Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dgu4520gr Ds en

Caricato da

ytnateTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dgu4520gr Ds en

Caricato da

ytnateCopyright:

Formati disponibili

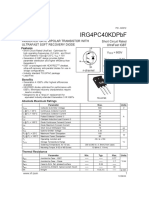

VBR(CES) = 450 V, IC = 20 A

N-channel Ignition IGBT

DGU4520GR Data Sheet

Description Packages

The DGU4520GR is 450 V IGBT with Zener diodes TO252

and gate resisters, and achieves an ignition coil drive

circuit without an external clamped circuit. The IGBT (4)

has low saturation characteristic, and can improve the

efficiency of the circuit.

Features

● Suitable for High Reliability Applications

● Complies with Automotive Quality Requirements

● Bare Lead Frame: Pb-free (RoHS Compliant) (1) (2) (3)

● Built-in Zener Diodes

● Built-in Gate Resisters

(2)(4)

● Low Saturation Voltage

● V(BR)CES ------------------------------------------------- 450 V (1) Gate

● IC----------------------------------------------------------- 20 A (2) Collector

(1)

● VCE(sat) -------------- 1.10 V typ. (VGE = 4.5 V, IC = 10 A) (3) Emitter

(4) Collector

Applications

(3)

● Ignition Coil Driver Circuits

Not to scale

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 1

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

Absolute Maximum Ratings

Unless otherwise specified, TA = 25 °C.

Parameter Symbol Conditions Rating Unit

Collector to Emitter Voltage VCE V(BR)CES V

Gate to Emitter Voltage VGE ±10 V

Continuous Collector Current IC TC = 25 °C 20 A

Power Dissipation PD TC = 25 °C 172 W

Self Clamped Inductive Switching See Figure 1 and 300

ESCIS mJ

Energy Equation (1).

VCC = 14 V,

Self Clamped Inductive Switching VGE = 5 V,

ISCIS 20 A

Current L = 1.5 mH,

RG = 1 kΩ

Reverse Avalanche Energy EAS(R) L = 6 mH 2000 mJ

Operating Junction Temperature TJ −40 to 175 °C

Storage Temperature TSTG −40 to 175 °C

Thermal Characteristics

Parameter Symbol Conditions Min. Typ. Max. Unit

Thermal Resistance

RθJC — — 0.87 °C/W

(Junction to Case)

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 2

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

Electrical Characteristics

Unless otherwise specified, TA = 25 °C.

Parameter Symbol Conditions Min. Typ. Max. Unit

Collector to Emitter Breakdown

V(BR)CES IC = 2 mA, VGE = 0 V 425 450 475 V

Voltage

Gate to Emitter Breakdown Voltage V(BR)GES IG = ±1 mA, VGE = 0 V ±10.0 ±11.5 ±13.0 V

Collector to Emitter Leakage

ICES VCE = 350 V, VGE = 0 V — — 100 µA

Current

Reverse Collector to Emitter

IECS VEC = 24 V — — 1.0 mA

Leakage Current

Gate to Emitter Leakage Current IGES VGE = ±5 V ±89 ±106 ±132 µA

Gate Threshold Voltage VGE(TH) VCE = 10 V, IC = 1 mA 1.40 1.75 2.10 V

VGE = 3.5 V,

— 1.16 1.39 V

IC = 10 A

VGE = 4.5 V,

— 1.10 1.32 V

IC = 10 A

TJ = 25 °C

VGE = 4.5 V,

— 1.25 1.50 V

IC = 15 A

VGE = 4.5 V,

— 1.39 1.67 V

Collector to Emitter Saturation IC = 20 A

VCE(sat)

Voltage VGE = 3.5 V,

— 1.15 1.50 V

IC = 10 A

VGE = 4.5 V,

— 1.08 1.40 V

I = 10 A

TJ = 150 °C C

VGE = 4.5 V,

— 1.31 1.77 V

IC = 15 A

VGE = 4.5 V,

— 1.58 2.13 V

IC = 20 A

Input Capacitance Cies — 1900 — pF

VCE = 10 V,

Output Capacitance Coes VGE = 0 V, — 460 — pF

f = 1.0 MHz

Reverse Transfer Capacitance Cres — 160 — pF

Turn-on Delay Time (Resistive) td(on)R Resistive load, — 1.3 — µs

Rise Time (Resistive) trR see Figure 2 — 3.8 — µs

Turn-off Delay Time (Inductive) td(off)L Inductive load, — 13.5 — µs

Fall Time (Inductive) tfL see Figure 3 — 2.7 — µs

Series Gate Resistor RG — 70 — Ω

Gate to Emitter Resistor RGE TJ = −40 to 175 °C 37.6 47.0 61.1(1) kΩ

(1)

Guaranteed by design.

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 3

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

Test Circuits and Waveforms

Conditions: VCE V(BR)CES

RG = 1 kΩ L

L = 1.5 mH

VCE VCC

VCC

RG t

IC IC

VGE DUT ISCIS

(IGBT)

(a) Test Circuit (b) Waveform

Figure 1. ESCIS Test Circuits and Switching Time Waveforms

(1)

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 4

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

VGE

10% t

Conditions:

VCE = 14 V VCE

VGE = 5 V

RG = 1 kΩ

RL = 1 Ω

RL

t

VCE IC

RG

5V

IC

90%

VGE DUT

(IGBT)

10%

t

trR

td(on)R

(a) Test Circuit (b) Waveform

Figure 2. Resistive Load Test Circuits and Switching Time Waveforms

VGE

90%

t

Conditions:

VCE = 300 V VCE

IC = 10 A

VGE = 5 V

RG = 1 kΩ L

L = 2 mH

VCE

t

IC

RG

5V

IC

90%

VGE DUT

(IGBT)

10%

t

tfL

td(off)L

(a) Test Circuit (b) Waveform

Figure 3. Inductive Load Test Circuits and Switching Time Waveforms

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 5

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

Rating and Characteristic Curves

60 60

VGE = 4.5 V

VGE = 5 V VGE = 4.5 V

VGE = 5 V

50 VGE = 4 V 50

VGE = 4 V

Collector Current, IC (A)

Collector Current, IC (A)

40 40

30 VGE = 3.5 V 30

VGE = 3.5 V

20 20

10 10

0 0

0 1 2 3 4 5 6 7 8 0 1 2 3 4 5 6 7 8

Collector–Emitter Voltage, VCE (V) Collector–Emitter Voltage, VCE (V)

Figure 4. Output Characteristics (TJ = −40 °C) Figure 5. Output Characteristics (TJ = 25 °C)

60 40

VGE = 5 V VCE = 5 V

50

VGE = 4.5 V

Collector Current, IC (A)

30

Collector Current, IC (A)

40

VGE = 4 V

30 20

VGE = 3.5 V

20

TJ = 175 °C

10

10 TJ = 25 °C

TJ = −40 °C

0 0

0 1 2 3 4 5 6 7 8 0 1 2 3 4

Collector–Emitter Voltage, VCE (V) Gate–Emitter Voltage, VGE (V)

Figure 6. Output Characteristics (TJ = 175 °C) Figure 7. Transfer Characteristics

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 6

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

1.10 1.20

Collector-Emitter Saturation, VCE (sat) (V)

Collector-Emitter Saturation, VCE (sat) (V)

1.18

1.05

VGE = 3.5 V

1.15

1.00 VGE = 3.5 V

1.13

VGE = 4.0 V

VGE = 4.0 V

0.95 1.10

1.08

0.90

VGE = 4.5 V VGE = 4.5 V

1.05

VGE = 5.0 V VGE = 5.0 V

0.85

1.03

0.80 1.00

-50 -25 0 25 50 75 100 125 150 175 -50 -25 0 25 50 75 100 125 150 175

Junction Temperature, TJ (°C) Junction Temperature, TJ (°C)

Figure 8. Saturation Voltage vs. Junction Figure 9. Saturation Voltage vs. Junction

Temperature (IC = 6 A) Temperature (IC = 10 A)

2.2 480

2.0 470

Collector Emitter Voltage (V)

Gate Threshold Voltage (V)

at VCE = 10 V, IC = 1 mA

at VGE = 0 V, IC = 2 mA

1.8 460

1.6 450

1.4 440

1.2 430

1.0 420

-50 -25 0 25 50 75 100 125 150 175 -50 -25 0 25 50 75 100 125 150 175

Junction Temperature, TJ (°C) Junction Temperature, TJ (°C)

Figure 10. Gate Threshold Voltage vs. Junction Figure 11. Collector–Emitter Voltage vs. Junction

Temperature Temperature

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 7

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

30 10000

RG = 1 kΩ , VGE = 5 V

VCC = 14 V, TJ = 25 °C

Inductive Switching Current, ISCIS (A)

25 Cies

20 1000

Capacitance (pF)

Coes

15

10 100

Cres

5 f = 1 MHz,

VGE = 0 V

0 10

0 2 4 6 8 10 0 10 20 30

Inductance, L (mH)

Collector–Emitter Voltage, VCE (V)

Figure 12. Inductive Switching Current vs. Figure 13. Capacitance Characteristics

Inductance

10 22

IC = 10 A, 20

VCE ≈ 14 V td(off)L + tfL

18

Gate -Emitter Voltage, VGE (V)

8

16 Inductive load,

Switching Time (ns)

IC = 10 A, VCE = 300 V,

14 VGE = 5 V, RG = 1 kΩ

6

12

10

4

8 td(on)R + trR

6

2 4

Resistive load,

2 IC = 12 A, VCE = 14 V,

VGE = 5 V, RG = 1 kΩ

0 0

0 10 20 30 40 25 50 75 100 125 150

Gate Charge, Qg (nC) Junction Temperature, TJ (°C)

Figure 14. Typical Gate Charge Figure 15. Switching Time vs. Junction

Temperature

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 8

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

10

Thermal Resistance (°C/W)

0.1

0.01 Single pulse,

VCE < 10 V

0.001

10 μ 100 μ 1m 10 m 100 m 1 10 100

Pulse Width (s)

Figure 16. Transient Thermal Resistance

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 9

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

Physical Dimensions

● TO252

NOTES:

- Dimensions in millimeters

- Bare lead frame: Pb-free (RoHS compliant)

- Excludes mold flash mold flash, protrusion or gate burrs.

- When soldering the products, it is required to minimize

the working time within the following limits:

Reflow

Preheat: 180 °C / 90 ± 30 s

Solder heating: 250 °C / 10 ± 1s, 2 times (260 °C peak)

Soldering Iron: 380 ± 10 °C / 3.5 ± 0.5 s, 1 time

Marking Diagram

S K DGU

45 20GR

Part Number

YWW XXXXX

Lot Number:

Y is the last digit of the year of manufacture (0 to 9)

WW is Work Week

XXXXX is the control number

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 10

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

DGU4520GR

Important Notes

● All data, illustrations, graphs, tables and any other information included in this document (the “Information”) as to Sanken’s

products listed herein (the “Sanken Products”) are current as of the date this document is issued. The Information is subject to any

change without notice due to improvement of the Sanken Products, etc. Please make sure to confirm with a Sanken sales

representative that the contents set forth in this document reflect the latest revisions before use.

● The Sanken Products are intended for use as components of electronic equipment or apparatus (transportation equipment and its

control systems, home appliances, office equipment, telecommunication equipment, measuring equipment, etc.). Prior to use of the

Sanken Products, please put your signature, or affix your name and seal, on the specification documents of the Sanken Products

and return them to Sanken. If considering use of the Sanken Products for any applications that require higher reliability (traffic

signal control systems or equipment, disaster/crime alarm systems, etc.), you must contact a Sanken sales representative to discuss

the suitability of such use and put your signature, or affix your name and seal, on the specification documents of the Sanken

Products and return them to Sanken, prior to the use of the Sanken Products. The Sanken Products are not intended for use in any

applications that require extremely high reliability such as: aerospace equipment; nuclear power control systems; and medical

equipment or systems, whose failure or malfunction may result in death or serious injury to people, i.e., medical devices in Class

III or a higher class as defined by relevant laws of Japan (collectively, the “Specific Applications”). Sanken assumes no liability or

responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any third party, resulting from

the use of the Sanken Products in the Specific Applications or in manner not in compliance with the instructions set forth herein.

● In the event of using the Sanken Products by either (i) combining other products or materials or both therewith or (ii) physically,

chemically or otherwise processing or treating or both the same, you must duly consider all possible risks that may result from all

such uses in advance and proceed therewith at your own responsibility.

● Although Sanken is making efforts to enhance the quality and reliability of its products, it is impossible to completely avoid the

occurrence of any failure or defect or both in semiconductor products at a certain rate. You must take, at your own responsibility,

preventative measures including using a sufficient safety design and confirming safety of any equipment or systems in/for which

the Sanken Products are used, upon due consideration of a failure occurrence rate and derating, etc., in order not to cause any

human injury or death, fire accident or social harm which may result from any failure or malfunction of the Sanken Products.

Please refer to the relevant specification documents and Sanken’s official website in relation to derating.

● No anti-radioactive ray design has been adopted for the Sanken Products.

● The circuit constant, operation examples, circuit examples, pattern layout examples, design examples, recommended examples, all

information and evaluation results based thereon, etc., described in this document are presented for the sole purpose of reference of

use of the Sanken Products.

● Sanken assumes no responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any third

party, or any possible infringement of any and all property rights including intellectual property rights and any other rights of you,

users or any third party, resulting from the Information.

● No information in this document can be transcribed or copied or both without Sanken’s prior written consent.

● Regarding the Information, no license, express, implied or otherwise, is granted hereby under any intellectual property rights and

any other rights of Sanken.

● Unless otherwise agreed in writing between Sanken and you, Sanken makes no warranty of any kind, whether express or implied,

including, without limitation, any warranty (i) as to the quality or performance of the Sanken Products (such as implied warranty

of merchantability, and implied warranty of fitness for a particular purpose or special environment), (ii) that any Sanken Product is

delivered free of claims of third parties by way of infringement or the like, (iii) that may arise from course of performance, course

of dealing or usage of trade, and (iv) as to the Information (including its accuracy, usefulness, and reliability).

● In the event of using the Sanken Products, you must use the same after carefully examining all applicable environmental laws and

regulations that regulate the inclusion or use or both of any particular controlled substances, including, but not limited to, the EU

RoHS Directive, so as to be in strict compliance with such applicable laws and regulations.

● You must not use the Sanken Products or the Information for the purpose of any military applications or use, including but not

limited to the development of weapons of mass destruction. In the event of exporting the Sanken Products or the Information, or

providing them for non-residents, you must comply with all applicable export control laws and regulations in each country

including the U.S. Export Administration Regulations (EAR) and the Foreign Exchange and Foreign Trade Act of Japan, and

follow the procedures required by such applicable laws and regulations.

● Sanken assumes no responsibility for any troubles, which may occur during the transportation of the Sanken Products including

the falling thereof, out of Sanken’s distribution network.

● Although Sanken has prepared this document with its due care to pursue the accuracy thereof, Sanken does not warrant that it is

error free and Sanken assumes no liability whatsoever for any and all damages and losses which may be suffered by you resulting

from any possible errors or omissions in connection with the Information.

● Please refer to our official website in relation to general instructions and directions for using the Sanken Products, and refer to the

relevant specification documents in relation to particular precautions when using the Sanken Products.

● All rights and title in and to any specific trademark or tradename belong to Sanken and such original right holder(s).

DSGN-AEZ-16003

DGU4520GR-DSE Rev.1.1 SANKEN ELCTRIC CO., LTD. 11

Feb. 13, 2019 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2018

Potrebbero piacerti anche

- mgd623s Ds enDocumento13 paginemgd623s Ds enali ülküNessuna valutazione finora

- Mgd623n Ds enDocumento13 pagineMgd623n Ds enJuanNessuna valutazione finora

- IBGT Magnetomed 7200Documento8 pagineIBGT Magnetomed 7200Leonell Romero BazanNessuna valutazione finora

- Irg 4 PC 40 KDocumento9 pagineIrg 4 PC 40 KBárbara RibeiroNessuna valutazione finora

- Data SheetDocumento8 pagineData SheetJorge EstebanNessuna valutazione finora

- IRG4BC30K: Features Features Features Features FeaturesDocumento8 pagineIRG4BC30K: Features Features Features Features Features5a DOHCNessuna valutazione finora

- Irg 4 BC 30 KDDocumento11 pagineIrg 4 BC 30 KDLucía MitchellNessuna valutazione finora

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocumento16 pagineInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeLucía MitchellNessuna valutazione finora

- Irg4Bc30Kd-S: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Short Circuit Rated Ultrafast IgbtDocumento10 pagineIrg4Bc30Kd-S: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Short Circuit Rated Ultrafast IgbtDeiry Katherine Marquez RamirezNessuna valutazione finora

- Infineon IRG4BH20K S DataSheet v01 - 00 ENDocumento9 pagineInfineon IRG4BH20K S DataSheet v01 - 00 ENMac GyverNessuna valutazione finora

- MGD623S: 600 V, 37 A, IGBT With Fast Recovery DiodeDocumento11 pagineMGD623S: 600 V, 37 A, IGBT With Fast Recovery DiodeMahmoud Digital-DigitalNessuna valutazione finora

- GIB10B60KD1Documento13 pagineGIB10B60KD1jhonnygarcia634Nessuna valutazione finora

- Psiix 20 12Documento3 paginePsiix 20 12Yl ZhangNessuna valutazione finora

- Afghl50t65sqdc 650v 50a 1,6v SicDocumento11 pagineAfghl50t65sqdc 650v 50a 1,6v SicRaduNessuna valutazione finora

- IRG4BC20S: FeaturesDocumento9 pagineIRG4BC20S: FeaturesatulNessuna valutazione finora

- STGB20NB41LZ: N-Channel Clamped 20A - D Pak Internally Clamped Powermesh™ IgbtDocumento9 pagineSTGB20NB41LZ: N-Channel Clamped 20A - D Pak Internally Clamped Powermesh™ IgbtCarlos Luis ColmenaresNessuna valutazione finora

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocumento16 pagineInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeSalah Al-AbsiNessuna valutazione finora

- Irg4Pc40Kd: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Short Circuit Rated Ultrafast IgbtDocumento10 pagineIrg4Pc40Kd: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Short Circuit Rated Ultrafast Igbtskbabu1978Nessuna valutazione finora

- IRG4PH50SDocumento9 pagineIRG4PH50SZlatko BakosNessuna valutazione finora

- DatasheetDocumento15 pagineDatasheetAnpolNessuna valutazione finora

- Irg4Pc40Kdpbf: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Short Circuit Rated Ultrafast IgbtDocumento11 pagineIrg4Pc40Kdpbf: Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery Diode Short Circuit Rated Ultrafast Igbthenz coupleNessuna valutazione finora

- STGB10NB37LZ: N-Channel Clamped 20A - D2Pak Internally Clamped Powermesh™ IgbtDocumento10 pagineSTGB10NB37LZ: N-Channel Clamped 20A - D2Pak Internally Clamped Powermesh™ IgbtVukica IvicNessuna valutazione finora

- Irg 4 BC 30 SPBFDocumento8 pagineIrg 4 BC 30 SPBFKentus WNessuna valutazione finora

- SGW15N60Documento14 pagineSGW15N60ZekoNessuna valutazione finora

- SGW25N120: Fast IGBT in NPT-technologyDocumento11 pagineSGW25N120: Fast IGBT in NPT-technologyaffes electroniqueNessuna valutazione finora

- Field Stop Trench IGBT AFGHL50T65SQ: 50 A, 650 V V 1.6 VDocumento8 pagineField Stop Trench IGBT AFGHL50T65SQ: 50 A, 650 V V 1.6 VSarah PedolNessuna valutazione finora

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocumento16 pagineInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeAntonio Carlos CardosoNessuna valutazione finora

- Irg4Pf50Wd: FeaturesDocumento11 pagineIrg4Pf50Wd: FeaturesGuillermoNessuna valutazione finora

- Irg 4 BC 30 UDocumento8 pagineIrg 4 BC 30 UQuickerManNessuna valutazione finora

- SGP02N120 SGD02N120, SGI02N120: Fast IGBT in NPT-technologyDocumento14 pagineSGP02N120 SGD02N120, SGI02N120: Fast IGBT in NPT-technologypserednickiNessuna valutazione finora

- FII 50-12E NPT IGBT Phaseleg: in Isoplus I4-PacDocumento4 pagineFII 50-12E NPT IGBT Phaseleg: in Isoplus I4-PacAndreNessuna valutazione finora

- IRG4PC50W: Features Features Features Features FeaturesDocumento9 pagineIRG4PC50W: Features Features Features Features FeaturesMiljan MirkovicNessuna valutazione finora

- Preliminary Data: IGBT With Antiparallel DiodeDocumento8 paginePreliminary Data: IGBT With Antiparallel DiodeMourad BjijNessuna valutazione finora

- IRG4PC30F: Features Features Features Features FeaturesDocumento8 pagineIRG4PC30F: Features Features Features Features FeaturesMehdi Houari ZaidNessuna valutazione finora

- Quiz 1 Data SheetDocumento9 pagineQuiz 1 Data SheetKanz EmadNessuna valutazione finora

- XPT Igbt: CopackDocumento7 pagineXPT Igbt: CopackAdityaJayakarNessuna valutazione finora

- NGB8202N - DatasheetDocumento8 pagineNGB8202N - DatasheetJhonn YorinNessuna valutazione finora

- K20N60 Infineon PDFDocumento13 pagineK20N60 Infineon PDFranduNessuna valutazione finora

- 2PG001Documento3 pagine2PG001pre269Nessuna valutazione finora

- Datasheet Igbt Lef75g602Documento7 pagineDatasheet Igbt Lef75g602Nguyễn ĐứcNessuna valutazione finora

- SGP15N60 SGW15N60: Fast IGBT in NPT-technologyDocumento11 pagineSGP15N60 SGW15N60: Fast IGBT in NPT-technologyMuhammad ZamanNessuna valutazione finora

- Irgpc 30 UDocumento6 pagineIrgpc 30 UJoaquin SilveraNessuna valutazione finora

- STGP10NB37LZ: N-Channel Clamped 20A - To-220 Internally Clamped Powermesh™ IgbtDocumento10 pagineSTGP10NB37LZ: N-Channel Clamped 20A - To-220 Internally Clamped Powermesh™ IgbtRogério NevesNessuna valutazione finora

- Irg4ph50k PDFDocumento7 pagineIrg4ph50k PDFAnonymous oyUAtpKNessuna valutazione finora

- Dsa 265279Documento7 pagineDsa 265279Vlady Lopez CastroNessuna valutazione finora

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocumento15 pagineInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeKontak SynthetizadorNessuna valutazione finora

- C30UD2 IR IGBT管Documento8 pagineC30UD2 IR IGBT管滕鼎Nessuna valutazione finora

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDocumento1 paginaMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrNessuna valutazione finora

- CRG15T60A83LDocumento10 pagineCRG15T60A83LVadim PopovichNessuna valutazione finora

- 1803 DataDocumento10 pagine1803 DataDarvin VargheseNessuna valutazione finora

- Igbt Irg 4p254sDocumento9 pagineIgbt Irg 4p254sMilagros Mendieta VegaNessuna valutazione finora

- IRG4P254S: Features Features Features Features FeaturesDocumento8 pagineIRG4P254S: Features Features Features Features Featuresjohan elian whiteNessuna valutazione finora

- Irg4Pc50Fpbf: Insulated Gate Bipolar TransistorDocumento9 pagineIrg4Pc50Fpbf: Insulated Gate Bipolar TransistorAnkitNessuna valutazione finora

- CE CGR: This Datasheet Has Been Downloaded From at ThisDocumento7 pagineCE CGR: This Datasheet Has Been Downloaded From at ThisFarooq AhmedNessuna valutazione finora

- Irg7R313Upbf: PDP Trench IgbtDocumento8 pagineIrg7R313Upbf: PDP Trench IgbtRodolfoNessuna valutazione finora

- ACEPACK™ 1 Sixpack Topology, 1200 V, 25 A, Trench Gate Field Stop M Series IGBT With Soft Diode and NTCDocumento15 pagineACEPACK™ 1 Sixpack Topology, 1200 V, 25 A, Trench Gate Field Stop M Series IGBT With Soft Diode and NTCfagundesbrNessuna valutazione finora

- High Voltage IGBTDocumento5 pagineHigh Voltage IGBTPedro HenriqueNessuna valutazione finora

- GB02N120 2Documento12 pagineGB02N120 2srikrishNessuna valutazione finora

- SSC3S931 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocumento23 pagineSSC3S931 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnateNessuna valutazione finora

- SSC3S900 Series Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocumento32 pagineSSC3S900 Series Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnateNessuna valutazione finora

- SSC3S927L Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocumento28 pagineSSC3S927L Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnateNessuna valutazione finora

- SSC3S921 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocumento28 pagineSSC3S921 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnateNessuna valutazione finora

- SSC3S910 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerDocumento31 pagineSSC3S910 Data Sheet: LLC Current-Resonant Off-Line Switching ControllerytnateNessuna valutazione finora

- fkv460s Ds en PDFDocumento1 paginafkv460s Ds en PDFytnateNessuna valutazione finora

- FKV550T: External Dimensions 1 ...... FM20Documento1 paginaFKV550T: External Dimensions 1 ...... FM20ytnateNessuna valutazione finora

- PRD40010 001e 02Documento2 paginePRD40010 001e 02ytnateNessuna valutazione finora

- Mosfet: Features PackageDocumento9 pagineMosfet: Features PackageytnateNessuna valutazione finora

- 60V N - CH Mosfet: Features Package-TO3PDocumento9 pagine60V N - CH Mosfet: Features Package-TO3PytnateNessuna valutazione finora

- Sanken Electric : Low On-State Resistance Built-In Gate Protection Diode SMD PKGDocumento6 pagineSanken Electric : Low On-State Resistance Built-In Gate Protection Diode SMD PKGytnateNessuna valutazione finora

- Specifications List by Part Number: 2-2 Mos FetsDocumento3 pagineSpecifications List by Part Number: 2-2 Mos FetsytnateNessuna valutazione finora

- External Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsDocumento2 pagineExternal Dimensions 1 ...... FM20: Absolute Maximum Ratings Electrical CharacteristicsytnateNessuna valutazione finora

- AB01B Data Sheet: V 800 V, I 0.5 A, T 200 Ns Fast Recovery DiodeDocumento5 pagineAB01B Data Sheet: V 800 V, I 0.5 A, T 200 Ns Fast Recovery DiodeytnateNessuna valutazione finora

- COS-11D Series: Superb Sound in A New Generation Ultra-Miniature Lavalier MicDocumento4 pagineCOS-11D Series: Superb Sound in A New Generation Ultra-Miniature Lavalier MicytnateNessuna valutazione finora

- File 1505214230Documento1 paginaFile 1505214230ytnateNessuna valutazione finora

- SPF0004 Data Sheet: V = 275 V, R = 0.26 Ω Dual N-channel Power MOSFETDocumento11 pagineSPF0004 Data Sheet: V = 275 V, R = 0.26 Ω Dual N-channel Power MOSFETytnateNessuna valutazione finora

- Mos Fet: Features Package - TO-263Documento9 pagineMos Fet: Features Package - TO-263ytnateNessuna valutazione finora

- MPM80 Series Data Sheet: 2 A Non-Isolated Buck Converter ModuleDocumento20 pagineMPM80 Series Data Sheet: 2 A Non-Isolated Buck Converter ModuleytnateNessuna valutazione finora

- FCP11N60/FCPF11N60: General Description FeaturesDocumento10 pagineFCP11N60/FCPF11N60: General Description FeaturesRodrigo MagNessuna valutazione finora

- Chapter 9 Frequency Response of BJT & MosfetDocumento54 pagineChapter 9 Frequency Response of BJT & Mosfetshubhankar palNessuna valutazione finora

- CP776Documento58 pagineCP776jeevan_v_mNessuna valutazione finora

- Color Codes and Irregular Marking-SampleDocumento23 pagineColor Codes and Irregular Marking-Samplemahrez laabidiNessuna valutazione finora

- Quad High-Side Gate Driver For Automotive Applications: Description Features and BenefitsDocumento20 pagineQuad High-Side Gate Driver For Automotive Applications: Description Features and BenefitsTuấn NeoNessuna valutazione finora

- Endeavor - 20210519 - Nexperia - Understanding and Solving Thermal Design Issues in MOSFET ApplicationDocumento8 pagineEndeavor - 20210519 - Nexperia - Understanding and Solving Thermal Design Issues in MOSFET ApplicationJNarigonNessuna valutazione finora

- Mitsubishi Ssts NewsDocumento32 pagineMitsubishi Ssts NewsLeo Le GrisNessuna valutazione finora

- DC MotorDocumento26 pagineDC MotorGerard AlfonsoNessuna valutazione finora

- Ee5311 Module 1 TransistorDocumento41 pagineEe5311 Module 1 TransistorSure AvinashNessuna valutazione finora

- High-Performance Crystal Oscillator Circuits: Theory and ApplicationDocumento10 pagineHigh-Performance Crystal Oscillator Circuits: Theory and Applicationsaikat_hazraNessuna valutazione finora

- Lab Volt 91004Documento24 pagineLab Volt 91004Anonymous BJMvQF3OmNessuna valutazione finora

- Survey On Grphene Transistor Over Silicon TransistorDocumento6 pagineSurvey On Grphene Transistor Over Silicon TransistorlambanaveenNessuna valutazione finora

- Krishnan Ramu - Entrepreneurship in Power Semiconductor Devices, Power Electronics, and Electric Machines and Drive Systems-CRC Press (2020)Documento451 pagineKrishnan Ramu - Entrepreneurship in Power Semiconductor Devices, Power Electronics, and Electric Machines and Drive Systems-CRC Press (2020)huynguyenwwNessuna valutazione finora

- FQPF 8 N 60 CFDocumento8 pagineFQPF 8 N 60 CFBhadreshkumar SharmaNessuna valutazione finora

- Low Noise AmplifierDocumento115 pagineLow Noise AmplifierIris ShtraslerNessuna valutazione finora

- FQPF10N60CDocumento10 pagineFQPF10N60Cmiloud1911Nessuna valutazione finora

- Kexin-Si2312 C382307Documento4 pagineKexin-Si2312 C382307balaicopierNessuna valutazione finora

- Simple PWM Boost Controller: Power Management Features DescriptionDocumento11 pagineSimple PWM Boost Controller: Power Management Features DescriptionJoe MiguelNessuna valutazione finora

- AON7430Documento6 pagineAON7430deyvid sanchezNessuna valutazione finora

- 2 SK 1120Documento6 pagine2 SK 1120ramon navaNessuna valutazione finora

- AZ1-FK: Service ManualDocumento33 pagineAZ1-FK: Service ManualGuillermoHernandezNessuna valutazione finora

- Biopotential AmplifiersDocumento15 pagineBiopotential AmplifiersJesus PeñaNessuna valutazione finora

- TPCA8109: Lithium Ion Battery Applications Power Management Switch ApplicationsDocumento7 pagineTPCA8109: Lithium Ion Battery Applications Power Management Switch ApplicationsDavid J. Pinto ApazaNessuna valutazione finora

- IGBT MitsubishiDocumento26 pagineIGBT Mitsubishimadhuvariar100% (3)

- Cambridge Institute of Technology MCQDocumento47 pagineCambridge Institute of Technology MCQSumanta BhattacharyyaNessuna valutazione finora

- Schools Division of Parañaque City Tle 10 Computer System Servicing First Quarter Week 4Documento11 pagineSchools Division of Parañaque City Tle 10 Computer System Servicing First Quarter Week 4Jezrhil R. VivarNessuna valutazione finora

- The Recycling Folded CascodeDocumento8 pagineThe Recycling Folded CascodeFelipe BertonNessuna valutazione finora

- Optocouplers For Variable Speed Motor ControlDocumento22 pagineOptocouplers For Variable Speed Motor Controln_navaneethNessuna valutazione finora

- A 500Μw 2.4Ghz Cmos Subthreshold Mixer For Ultra Low Power ApplicationsDocumento4 pagineA 500Μw 2.4Ghz Cmos Subthreshold Mixer For Ultra Low Power ApplicationsRF_RAJANessuna valutazione finora

- Lecture 14 - Digital Circuits: Inverter Basics - Outline: - AnnouncementsDocumento25 pagineLecture 14 - Digital Circuits: Inverter Basics - Outline: - Announcementsayush guptaNessuna valutazione finora