Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Effect of Normalizing and Hardening On Mechanical

Caricato da

nvc_vishwanathanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Effect of Normalizing and Hardening On Mechanical

Caricato da

nvc_vishwanathanCopyright:

Formati disponibili

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/266866998

Effect of Normalizing and Hardening on Mechanical Properties of Spring

Article · July 2011

CITATIONS READS

4 2,943

4 authors, including:

Olayide Adetunji P. O. Aiyedun

University of Agriculture, Abeokuta University of Agriculture, Abeokuta

76 PUBLICATIONS 183 CITATIONS 37 PUBLICATIONS 68 CITATIONS

SEE PROFILE SEE PROFILE

olasunkanmi Salami Ismaila

University of Agriculture, Abeokuta

90 PUBLICATIONS 297 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

ASSESSMENT OF NOISE DOSE IMPACT ON BLOOD PRESSURE AND HEART RATE FROM PORTABLE PERSONAL AUDIO DEVICE View project

Nanomaterial for Sorbent Application View project

All content following this page was uploaded by olasunkanmi Salami Ismaila on 24 October 2014.

The user has requested enhancement of the downloaded file.

Journal of Minerals and Materials Characterization and Engineering, 2012, 11, 832-835

Published Online August 2012 (http://www.SciRP.org/journal/jmmce)

Effect of Normalizing and Hardening on Mechanical

Properties of Spring

O. R. Adetunji*, P. O. Aiyedun, S. O. Ismaila, M. J. Alao

Mechanical Engineering Department, College of Engineering, Federal University of Agriculture, Abeokuta, Nigeria

Email: *adetunjiolayide@yahoo.co.uk

Received May 27, 2012; revised July 7, 2012; accepted July 30, 2012

ABSTRACT

This study was carried out to investigate the effect of heat treatment (Normalizing and Hardening) on the mechanical

properties of springs. The springs were made from mild steel rod having a diameter of 6 mm, a total of 15 springs were

made. The springs were then subjected to various heat treatment processes which included; normalizing, hardening and

tempering. The heat treated springs were then subjected to various test in other to determine their mechanical properties,

these included; impact toughness test, hardness test and tension test. The normalized spring had more strength, was

harder and was much tougher than both the annealed and as received springs. The water quenched springs were the

hardest of all the heat treated springs, were very brittle and had the lowest percentage elongation. Their strength was

also lower than that of the normalized and as received springs. The water quenched and tempered springs had better

mechanical properties required for spring making, they had the optimum combination of hardness, strength and tough-

ness when compared with the other heat treated springs.

Keywords: Normalizing; Hardening; Tempering; Impact Toughness; Tension; Spring

1. Introduction rial plates attached at the ends to the vehicle under-

body.

A spring is defined as an elastic body, whose function is

3) Torsion bars: are a long straight steel bar fastened

to distort when loaded and to recover to its original shape

to the chassis at one end and to a suspension part at the

when the load is removed. The various important appli-

other which when twisted provides the spring force.

cations of springs are as follows:

4) Air springs: is a mechanical device using confined

a) To cushion, absorb or control energy due to either

air to absorb the shock of motion?

shock or vibration as in car springs, railway buffers, air-

craft landing gears, shock absorbers and vibration damp-

1.1. Heat Treatment

ers.

b) To apply forces as in brakes, clutches and spring This is the heating and cooling of a solid metal or alloy

loaded valves. in such a way as to obtain desired conditions or proper-

c) To control motion by maintaining contact between ties. The term heat treatment process is in and of itself

two elements as in cams and followers. only a very generic term; it covers all specific methods

d) To measure forces as in spring balances and engine [2]. Thus emphasis will be made on those forms of heat

indicators. treatment that are most commonly used in the spring in-

e) To store energy as in watches. dustry these are: Annealing, Normalizing, Hardening and

There are various types of springs theses are: coil Tempering.

springs, leaf springs, torsion bars and air springs [1].

1) Coil springs: is a mechanical device which is typi- 1.2. Normalizing/Stress Relieving

cally used to store energy and subsequently release it to

Heating to a suitable temperature, holding long enough to

absorb shock, or to maintain a force between contacting

reduce residual stresses, and then cooling slowly enough

surfaces.

to minimize the development of new residual stresses. It

2) Leaf springs: are suspension springs made up of

relieves the stresses that occur as a result of the spring

several thin, curved, hardened-steel or composite-mate-

forming operation. It also returns the material to the

*

Corresponding author. strength levels prior to the forming operation and can

Copyright © 2012 SciRes. JMMCE

O. R. ADETUNJI ET AL. 833

actually increase the strength to levels greater than origi- 2.1. Normalizing/Stress Relieving

nally supplied [3].

In normalizing the springs were heated to 550˚C, 700˚C

The normalizing of steel is carried out by heating ap-

and 900˚C respectively, after the desired temperature had

proximately 100˚F (38˚C) above the upper critical tem- been obtained they were removed from the furnace and

perature (Ac3 or Acm) followed by cooling in air to allowed to cool in air till room temperature was obtained.

room temperature Normalizing is often considered from They will have a different property if the springs have

both a thermal and a micro structural standpoint. In the cooled down to room temperature in the furnace.

thermal sense, normalizing is austenitizing followed by a

relatively slow cooling. 2.2. Hardening (Water Quenching)

1.3. Hardening (Water Quenching) In water quenching the springs were heated to about 850˚C

to ensure conversion to austenite had been achieved. The

Quenching can be done by plunging the hot steel in water. springs were then taken out of the furnace and placed in a

The water adjacent to the hot steel vaporizes, and there is bath of water to ensure that rapid cooling of the spring

no direct contact of the water with the steel. This slows occurred.

down cooling until the bubbles break and allow water

contact with the hot steel. Water quenching produces 2.3. Tempering

steel with a very high hardness but also results in very

brittle and fragile steel with a low tensile strength also. In tempering the three water quenched steel were heated

As the water contacts and boils, a great amount of heat is to 300˚C, 500˚C and 600˚C respectively and were then

removed from the steel. With good agitation, bubbles can allowed to cool down gradually. This was done to relieve

be prevented from sticking to the steel, and thereby pre- some of the stress that occurred during water quenching

vent soft spots. Water is a good rapid quenching medium, and to also reduce the hardness of the steel rod, thus

provided good agitation is done. However, water is cor- making it more tougher.

rosive with steel, and the rapid cooling can sometimes The remaining three springs were not subjected to any

cause distortion or cracking [3]. heat treatment and shall thus be used for comparison with

the other heat treated springs.

Three new set of springs are normalized, this is done

1.4. Tempering

by heating them to the following respective temperature

Tempering is usually done after quenching, it involves 550˚C, 700˚C and 850˚C after which they are removed

re-heating of the steel in order to reduce the hardness of from the furnace and allowed to cool in air to atmos-

the quenched steel and improve the ductility, toughness pheric temperature.

and strength of the spring. Tempering is usually done 1) Three new set of springs are then heated to 850˚C

hand in hand with quenching and is usually a tradeoff after which they are removed from the furnace and

between hardness and toughness/strength of steel. This placed in a bath of water, a process known as water

research is aimed at evaluating the effect of normalizing, quenching.

hardening and tempering on the impact toughness, hard- 2) The three set of springs which have been water

ness and tensile strength of springs. quenched from 850˚C are then tempered by heating them

to the following temperature 300˚C, 500˚C and 600˚C

2. Experimental Methodology respectively after which they are allowed to cool at a

slow rate.

The springs were made using mild steel rods having a

diameter of 6 mm. The following were the steps taken 2.4. Impact Toughness

during the making of the springs. The mandrel and one

end of the steel rod were clamped together with the use The impact test is done with an impact tester. This is

of a g clamp. The steel rod was clamped to the beginning used to determine toughness of the steel wire used for the

of the mandrel [4-6]. spring the impacter was allowed to fall from a certain

a) The steel rod was then wound round the mandrel at height in other to crush the steel rod. The height from

the desired pitch. which the impacter is released can be used to measure

b) When the desired number of turns was reached i.e. the degree of hardness of the steel rod by the amount of

8 turns. The steel rod was then cut off from the unwound energy absorbed by the rod before fracture.

steel rod with the help of a saw.

c) The mandrel with the spring wound round it was

2.5. Tensile Test

both removed from the g-clamp after which the spring The tensioning machine was used to determine the

was removed from the mandrel. strength of the spring. A force is applied axially via

Copyright © 2012 SciRes. JMMCE

834 O. R. ADETUNJI ET AL.

weights on the tensioning machine. The amount of force 3. Result and Discussion

required to produce a certain amount of deflection was The results obtained for tension test of normalized springs

then recorded for all the spring samples. are contained in Table 1, tension test for water quenched,

tempered and as received springs in Table 2, impact

2.6. Hardness Test toughness and hardness test for normalized springs in

The surface hardness test was measured by Matsuzawa Table 3 and impact toughness and hardness test for har-

DXT3 Rockwell test device according to the ISO stan- dened and tempered springs in Table 4.

dards, this was done to determine the hardness of the

Table 1. Tension test for normalized springs.

various heat treated springs. The water quenched spring

was subjected to an incremental load of 4 kg and an Extension (cm) Extension (cm) Extension (cm)

Load

Normalized at Normalized at Normalized at

extension of 0.15 cm was measured until an extra load (kg)

550˚C 700˚C 850˚C

of 4 kg was added to the 16 kg mass and an extension 4 0.5 0.6 0.5

of 0.3 cm was measured, which indicated that 16 kg 8 1.0 1.2 1.0

was the yield load of the water quenched springs, simi-

12 1.5 1.8 1.5

larly the yield load of the normalized and as received

16 2.0 2.4 2.0

springs can be obtained from Section 3 (Result and Dis-

20 2.7 3.3 2.5

cussion).

Table 2. Tension test for water quenched, tempered and as received springs.

Extension (cm) Water Extension (cm) Tempering Extension (cm) Tempering Extension (cm) Tempering As Received

Load (kg) at 600˚C

Quenched at 850˚C at 300˚C at 500˚C spring

4 0.15 0.45 0.55 0.6 0.4

8 0.3 0.9 1.1 1.2 0.8

1.8

12 0.45 1.3 1.6 1.2

2.4

16 0.6 1.7 2.1 1.6

20 0.9 2.0 2.8 3.0 2.0

24 2.5 3.8 2.6

Table 3. Impact toughness and hardness test for normalized springs.

YL Yield Stress Extension Toughness Hardness

S/No Spring Description % Elongation

(kg) (kg/mm) (cm) (Joules) (RC)

1 Normalized at 550 16 0.555 2.4 25 45 50

2 Normalized at 700 16 0.555 3.0 30 49 47

3 Normalized at 850 24 0.848 3.0 37.5 58 38

Table 4. Impact toughness and hardness test for hardened and tempered springs.

YL Yield Stress Extension Toughness Hardness

S/No Spring description % Elongation

(kg) (kg/mm) (cm) (Joules) (Rc)

1 Water quenched at 850 16 0.565 0.6 7.5 20 49

2 Tempered at 300 20 0.565 1.7 21.25 47 45

3 Tempered at 500 16 0.707 2.6 32.25 55 38

4 Tempered at 600 20 0.565 2.4 31 45 35

Copyright © 2012 SciRes. JMMCE

O. R. ADETUNJI ET AL. 835

3.1. Normalized Springs spring reduced, the toughness and ductility increased

when compared to the water quenched springs.

As the steel is heated above the critical temperature,

about 1335˚F (724˚C), it undergoes a phase change, re-

4. Conclusions

crystallizing as austenite. Continued heating to the hard-

ening temperature, 1450˚F - 1500˚F (788˚C - 816˚C) en- The normalized spring had more strength, was harder and

sures complete conversion to austenite. At this point the was much tougher than as received springs.

steel is no longer magnetic, and its color is cherry-red, The water quenched springs were the hardest of all the

normalizing has a slower rate of cool than annealing and heat treated springs, were very brittle and had the lowest

this accounts for the springs having a greater strength percentage elongation. Their strength was also lower than

than the annealed spring, and also accounts for it being that of the normalized and as received springs.

harder and less ductile than the annealed springs [7,8]. The tempered water quenched springs had better me-

chanical properties required for spring making, they had

3.2. Hardening and Tempering the optimum combination of hardness, strength and

toughness when compared with the other heat treated

As the steel is heated above the critical temperature,

springs.

about 1335˚F (724˚C), it undergoes a phase change, re-

crystallizing as austenite (i.e. it changes from body cen-

tered cubic to face centered cubic) Continued heating to REFERENCES

the hardening temperature, 1450˚F - 1500˚F (788˚C - [1] W. Harris, “How Car Suspensions Work,” 2005.

816˚C) ensures complete conversion to austenite, the http://auto.howstuffworks.com/car-suspension.htm

springs are then cooled suddenly by quenching in a bath [2] E. T. George, “Steel Heat Treatment: Metallurgy and

of water, a new crystal structure, martensite, is formed as Technologies,” CRC Press, Boca Raton, 2006.

seen in the micro structural analysis above. Martensite is

[3] R. A. Higgins, “Engineering Metallurgy Hodder and Stogh-

characterized by an angular needle-like structure and ton,” London, 1980.

very high hardness, as seen from the hardness test carried

[4] T. D. Gillespie, “Fundamentals of Vehicle Dynamics,”

out. While martensitic steel is extremely hard, it is also Society of Automotive Engineers, New York, 2009.

extremely brittle and will break, chip, and crumble with

[5] T. Kadrinm, “ASM Materials Engineering Dictionary,”

the slightest shock. Furthermore, internal stresses remain ASM International, 1992. www.asminternal.org

in the spring from the sudden quenching; these will also

[6] H. Loretta, “How to Make Springs,” 2000.

facilitate breakage of the spring. Tempering relieves http://home.earthlink.net/-bazillion/intro.html

these stresses and causes partial decomposition of the

[7] J. M. Pellizzari, M. Zadra and A. Molinari, “Tribological

martensite into ferrite and cementite. The amount of this Properties of Surface Engineered Hot Work Tool Steel for

partial phase change is controlled by the tempering tem- Aluminum Extrusion Dies,” Surface Engineering, Vol. 23,

perature. The tempered steel is not as hard as pure mart- No. 3, 2007, pp. 165-168.

ensite, but is much tougher. This can be observed from doi:10.1179/174329406X150477

the result tabulated above where by the water quenched [8] O. A. Fayol, C. A. Boher, R. B. Gras and F. A. Rezai-

sprigs have the highest hardness and are the least ductile Aria, “Analysis of the Friction and Wear Behavior of Hot

from all the springs, but after the water quenched steel Work Tool Steel for Forging,” Wear, Vol. 255, No. 7-12,

were tempered it was observed that the hardness of the 1985, pp. 1444-1454.

Copyright © 2012 SciRes. JMMCE

View publication stats

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Glass Content PDFDocumento99 pagineGlass Content PDFnvc_vishwanathanNessuna valutazione finora

- Excessive PWHTDocumento8 pagineExcessive PWHTnvc_vishwanathanNessuna valutazione finora

- Data SheetDocumento1 paginaData Sheetpradip panthaNessuna valutazione finora

- SinteringDocumento92 pagineSinteringnvc_vishwanathanNessuna valutazione finora

- Estimation of Atmospheric Corrosion of High-Strength, Low-Alloy SteelsDocumento8 pagineEstimation of Atmospheric Corrosion of High-Strength, Low-Alloy Steelsnvc_vishwanathanNessuna valutazione finora

- 2020 TOCICO Virtual Conference Program: Track 1Documento1 pagina2020 TOCICO Virtual Conference Program: Track 1nvc_vishwanathanNessuna valutazione finora

- The Austenite Grain Growth Behavior and Mathematical Model of 20crmntihDocumento6 pagineThe Austenite Grain Growth Behavior and Mathematical Model of 20crmntihnvc_vishwanathanNessuna valutazione finora

- Crack Tip Opening Displacement (Ctod) in Single Edge Notched Bend (Sen (B) )Documento328 pagineCrack Tip Opening Displacement (Ctod) in Single Edge Notched Bend (Sen (B) )Kingsly PrakashNessuna valutazione finora

- ThermoFischer Scientific Product PDFDocumento2 pagineThermoFischer Scientific Product PDFnvc_vishwanathanNessuna valutazione finora

- Niton XL3t GOLDD DatasheetDocumento2 pagineNiton XL3t GOLDD DatasheetDanielHanccoNessuna valutazione finora

- Defects in Hot Rolled Products1Documento33 pagineDefects in Hot Rolled Products1karunadkumari89% (38)

- HCM Statement On COVID19Documento3 pagineHCM Statement On COVID19nvc_vishwanathanNessuna valutazione finora

- Zero Depreciation ICICIDocumento2 pagineZero Depreciation ICICInvc_vishwanathanNessuna valutazione finora

- Green Steel For Better FutureDocumento39 pagineGreen Steel For Better Futurenvc_vishwanathanNessuna valutazione finora

- Failure Analysis of Axle Shaft of A Fork LiftDocumento11 pagineFailure Analysis of Axle Shaft of A Fork Liftnvc_vishwanathanNessuna valutazione finora

- ATHARVASHIRSHADocumento5 pagineATHARVASHIRSHAAnupam Patil100% (1)

- Niobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener ApplicationsDocumento7 pagineNiobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener Applicationsnvc_vishwanathanNessuna valutazione finora

- Cardioprotection With AlcoholDocumento14 pagineCardioprotection With Alcoholnvc_vishwanathanNessuna valutazione finora

- Better Efficient TransformersDocumento3 pagineBetter Efficient Transformersnvc_vishwanathanNessuna valutazione finora

- Excel - Create A Speedometer Chart TutorialsDocumento7 pagineExcel - Create A Speedometer Chart Tutorialsnvc_vishwanathanNessuna valutazione finora

- Five Yoga Poses For Better DigestionDocumento3 pagineFive Yoga Poses For Better Digestionnvc_vishwanathanNessuna valutazione finora

- Eight Smart Money Moves To Make Before The Age of 30 - The Economic TimesDocumento9 pagineEight Smart Money Moves To Make Before The Age of 30 - The Economic Timesnvc_vishwanathanNessuna valutazione finora

- Health Benefits of A High Fibre Diet - RediffDocumento15 pagineHealth Benefits of A High Fibre Diet - Rediffnvc_vishwanathanNessuna valutazione finora

- SMS Seimag - Twenty Years of CSPDocumento27 pagineSMS Seimag - Twenty Years of CSPnvc_vishwanathanNessuna valutazione finora

- Millets - TypesDocumento2 pagineMillets - Typesnvc_vishwanathanNessuna valutazione finora

- New 1600 KV Ultra High Voltage Research Centre at Ambad MIDC - The Times of IndiaDocumento1 paginaNew 1600 KV Ultra High Voltage Research Centre at Ambad MIDC - The Times of Indianvc_vishwanathanNessuna valutazione finora

- Sanskrit TextbookDocumento113 pagineSanskrit TextbookAshwini90% (80)

- Panchal (Nirma University) - Comparative Study of RCC-Steel-Composite High Rise BuildingDocumento6 paginePanchal (Nirma University) - Comparative Study of RCC-Steel-Composite High Rise Buildingnvc_vishwanathanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 11-02-24r Glaverbel-SunergyDocumento16 pagine11-02-24r Glaverbel-SunergydatanotionNessuna valutazione finora

- ARE Non-Stick Utensils Safe For HumanDocumento13 pagineARE Non-Stick Utensils Safe For HumanSoft TechNessuna valutazione finora

- Liebert PDX PCW Thermal Management System User ManualDocumento184 pagineLiebert PDX PCW Thermal Management System User ManualJeffNessuna valutazione finora

- BOQ and Estimates - CWR FDocumento715 pagineBOQ and Estimates - CWR FRajesh GangwalNessuna valutazione finora

- TSLDocumento2 pagineTSLwaleed El-azabNessuna valutazione finora

- Fa L-G - Stabilised Mud Blocks - Clay Fly Ash Burnt Brick - Fly Ash & Lime BrickDocumento6 pagineFa L-G - Stabilised Mud Blocks - Clay Fly Ash Burnt Brick - Fly Ash & Lime Brickaparna baburajNessuna valutazione finora

- FXSQ-A EEDEN20 Data Books EnglishDocumento37 pagineFXSQ-A EEDEN20 Data Books EnglishommfcNessuna valutazione finora

- Geopolymer Chemistry and ApplicationsDocumento38 pagineGeopolymer Chemistry and Applicationsanon_203503169Nessuna valutazione finora

- Keyboard Shortcut Commands by Category: However, This List Covers Many of The Out-Of-The-Box Shortcuts AvailableDocumento7 pagineKeyboard Shortcut Commands by Category: However, This List Covers Many of The Out-Of-The-Box Shortcuts AvailabledasaNessuna valutazione finora

- NFPA Fire Design GuidanceDocumento6 pagineNFPA Fire Design Guidancerashal100% (1)

- Plumbing Questionnaires PDFDocumento53 paginePlumbing Questionnaires PDFEmilySisnerosMenoriasNessuna valutazione finora

- Keep Your Facility Fully Operational.: Chemetall Maintenance ProductsDocumento8 pagineKeep Your Facility Fully Operational.: Chemetall Maintenance Productseggy mushadiNessuna valutazione finora

- Green Buildings Operation and Maintenance: Case Study On Obstacles and OptimizationDocumento16 pagineGreen Buildings Operation and Maintenance: Case Study On Obstacles and OptimizationAbuNessuna valutazione finora

- Natural Hydraulic Lime For Blended Cement Mortars: Behavior From Fresh To Hardened StatesDocumento40 pagineNatural Hydraulic Lime For Blended Cement Mortars: Behavior From Fresh To Hardened Statesayat arahmanNessuna valutazione finora

- Henk JonkersDocumento25 pagineHenk Jonkersestld2Nessuna valutazione finora

- E10 Rod Extensometer: Precisely MeasuredDocumento4 pagineE10 Rod Extensometer: Precisely MeasuredAlberto MartinezNessuna valutazione finora

- FM200 DiffrenceDocumento13 pagineFM200 Diffrencemeena34Nessuna valutazione finora

- Regulatory Reform (Fire Safety) Order 2005: Estate LocationDocumento20 pagineRegulatory Reform (Fire Safety) Order 2005: Estate LocationtitsNessuna valutazione finora

- Aircraft Electrical SystemDocumento16 pagineAircraft Electrical SystemEvan TubaleNessuna valutazione finora

- Material Product Data SheetDocumento4 pagineMaterial Product Data SheethungNessuna valutazione finora

- Ficha Balflex Baldril 300 PsiDocumento1 paginaFicha Balflex Baldril 300 PsiJUANPANIAGUANessuna valutazione finora

- Sample Pn01cs2s01Documento6 pagineSample Pn01cs2s01Lynn BishopNessuna valutazione finora

- 4A Dough Rheology (2021)Documento24 pagine4A Dough Rheology (2021)ArinaAdilaNessuna valutazione finora

- User Note: Double Underlined With Turquoise HighlightDocumento201 pagineUser Note: Double Underlined With Turquoise Highlightchristian reyesNessuna valutazione finora

- Resilmount Clip - Data SheetDocumento2 pagineResilmount Clip - Data SheetKhader Abu-daggaNessuna valutazione finora

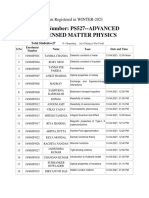

- Course Number: PS527 - ADVANCED Condensed Matter Physics: Students Registered in WINTER-2021Documento2 pagineCourse Number: PS527 - ADVANCED Condensed Matter Physics: Students Registered in WINTER-2021Kiron SkNessuna valutazione finora

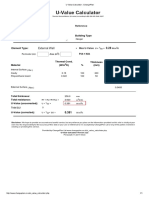

- U Value Calculator - With Liner Only1Documento1 paginaU Value Calculator - With Liner Only1muathNessuna valutazione finora

- Create Components of BUTTERFLY VALVE and Then Assemble ThemDocumento12 pagineCreate Components of BUTTERFLY VALVE and Then Assemble Themnishantrautela1Nessuna valutazione finora

- Chemical Mechanical PolishingDocumento2 pagineChemical Mechanical Polishingraja30gNessuna valutazione finora

- Experiment No Sand Control Test: Moisture Content Test: - To Determine The Moisture Content in The Given Sample.Documento3 pagineExperiment No Sand Control Test: Moisture Content Test: - To Determine The Moisture Content in The Given Sample.Dhananjay Shimpi100% (1)