Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AgustaWestland AW139 G-CHCV 10-10

Caricato da

arun RajannaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AgustaWestland AW139 G-CHCV 10-10

Caricato da

arun RajannaCopyright:

Formati disponibili

AAIB Bulletin: 10/2010

G-CHCV EW/C2008/12/03

SERIOUS INCIDENT

Aircraft Type and Registration: AgustaWestland AW139, G-CHCV

No & Type of Engines: 2 Pratt & Whitney Canada PT6C-67C turboshaft engines

Year of Manufacture: 2007

Date & Time (UTC): 23 December 2008 at 1405 hrs

Location: The North Sea, 65 nm north-east of North Denes

Heliport

Type of Flight: Commercial Air Transport (Passenger)

Persons on Board: Crew - 2 Passengers - 8

Injuries: Crew - None Passengers - None

Nature of Damage: None

Commander’s Licence: Airline Transport Pilots Licence (Helicopters)

Commander’s Age: 45 years

Commander’s Flying Experience: 7,311 hours (of which 833 hours were on type)

Last 90 days - 113 hours

Last 28 days - 43 hours

Information Source: AAIB Field Investigation

Synopsis

Whilst on a flight from North Denes Heliport to a The spurious warnings and the loss of indications were

North Sea drilling platform, the aircraft’s crew alerting found to be due to corrosion in an avionic module.

system displayed a vne miscompare message. This The corrosion had occurred due to the module cabinet

was followed by the loss of No 2 engine indications being cooled by unfiltered, non-conditioned air drawn

and other aircraft system parameters. The No 1 engine from intakes on the fuselage underside. The situation

parameters indicated normal operation and the crew was exacerbated by the helicopter being operated in a

elected to return to North Denes Heliport. Whilst still maritime environment.

in cloud, the crew received indications that there was

a fire in the baggage compartment at the rear of the One Safety Recommendation is made.

aircraft. The commander then lost all altitude, airspeed

History of the flight

and vertical speed information from his Primary Flight

Display. Once below cloud, another company helicopter The crew of G-CHCV were on their first flight of the day

flew alongside G-CHCV and confirmed that there was and were tasked to carry eight passengers from North

no evidence of fire and a safe landing ensued. Denes Heliport to the Noble Julie Robertson drilling

© Crown copyright 2010 10

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

platform 88 nm to the north north-east. The en route and failure of the No 2 MAU except there was no 2 mau

destination weather was forecast to be wind from 240° message displayed on either Primary Flight Display

at 8 kt, visibility 6 km, overcast cloud at 1,200 ft and (PFD).

temperature 9°C.

At 1401 hrs, the crew decided to return to North Denes

G-CHCV took off at 1332 hrs and climbed to 2,000 ft and, after coordination with Anglia Radar, they turned

on the regional QNH of 1030 mb where it was in IMC. right on track for the heliport and began a descent to

The aircraft commander was PF in the right seat and the 1,500 ft. During the descent, the CAS generated a bag

crew were in contact with Anglia Radar. The flight was fire warning, with its associated aural warning, indicating

uneventful until about 23 nm from the destination, when a fire in the baggage compartment. There was no red

the crew recalled receiving a Crew Alert System (CAS) light on the fire control panel, no smell of burning and no

amber vne miscompare message. This message is smoke visible inside the cabin. The crew were unable to

displayed when there is a difference in VNE , as calculated

1

check for smoke outside as they were flying in cloud and

by each of the two Modular Avionics Units (MAUs). the PNF declared a Mayday. During the transmission,

information from the No 2 Air Data System (ADS)

Immediately afterwards, the CAS displayed an eng disappeared from the aircraft commander’s PFD and he

analog failure caution message, indicating the lost indications of barometric altitude, vertical speed and

failure of an analogue engine parameter sensor. At the airspeed. The PNF switched No 1 ADS information to

same time, information relating to No 2 engine systems the right PFD, which restored these parameters to the

was lost on the power plant page of the multi-function commander’s display but meant that both PFDs were

display (MFD). The crew reported losing indications using the same source for information.

of No 2 engine power index (a single scale composite

display that provides the pilot with an indication of The crew decided to descend to VMC below cloud,

engine performance), inter-turbine temperature (ITT), expecting to have to descend to about 1,200 ft amsl.

oil temperatures and pressures and free turbine rotor rpm. In the event, they descended to below 200 ft amsl, to

In addition, they lost indications of the No 2 hydraulic be in sight of the surface, and found the visibility to be

system, the No 2 fuel quantity and the No 2 radio 2,000 m. They assessed that the sea state was suitable for

altimeter. There was also a caution message indicating ditching and briefed for such an event, in case it proved

failure of the No 2 pitot system. necessary. During the transit back to North Denes the

crew were unable to couple the flight director to the

There was no indication of a failure of the No 2 DC autopilot. About 10 nm before reaching the heliport,

generator and the torque indication on the No 1 engine indications of the No1 free power turbine rpm (Nf1) and

was indicating 50%. The crew assessed that these

main rotor rpm (Nr) disappeared momentarily from both

indications were consistent with both engines operating

PFDs but there was no associated loss of power.

normally. They also concluded that the warnings and

cautions displayed on the CAS were consistent with Just before reaching North Denes, a company helicopter

Footnote flew alongside and confirmed that there was no smoke

1

VNE the calculated helicopter never exceed speed. coming from G-CHCV’s baggage compartment. At

© Crown copyright 2010 11

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

1448 hrs, the aircraft landed without further incident. recording and maintenance capabilities. Operation is

After landing, the passengers were evacuated, the aircraft via cockpit controls, sensors, displays and integrated

was shut down and the emergency services inspected the computers.

baggage compartment to confirm that there was no fire.

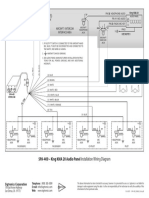

At the heart of the system are the two MAUs; a generic

Helicopter description

block diagram of the system is shown in Figure 1.

There are two basic variants of the AW 139: the ‘short Each MAU consists of a cabinet equipped with Line

nose’, which includes G-CHCV, and the later ‘long Replaceable Modules (LRMs) which, for the AW139,

nose’, which include SAR aircraft. Approximately may be different for each MAU, although most are

170 short nose and 30 long nose aircraft are in service duplicated. The module content can also vary between

(as at February 2009), with the latter being the current individual airframes: for example, MAU 1 contains

production version. a video module on Search and Rescue (SAR) aircraft,

which are also flown by G-CHCV’s operator. This

The helicopter is equipped with the Honeywell Primus processes the output from airframe-mounted video

EPIC integrated avionic system, which was developed cameras. Communication and data processing within

for fixed wing aircraft and currently equips types that each MAU is managed by the Network Interface

include the Gulfstream IV and V, the Dassault Falcon X Controller/Processor (NIC/PROC), which also transmits

and Embraer 170/190 series aircraft. The AW139 is and receives data from other systems on the aircraft

the first helicopter application for the system, with the on Aircraft Standard Communication Buses (ASCB)

type entering service during 2003. The EPIC system and Local Area Networks (LAN). A software function

comprises two MAUs, each consisting of a cabinet that within the NIC/PROC monitors the aircraft systems and

contains the functional modules, and each MAU has a provides warnings, cautions and advisories through the

main and auxiliary power supply. Should a MAU fail, CAS display.

multiple CAS cautions will be generated that could

degrade the operational capability of the helicopter. Data from all airframe sensors are not wired directly to

Description of the avionic system each MAU but wired separately to ensure segregation

and to allow the MAUs to compare between duplicate

1. Basic architecture

sensors. Each MAU has visibility of data acquired by

The Primus EPIC system architecture is the same for the other as, once acquired by the respective MAU, it is

both the long and short nose airframes. However, in the digitised and transmitted on the databuses. A majority of

long nose aircraft the MAU cabinets are located in the these parameters is acquired in the MAU Custom Input/

nose compartment, whereas in the short nose version Output module (CSIO).

they are installed either side of the baggage compartment

aft of the cabin. Unlike all but one of the fixed wing Engine parameters are acquired by the MAUs from

installations, non-conditioned air is used for cooling the Electronic Engine Controllers (EECs). Each EEC

the MAU cabinets. The MAU’s function is to integrate collects data from sensors installed on its respective

the systems and sub-systems that supply the aircraft engine and digitises it. This data is then transmitted

with navigation, communication, autoflight, indicating, to both MAUs so that in the event of a MAU failure

© Crown copyright 2010 12

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

First Officer’s DUs Captain’s DUs

SYSTEM NETWORK AND DATABUSES (ASCB, LAN)

MAU 1 MAU 2

Other digital,

CMC GPS analogue and

Other digital,

Actuator I/O Actuator I/O discrete inputs

analogue and

Processor B1 Processor B2

MODULES

MODULES

discrete inputs

Actuator I/O Actuator I/O

Processor A1 Processor A2

NIC/PROC 1 NIC/PROC 2

Control I/O 1 Control I/O 2

Custom I/O 1 Custom I/O 2

Power Supply Power Supply

Engine 1

analogue Engine 2

EEC EEC analogue

parameters Engine 1 Engine 2 parameters

Figure 1

AW139 MAU installation

© Crown copyright 2010 13

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

(caused, for example, by a power supply problem or a faults from member systems, conducts Built

self-diagnosed shut‑down), the data from both engines in Test (BIT) routines and compiles a Fault

remains available. Data received from the EECs is History Database (FHDB).

referred to as ‘digital’ engine data. For redundancy

●● Control Input/Output (CIO) module. This

purposes, some sensors are wired directly from the

supplies an interface for external input/output

engine sensors to each MAU, bypassing the EECs.

data on the ASCB and other data buses. It also

These parameters are referred to as ‘analogue’ engine

supplies an interface for the system display

parameters as they are acquired by the MAUs directly

controllers, the multifunction cockpit display

from the sensor. No 1 engine analogue parameters

units and CCD devices and additionally

are only connected to MAU 1 and No 2 engine to

contains audio warning circuitry for the crew

MAU 2. The MAUs digitise the analogue parameters

alerting system.

and transmit them on the ASCB. In the event of loss

of any analogue engine parameters, an ENG ANALOGUE ●● Custom Input/Output (CSIO) modules (one in

FAILURE message is displayed on the CAS. each MAU cabinet). This module performs a

similar function to the CIO, with more databus

Engine parameters are usually displayed on the MFD, transmitter/receivers. There are also a number

with the system always defaulting (on power up) to the of additional aircraft-specific inputs, including

digital source. Logic within the Display Units (DUs) analogue discretes and 28V dc. An example

will always attempt to select valid engine parameters would be the bag fire sensor, which is processed

from the ASCBs. In the event of a fault with the in each CSIO module in MAU 1 and MAU 2,

digital data, the display can be ‘forced’ into analogue CSIO1 and CSIO2, respectively.

mode by using the cursor control device (CCD) on the

MAU installation

cockpit pedestal to select a drop-down menu from the

Powerplant system and selecting ‘analog’ from the In order to meet the MAU installation requirements

options. for the short nose aircraft, the helicopter manufacturer

provided ducting that directed cooling air from two

2. Module description

scoops on the underside of the rear fuselage. The ducts

The modular design of the MAU provides flexibility in were asymmetrically disposed, such that the outlet of

installation of the Primus EPIC system. Customisation one of them was immediately underneath the MAU 2

of each airframe specific application is made possible cabinet. No outside air is used for cooling in the long

by adding or removing the appropriate modules. In nose MAU installation.

addition to the NIC/PROC, the MAU cabinets in

G-CHCV also contained the following modules which Honeywell specified the MAU installation requirements

were of relevance to the investigation: in an Installation Bulletin which details items such as

dimensional, cooling and environmental requirements.

●● Central Maintenance Computer (CMC) Part of this bulletin highlights that, when installed in the

Module. This contains the CMC function and airframe, the MAU must be protected against exposure

the data loading function. It collects active to water.

© Crown copyright 2010 14

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

Figure 2

AW139 MAU Cooling Duct Intake Scoops

MAU hardware qualification applying power within one hour. A further 15 minutes

is then allowed to warm up the equipment before

The environmental requirements for the MAU were

determining whether or not susceptibility exists. For

agreed between Honeywell, AgustaWestland and the

the water proofness tests, the manufacturer confirmed

certification authorities during system development.

that the MAU was powered and suffered no failures

These environmental requirements reference an RTCA

when the environmental testing was performed.

document DO160D, ‘Environmental Conditions and

Test Procedures for Airborne Equipment’, which The individual modules that are installed in each

defines a series of minimum standard environmental test MAU were not required to be tested separately.

conditions and applicable test procedures. Standards Honeywell applied a spray-on conformal coating

within DO160D are commonly adopted by airframe during manufacture which conferred a degree of water

manufacturers and recognised by airworthiness resistance. Whilst it is possible to provide a higher

authorities. level of protection, for example by dipping the circuit

boards into a container of the same liquid, it results in

Amongst the tests agreed were those for ‘humidity

them being more difficult to repair during service.

and water proofness’ (sic), for which the MAU was

found to be compliant. DO160D calls for the humidity Honeywell noted that no contamination-induced

test to be performed in a controlled test chamber but incidents had been reported in other Primus EPIC

without requirements for the equipment under test to be installations.

operational. Compliance is achieved by removing the

equipment from the test chamber after exposure and

© Crown copyright 2010 15

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

Baggage compartment fire detection in cruise at a radio height of 2,100 ft, on a magnetic

heading of 022°M and an indicated airspeed (IAS) of

The baggage area is monitored by a smoke detector

145 kt. At 1358:48 hrs, the outside air temperature

which is connected to both MAUs and the fire warning

(OAT) parameter began increasing from 7°C and,

panel. If a baggage fire warning is detected, the crew

over a 30-second period, reached 26°C, before failing

should be alerted by a red light on the fire warning

(characterised by a drop to 0°C (see Figure 4). No 2

panel, a BAG FIRE CAS message and audio warning.

engine oil temperature, the tail rotor gearbox (TGB)

The CAS warning will be displayed if either MAU

and intermediate gearbox (IGB) oil temperatures and

detects a trigger from the smoke detector, but all audio

No 2 hydraulic system temperature also exhibited this

warnings are generated by MAU 2. Figure 3 shows the

characteristic rise, followed by failure. For clarity,

system schematic diagram.

Figure 4 only shows the OAT and No 2 engine oil

Recorded information temperature.

The aircraft was fitted with a Multi Purpose Flight At the same time as the loss of these temperature

Recorder (MPFR) which combined the functions of both parameters, data was lost from one of the two radio

flight data and cockpit voice recording. The MPFR was altimeters, No 2 engine ITT and, 20 seconds later, the

downloaded by the operator and provided to the AAIB No 2 engine power index. The loss of No 2 ITT caused

for analysis. The MAU also contained a Fault History the ENG ANALOGUE FAILURE warning and, five seconds

Database (FHDB) which logged detected failures for later, the VNE MISCOMPARE warning was recorded.

maintenance purposes. Due to late notification of the

event, the voice recording was overwritten. VNE is calculated as a function of pressure altitude and

temperature. When there is a failure in the OAT probe,

Data recorded by the MPFR is supplied by MAU 2, the VNE computation is based on the current pressure

which transmits the same data as shown on the altitude and the largest temperature value in a VNE

commander’s displays. It indicated that G-CHCV was ‘lookup’ table. A VNE MISCOMPARE CAS warning is

Smoke FIRE

Detector WARNING

PANEL

MAU 1 MAU 2

Audio

BAG FIRE Warning

CAS MESSAGE

Figure 3

The baggage compartment fire detection system schematic

© Crown copyright 2010 16

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

Figure 4

G-CHCV MPFR recorded parameters

generated when the VNE calculated by MAU 1 differs data shows loss of further engine analogue parameters

from that calculated by MAU 2. and the failure of No 2 ADC (Air Data Computer

No 2). This loss of data appeared to be reversible, with

At 1401 hrs, G-CHCV turned back towards North Denes some data apparently recovering but then failing again

and began a descent from 2,100 ft to 1,600 ft. Just over (Figure 4).

five minutes later, the first baggage fire warning was

recorded. The descent then continued, with G-CHCV Also recorded were more ENG ANALOGUE FAILURE and

levelling off at a radio altitude of approximately 200 ft VNE MISCOMPARE messages and a total of 25 separate

and an IAS of 110 kt. During this descent, the recorded baggage fire warnings. No loss of digital engine

© Crown copyright 2010 17

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

parameters was recorded and it was not possible 2. An aircraft had been left out overnight

to ascertain whether the digital or analogue engine during which there had been torrential rain.

parameters had been selected for display on the MFD. During the flight, whilst in IMC, the fdr

There is a flight recorder parameter which should fail and cvr fail CAS messages appeared

indicate this but, after investigation it was found not to followed shortly afterwards by eng

be working. The manufacturer has confirmed that this analogue fail and vne miscompare.

will be rectified in the next MAU software standard. The warnings disappeared after a short time

but later the bag fire message appeared for

An analysis of the CSIO2 module FHDB from approximately 10 seconds although there

14 December 2008 up to the incident flight did not were no signs of fire or smoke. Later in the

reveal any other VNE MISCOMPARE, ENG ANALOGUE flight, the servo 2 message illuminated and,

FAILURE or baggage fire warnings. Recorded analogue later still, a number of messages appeared

data from MAU1 revealed that at 1433:32 hrs, there including: nose door; eng analogue

was a momentary loss of No 1 engine Ng and Nf and the fail; vne miscompare; 1 fuel low; hook

analogue Nr calculated by MAU 1. This loss of data arm; float arm. While dealing with these

lasted for between one and seven seconds and could indications, the crew noticed that the aircraft

not be explained by the manufacturer. All other failed had descended from 8,000 to 4,700 ft. The

parameters and spurious warnings were attributed to autopilot was engaged but none of the flight

data generated by the MAU 2 CSIO card. director modes that had been selected were

annunciated on the PFD. While climbing,

Similar incidents to AgustaWestland AW139

following this uncommanded descent, the

helicopters

CAS displayed 1 eng out followed by

During the investigation of the incident to G-CHCV, 2 eng out. Other indications confirmed

the AAIB became aware of three similar incidents: the engines were still functioning. The

crew saw the ground through some breaks

1. An aircraft was transiting at 3,000 ft in in the cloud and were able to descend and

IMC when a bag fire message appeared make a visual approach to a nearby airport.

on the CAS. There was no red light on the A number of CAS messages remained on

fire control panel. About 10 to 15 seconds the MFD until after landing.

later a list of cautions appeared, including

an amber 2 mau indication on the PFD. 3. An aircraft had made an approach to a

The crew began a descent during which hospital in poor weather and was climbing

the baggage fire indication disappeared. in IMC during a go-around from a missed

The crew declared a PAN and carried out approach. The pilot saw multiple CAS

the actions in the emergency checklist, messages and noticed that the airspeed,

following which the aircraft landed without altitude and radio altitude had disappeared

further incident. No evidence of fire was from his PFD. He switched No 1 ADS

found during the subsequent inspection. information to his PFD, which restored the

© Crown copyright 2010 18

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

lost parameters, declared a PAN and decided fault history database (FHDB) generated by the Central

to fly another approach. While climbing to Maintenance Computer (CMC) was downloaded and

2,500 ft, he switched guidance controllers was found to contain a number of continuous failure

and re-engaged the heading and altitude entries. This, together with data from the MPFR,

acquire modes, confirming that the correct was reviewed by Honeywell, who advised removal

annunciations appeared on the PFD. He of the NIC/PROC, power supply module and the

began to programme the flight management CSIO card from MAU 2 and these were despatched

system for a further approach when he was to the manufacturer’s facility. There, an examination,

told by the crewman that the aircraft was together with some initial tests, was conducted under

approaching 3,000 ft. The pilot re-selected the auspices of a local FAA official, who was appointed

2,500 ft and noticed that a rate of descent of to look after the AAIB’s interests.

750 ft/min was being shown on the PFD. He

began to review the CAS messages with the The power supply module was found to be clean and

crewman and saw that failures were indicated functioned correctly on test. Similarly, no problems

in the following systems: electrical, fuel were found with the NIC/PROC module. However,

and hydraulic; flight management; weather inspection of the CSIO2 card revealed that it was

radar; flight control unit and autopilot; GPS contaminated with dirt and debris. In addition there

and other avionics and aid data. When he was evidence of corrosion with what appeared to be

looked back at the PFD, the pilot saw that copper oxide on the pins of some of the circuit card

the aircraft was approaching 3,300 ft. He components. Figures 5a and 5b show photographs of

regained control and flew the approach but, the module and an example of the corrosion, the latter

once again, was unable to land due to the being from one of the Australian incident helicopters.

weather. He then undertook a manually It was then decided to conduct a series of tests on this

flown diversion to a nearby airport where he module on Honeywell’s MAU system test bench.

landed successfully.

Tests on the CSIO2 circuit board

Initial investigation of the G-CHCV modules

The presence of contamination and corrosion on the

As noted earlier, no evidence of a fire was found after CSIO2 card strongly suggested that moisture had been

the aircraft had landed. The aircraft was subsequently present on the board during service and, thus, may

powered up electrically and the systems functioned have been responsible for the incident to G-CHCV,

normally, with no repeat of the multiple failure although no indications of water were apparent on the

indications. MAU modules after the event. However, during the

investigations of the Australian incidents, water was

MAU 2 was removed from the aircraft, which allowed found to be present in and around the MAU cabinets.

the associated wiring and connectors to be inspected Accordingly, it was decided to examine the behaviour

for damage; no defects were found. The MAU 2 of the CSIO2 card under damp conditions by subjecting

modules were then removed and visually inspected for it to a water spray during operation.

water damage, overheating, or any other defect. The

© Crown copyright 2010 19

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

(Photo: Honeywell)

Figure 5a

A CSIO2 module

(Photo: Honeywell)

Figure 5b

Example of corrosion on another CSIO2 processor

© Crown copyright 2010 20

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

Honeywell examined the CSIO2 module components data represented everything that was available to the

with a view to establishing the input/output functions software responsible for such functions as the autopilot

that were implicated in generating the invalid data that and cockpit displays.

was responsible for the multiple CAS messages. Table 1

lists the signal inputs that were investigated. The CSIO2 card operated normally, with no CAS

messages. Thus it was considered that the contamination

The tests were conducted at a Honeywell facility in the and corrosion had little or no effect when dry. The

presence of the AAIB and the helicopter manufacturer. system was allowed to reach its working temperature,

The MAU system test bench was linked to an AW139 following which a short water spray, using deionised

flight deck, which effectively functioned as a fixed water, was applied to the area of the board that included,

base simulator. The system was loaded with the same amongst other components, the central processing unit

application software standard which was installed on (CPU), which had the most corrosion. This resulted

G-CHCV and the CSIO2 card was mounted on an in a number of amber CAS messages, including vne

extender board, which allowed it to be visible and miscompare, although this subsequently disappeared.

accessible during test. The bench was then powered The OAT indication disappeared, followed by an ads 2

up so that any cockpit effects could be monitored. failure message. This was accompanied by the loss of

All the ASCB data generated during the tests was altitude, airspeed and vertical speed indications from the

recorded and later analysed by Honeywell. This right hand cockpit display. These were replaced with

Table 1

© Crown copyright 2010 21

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

red Xs, as occurred on the incident flight. In addition, meaningless. However, it was decided to direct the

some engine analogue indications failed, although the final spray application in between the two circuit card

digital parameters remained. assemblies that comprised the CSIO2 module. This

After a few minutes the cockpit display indicated a resulted in three amber CAS captions, two of which

slow decrease in altitude; there was no autopilot audio subsequently disappeared. Then eng 1 out, eng 2

warning, although there was a chime. The observed out messages appeared, together with the associated

effect was assumed to be the result of the loss of the audio warning. There was also a momentary bag fire

No 2 ADS and appeared to mirror closely one of the warning. The module was then dried out but failed

Australian events. The problem was rectified by to reset, which suggested that permanent damage had

coupling the Flight Director to No 1 ADS. occurred as a result of the repeated water applications.

This was confirmed on a subsequent attempt to subject

A second water spray was then applied to the CSIO2 the module to an automated test, when the associated

card, this time slightly away from the CPU, in the area software failed to load.

of a bank of multiplexers. This produced no additional

effects. A heat gun was used to dry the module, but An ‘as new’ CSI02 card was installed in the test bench

none of the displayed faults unlatched. However, after MAU and a water spray applied to the general area of

MAU 2 was powered down and then restarted, all the CPU. After a few minutes the engine analogue

indications returned to normal. data failed and an ads2 message appeared, although all

indications subsequently recovered to normal.

Next, the spray was applied to the lower half of the CPU,

with the remainder of the board masked off with a piece It was considered that the recovery of the replacement

of card. This produced no cockpit effects, so the test was card, as it dried out, reflected the fact that the

repeated with the complete CPU exposed, again with no deionised water was of low conductivity, whereas, the

effects. Two more sprays were applied close to the CPU, contaminated components on the card from G-CHCV

the second of which provoked three amber CAS messages became conductive when wet, and remained so for

and one red warning, mgb oil temp. This represented considerably longer than with deionised water alone.

the main gearbox over-temperature discrete, which was

processed by the CSIO2 module. It was noted that the Finally, a fire detector sensor, which comprised a

MGB temperature indication had remained within the photoelectric device that operated on the light-scattering

green, ie normal, area of the indicating scale. principle, was tested by spraying a water mist at it. This

produced the appropriate warning when connected to a

A reset operation was carried out in order to clear serviceable CSIO module.

the CAS captions, followed by two additional spray

Analysis of tests

applications. This produced the same captions as in

the previous test, plus a drifting OAT 2 indication and After the tests, Honeywell conducted a detailed analysis

the loss of some analogue indications. By this time of the extensive ACSB data, which was compared with

the card was wet from the repeated spray applications, the FHDB data from G-CHCV and the other incidents.

with the effects most probably becoming increasingly The key findings are summarised as follows:

© Crown copyright 2010 22

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

1. The tests reproduced the loss of engine analogue 4. The OAT is used by the ADS, which in turn

parameters, together with instances where is used by the AFCS. If it determines that

digital engine parameter group data was any differences between the ADS1 and

recorded as ‘invalid and stale’. However, ADS2 signals exceed monitoring thresholds,

there was no effect on displays, as valid data the AFCS declares that the ADS data is

continued to be supplied via MAU1. It was invalid. This results in the cancellation of

noteworthy that no similarly invalid digital Flight Director modes and the removal of the

engine parameter data was observed on the associated mode annunciations and guidance

G-CHCV recording, although there was the cues from the PFD. Other ADS signals

loss of engine analogue parameters. monitored by the AFCS include Pressure

Altitude, Altitude Rate and Calibrated

2. The data indicated that the CSIO2 module

Airspeed.

triggered the CAS bag fire caption after

water was sprayed between the two circuit

Finally, the investigation did not provide an explanation

boards of the module. Additional messages

for the apparent loss of digital engine data reported by the

were generated simply as a result of water

crew of G-CHCV. During the tests, digital data remained

shorting out the ‘Bag Fire 28V/Open

available at all times, although the analogue failures

Discrete’ signal. However, it should be noted

were reproduced. Honeywell speculated that a graphical

that the warning light on the Fire Control

generation function software fault within the cockpit

Panel is not connected to CSIO2 (or any

display units may have displayed the digital data as failed,

other MAU module) and is only illuminated

when in fact it was valid. Alternatively, a similar software

following activation of the bag fire sensor

fault, either within the display units or the NIC/PROC,

(see Figure 3).

may have displayed analogue data despite digital data

3. The slow increase of the OAT 2 parameter seen having been selected. However, Honeywell considered

in the G-CHCV MPFR data was also reflected these scenarios to be unlikely in the light of a lack of other

in the ASCB data from the tests. One possible indications of hardware or software failures.

scenario was that failures in the analogue

Examination of other MAU modules

processors resulted in a loss of calibration,

causing large changes in the calculated value. In addition to the three incidents referred to earlier,

The software imposes a heavy filter on this other similar incidents came to light during the course

value in order to damp out small fluctuations. of the investigation. Honeywell was also aware of a

Thus it would, in Honeywell’s estimation, number of CSIO modules that their service centres

take around 30 seconds for the parameter to had reported as displaying evidence of corrosion,

ramp up to a value where it became invalid, although without associated incidents. Many of the

when the OAT display consists of a series of modules were examined in Honeywell laboratories,

dashes. This represented a similar time period which included energy dispersive X-ray analysis of the

to the G-CHCV event, following which the corrosion products. A high proportion was found to

signal was lost. contain elements such as sodium and chlorine, which

© Crown copyright 2010 23

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

was indicative of operation in maritime environments. a baggage fire warning, ie CAS message, red light on

Other contaminants were consistent with dust and dirt Fire Panel and audio warning.

being blown into the MAU cabinet.

Finally, as part of a product improvement update,

The investigation additionally found that CIO and power Honeywell upgraded the Primus EPIC software to

supply modules had been affected by corrosion, although Phase 5 software in late 2009. This upgrade included

there had been no resulting incidents. All the affected correcting the problem of the MPFR not recording

modules were located in MAU 2, with their location which engine parameters, analogue or digital, have been

close to a cabinet vent which was, in turn, near to the selected for display.

cooling duct outlet.

Analysis

Safety action 1. Incident causes

In April 2009 AgustaWestland issued a Service Bulletin, The incidents involving G-CHCV and other helicopters

Bollettino Tecnico BT AW139-166, which applied to occurred as a result of corrosion on the CSIO2 module

short nose configuration helicopters. The purpose of installed in MAU 2. The corrosion had affected

the BT was twofold. Firstly, the power supply, CIO numerous pins on the components of the circuit board

and CSIO modules of both MAUs were to be inspected assemblies, which shorted out when they became

for evidence of corrosion. The BT contained guidance conductive under the action of moisture, which in turn

material on accept/reject criteria, in order to assist resulted in corrupted data being processed. In the case

in this process. Secondly, the cooling air duct was of G-CHCV, the resultant cascade of spurious warnings

modified so that the outlet was moved away from the caused confusion on the flight deck as, in addition to

lower surface of the MAU 2 cabinet. the loss of ADS related information, the crew had

difficulty in assessing the operational state of other

This BT was applicable to 168 short nose AW139 aircraft systems. The bag fire warning had a particular

helicopters and, at March 2010, had been completed on significance, as it raised the possibility of having to

137, not applied on one, with no information available ditch, with the attendant risks to the aircraft and its

on the remaining 30. Embodiment of this BT is not occupants. Had the aircraft been equipped with the

mandatory. onboard video package, as installed in the SAR variant,

the airframe mounted cameras could have been used to

In the case of the bag fire warnings, the absence of inspect for evidence of fire. Other incidents involved

the red light on the fire warning panel indicated that uncommanded descents, following disengagement of

it had not been triggered by the smoke detector. The the autopilot and the potential risk to the aircraft with a

investigation indicated that the warnings were generated busy, possibly distracted crew dealing with other CAS

by a spurious signal in CSIO2. warnings. In all cases, upon reset on ground, the system

recovered and the faults could not be reproduced during

Shortly after this incident, the Flight Manual was

on-aircraft troubleshooting.

amended so that the flight crew should only take

action if all three indicators are present in the event of

© Crown copyright 2010 24

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

The nature of the occurrences, together with the detailed the flight and subsequently was not reselected to digital.

investigation conducted by Honeywell in support of the However, the crew did not recall having changed the

investigation, served to underline the complexity and engine data display during the flight.

high degree of integration of the Primus EPIC system.

2. MAU installation and validation

In particular, the level of integration resulted in an

interdependency of the aircraft systems which rendered During the course of the investigation it became

them vulnerable to what was, essentially, a common apparent that the issue of corrosion was widespread,

mode failure. This was abundantly illustrated by the although in many cases it had not progressed to the stage

fact that information from the engines, drive train, where it caused an incident. Whilst the corrosion had

air data, fire detection and other systems is processed also affected other modules, the incidents invariably

by the CSIO2 module; the redundancy conferred by stemmed from the CSIO module in MAU 2. The source

multiple data paths is somewhat negated by this single of the corrosion was attributed to moisture in unfiltered

point module. cooling air, which was drawn from a duct intake on

the fuselage underside and discharged directly onto

The tests did not explain the apparent loss of digital the MAU 2 cabinet, with the affected modules being

engine data reported by the crew of G-CHCV; digital located close to the cabinet vents.

data remained available during the tests, although many

of the analogue parameters had failed. The MPFR data The corrosion and the ensuing incidents are typical of

from the incident similarly recorded no loss of digital development problems that can occur on new or, in

data, although it was not possible to determine whether this case, relatively new, aircraft types. This was the

the digital or analogue displays had been selected. first helicopter application for the Primus EPIC, which

Honeywell investigated the possibility that a potential differed from its previous, fixed-wing installations

software failure could result in the cockpit display in that unfiltered, non-conditioned air was used for

units and/or the NIC/PROC not displaying digital data cooling. This, in combination with the helicopter’s

or displaying it as having failed, despite there being predominant operation at low altitudes in salt-laden air,

valid engine data on the ASCB. However, there were generated the conditions that resulted in corrosion on the

no other indications of such failures, which would have module components. With the benefit of hindsight, it

been in addition to, and coincident with, the failures on might have been beneficial if the avionic and helicopter

the CSIO2 module. Despite the fact that the NIC/PROC manufacturers had been aware of such a possibility and

was changed following the incident, it is considered developed a temporary module inspection programme

that a failure of this nature was unlikely. for the early years of service. Honeywell service stations

were noting evidence of corrosion on modules returned

The cockpit displays would have defaulted to digital for repair and had recently initiated an investigation.

data when the helicopter was powered up. Changing to

analogue data requires the use of a cursor control device As part of the certification process, the MAU

and, hence, is unlikely to have been accomplished had demonstrated compliance with the specified

accidentally by one of the crew. A potential explanation environmental standards; some confidence in the

is that the analogue display had been selected earlier in process has been demonstrated in that the incidents

© Crown copyright 2010 25

AAIB Bulletin: 10/2010 G-CHCV EW/C2008/12/03

discussed here have not occurred on any other Primus of equipment, in terms of loss of essential parameter

EPIC-equipped aircraft. With complex equipment it is indications and spurious system warnings.

difficult to predict, using failure mode/effect analyses,

the full range of failure modes and their associated After extensive testing and investigation, it has been

indications. Honeywell had anticipated the common concluded that the Primus EPIC system MAU installed

mode failure of moisture ingress in the MAU cabinets on the short nose version AW139 is susceptible to

and had addressed this by means of the requirements in failures in the event of moisture ingress. Although

the Installation Bulletin. measures have been introduced to remove a likely

source of moisture, the modification to the ducted air

Environmental testing is unlikely to generate corrosion supply to MAU 2 is not mandatory. As a result, the

and its associated products. However moisture following Safety Recommendation is made:

penetration may well produce the sort of problems

Safety Recommendation 2010-077

likely to occur in service, a fact that was demonstrated

during this investigation when a ‘new’ CSIO module It is recommended that the European Aviation Safety

was subjected to water spray tests. Agency mandate the embodiment of the AgustaWestland

Bollettino Tecnico BT AW139-166 on all short nose

Safety Recommendation

versions of the AgustaWestland AW139.

In the event of a common mode failure in part of an

integrated avionic system, there can be potentially more

serious consequences, relative to earlier generations

© Crown copyright 2010 26

Potrebbero piacerti anche

- The Crash of an Alaska Airlines Boeing 727 Juneau, Alaska September 4, 1971Da EverandThe Crash of an Alaska Airlines Boeing 727 Juneau, Alaska September 4, 1971Nessuna valutazione finora

- 223 05S16 PDFDocumento8 pagine223 05S16 PDFmycopteraviationNessuna valutazione finora

- Mandatory: Bollettino TecnicoDocumento7 pagineMandatory: Bollettino TecnicomycopteraviationNessuna valutazione finora

- BT139394EDocumento23 pagineBT139394Ehin wongyai100% (1)

- S-76 Barrier Filter PamphletDocumento20 pagineS-76 Barrier Filter PamphletJoness9Nessuna valutazione finora

- Aerospace Actuators 2: Signal-by-Wire and Power-by-WireDa EverandAerospace Actuators 2: Signal-by-Wire and Power-by-WireNessuna valutazione finora

- Ewis Job CardDocumento4 pagineEwis Job CardNikolaos KechagiasNessuna valutazione finora

- BT, AD Forms StatusDocumento43 pagineBT, AD Forms StatusRachyita SinghNessuna valutazione finora

- Boeing 787 and Lithium Ion Battery FailureDocumento3 pagineBoeing 787 and Lithium Ion Battery Failuresenkum812002Nessuna valutazione finora

- Obogs System Training: Life SupportDocumento30 pagineObogs System Training: Life SupportKim GomezNessuna valutazione finora

- 2012-05-09 Apache Maintenance ManualDocumento5 pagine2012-05-09 Apache Maintenance ManualScott McLainNessuna valutazione finora

- Advanced Light HelicopterDocumento20 pagineAdvanced Light HelicopterChandrashekar HiremathNessuna valutazione finora

- 1 Aerodynamics Flight ControlsDocumento87 pagine1 Aerodynamics Flight ControlsAnonymous OZxPZgFcNessuna valutazione finora

- AFCSDocumento23 pagineAFCSFaizin Khaniff100% (1)

- Sb1000 Rev BDocumento4 pagineSb1000 Rev BmycopteraviationNessuna valutazione finora

- FS - M - Sikorsky S 70A L UH 60 A L Maintenance PracticalDocumento1 paginaFS - M - Sikorsky S 70A L UH 60 A L Maintenance PracticalAustin BanttariNessuna valutazione finora

- Component Symbols: Pressure TransmitterDocumento21 pagineComponent Symbols: Pressure TransmitterItgeltbayarNessuna valutazione finora

- Turboshaft Engines: 1,700-2,000 SHP ClassDocumento2 pagineTurboshaft Engines: 1,700-2,000 SHP Class唐波Nessuna valutazione finora

- Goodrich Ecu OspsDocumento4 pagineGoodrich Ecu OspsturboshaftNessuna valutazione finora

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsDa EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNessuna valutazione finora

- Modeling Aircraft Fuel ConsumptionDocumento123 pagineModeling Aircraft Fuel ConsumptionTATATAHERNessuna valutazione finora

- 05 10Documento22 pagine05 10gayathrisicwai100% (1)

- Aircrew Standards Manual FY2015 V1Documento211 pagineAircrew Standards Manual FY2015 V1Anonymous Pb39klJ100% (1)

- ARINC 429 CommentaryDocumento22 pagineARINC 429 CommentaryIsaac MoraNessuna valutazione finora

- Aeroflex IFR6000 Test Set Operations Manual 6093Documento258 pagineAeroflex IFR6000 Test Set Operations Manual 6093chrismosf100% (1)

- SB 139487Documento26 pagineSB 139487mycopteraviationNessuna valutazione finora

- 1SNEMAG007 Complet BafDocumento27 pagine1SNEMAG007 Complet BafageeshpkNessuna valutazione finora

- EC 130 B4-02 Intro To FM and LimitsDocumento39 pagineEC 130 B4-02 Intro To FM and LimitsMZJ100% (1)

- Avionics Avidyne MFDDocumento83 pagineAvionics Avidyne MFDEngr Rana Ali Safian100% (1)

- Axel Humpert, Clive Schley Eurocopter Deutschland GMBH Donauwoerth, GermanyDocumento10 pagineAxel Humpert, Clive Schley Eurocopter Deutschland GMBH Donauwoerth, GermanyVishnu SankarNessuna valutazione finora

- Ec130 MFP Pilot - PoiDocumento4 pagineEc130 MFP Pilot - PoiJessie DinoyNessuna valutazione finora

- Type Ratings FaaDocumento14 pagineType Ratings FaaricardotorresNessuna valutazione finora

- 12 - Rads SatDocumento277 pagine12 - Rads Satcleber100% (1)

- Technical Data: EurocopterDocumento59 pagineTechnical Data: EurocopterBalaji KNessuna valutazione finora

- A330-200/300 Technical Training Manual Maintenance Course - T1+T2 (LVL 2&3) (Ge Cf6/Us) CommunicationsDocumento176 pagineA330-200/300 Technical Training Manual Maintenance Course - T1+T2 (LVL 2&3) (Ge Cf6/Us) CommunicationsmarkNessuna valutazione finora

- Flight Control SystemDocumento15 pagineFlight Control SystemArcer 97100% (1)

- ISAT-200A User Guide: DOC1037 Document Revision 01.001Documento29 pagineISAT-200A User Guide: DOC1037 Document Revision 01.001kamalmatsaidNessuna valutazione finora

- Aviation Structural Mechanic S 3 2Documento397 pagineAviation Structural Mechanic S 3 2jjonasNessuna valutazione finora

- 79ce95a9 5056 A318 A83f426857b0b89fDocumento238 pagine79ce95a9 5056 A318 A83f426857b0b89fJacob Jack YoshaNessuna valutazione finora

- Aircraft Gas Turbine Engine TestingDocumento7 pagineAircraft Gas Turbine Engine Testingfazelamjad70Nessuna valutazione finora

- Topic: Reference: - LTN Précis, Internet Desired Teaching Objectives (Dtos)Documento9 pagineTopic: Reference: - LTN Précis, Internet Desired Teaching Objectives (Dtos)falcon21152115Nessuna valutazione finora

- DP4100 Operating Instructions 04.2005Documento28 pagineDP4100 Operating Instructions 04.2005Richard Thodé JrNessuna valutazione finora

- Agardag300 RevoDocumento31 pagineAgardag300 RevocmpmarinhoNessuna valutazione finora

- Ata 34Documento149 pagineAta 34ouss.cfpncNessuna valutazione finora

- Av-15 Avionics Ramp TesterDocumento1 paginaAv-15 Avionics Ramp TesterAfandi Mohamad ZainiNessuna valutazione finora

- EC-155B1 Complimentary Flight Manual - Section 7 Description and SystemsDocumento118 pagineEC-155B1 Complimentary Flight Manual - Section 7 Description and SystemsFlightdispatch Airjuan100% (1)

- Aw139 17 088Documento9 pagineAw139 17 088ttppNessuna valutazione finora

- EASA OEB Final Report Eurocopter AS365 EC 155 B B1!02!08022012Documento41 pagineEASA OEB Final Report Eurocopter AS365 EC 155 B B1!02!08022012Sezgin BayrakNessuna valutazione finora

- Aircraft APU Emissions at Zurich AirportDocumento18 pagineAircraft APU Emissions at Zurich AirportAnonymous TDyZWu22S3Nessuna valutazione finora

- Chapter 76 - Engine Controls: BHT-206L4-MM-9Documento22 pagineChapter 76 - Engine Controls: BHT-206L4-MM-9Raisa RabeyaNessuna valutazione finora

- Tp6980e 4 2010Documento32 pagineTp6980e 4 2010oguier100% (1)

- E-680 - Revision 37 - 19.03.2017Documento201 pagineE-680 - Revision 37 - 19.03.2017Rafael Angel DaboinNessuna valutazione finora

- Point A: SPA-400 - King KMA 20 Audio Panel Installation Wiring DiagramDocumento1 paginaPoint A: SPA-400 - King KMA 20 Audio Panel Installation Wiring DiagramAdrian TodeaNessuna valutazione finora

- Instruments (R)Documento203 pagineInstruments (R)Nguyên PhạmNessuna valutazione finora

- Flight Standardization Board (FSB) Report: U.S. Department of Transportation Federal Aviation AdministrationDocumento25 pagineFlight Standardization Board (FSB) Report: U.S. Department of Transportation Federal Aviation AdministrationLaura MelloNessuna valutazione finora

- 2.1 Introduction To Flight Control SystemsDocumento38 pagine2.1 Introduction To Flight Control SystemsFanhang ZhangNessuna valutazione finora

- Alert Service Bulletin: ASB EC135-62A-029Documento10 pagineAlert Service Bulletin: ASB EC135-62A-029fredson mirandaNessuna valutazione finora

- 1AW139 CMP Initial Pages 31.10.2012Documento5 pagine1AW139 CMP Initial Pages 31.10.2012Fayssal BkzNessuna valutazione finora

- WX 10 Stormscope ManualDocumento3 pagineWX 10 Stormscope Manualalex castro0% (1)

- (Type Here) : P H o N E: 4 8 0 - 8 2 4 - 2 7 0 0Documento18 pagine(Type Here) : P H o N E: 4 8 0 - 8 2 4 - 2 7 0 0arun RajannaNessuna valutazione finora

- ATR BlackFriday SaleDocumento1 paginaATR BlackFriday Salearun RajannaNessuna valutazione finora

- E85001-0239 - Control Relay ModulesDocumento6 pagineE85001-0239 - Control Relay Modulesarun RajannaNessuna valutazione finora

- CCF 2020Documento11 pagineCCF 2020arun RajannaNessuna valutazione finora

- 05 - Annex A Technical ProposalDocumento7 pagine05 - Annex A Technical Proposalarun Rajanna100% (1)

- E85001-0241 - Input Modules PDFDocumento4 pagineE85001-0241 - Input Modules PDFarun RajannaNessuna valutazione finora

- CCF 2020Documento11 pagineCCF 2020arun RajannaNessuna valutazione finora

- Input Modules: Siga-Mm1 & Siga-WtmDocumento4 pagineInput Modules: Siga-Mm1 & Siga-Wtmarun RajannaNessuna valutazione finora

- Potomac Aviation, Inc.:, Reagan National Airport - Hangar 7, Washington, DC 20001 USADocumento2 paginePotomac Aviation, Inc.:, Reagan National Airport - Hangar 7, Washington, DC 20001 USAarun RajannaNessuna valutazione finora

- Potomac Aviation, Inc.:, Ronald Reagan National Airport, Hangar 7, Washington, DC 20001 USADocumento2 paginePotomac Aviation, Inc.:, Ronald Reagan National Airport, Hangar 7, Washington, DC 20001 USAarun RajannaNessuna valutazione finora

- Part or Material Certification Form: ISO 9001:2015 QMS 06531Documento1 paginaPart or Material Certification Form: ISO 9001:2015 QMS 06531arun RajannaNessuna valutazione finora

- C 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) MumbaiDocumento2 pagineC 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) Mumbaiarun RajannaNessuna valutazione finora

- Potomac Aviation, Inc.:, Reagan National Airport - Hangar 7, Washington, DC 20001 USADocumento2 paginePotomac Aviation, Inc.:, Reagan National Airport - Hangar 7, Washington, DC 20001 USAarun RajannaNessuna valutazione finora

- Potomac Aviation, Inc.:, Reagan National Airport - Hangar 7, Washington, DC 20001 USADocumento2 paginePotomac Aviation, Inc.:, Reagan National Airport - Hangar 7, Washington, DC 20001 USAarun RajannaNessuna valutazione finora

- The United KingdomDocumento1 paginaThe United Kingdomarun RajannaNessuna valutazione finora

- Ec120 Maintenance Manual PDFDocumento2 pagineEc120 Maintenance Manual PDFarun Rajanna0% (2)

- Information Notice: Subject: Fuel Fuel Quality (Was Previously Service Letter No. 1255-28-95)Documento3 pagineInformation Notice: Subject: Fuel Fuel Quality (Was Previously Service Letter No. 1255-28-95)arun RajannaNessuna valutazione finora

- Ec120 PDFDocumento14 pagineEc120 PDFarun RajannaNessuna valutazione finora

- h1 Aw139 Brochure Final Nov 2017Documento8 pagineh1 Aw139 Brochure Final Nov 2017arun RajannaNessuna valutazione finora

- ParlistDocumento8 pagineParlistarun Rajanna100% (1)

- 2017 AugustaDocumento2 pagine2017 Augustaarun RajannaNessuna valutazione finora

- HECTOR BrochureDocumento43 pagineHECTOR BrochurenegsNessuna valutazione finora

- IFSSO Newsletter Jul-Sep 2010Documento2 pagineIFSSO Newsletter Jul-Sep 2010rjotaduranNessuna valutazione finora

- 353 Version 7thDocumento1 pagina353 Version 7thDuc NguyenNessuna valutazione finora

- Upadhyayaetal TrueliqtrigcurveDocumento14 pagineUpadhyayaetal TrueliqtrigcurveVetriselvan ArumugamNessuna valutazione finora

- M.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanDocumento43 pagineM.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanSSNessuna valutazione finora

- Presentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadDocumento14 paginePresentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadAndres EduardoNessuna valutazione finora

- Gics-In-India Getting Ready For The Digital WaveDocumento81 pagineGics-In-India Getting Ready For The Digital Wavevasu.gaurav75% (4)

- The Chulalongkorn Centenary ParkDocumento6 pagineThe Chulalongkorn Centenary ParkJack FooNessuna valutazione finora

- Verilog GATE AND DATA FLOWDocumento64 pagineVerilog GATE AND DATA FLOWPRIYA MISHRANessuna valutazione finora

- Model 900 Automated Viscometer: Drilling Fluids EquipmentDocumento2 pagineModel 900 Automated Viscometer: Drilling Fluids EquipmentJazminNessuna valutazione finora

- List of Bird Sanctuaries in India (State-Wise)Documento6 pagineList of Bird Sanctuaries in India (State-Wise)VISHRUTH.S. GOWDANessuna valutazione finora

- Manual TV Hyundai HYLED3239iNTMDocumento40 pagineManual TV Hyundai HYLED3239iNTMReinaldo TorresNessuna valutazione finora

- Carbonate Platform MateriDocumento8 pagineCarbonate Platform MateriNisaNessuna valutazione finora

- Iroquois Clothes and WampumDocumento3 pagineIroquois Clothes and Wampumapi-254323856Nessuna valutazione finora

- Thompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsDocumento49 pagineThompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsMike Cedersköld100% (5)

- TRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateDocumento4 pagineTRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateCarlo OlivarNessuna valutazione finora

- Earth and Life Science, Grade 11Documento6 pagineEarth and Life Science, Grade 11Gregorio RizaldyNessuna valutazione finora

- PMDG 737NGX Tutorial 2 PDFDocumento148 paginePMDG 737NGX Tutorial 2 PDFMatt HenryNessuna valutazione finora

- Retail Operations ManualDocumento44 pagineRetail Operations ManualKamran Siddiqui100% (2)

- Medical Equipment Quality Assurance For Healthcare FacilitiesDocumento5 pagineMedical Equipment Quality Assurance For Healthcare FacilitiesJorge LopezNessuna valutazione finora

- Carte EnglezaDocumento112 pagineCarte EnglezageorgianapopaNessuna valutazione finora

- Chapter I. Scope of Distributive Trade StatisticsDocumento11 pagineChapter I. Scope of Distributive Trade StatisticsNguyễn Hà Diệu LinhNessuna valutazione finora

- Pepperberg Notes On The Learning ApproachDocumento3 paginePepperberg Notes On The Learning ApproachCristina GherardiNessuna valutazione finora

- Measures For FloodsDocumento4 pagineMeasures For FloodsMutsitsikoNessuna valutazione finora

- Region: South Central State: Andhra PradeshDocumento118 pagineRegion: South Central State: Andhra PradeshpaulinNessuna valutazione finora

- GSE v. Dow - AppendixDocumento192 pagineGSE v. Dow - AppendixEquality Case FilesNessuna valutazione finora

- Products ListDocumento11 pagineProducts ListPorag AhmedNessuna valutazione finora

- Weekly Lesson Plan: Pry 3 (8years) Third Term Week 1Documento12 pagineWeekly Lesson Plan: Pry 3 (8years) Third Term Week 1Kunbi Santos-ArinzeNessuna valutazione finora

- 377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1Documento7 pagine377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1zdravkamajkicNessuna valutazione finora

- Project On Mahindra BoleroDocumento35 pagineProject On Mahindra BoleroViPul75% (8)

- Work Permits New Guideline Amendments 2021 23.11.2021Documento7 pagineWork Permits New Guideline Amendments 2021 23.11.2021Sabrina BrathwaiteNessuna valutazione finora