Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aker Kvaerner Design On Fixed Topside PDF

Caricato da

Văn HoàngTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aker Kvaerner Design On Fixed Topside PDF

Caricato da

Văn HoàngCopyright:

Formati disponibili

Aker Kværner Engineering & Technology

Technology & Front End

Report

TECHNICAL DOCUMENTATION FRONT SHEET

Type of Report : Pages :1 of 9

For Information Volume:

Classification:

None

BLOCK – “F” GAS PLATFORM

- US GOM FIT FOR PURPOSE FACILITY

Issued for Information A Aug 10 DRL DJ / GW DRL

Reason for issue Rev. Issue Date Made Chk'd Proj.

by by Appr.

PO No.: H1076050 Doc No.:1076050-AKI-Z-RA-1001 Responsible Party: AKI - FE

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 2 of 9

INDEX

1. INTRODUCTION .......................................................................................................3

2. FACILITY DESCRIPTION ........................................................................................4

2.1. Well Bay ......................................................................................................................4

2.2. Production System .......................................................................................................4

2.3. Gas Dehydration System .............................................................................................4

2.4. Produced Water Treatment ..........................................................................................4

2.5. Relief System...............................................................................................................5

2.6. Power Generation ........................................................................................................5

2.7. Instrument Air System.................................................................................................5

2.8. Fuel Gas System ..........................................................................................................5

2.9. Diesel Fuel System ......................................................................................................5

2.10. Compression ................................................................................................................5

2.11. Material Handling........................................................................................................6

2.12. Safety Systems............................................................................................................6

2.13. Buildings - Power Distribution & Control Room........................................................6

2.14. Living Quarters & HD .................................................................................................6

2.15. Other Utilities ..............................................................................................................6

3. PROPOSED STUDY DELIVERABLES....................................................................7

4. AKER KVAERNER EXPERIENCE ..........................................................................9

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 3 of 9

1. INTRODUCTION

This file note presents a description of typical Gulf of Mexico practices for low cost “fit for purpose”

gas platform production facilities.

Gulf of Mexico “shallow water” operations (up to ~300 ft) utilize Jack – Up MODU drilling or skidded

API MASE (Minimum Area Self Erecting) Drill Rigs.

With the Block “F” Field located in 120M (390 ft) – this file note focuses on use of Skidded API

Rigs.

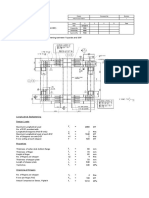

A typical API Rig Platform for gas production is illustrated below with provision of 13 – 18,000 sq. ft

main deck area provided to accommodate the rig with operating weights of up to 6,000 ST.

Typical overall topside dry weight is ~ 2200 to 2750 Tons including ~1000 tons of production

equipment and utilities – excluding the leased drill rig and associated leased rig power plant and

temporary sleeper cabins. The installed Cost of this platform would typically be $125M to

$145M – excluding any local taxes or duties.

These types of Gas Platforms have the following functionality:

• Dry Tree Wellbay with typically up to 15 slots and manifolds designed for well shut – in

pressure with test log.

• Production rates of up to 150 Mmscfd – free flowing initially. Compression – space for future

addition of gas engine reciprocating unit (s)

• VRU – provision of a small VRU unit to recover flash gas

• Condensate coalescing and Produced Water treatment with IGF unit to 15 ppm

• Often no gas dehydration if sweet gas – though space for electric dehydration if higher CO2

• Main deck space and payload for a API skidded Rig and associated engine skid and

sleepers

• Topsides structure consists of a two – level deck and sub – cellar located on a 4 or 6 batter

- leg jacket and skirt piles.

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 4 of 9

2. FACILITY DESCRIPTION

This section describes typical GOM practices for the respective facility system designs.

2.1. WELL BAY

Wellbays for these types of gas developments are typically 6 to 15 slots on 7’6” or 8’ spacing –

dependent on well completion size and rating. Trees are rated up to 10,000 psi as required to

exceed maximum shut – in pressure. Provision of local well control panel and HPU unit for tree

valves and main gas export departure SDV valve.

Hydrates – most shallow water GOM well systems do not have methanol injection upstream of

choke as sea temperature is favourable and pressures typically less than 4000 psi. For higher shut

– in pressures it is prudent to have methanol injection above the downhole SSCV and upstream of

the choke for initial start – up if well shut in at sea temperature.

2.2. PRODUCTION SYSTEM

Single horizontal production separator with inlet even flow device, vane pack demister and vortex

breaker. Design pressure to suit ANSI 600 flange rating at 1460 psig. Three – phase separation of

water and condensate. Parallel test separator. Condensate routed through a coalescer operating at

sales gas pressure and routed into the gas export line. Sales gas Metering skid provided and gas

export pig launcher, SDV and corrosion inhibition for the export pipeline.

2.3. GAS DEHYDRATION SYSTEM

If required by Contract or high CO2 – then Operators select a standard glycol dehydration unit (no

gas stripping to achieve say 6 lb/Mmscf); with either direct fired or electric elements. Typically 200

kw unit (10 gpm glycol) for a 100 Mmscfd capacity and 100 deg F inlet gas. Provision of inlet filter

scrubber (Peco type).

2.4. PRODUCED WATER TREATMENT

Produce water is routed from the Production Separator to the Water Skimmer and skimmed

condensate is pumped back to the separator using Texsteam H.P. gas - driven plunger pumps.

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 5 of 9

The produced water is then treated in an IGF unit (multi - compartment with induced draft agitators)

– with oil skimmed off to the closed drain sump and produced water routed to the open drain tank

and overboard below 15 ppm.

2.5. RELIEF SYSTEM

Vent systems are often deployed for gas platforms with a 316L HP vent header and HP flare drum

for cold blowdown with a fluidic molecular seal on the vent tip boom and CO2 snuffing system. The

HP scrubber pumps are air driven diaphragm type to route the liquids to the closed drain tank.

2.6. POWER GENERATION

The size of the Power Generation system is indicative of the complexity of the facility. GOM gas

platforms have minimal facilities, wide us of gas – driven pumps and minimal buildings with

enclosed HVAC demands. Typical power units are simple gas engine “enginators” sized 2 x 100%

at 300 to 500 kw each plus a diesel emergency unit sized at 200 kw. With gas dehydration – if

electric regeneration is used – then the power units will need to be 3 x 50 percent configuration.

Power and complexity savings are achieved as follows –

• Use of HP gas Texsteam driven pumps (plunger) and Wilden diaphragm types.

• No RO Unit – use ship bunkering of potable water

• Drill rig supplies own temporary pump in platform casing and powered by Rig.

• No fuel gas superheating required for gas engines versus use of turbines

• Closed drain Sump Pumps use air driven pumps to route to PW Skimmer Oil bucket and

then thru the HP Gas driven Texsteam Pumps to the production separator.

• No SW Lift Pumps – use a small SW lift Pump or Jockey Pump for wash down services

only. No cooling, no potable water service, no platform supply to the drill rig water

• No hypochlorite unit.

2.7. INSTRUMENT AIR SYSTEM

Typically 2 x 200 scfm units with filters, driers and receiver.

2.8. FUEL GAS SYSTEM

Simple scrubber receiver operating at sales gas pressure with letdown through filter separators.

Dry gas – so no hydrate and no superheat required for gas engines.

2.9. DIESEL FUEL SYSTEM

With a much reduced power generation demand – the crane pedestal often provides a 7 day

supply 980 – 100 bbl) for the emergency gen set with the main generators running off “buy – back”

gas in the event of platform shutdown. Simple transfer boost pumps provided and filters to supply

the EG, Crane and Survival Craft.

2.10. COMPRESSION

Some installations have a gas driven VRU – self contained with belt driven radiator.

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 6 of 9

2.11. MATERIAL HANDLING

Typically 35 / 5 ton 100 ft boom crane and 460 HP diesel engine. Electric and manual hoists and

monorails provided as required on the decks.

2.12. SAFETY SYSTEMS

Two x 100 percent diesel firewater pumps per NFPA. 2 x 50 man POB TEMPSC. F & G Systems

per API RP 14C, 14J and USCG.

2.13. BUILDINGS - POWER DISTRIBUTION & CONTROL ROOM

This is provided in a single MCC Building normally located on the upper Main Deck next to the LQ.

Workshop and Warehouse Buildings are located on the Production Deck.

2.14. LIVING QUARTERS & HD

Normally the permanent LQ is only sized for the longterm operation – typically 12 to 15 beds. The

drilling rig supplies its own temporary sleeper units (pressurized and fire proof).

2.15. OTHER UTILITIES

Potable water by bunkering – though ROs are low cost but add to the power load. Sewage units

are typically macerator type. Wash down pump and storage tank. Open Drain Sump Tank and air

pumps.

TYPICAL STRUCTURE – WITH AND WITHOUT DRILLING RIG

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 7 of 9

3. PROPOSED STUDY DELIVERABLES

1. FACILITY BASIS ..................................................................................................... 4

2. FACILITY DESCRIPTION ....................................................................................... 7

2.1. MANIFOLD SYSTEMS............................................................................................ 7

2.2. PRODUCTION SEPARATION ................................................................................ 7

2.3. CONDENSATE TREATING..................................................................................... 8

2.4. VRU COMPRESSION SYSTEM ............................................................................ 8

2.5. VENT SYSTEM ....................................................................................................... 9

2.6. GAS DEHYDRATION & GAS SALES...................................................................... 9

2.7. BOOST GAS COMPRESSION (IF APPLICABLE)................................................... 9

2.8. PRODUCED WATER .............................................................................................. 9

2.9. UTILITY WATER SYSTEM ................................................................................... 10

2.10. POWER GENERATION ........................................................................................ 10

2.11. FIRE WATER & SAFETY SYSTEMS .................................................................... 11

2.12. MATERIAL HANDLING ......................................................................................... 11

2.13. LIVING QUARTERS.............................................................................................. 11

2.14. CHEMICAL INJECTION ........................................................................................ 11

3. DECK LAYOUT & SAFETY CONSIDERATIONS .................................................. 12

3.1. SAFETY IN DESIGN ASPECTS........................................................................... 12

3.1.1. SAFETY GOALS ................................................................................................... 12

3.1.2. Layout and Orientation .......................................................................................... 12

3.1.3. Isolation, Shutdown and Blowdown ....................................................................... 13

3.1.4. Bunding and Drainage........................................................................................... 14

3.1.5. Hazardous Area Classification............................................................................... 14

3.1.6. Ventilation ............................................................................................................. 15

3.1.7. Explosion Mitigation and Protection....................................................................... 15

3.1.8. Passive Fire Protection.......................................................................................... 16

3.1.9. Active Fire Protection ............................................................................................ 16

3.1.10. Fire Detection........................................................................................................ 18

3.1.11. Combustible Gas Detectors................................................................................... 19

3.1.12. Egress Routes....................................................................................................... 19

3.1.13. Temporary Refuge ................................................................................................ 20

3.1.14. Evacuation / Escape Systems ............................................................................... 21

3.2. Layout Configuration Issues .................................................................................. 22

3.3. Structural Engineering ........................................................................................... 22

3.3.1. Structural Design Premise..................................................................................... 22

3.3.2. Concept Topsides & Jacket framing ...................................................................... 22

3.3.3. Concept Pile Foundation Design ........................................................................... 22

3.3.4. Installation Methodology........................................................................................ 22

3.3.5. Topsides, Jacket & Piling Bulk MTOs .................................................................... 22

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 8 of 9

4. EXECUTION PLAN ............................................................................................... 23

4.1. Background ........................................................................................................... 23

4.2. Execution Method.................................................................................................. 23

4.2.1. Engineering ........................................................................................................... 24

4.2.2. Procurement.......................................................................................................... 24

4.2.3. Fabrication & Installation ....................................................................................... 25

5. CAPEX COST ESTIMATE .................................................................................... 26

6. APPENDICES ....................................................................................................... 26

6.1. LAYOUT................................................................................................................ 32

6.2. PROCESS FLOW SCHEMATICS ......................................................................... 32

6.3. PROCESS STREAM SUMMARIES....................................................................... 32

6.4. EQUIPMENT LIST, COSTS & LLI’s....................................................................... 32

6.5. ELECTRICAL LOAD LIST ..................................................................................... 32

6.6. OTHER DATA ....................................................................................................... 32

Study Cost of $150,000 and a Duration of 10 - 12 Weeks from ARO.

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Aker Kværner Engineering & Technology

Technology & Front End

Report

Title: Doc. No.: Rev.: Date: Page:

CPC Block “F” Gas Platform 1076050-Z-RA-1001 A Aug 10 07 9 of 9

4. AKER KVAERNER EXPERIENCE

Aker Kvaerner Houston through it’s acquisition in the late 90’s of Enercon have appreciable

experience of fixed structure platforms in GOM and International.

In addition – the Aker Kvaerner Kuala Lumpur Office has many fixed platform projects in Malaysia

and South China Sea area.

An example below is for a Aker Kvaerner platform handling 600 Mmscfd (8 times larger than

Block “F”) – yet has a topsides weight of only 4000 MT.

10099-Z-1000 CPC Block - F - Aker Kvaerner Rev A Aug 15.doc

Potrebbero piacerti anche

- EEDIDocumento5 pagineEEDIvamsiarangi100% (2)

- Shell (1990) Layout Considerations For Offshore Topsides Facilities PDFDocumento76 pagineShell (1990) Layout Considerations For Offshore Topsides Facilities PDFVăn HoàngNessuna valutazione finora

- KRAKEN (Structural Basis of Design)Documento39 pagineKRAKEN (Structural Basis of Design)ANIL KUMAR100% (1)

- Condições Climáticas Bacia de CamposDocumento85 pagineCondições Climáticas Bacia de CamposÍcaro ReisNessuna valutazione finora

- Men Who Built AmericaDocumento3 pagineMen Who Built Americaapi-299776435Nessuna valutazione finora

- Guidelines For Floating Offshore Facilities For LNG/LPG Production, Storage and OffloadingDocumento80 pagineGuidelines For Floating Offshore Facilities For LNG/LPG Production, Storage and Offloadingkaspersky2009100% (2)

- Fpso Design and Conversion Practice: OGP Conference London, March 17, 2003Documento30 pagineFpso Design and Conversion Practice: OGP Conference London, March 17, 2003Aleksandr FilonenkoNessuna valutazione finora

- Steel Catenary RisersDocumento29 pagineSteel Catenary RisersZadeh NormanNessuna valutazione finora

- 0028/ND - Guidelines For The Transportation and Installation of Steel JacketDocumento38 pagine0028/ND - Guidelines For The Transportation and Installation of Steel JacketIkhwan Shafiq ZainalNessuna valutazione finora

- Webinar Presentation Subsea Manifold InstallationDocumento55 pagineWebinar Presentation Subsea Manifold InstallationTeck Tiong HuanNessuna valutazione finora

- 5 Supplimetary Information ReportDocumento39 pagine5 Supplimetary Information ReportANIL KUMARNessuna valutazione finora

- OTC13999 Development For A Deep Sea FPSO Suitable For The GoMDocumento8 pagineOTC13999 Development For A Deep Sea FPSO Suitable For The GoMAnil ChananaNessuna valutazione finora

- SACS MOSES InteropTransportation v1.3Documento11 pagineSACS MOSES InteropTransportation v1.3Muh. Saeful MHNessuna valutazione finora

- MARIN Seminar 04oct2016 v2Documento59 pagineMARIN Seminar 04oct2016 v2anon_723643771Nessuna valutazione finora

- 2002 Rio Fpso 1stDocumento269 pagine2002 Rio Fpso 1stAlex Rodriguez100% (1)

- BP Angelin Project: Jacket Loadout Analysis ReportDocumento48 pagineBP Angelin Project: Jacket Loadout Analysis ReportDhanu PadhuNessuna valutazione finora

- Fixed PlatformsDocumento98 pagineFixed Platformsusman nawazNessuna valutazione finora

- ABS Jacket Analysis ProcedureDocumento8 pagineABS Jacket Analysis ProcedureJolly Jack100% (1)

- Design Offshore PDFDocumento64 pagineDesign Offshore PDFAhmed MohammedNessuna valutazione finora

- QualifDocumento72 pagineQualifsabah8800Nessuna valutazione finora

- An Investigation of The Effects of Wind-Induced Inclination On Floating Wind Turbine Dynamics - Heave Plate ExcursionDocumento10 pagineAn Investigation of The Effects of Wind-Induced Inclination On Floating Wind Turbine Dynamics - Heave Plate ExcursionCarlos GarridoNessuna valutazione finora

- Safety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsDocumento19 pagineSafety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsFoyez AhmadNessuna valutazione finora

- TMR4225 Marine Operations - 7b - Offshore Loading Operations - 2020Documento37 pagineTMR4225 Marine Operations - 7b - Offshore Loading Operations - 2020Manoj GuptaNessuna valutazione finora

- 337TO 003 World's Largest FLNG PreludeDocumento9 pagine337TO 003 World's Largest FLNG PreludeRamNessuna valutazione finora

- Construction and WeightDocumento79 pagineConstruction and Weightusman nawazNessuna valutazione finora

- Simple Stability MosesDocumento11 pagineSimple Stability Mosesikhwanul_muslimNessuna valutazione finora

- Sea FasteningDocumento2 pagineSea FasteningOlanrewaju Tope100% (1)

- Topside Seafastening.002Documento6 pagineTopside Seafastening.002Sai SushankNessuna valutazione finora

- 350 BERTH Technical Specifications (Wo Pipelay)Documento55 pagine350 BERTH Technical Specifications (Wo Pipelay)jrladduNessuna valutazione finora

- General FPSODocumento22 pagineGeneral FPSOaravind grandhi100% (2)

- Thesis Manuscript - Airindy Felisita - 11Documento232 pagineThesis Manuscript - Airindy Felisita - 11klop disposableNessuna valutazione finora

- Report On GCDocumento35 pagineReport On GCSandeep SuryavanshiNessuna valutazione finora

- 10013T2ADECMooringStudyFinal PDFDocumento54 pagine10013T2ADECMooringStudyFinal PDFmyusuf_engineerNessuna valutazione finora

- Mudmat Role in Offshore Drilling Operations: August 2015Documento4 pagineMudmat Role in Offshore Drilling Operations: August 2015Dr R Panneer SelvamNessuna valutazione finora

- Understanding The Design of Liquefied Gas CarriersDocumento18 pagineUnderstanding The Design of Liquefied Gas CarriersShayne229100% (1)

- A 534410Documento145 pagineA 534410thlim19078656100% (1)

- Inclining Test ProceduresDocumento74 pagineInclining Test ProceduresIonut ArdeleanuNessuna valutazione finora

- FPSODocumento143 pagineFPSORagunath KarthickNessuna valutazione finora

- 8E.2 - Evaluation - Barge - MotionDocumento7 pagine8E.2 - Evaluation - Barge - MotionSiva ShankarNessuna valutazione finora

- Quayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)Documento35 pagineQuayside Mooring Analysis - Floatel Triumph at Kemaman (P30049-MA-REV 0) (2095)cliff1234Nessuna valutazione finora

- Technical Specification 1700Documento10 pagineTechnical Specification 1700bourneremembersNessuna valutazione finora

- Droped ObjectDocumento19 pagineDroped ObjectOgangwu BenjaminNessuna valutazione finora

- Mathcad - InPEX Masela FLNG Korea-Batam (Calm)Documento5 pagineMathcad - InPEX Masela FLNG Korea-Batam (Calm)fahmyits100% (1)

- ABS Fatigue Life Assessment 2014Documento1 paginaABS Fatigue Life Assessment 2014Fandy SipataNessuna valutazione finora

- Offshore Helideck Design GuidelinesDocumento307 pagineOffshore Helideck Design Guidelinestambok100% (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDa EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNessuna valutazione finora

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDa EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNessuna valutazione finora

- ACR700.Simulator - Manual.2009 10Documento45 pagineACR700.Simulator - Manual.2009 10yaprak dönerNessuna valutazione finora

- Sepa15015 MFSFD CV 21 Cal 101 - 1Documento23 pagineSepa15015 MFSFD CV 21 Cal 101 - 1Pruthviraj JuniNessuna valutazione finora

- Fuel Oil I&C Conceptual Basic Design: I.P.D.C. Project: Shirvan Gas Turbine Power Plant (Bop2 Portion)Documento14 pagineFuel Oil I&C Conceptual Basic Design: I.P.D.C. Project: Shirvan Gas Turbine Power Plant (Bop2 Portion)Ehsan PourangNessuna valutazione finora

- TECHNICAL373A Pages 2 5Documento4 pagineTECHNICAL373A Pages 2 5austintanNessuna valutazione finora

- Curs 4 Mept - en - Rev 2021Documento63 pagineCurs 4 Mept - en - Rev 2021Necula Alexandra Mihaela100% (1)

- FSO Federal IIDocumento65 pagineFSO Federal IIuud nasrulloh100% (2)

- Differences in Marine and Land Based Power Generation ApplicationDocumento7 pagineDifferences in Marine and Land Based Power Generation ApplicationChaitra Pm0% (1)

- Hvac Boq-07082014Documento18 pagineHvac Boq-07082014Kohilan NahivNessuna valutazione finora

- Ine - Chiller Carrier - 30rb090Documento13 pagineIne - Chiller Carrier - 30rb090yves2329Nessuna valutazione finora

- 8 Unit of 4.1MW Genset (LFO) Specifications20090914Documento25 pagine8 Unit of 4.1MW Genset (LFO) Specifications20090914alexNessuna valutazione finora

- Aux. Steam Distribution & Cond. Return Sys. Description: I.P.D.C. Project: Shirvan 6×159 M.W. Gas Turbine Power PlantDocumento9 pagineAux. Steam Distribution & Cond. Return Sys. Description: I.P.D.C. Project: Shirvan 6×159 M.W. Gas Turbine Power PlantepbamdadNessuna valutazione finora

- Investment Plan 2006 - Reason ReportDocumento25 pagineInvestment Plan 2006 - Reason ReportfuongbcNessuna valutazione finora

- GE HelitechDocumento24 pagineGE HelitechDamien HolmesNessuna valutazione finora

- PCP VenezuelaDocumento6 paginePCP VenezuelakurtbkNessuna valutazione finora

- Rescue Boat Launching MethodDocumento7 pagineRescue Boat Launching MethodAurvin Singh100% (1)

- (123doc) de Thi Thuye N Cong Nhan Va N Ha NH Lo Ma y Nam 2015 Nha Ma y Nhie T Die N Pha La IDocumento15 pagine(123doc) de Thi Thuye N Cong Nhan Va N Ha NH Lo Ma y Nam 2015 Nha Ma y Nhie T Die N Pha La IVăn HoàngNessuna valutazione finora

- CMGPP FD PR BOD 0001 - Process Basis of Design - Rev.0Documento14 pagineCMGPP FD PR BOD 0001 - Process Basis of Design - Rev.0Văn HoàngNessuna valutazione finora

- FS PP Dung QuatDocumento199 pagineFS PP Dung Quateagleonsky100% (1)

- P&IDsDocumento4 pagineP&IDsRamadhan PrasetyaNessuna valutazione finora

- Tatoraytechsheet PDFDocumento2 pagineTatoraytechsheet PDFAnubhavAgarwalNessuna valutazione finora

- CMGPP DD PE SPE 0001 Piping Material Specification Rev.3Documento80 pagineCMGPP DD PE SPE 0001 Piping Material Specification Rev.3Tuấn VũNessuna valutazione finora

- Flowsheet Symbols and PenI Diagrams PDFDocumento30 pagineFlowsheet Symbols and PenI Diagrams PDFRajeshNessuna valutazione finora

- Process Control Fundamentals 2Documento73 pagineProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- Piping EngDocumento7 paginePiping EngVăn HoàngNessuna valutazione finora

- (S. Pushpavanam (Eds.) ) Control and Optimisation o (B-Ok - CC) PDFDocumento270 pagine(S. Pushpavanam (Eds.) ) Control and Optimisation o (B-Ok - CC) PDFDeepshikhaSinghNessuna valutazione finora

- Review: Polypropylene Unit: Answer: A A. in A Chain Without The Elimination of WaterDocumento9 pagineReview: Polypropylene Unit: Answer: A A. in A Chain Without The Elimination of WaterVăn HoàngNessuna valutazione finora

- Internal Memorandum - Good Onshore LayoutsDocumento2 pagineInternal Memorandum - Good Onshore LayoutsVăn HoàngNessuna valutazione finora

- Refrigeration & Air-Conditioning Interview & Viva Questions With AnswersDocumento23 pagineRefrigeration & Air-Conditioning Interview & Viva Questions With AnswersVăn HoàngNessuna valutazione finora

- Nha ModelDocumento1 paginaNha ModelVăn HoàngNessuna valutazione finora

- Safety and Environmental DepartmentDocumento23 pagineSafety and Environmental DepartmentVăn HoàngNessuna valutazione finora

- LNG UVCE MitigtionDocumento47 pagineLNG UVCE MitigtionVăn HoàngNessuna valutazione finora

- APAC, Malaysia and Brunei OrganizationDocumento13 pagineAPAC, Malaysia and Brunei OrganizationVăn HoàngNessuna valutazione finora

- Don't Want To UploadDocumento8 pagineDon't Want To UploadVăn HoàngNessuna valutazione finora

- 2014 05 23 &30 - HUAN - TelecommunicationsDocumento48 pagine2014 05 23 &30 - HUAN - TelecommunicationsVăn HoàngNessuna valutazione finora

- Atmospheric Tank Fire ProtectionDocumento77 pagineAtmospheric Tank Fire ProtectionVăn HoàngNessuna valutazione finora

- Aker Kvaerner Design On Fixed TopsideDocumento9 pagineAker Kvaerner Design On Fixed TopsideVăn HoàngNessuna valutazione finora

- 01 PDS 004 - 1Documento3 pagine01 PDS 004 - 1Văn HoàngNessuna valutazione finora

- BPA - A Safety and Handling GuideDocumento16 pagineBPA - A Safety and Handling GuideVăn HoàngNessuna valutazione finora

- Platform Layout HierarchyDocumento1 paginaPlatform Layout HierarchyVăn HoàngNessuna valutazione finora

- Good Onshore LayoutsDocumento2 pagineGood Onshore LayoutsVăn HoàngNessuna valutazione finora

- Boundary Limit of Pip - Export Line SystemDocumento5 pagineBoundary Limit of Pip - Export Line SystemVăn HoàngNessuna valutazione finora

- PSV Data BookDocumento16 paginePSV Data Bookkenoly123Nessuna valutazione finora

- Cuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingDocumento9 pagineCuu Long Joint Operating Company: Calculation: Su Tu Trang FFD-P1 Line SizingVăn HoàngNessuna valutazione finora

- Daytona 350Documento48 pagineDaytona 350coco FadhNessuna valutazione finora

- Food and Nutrition EssayDocumento5 pagineFood and Nutrition EssayKavi BharathiNessuna valutazione finora

- GLA100Documento2 pagineGLA100Al De LeonNessuna valutazione finora

- Pressure Loss AwwaDocumento1 paginaPressure Loss AwwaSashiNessuna valutazione finora

- Daf ElectricDocumento74 pagineDaf ElectricHarlinton descalzi67% (6)

- Eng Sicor Catalogue GearlessDocumento52 pagineEng Sicor Catalogue GearlessEmeka Pius OramunwaNessuna valutazione finora

- Maching Learning Methods Used in Data MiningDocumento11 pagineMaching Learning Methods Used in Data MiningYunir Causil NoyaNessuna valutazione finora

- KELE Control Dif Presion AireDocumento2 pagineKELE Control Dif Presion AireCarlos Enrique Godoy SifontesNessuna valutazione finora

- Lecture Notes 08Documento25 pagineLecture Notes 08Abdul Hakeem Semar KamaluddinNessuna valutazione finora

- SM00092A - NX Fault CodesDocumento43 pagineSM00092A - NX Fault Codesdario_es60% (5)

- MGG155N2: Gaseous Generator Parts ManualDocumento94 pagineMGG155N2: Gaseous Generator Parts ManualYAKOVNessuna valutazione finora

- Whirlpool Awm 4120Documento16 pagineWhirlpool Awm 4120Zoran ProkicNessuna valutazione finora

- Example For Corporate Presentation Veolia PresentationDocumento41 pagineExample For Corporate Presentation Veolia PresentationswordprakashNessuna valutazione finora

- Operator's Manual: EH Series Desiccant DryerDocumento52 pagineOperator's Manual: EH Series Desiccant Dryermakhrufharsono 86Nessuna valutazione finora

- Plant Maintenance and Work Service - Practice: March 9, 2021Documento20 paginePlant Maintenance and Work Service - Practice: March 9, 2021THEOPHILUS ATO FLETCHERNessuna valutazione finora

- G 08Documento7 pagineG 08zbkt07Nessuna valutazione finora

- Jaypee Water Pre Treatment Plant: A Project ReportDocumento15 pagineJaypee Water Pre Treatment Plant: A Project ReportRachit KhandelwalNessuna valutazione finora

- 270 Boiler Control - One Modulating Boiler and DHWDocumento24 pagine270 Boiler Control - One Modulating Boiler and DHWe-ComfortUSANessuna valutazione finora

- Clam Basic Series Operators ManualDocumento16 pagineClam Basic Series Operators ManualRosanella GalindoNessuna valutazione finora

- Physics 211 Lab 1Documento2 paginePhysics 211 Lab 1Randy KingeryNessuna valutazione finora

- Solenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticDocumento8 pagineSolenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticVivin Welroy RodriguesNessuna valutazione finora

- (Page113-134) GCSE Physics Mark Scheme Paper 1 Nov 18Documento12 pagine(Page113-134) GCSE Physics Mark Scheme Paper 1 Nov 18ShaguNessuna valutazione finora

- TRC Unit SpecDocumento12 pagineTRC Unit SpecJohn ChirinosNessuna valutazione finora

- 61R Compact Raise Borer Technical Specification WorksheetDocumento4 pagine61R Compact Raise Borer Technical Specification WorksheetRoiNessuna valutazione finora

- Sizing Phase-Change Energy Storage Units For Air-Based Solar Heating SystemsDocumento5 pagineSizing Phase-Change Energy Storage Units For Air-Based Solar Heating Systemsfabio1199Nessuna valutazione finora

- VLSI Design Unit-2 Mosfet TransistorDocumento5 pagineVLSI Design Unit-2 Mosfet Transistorselvi0412Nessuna valutazione finora

- Rame ProfileDocumento6 pagineRame Profiletri_purwadiNessuna valutazione finora

- Siemons - Cello Bowing TechniqueDocumento15 pagineSiemons - Cello Bowing TechniqueMassa Awaj100% (2)

- A Level Physics Units & SymbolDocumento3 pagineA Level Physics Units & SymbolXian Cong KoayNessuna valutazione finora