- QW-484A (WPQ) GTAW 4MM FilletDocumento2 pagineQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Documento3 pagineWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNessuna valutazione finora

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocumento1 paginaAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNessuna valutazione finora

- Welding Coordinator WeldMap Weld Data Sheet PDFDocumento1 paginaWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNessuna valutazione finora

- PWPS Fillet WeldDocumento2 paginePWPS Fillet WeldUgonnaNessuna valutazione finora

- Piping WpsDocumento37 paginePiping WpsZulfokar FahdawiNessuna valutazione finora

- Wps For Smaw06-001 (Pipe 6g CS)Documento10 pagineWps For Smaw06-001 (Pipe 6g CS)walitedisonNessuna valutazione finora

- Welding Procedure Specification (WPS) : Supporting PQR 01Documento2 pagineWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNessuna valutazione finora

- PQR Is7307Documento1 paginaPQR Is7307Tridib Dey100% (1)

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocumento3 pagineSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNessuna valutazione finora

- Procurement Services: Industry & Facilities DivisionDocumento10 pagineProcurement Services: Industry & Facilities Divisionkbpatel123Nessuna valutazione finora

- NSH-DALM-JERP-WPS-11-P2 Rev.00Documento10 pagineNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNessuna valutazione finora

- PQR - 152Documento3 paginePQR - 152MAT-LIONNessuna valutazione finora

- Wps Model 2 PDFDocumento17 pagineWps Model 2 PDFbeyNessuna valutazione finora

- List Applicable WPS StructureDocumento7 pagineList Applicable WPS StructureFerdie OSNessuna valutazione finora

- PQR - PipeDocumento3 paginePQR - PipeAdvanced Quality Centre AQC100% (1)

- Qualified Welder List Valid Until - 03-12-2019Documento2 pagineQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocumento6 pagineWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNessuna valutazione finora

- WPS E6013+e7018Documento2 pagineWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Documento2 pagineWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- R016611Documento4 pagineR016611Alam MD SazidNessuna valutazione finora

- DPT Test Report FormatDocumento1 paginaDPT Test Report FormatAlam MD SazidNessuna valutazione finora

- MTC - Rel-01 (Rev.00)Documento16 pagineMTC - Rel-01 (Rev.00)Alam MD SazidNessuna valutazione finora

- CV Faisal ZAFAR SHAHIDDocumento6 pagineCV Faisal ZAFAR SHAHIDAlam MD SazidNessuna valutazione finora

- Third Party QC For SWCC Man IndiaDocumento1 paginaThird Party QC For SWCC Man IndiaAlam MD SazidNessuna valutazione finora

- Limak - Sawaed WpsDocumento1 paginaLimak - Sawaed WpsAlam MD SazidNessuna valutazione finora

- Sawaed PT Report No. 02 For SWCC Jubail Emergency LineDocumento1 paginaSawaed PT Report No. 02 For SWCC Jubail Emergency LineAlam MD SazidNessuna valutazione finora

- Letter From Man Industries India For MD Sazid AlamDocumento1 paginaLetter From Man Industries India For MD Sazid AlamAlam MD SazidNessuna valutazione finora

- List of WPS (Jerp) PDFDocumento2 pagineList of WPS (Jerp) PDFAlam MD SazidNessuna valutazione finora

- NSH-DALM-JERP-WPS-11-P2 Rev.00Documento10 pagineNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNessuna valutazione finora

- Peneterant Testing For NDT - Procedure Details - Latest FinalDocumento8 paginePeneterant Testing For NDT - Procedure Details - Latest FinalAlam MD Sazid100% (1)

- WPSDocumento2 pagineWPSAlam MD Sazid100% (1)

- Cathodic ProtectionDocumento52 pagineCathodic Protectionredback666100% (2)

- P6022mab Amd 128 11541 01 - S4Documento1 paginaP6022mab Amd 128 11541 01 - S4Alam MD SazidNessuna valutazione finora

- Ch3pro220 1 PDFDocumento25 pagineCh3pro220 1 PDFpippo2378793Nessuna valutazione finora

- Peneterant Testing For NDT Procedure Details LatestDocumento7 paginePeneterant Testing For NDT Procedure Details LatestAlam MD SazidNessuna valutazione finora

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Documento2 pagineLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNessuna valutazione finora

- Letter From Man Industries India For MD Sazid AlamDocumento1 paginaLetter From Man Industries India For MD Sazid AlamAlam MD SazidNessuna valutazione finora

- P6022mab Amd 128 11095 04 - S1 PDFDocumento1 paginaP6022mab Amd 128 11095 04 - S1 PDFAlam MD SazidNessuna valutazione finora

- Signed Acceptance of Job OfferDocumento2 pagineSigned Acceptance of Job OfferAlam MD Sazid0% (1)

- PID SymbolsDocumento18 paginePID SymbolsAnonymous f9EEXptHCNessuna valutazione finora

- Piping Isometric Drawings GuideDocumento857 paginePiping Isometric Drawings GuideHugo Ruiz67% (3)

- Seed License Documents NewDocumento8 pagineSeed License Documents NewAlam MD SazidNessuna valutazione finora

- Experience LetterDocumento1 paginaExperience LetterAlam MD Sazid50% (2)

- Prime Minister Employment Generation ProgrammeDocumento1 paginaPrime Minister Employment Generation ProgrammeAlam MD SazidNessuna valutazione finora

- Accoutnt Statement PDFDocumento3 pagineAccoutnt Statement PDFAlam MD SazidNessuna valutazione finora

- ch9 1Documento38 paginech9 1Karam AlmasriNessuna valutazione finora

- Mowe Letter For Aico Approval For Pipeline Inspection PDFDocumento1 paginaMowe Letter For Aico Approval For Pipeline Inspection PDFAlam MD SazidNessuna valutazione finora

- Schärer-Elektronik AG CH - 5614 Sarmenstorf: Trip Circuit Supervision Relay TSG 910Documento2 pagineSchärer-Elektronik AG CH - 5614 Sarmenstorf: Trip Circuit Supervision Relay TSG 910electrical tecNessuna valutazione finora

- Polymer: Huige Wei, Jiahua Zhu, Shijie Wu, Suying Wei, Zhanhu GuoDocumento12 paginePolymer: Huige Wei, Jiahua Zhu, Shijie Wu, Suying Wei, Zhanhu GuoAlrayyan RashidNessuna valutazione finora

- Service Manual - Siau282005ea - Rza(s) - C (1) (2) V (Y) 1Documento298 pagineService Manual - Siau282005ea - Rza(s) - C (1) (2) V (Y) 1jpj54ktqjdNessuna valutazione finora

- DKM AC CatalogueDocumento65 pagineDKM AC Cataloguejlruiz06Nessuna valutazione finora

- 150-600 Gate ValveDocumento4 pagine150-600 Gate ValveSaquib NishatNessuna valutazione finora

- 9241 Series Bugatti Ball Valve UL FM NSF61 600WOGDocumento1 pagina9241 Series Bugatti Ball Valve UL FM NSF61 600WOGjhoger2012Nessuna valutazione finora

- Rigging JSA SafetyDocumento5 pagineRigging JSA SafetyaQiLGunawanNessuna valutazione finora

- Hipon 20 DechloDocumento3 pagineHipon 20 DechloLopez GardoNessuna valutazione finora

- 2000 Evtm RangerDocumento121 pagine2000 Evtm RangertheclockworkNessuna valutazione finora

- A Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Documento9 pagineA Mini-Project Report Course Code: 17AE4DCAP-I: "Model of Air-Compressor Using A Syringe"Shreya Giri0% (1)

- Distribution ReservoirsDocumento14 pagineDistribution ReservoirsBinyam KebedeNessuna valutazione finora

- Layout Room INDUSTRI FARMASIDocumento1 paginaLayout Room INDUSTRI FARMASIDwi MeliniaNessuna valutazione finora

- Ecological and Energetic Assessment of Re-Refining Used Oils To Base OilsDocumento104 pagineEcological and Energetic Assessment of Re-Refining Used Oils To Base OilsFernando SImonelliNessuna valutazione finora

- Separator 01dyDocumento44 pagineSeparator 01dyFadhil KhalidNessuna valutazione finora

- Manesty DistillationDocumento15 pagineManesty DistillationGaurav Sharma0% (1)

- CWWS ULTRA-SEP Brochure (2008)Documento12 pagineCWWS ULTRA-SEP Brochure (2008)Steve OsuohaNessuna valutazione finora

- Aliplast Katalog enDocumento140 pagineAliplast Katalog enJelena GraovčevićNessuna valutazione finora

- Septic TankDocumento1 paginaSeptic TankAnonymous 2a0rZk7Nessuna valutazione finora

- iKOTE CM 30R (TDS) 02-APRIL-2024Documento2 pagineiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNessuna valutazione finora

- All OvershotsDocumento25 pagineAll OvershotsnjileoNessuna valutazione finora

- Laser Tattoo Paper ENG PDFDocumento1 paginaLaser Tattoo Paper ENG PDFIgor Cece GigoNessuna valutazione finora

- Baldor-Maska Catalog (MM) - CA6001Documento20 pagineBaldor-Maska Catalog (MM) - CA6001dark_followerNessuna valutazione finora

- TALAT Lecture 3501: Alloys and PropertiesDocumento8 pagineTALAT Lecture 3501: Alloys and PropertiesCORE MaterialsNessuna valutazione finora

- Farrat Plate BrochureDocumento12 pagineFarrat Plate BrochureShaneLinehanNessuna valutazione finora

- Honda Small Engines GXV340 and GXV390 ManualDocumento16 pagineHonda Small Engines GXV340 and GXV390 ManualPeter HorniakNessuna valutazione finora

- Man Made FibreDocumento23 pagineMan Made FibreKhushboo ThakurNessuna valutazione finora

- Gerb Formulas PDFDocumento4 pagineGerb Formulas PDFMuthu KumarNessuna valutazione finora

- Av en Valves PDFDocumento246 pagineAv en Valves PDFWahyuNessuna valutazione finora

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocumento4 pagineDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNessuna valutazione finora

- Rina Tannenbaum Resume October 2012Documento33 pagineRina Tannenbaum Resume October 2012Rina TannenbaumNessuna valutazione finora