Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Yd-011 Tds

Caricato da

Oswaldo Manuel Ramirez MarinDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Yd-011 Tds

Caricato da

Oswaldo Manuel Ramirez MarinCopyright:

Formati disponibili

ISO-9001

ISO-14001

KUKDO

December 9,

YD-011 Standard Solid Epoxy Resin 2004

General Description YD-011 40 G-0930 16 R/H=100/100

EPOKUKDO YD-011 is a Bisphenol-A type unmodified Talc 35 YD-011 6

solid Epoxy Resin which can be softened at medium Solvent 25 Solvent 78

o

temperature(over 40 C). Its properties after curing are

excellent for mechanical strength, adhesive strength and Top coating paint

chemical resistance. YD-011 is recommended for

Resin wt% Hardener wt% Mixing Ratio

industrial coating primer, top coating and construction &

YD-011X75 40.0 G-5022 60.0 R/H=100/33

civil work application in solution form with Xylene or

TiO2 30.0 n-Butanol 7.0 Finger touch

other various solvents.

Aerosil #200 0.5 Solvent 7.0 drying : 9hrs

Orben 0.5 Naphtha

Resin Properties

Methyl 12 Xylene 26.0

Item YD-011 Test Method

Cellosolve

EEW(g/eq) 450-500 KD-AS-001 n-Butanol 3.0

*1

Solution Viscosity D-F KD-AS-007 Xylene 6.0

*2 o

Softening Point ( C) 60-70 KD-AS-020

Specific Gravity*3 (20°C) 1.16-1.20 KD-AS-040 (Cured film Properties)

Color(G) 1.0 max. KD-AS-025 No ageing No ageing

*1 Gardner Holdt Method, Butyl Carbiyol NV 40% Solution Cure Condition Curing Curing

*2 Ball & Ring Method *3 Reference data 20°C/7days 150°C/15min

Flexural strength Excellent Excellent

Usage of YD -011 JIS K-5400

Film

1. Coating : 2mmø

mechanical

General paints, Electrodeposition coating, Baking paint, Impact strength Excellent Excellent

property

Marine paint, Anticorrosive industrial paints JIS K-5400

2. Aliphatic Amine-Adduct type : 1Kg×50cm×1/4”

Modifier for aliphatic amine Chemical Cross cut 100/100 100/100

3. Construction civil works : Resistance Erichsen(mm) 8.0 8.0

Primer, Top coating, Water proof, A dhesive, Repair paint

Hydrochloric Excellent Excellent

4. Laminates :

Acid(10%)

Laminating, PCB, Filament winding, Composite

Sulfuric Excellent Excellent

Acid(10%)

Application 10% Nitric Acid Bad Little bad

Primer type(Lining Coating)

5% Caustic Soda Excellent Excellent

Resin wt% Hardener wt% Mixing Ratio 3% Salt water Excellent Excellent

For literature and technical assistance, visit our website at www.kukdo.com

ISO-9001

ISO-14001

KUKDO

December 9,

YD-011 Standard Solid Epoxy Resin 2004

Toluene Excellent Excellent Dimethyl formamide % 15

Gasoline Excellent Excellent Methyl Cellosolve % 15

Boiling Excellent Excellent BDMA % 0.35

water (2hr) MEK % 49

Varnish Glass fiber cloth Various

Tar Epoxy Paint Form Resin Contents wt% 50

Resin wt% Hardener wt% Mixing Ratio Stroke cure time - Sec 390

o

YD-011X75 48.0 G-0930 12.0 R/H=100/25 (at 160 C) 3days after Sec 270

Tar 35.0 DMP-30 0 Pot life : 6days after Sec 220

Talc 25.0 Xylene 8.0 2hrs up 9days after Sec 170

CaCO3 10.0 Toluene 6.0

Aerosil #200 0.5 U-lex 170 3.0 Mechanical properties of cured film

Item 1 2 3 4

Casting molding Flexural Strength

o o o o

Mixing YD-011 % 298 JIS K-5400 (2mmF )

ratio DAM % 32 Impact strength

x o o o

Resolin % 10 1/4" × 50cm × 1Kg

Silica Powder % 625 Appearance o o-x o o

Stearic Acid % 30 Cross cut 67 100 100 100

Calcium Erichsen(mm) 6.1 10.1 11.8 12.0

Pigment % 5

Cured Flexural strength Kg/mm2 9.5 Chemical resistance at 25o C for 7days immersed

properties Tensile strength Kg/mm2 6.6 Item 1 2 3 4

o

HDT C 103 Water E E E E

Volume Resistivity ohmcm(13o C) 7.7×1015 10% Hydrochloric Acid E E E E

o 14

Surface Resistivity Mohmcm(13 C) 6.0×10 10% Sulfuric Acid E E E E

o

Molding condition : Temperature 170-175 C × 1hr 10% Nitric Acid E E B LB

2

Pressure 250 Kg/cm 5% Caustic Soda E E E E

3% Salt water E E E E

Laminate application and cured properties Toluene G E E E

Mixing YD-011 % 100 Gasoline E E E E

Composition Acetone % 25 Boiling water at 2hrs B LB B B

Dicyandiamide % 4 Boiling water at 3hrs B B E E

E : Excellent, G : Good, LB : Little bad, B : Bad

For literature and technical assistance, visit our website at www.kukdo.com

ISO-9001

ISO-14001

KUKDO

December 9,

YD-011 Standard Solid Epoxy Resin 2004

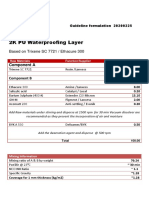

Application and Cured properties of YD-011 Formulation 4

Formulation 1 Resin YD-011 50.0

YD-011 50.0 n-Butanol 25.0

Xylene 10.7 Xylene 25.0

Resin Toluene 25.8 G-5022 25.0

IPA 5.0 Hardener n-Butanol 12.5

Methanol 2.5 Xylene 12.5

DETA 3.0 Curing Condition 15min at 150o C Hardener 50Phr

Hardener Xylene 1.5

Toluene 1.5 Applying methods for test

o

Curing Condition at 20 C 7days Hardener 6Phr 1,2,3 formulation : room temperature type

After dipping, keep one day and do dipping again, and

Formulation 2 dry for 7 days.

YD-011 50.0 4 formulation : baking type

Resin Xylene 25.0 After dipping, heat for 1hour at 50o C, cool down, do

n-Butanol 25.0 dipping two times, heat again for 3hours at 50o C and

DETA 7.50 bake it for 15minutes at 150o C.

n-Butanol 13.75

Xylene 13.75 Film thickness

Hardener

YD-011 32.50 Formulation 1 2 3 4

n-Butanol 16.25 100 70 70 60

Toluene 16.25 Thickness(mm) (150) (100) (100) (90)

Curing Condition at 20o C 7days Hardener 34.3Phr 200 130 130 110

Minimum (Average) Maximum

Formulation 3

Pot life

YD-011 50.0

Resin n-Butanol 25.0 Formulation 1 2 3 4

Xylene 25.0 60

G-5022 25.0 Pot life 7hr 10min 5hr 12hr (90)

Hardener n-Butanol 12.5 110

Xylene 12.5

Curing Condition at 25o C 7days Hardener 50Phr FDA Status

EPOKUKDO YD-011 has broad application in surface

coatings. When it properly formulated and fully cured for

For literature and technical assistance, visit our website at www.kukdo.com

ISO-9001

ISO-14001

KUKDO

December 9,

YD-011 Standard Solid Epoxy Resin 2004

food contact application, YD-011 will comply with the

U.S Food, Drug and Cosmetic Act as amended under food

additive Regulation 21 CFR 175.300. If any of your

intended uses involves food contact, we suggest that you

can consult with legal and technical experts and with the

Food and Drug Administration. It will also be necessary

to consult with KUKDO Chemical Co. and the other raw

material suppliers regarding the FDA status of the

materials prior to commercialization or use.

Packaging

PE bag of 25Kg Net weight

35 bags on a pallet wrapped in a large carton

For literature and technical assistance, visit our website at www.kukdo.com

Potrebbero piacerti anche

- 21 - Resins For Road Marking PaintsDocumento4 pagine21 - Resins For Road Marking Paintsraj jangid100% (1)

- 8 Interior and Exterior Emulsion PaintsDocumento28 pagine8 Interior and Exterior Emulsion PaintsAPEX SON100% (1)

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- Industrial Surfactants: An Industrial GuideDa EverandIndustrial Surfactants: An Industrial GuideValutazione: 5 su 5 stelle5/5 (2)

- 2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Documento2 pagine2K-PU Flooring, Flexible, Self-Leveling, Solvent-Free, 50-65-75 Shore A (V 44409 - 0)Oswaldo Manuel Ramirez MarinNessuna valutazione finora

- Elvacite Brochure 06 02Documento40 pagineElvacite Brochure 06 02manox007Nessuna valutazione finora

- Acrylic Resins ElementisDocumento53 pagineAcrylic Resins ElementisEmilio Hipola100% (2)

- Additive Coatings and Inks Ver 2.1 2021Documento8 pagineAdditive Coatings and Inks Ver 2.1 2021nano100% (1)

- Omnova Coatings PresentationDocumento12 pagineOmnova Coatings PresentationNatalia Rodriguez100% (1)

- Guide Formulation For Road Marking PaintDocumento1 paginaGuide Formulation For Road Marking PaintBoonyarit Lurdgrienggraiying100% (2)

- Brand+Acronal Brochure Resins+Industrial+Coatings+Selection+Guide EnglishDocumento15 pagineBrand+Acronal Brochure Resins+Industrial+Coatings+Selection+Guide Englishgemm88Nessuna valutazione finora

- 5 - Body Filler - Polyester Putty - 2019 EditionDocumento2 pagine5 - Body Filler - Polyester Putty - 2019 Editiondamax rec100% (1)

- APAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFDocumento10 pagineAPAC - Literature - Coating - Epoxy Resin & Hardeners For Coating Selector Guide PDFraahul_nNessuna valutazione finora

- Recommended Epoxy FormulationsDocumento2 pagineRecommended Epoxy Formulationsuzzy2Nessuna valutazione finora

- Can Coating Formulations (Sheet 1 To 4)Documento3 pagineCan Coating Formulations (Sheet 1 To 4)No NameNessuna valutazione finora

- Alkyd Resin Technology Formulating Techniques and Allied Calculations - Patton, T. C.Documento216 pagineAlkyd Resin Technology Formulating Techniques and Allied Calculations - Patton, T. C.Kevin Lora VillarrealNessuna valutazione finora

- Alkyd Resin ManufacturerDocumento5 pagineAlkyd Resin ManufacturerDonald_12Nessuna valutazione finora

- TEGODocumento49 pagineTEGOMiguelAlegriaNessuna valutazione finora

- Catalog Kukdo PDFDocumento27 pagineCatalog Kukdo PDFDivisi Laboratorium Kemaki50% (2)

- Cymel® 303 LF: Product Description Typical PropertiesDocumento2 pagineCymel® 303 LF: Product Description Typical Propertiesهیمن مNessuna valutazione finora

- Epoxy 2kDocumento3 pagineEpoxy 2kMitra YuningsihNessuna valutazione finora

- 2K PU SB Waterproofing Formulation LCDocumento2 pagine2K PU SB Waterproofing Formulation LCM IdreesNessuna valutazione finora

- S2300 PaintDocumento40 pagineS2300 PaintArun KastwarNessuna valutazione finora

- LoVOCoat - For Low VOC High Performance Solvent Borne CoatingsDocumento4 pagineLoVOCoat - For Low VOC High Performance Solvent Borne CoatingskarlaNessuna valutazione finora

- Croda How To LoVOCoatDocumento6 pagineCroda How To LoVOCoatkarla100% (1)

- 01 - 2K PU SB Auto Refinish & Ind Systems 08-10Documento67 pagine01 - 2K PU SB Auto Refinish & Ind Systems 08-10محمد عزتNessuna valutazione finora

- Acronal S 400 Ap PDFDocumento3 pagineAcronal S 400 Ap PDFRajuNSanaboinaNessuna valutazione finora

- Rhodoline 642 PDFDocumento2 pagineRhodoline 642 PDFhemya7Nessuna valutazione finora

- Additives John Du BYKDocumento78 pagineAdditives John Du BYKdougNessuna valutazione finora

- Defoamers. Dispersions & Pigments Division Formulation AdditivesDocumento51 pagineDefoamers. Dispersions & Pigments Division Formulation AdditivesLong An DoNessuna valutazione finora

- Primal Ac 369sDocumento20 paginePrimal Ac 369shongducxxx100% (1)

- ARKEMA COATEX Presentation COADIS 123 K Hidrophobic Dispersant PDFDocumento22 pagineARKEMA COATEX Presentation COADIS 123 K Hidrophobic Dispersant PDFJose E BatistaNessuna valutazione finora

- Polymer EmulsionDocumento1 paginaPolymer EmulsionSudhir Mahajan33% (3)

- EDAPLAN METOLAT GF For Inorg Pigments 2017Documento18 pagineEDAPLAN METOLAT GF For Inorg Pigments 2017manuel h.ddc.Nessuna valutazione finora

- GF 2K SB Polyaspartic Waterproofing MembraneDocumento2 pagineGF 2K SB Polyaspartic Waterproofing Membraneप्रज्ञेश कुमार100% (1)

- Allnex Phenolic Resins GuideDocumento12 pagineAllnex Phenolic Resins GuideMOHAMEDNessuna valutazione finora

- Paints, Varnishes, and Related Products: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetDocumento45 paginePaints, Varnishes, and Related Products: Bailey's Industrial Oil and Fat Products, Sixth Edition, Six Volume SetAbbas AliNessuna valutazione finora

- Ucar Latex 379G: The Best Just Got BetterDocumento12 pagineUcar Latex 379G: The Best Just Got BetterQuimicosgenericosgaffaro GaffaroNessuna valutazione finora

- Jo GradeDocumento40 pagineJo GradeEvonne TanNessuna valutazione finora

- Acematt Matting Agents For The Coatings IndustryDocumento32 pagineAcematt Matting Agents For The Coatings IndustryhatemNessuna valutazione finora

- Alkyd Resin CalculationsDocumento2 pagineAlkyd Resin CalculationsAli RazaNessuna valutazione finora

- Coil CoatingDocumento16 pagineCoil CoatingDuc NguyenNessuna valutazione finora

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDocumento5 pagineSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakimNessuna valutazione finora

- Product Overview Reactive Adhesives Sealants WEB PDFDocumento6 pagineProduct Overview Reactive Adhesives Sealants WEB PDFPranshu JainNessuna valutazione finora

- Li Edaplan Metolat Dispersing TechnologyDocumento15 pagineLi Edaplan Metolat Dispersing TechnologyPulbere NeagraNessuna valutazione finora

- Catalogo Paints ING Out15Documento12 pagineCatalogo Paints ING Out15bexigaobrotherNessuna valutazione finora

- Evonik-Ancamide 221-X70 - EUDocumento5 pagineEvonik-Ancamide 221-X70 - EUMOHAMED100% (1)

- Pigment For TiO2 ExtenderDocumento10 paginePigment For TiO2 ExtenderDuc NguyenNessuna valutazione finora

- Long Durability Exterior CoatingDocumento1 paginaLong Durability Exterior CoatingAmit BholaNessuna valutazione finora

- Curative CalculationDocumento2 pagineCurative Calculationamarghumatkar_466819Nessuna valutazione finora

- Resins For Architectural Coatings - Arkema AmericasDocumento12 pagineResins For Architectural Coatings - Arkema AmericasLong An Do100% (1)

- RosinDocumento42 pagineRosinVingiu Katre100% (1)

- Starting Formulation 1kDocumento1 paginaStarting Formulation 1kForever100% (1)

- Polishes, Coatings and SealersDocumento30 paginePolishes, Coatings and SealersIdkaNessuna valutazione finora

- Woodcoatings PDFDocumento22 pagineWoodcoatings PDFnano100% (1)

- 2K Solvent Free Waterproofing FormulationDocumento2 pagine2K Solvent Free Waterproofing FormulationM Idrees100% (2)

- Polyurethane Amine CatalystsDocumento19 paginePolyurethane Amine Catalystsธนพล กัตติยบุตรNessuna valutazione finora

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Da EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Nessuna valutazione finora

- Inz 2K Polyaspartics Topcoat White GuideDocumento2 pagineInz 2K Polyaspartics Topcoat White GuideOswaldo Manuel Ramirez Marin100% (1)

- Durepox 2K Primer TDSDocumento4 pagineDurepox 2K Primer TDSOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Croda B-Tough C Toughening January 2018Documento4 pagineCroda B-Tough C Toughening January 2018Oswaldo Manuel Ramirez MarinNessuna valutazione finora

- TDS Byk-Catalyst 450 enDocumento2 pagineTDS Byk-Catalyst 450 enOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Evonik-Ancamine 2280 - EUDocumento5 pagineEvonik-Ancamine 2280 - EUOswaldo Manuel Ramirez MarinNessuna valutazione finora

- VISCOLAM202 D20 Acrylic 20 Thickeners 202017Documento33 pagineVISCOLAM202 D20 Acrylic 20 Thickeners 202017Oswaldo Manuel Ramirez MarinNessuna valutazione finora

- Troythix A Usa Eng PdsDocumento2 pagineTroythix A Usa Eng PdsOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Bentone SDTS-2 MTR Aghs en PDFDocumento9 pagineBentone SDTS-2 MTR Aghs en PDFOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Arkema Encor DT 250 PdsDocumento10 pagineArkema Encor DT 250 PdsOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Safety Data Sheet: 1. IdentificationDocumento6 pagineSafety Data Sheet: 1. IdentificationOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Evonik-Ancamine K54 EUDocumento2 pagineEvonik-Ancamine K54 EUOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Tech Tip 4 - Removing BubblesDocumento2 pagineTech Tip 4 - Removing BubblesOswaldo Manuel Ramirez MarinNessuna valutazione finora

- JanaBrochure2016 PDFDocumento16 pagineJanaBrochure2016 PDFOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Tds Garamite-7305 enDocumento4 pagineTds Garamite-7305 enOswaldo Manuel Ramirez MarinNessuna valutazione finora

- 521 Mio Coatings-What Are TheyDocumento3 pagine521 Mio Coatings-What Are TheyOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Byk 410Documento4 pagineByk 410Oswaldo Manuel Ramirez MarinNessuna valutazione finora

- Safety Data Sheet: Section 1. IdentificationDocumento6 pagineSafety Data Sheet: Section 1. IdentificationOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Laropal A 81 June 2014 R2 ICDocumento3 pagineLaropal A 81 June 2014 R2 ICOswaldo Manuel Ramirez MarinNessuna valutazione finora

- SYC - Catalogo ENG 7Documento15 pagineSYC - Catalogo ENG 7Oswaldo Manuel Ramirez Marin50% (2)

- Kronos 2190Documento1 paginaKronos 2190Oswaldo Manuel Ramirez MarinNessuna valutazione finora

- Amershield Voc Clear Coat ResinDocumento6 pagineAmershield Voc Clear Coat ResinOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Substituent EffectsDocumento1 paginaSubstituent EffectsOswaldo Manuel Ramirez MarinNessuna valutazione finora

- Pulsating Heat Pipe ReportDocumento65 paginePulsating Heat Pipe ReportIdul Azharul HoqueNessuna valutazione finora

- 310 311 320 321 Toilet Warranty Codes PDFDocumento11 pagine310 311 320 321 Toilet Warranty Codes PDFTerri MartinNessuna valutazione finora

- Iecex Bas 13.0069XDocumento4 pagineIecex Bas 13.0069XFrancesco_CNessuna valutazione finora

- DrosteDocumento4 pagineDrosteapi-478100074Nessuna valutazione finora

- Cultures of The West A History, Volume 1 To 1750 3rd PDFDocumento720 pagineCultures of The West A History, Volume 1 To 1750 3rd PDFtonnyNessuna valutazione finora

- TSAR-1 Reverb Quick GuideDocumento1 paginaTSAR-1 Reverb Quick GuidedraenkNessuna valutazione finora

- Attention: 6R60/6R75/6R80 Installation GuideDocumento4 pagineAttention: 6R60/6R75/6R80 Installation GuideEdwinferNessuna valutazione finora

- Classical Mechanics MCQ GamecampuscoDocumento3 pagineClassical Mechanics MCQ GamecampuscoFaryal TalibNessuna valutazione finora

- Quantum Data-Fitting: PACS Numbers: 03.67.-A, 03.67.ac, 42.50.DvDocumento6 pagineQuantum Data-Fitting: PACS Numbers: 03.67.-A, 03.67.ac, 42.50.Dvohenri100Nessuna valutazione finora

- EVC AC Charger CatalogDocumento2 pagineEVC AC Charger CatalogRaison AutomationNessuna valutazione finora

- Imamsha Maharaj Na Parcha NewDocumento16 pagineImamsha Maharaj Na Parcha NewNARESH R.PATELNessuna valutazione finora

- Sample Minutes of MeetingDocumento3 pagineSample Minutes of MeetingMohamad AzmeerNessuna valutazione finora

- 10 TazmahalDocumento12 pagine10 TazmahalSifat E Noor SahibaNessuna valutazione finora

- Performance Task 1st Quarter Poetry Writing WorkshopDocumento3 paginePerformance Task 1st Quarter Poetry Writing WorkshopNicole john ZuluetaNessuna valutazione finora

- The Eclectic (OLI) Paradigm of International Production - Past, Present and FutureDocumento19 pagineThe Eclectic (OLI) Paradigm of International Production - Past, Present and FutureJomit C PNessuna valutazione finora

- WCDMA19 Prfile Descriptions W19P8 08A APPRDocumento254 pagineWCDMA19 Prfile Descriptions W19P8 08A APPRoaguilar83Nessuna valutazione finora

- Cyber Frauds, Scams and Their Victims - Mark Button, Cassandra CrossDocumento253 pagineCyber Frauds, Scams and Their Victims - Mark Button, Cassandra CrossMitesh MehtaNessuna valutazione finora

- Analog Digital Thermopile Application Note PDFDocumento18 pagineAnalog Digital Thermopile Application Note PDFGopal HegdeNessuna valutazione finora

- AS Film Production Lesson.Documento13 pagineAS Film Production Lesson.MsCowanNessuna valutazione finora

- Lazard Levelized Cost of Storage v20Documento46 pagineLazard Levelized Cost of Storage v20macNessuna valutazione finora

- Mooring OperationsDocumento5 pagineMooring OperationsHerickson BerriosNessuna valutazione finora

- GSM Sniffing - Telegraph+Documento9 pagineGSM Sniffing - Telegraph+Sridhar PNessuna valutazione finora

- Acid Bases and Salts Previous Year Questiosn Class 10 ScienceDocumento5 pagineAcid Bases and Salts Previous Year Questiosn Class 10 Scienceclashhunting123123Nessuna valutazione finora

- Mrr2 Why The Future Doesnt Need UsDocumento3 pagineMrr2 Why The Future Doesnt Need UsSunshine Glory EgoniaNessuna valutazione finora

- Punctuation WorksheetsDocumento10 paginePunctuation WorksheetsRehan Sadiq100% (2)

- Freeman Has Been A Partner in A Commercial Construction CompanyDocumento1 paginaFreeman Has Been A Partner in A Commercial Construction CompanyMuhammad ShahidNessuna valutazione finora

- Reducing Motor Vehicle Crashes in B.C.Documento260 pagineReducing Motor Vehicle Crashes in B.C.Jeff NagelNessuna valutazione finora

- Student Ought To Possess To Produce Clean-Up and In-Between DrawingsDocumento2 pagineStudent Ought To Possess To Produce Clean-Up and In-Between Drawingscristian friasNessuna valutazione finora

- InflammationDocumento44 pagineInflammationramsiyaNessuna valutazione finora

- LoratadinaDocumento3 pagineLoratadinapapaindoNessuna valutazione finora