Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Gathering Instrument For Trainee

Caricato da

Mario TanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Gathering Instrument For Trainee

Caricato da

Mario TanCopyright:

Formati disponibili

RM Training Center

Tacloban City, Leyte

Data Gathering Instrument for Trainee’s

Characteristics

Name: ________________________________Date:___________________

School/Institute: ________________________________________

Instruction: Please answer the following instrument according

to the characteristics described below. Encircle the letter of your

choice that best describes you as a learner. Blank spaces are provided

for some data that need your response.

Characteristics of learners

Language, literacy Average grade in: English Average grade in: Math

and numeracy a. 95 and above a. 95 and above

(LL&N) b. 90 to 94 b. 90 to 94

c. 85 to 89 c. 85 to 89

d. 80 to 84 d. 80 to 84

e. 75 to 79 e. 75 to 79

Cultural and Ethnicity/culture:

language

background a. Waray2x

b. Bisaya

c. Cebuano

d. Ilocano

e. Tagalog

g. Others( please specify)

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Education & Highest Educational Attainment:

general knowledge

a. High School Level

b. High School Graduate

c. College Level

d. College Graduate

e. with units in Master’s degree

f. masteral Graduate

g. With units in Doctoral Level

h. Doctoral Graduate

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Sex a. Male

b. Female

Age Your age:

Physical ability 1. Disabilities(if any)

2. Existing Health Conditions (Existing illness if

any)

a. None

b. Asthma

c. Heart disease

d. Anemia

e. Hypertension

f. Diabetes

g. Others(please specify)

Previous experience Machining Certificates

with the topic a. Machining certified

b. Machining graduate

c. Machining trainer

d. Machining lead trainer

Number of years as a competency trainer

List down trainings related to Machining

Previous learning

experience a.

b.

National Certificates acquired and NC level

Training Level

completed a.

b.

Other courses related to Machining

Special courses a. Units in education

b. Master Degree units in education

c. Other(please Specify)

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Learning styles a. Visual - The visual learner takes mental

pictures of information given, so in order for this

kind of learner to retain information, oral or

written, presentations of new information must

contain diagrams and drawings, preferably in color.

The visual learner can't concentrate with a lot of

activity around him and will focus better and learn

faster in a quiet study environment.

b. Kinesthetic - described as the students in

the classroom, who have problems sitting still

and who often bounce their legs while tapping their

fingers on the desks. They are often referred to as

hyperactive students with concentration issues.

c. Auditory- a learner who has the ability to

remember speeches and lectures in detail but

has a hard time with written text. Having to read

long texts is pointless and will not be retained by

the auditory learner unless it is read aloud.

d. Activist - Learns by having a go

e. Reflector - Learns most from activities where

they can watch, listen and then review what has

happened.

f. Theorist - Learns most when ideas are linked to

existing theories and concepts.

Other needs g. Pragmatist

a. Financially - Learns most from learning

challenged

activitiesstudent

b. Working that are directly relevant to their

c. Solo parent situation.

d. Others(please specify)

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

What's Your Learning Style?

For these questions, choose the first answer that

comes to mind and click on a, b, or c. Do not spend too much time

thinking about any one question.

1. When you study for a test, would you rather

A. read notes, read headings in a book, and look at diagrams and

illustrations?

B. have someone ask you questions, or repeat facts silently to

yourself?

C. write things out on index cards and make models or

diagram

2. Which of these do you do when you listen to music?

A. daydream (see things that go with the music)

B. hum a along

C. move with the music, tap your foot, etc.

3. When you work at solving a problem do you

A. make a list, organize the steps, and check them off as they are

done?

B. make a few phone calls and talk to friends or experts?

C. make a model of the problem or walk through all the steps in your

mind?

4. When you read for fun, do you prefer

A. a travel book with a lot of pictures in it?

B. a mystery book with a lot of conversation in it?

C. a book where you answer questions and solve problems?

5. To learn how a computer works, would you rather

A. watch a movie about it?

B. listen to someone explain it?

C. take the computer apart and try to figure it out for yourself?

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

6. You have just entered a science museum, what will you do first?

A. look around and find a map showing the locations of the various

exhibits.

B. talk to a museum guide and ask about exhibits.

C. go into the first exhibit that looks interesting, and read

directions later.

7. What kind of restaurant would you rather not go to?

A. one with the lights too bright

B. one with the music too loud

C. one with uncomfortable chairs

8. Would you rather go to

A. an art class?

B. a music class?

C. an exercise class?

9. Which are you most likely to do when you are happy?

A. grin

B. shout with joy

C. jump for joy

10. If you were at a party, what would you be most likely to remember the

next day?

A. the faces of the people there, but not the names

B. the names but not the faces

C. the things you did and said while you were there

11. When you see the word "d - o - g", what do you do first?

A. think of a picture of a particular dog

B. say the word "dog" to yourself silently

C. sense the feeling of being with a dog (petting it, running with it, etc.)

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

12. When you tell a story, would you rather

A. write it?

B. tell it out loud? C. act it

out?

13. What is most distracting for you when you are trying to concentrate?

A. visual distractions

B. noises

C. other sensations like, hunger, tight shoes, or worry

14. What are you most likely to do when you are angry?

A. scowl

B. shout or "blow up"

C. stomp off and slam doors

15. When you aren't sure how to spell a word, which of these are you

most likely to do?

A. write it out to see if it looks right

B. sound it out

C. write it out to see if it feels right

16. Which are you most likely to do when standing in a long line at the

movies?

A. look at posters advertising other movies

B. talk to the person next to you

C. tap your foot or move around in some other way

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

TO DETERMINE YOUR LEARNING STYLE:

Total your a's, b's, and c's. If you scored mostly

A's you may have a visual learning style.

B’s you may have an auditory learning style

C’s you may have a kinesthetic learning style

Total Score: A’s ________ you are a visual learning style

B’s ________ you are an auditory learning style

C’s ________ you are a kinesthetic learning style

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

FORM 1.1 SELF-ASSESSMENT CHECK

Name: _____________________________________________________Date: ________

School/Institution:________________________________________________________

INSTRUCTIONS: This Self-Check Instrument will give the trainer necessary

data or information which is essential in planning

training sessions.Please check the appropriate

box of your answer to the questions below.

Qualification: SHIELDED METAL ARC WELDING (SMAW) NC II

Unit of Competency: Weld Carbon Steel Plates and Pipes Using SMAW

Instruction:

Read each of the questions in the left-hand column of the chart.

Place a check in the appropriate box opposite each question to indicate your answer.

Can I? YES NO

Perform root pass*

Clean root pass*

Weld subsequent/filling passes*

Perform capping*

Interpret drawing

Identify materials and consumables

Identify welding codes

Perform basic math computations and mensuration

Identify weld defects*

Rectify weld defects*

Apply weld techniques*

Handle materials, tools and equipment

Observe safety practices*

Pass weld visual inspection*

I agree to undertake assessment in the knowledge that information gathered will only be

used for professional development purposes and can only be accessed by concerned

assessment personnel and my manager/supervisor.

Candidate’s name

Date:

& signature:

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Evidence of Current Competencies R ecquired related to

Job/Occupation form 1.2:

Current

Proof/Evidence Means of validating

competencies

WELD CARBON Certificate of Check the authenticity of

PLATES AND Employment the Employment

PIPES USING Certificate

SMAW

Prepared by:

Romarico Mendiola Jr

TRAINER

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Identifying Training Gaps

Summary of Current Competencies Versus Required

Competencies Form 1.3

Required Units of Current Training

Competency/Learning Competencies Gaps/Requirements

Outcomes based on CBC

1. Weld Carbon Steel Plates and Pipes Using SMAW

1.1 . Perform root pass Perform root pass

1.2 Clean root pass Clean root pass

1.3 Weld subsequent/ Weld subsequent/

filling passes filling passes

Perform capping

1.4 Perform capping

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

TRAINING NEEDS

Form No. 1.4

Training Needs Module Title/Module

of Instruction

(Learning Outcomes)

Weld Metal Plates

Perform root pass and Pipes Using Smaw

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

PRE – ASSESSMENT TEST

Name: Date:

Qualification:

Test I- Multiple Choice

INSTRUCTION: Choose the correct letter of the best answer; write the letter

of your choice on your answer sheet.

1. Cutting __________ should be operational and should conform to acceptable

OH&S standards?

A. Specification

B . Tolerance

C. Cutting

D. Equipment

2. ____________should conform to acceptable OH&S requirement and standards.

A. PPE

B. CBLM

C. TR

D. LM

3. What is the first welding pass in term of shielded metal standard?

A. Hot pass

B. Root pass

C. Capping pass

D. filling pass

4. The metal that is to be worked or welded.

A. Base plate

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

B. Welding

C. Electrode

D. None of the above

5. Joining two metals by applying heat to melt and fuse them, with or without

filler metal.

A. Electrode

B. Welding

C. Carbon steel plate

D. None of the above

6. The current-carrying rod used to strike an arc between rod and metal.

A. Current

B. Metal

C. Welding electrode

D. None of the above

7. A gas mixing and burning tool for the welding of metal.

A. Metal

B. welding torch

C. Carbon

D. All of the above

8. An irregularity that spoils the weld appearance or impairs the effectiveness

of the weld or weldment by causing weakness or failure.

A. strong

B. Weak

C. Welding defect

D. all of the above

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

9. What is the second pass in welding term?

A. Hot pass

B. Root pass

C. High pass

D. Long pass

10. In grinding the materials what equipment to use?

A. Pencil

B. Paper

C. Welding

D. Portable grinder

11. Joining two metals by applying heat to melt and fuse them, with or

without filler metal.

A. Standard

B. Competency

C. Welding

D. None of the abov

12. An assembly or structure whose component parts are joined by welding

A. Electrode

B. Grinding disc

C. Stone

D. Welment

13. Filler metal in the form of a rod or heavy wire.

A. Electric wire

B. Electric Stove

C. Welding Electrode

D. All of the above

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

14. The junction of weld metal and the base metal, or the junction of

base metal parts when filler metal is not used.

A. Weld line

B. weld defects

C. weld carbon

D. Welding

15.A gas mixing and burning tool for the welding of metal

A. Welding torch

B. Torch

C. Hammer

D. wire brush

16. A deposit of filler metal from a single welding pass.

A. Root pass

B. Weld bead

C. Hot pass

D. All of the above

17. An assembly or structure whose component parts are joined by.

A. Weldment

B. Flat bar

C. Horizontal

D. None of the above

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

18. Shielded Metal Arc Welding stands for.

A. SMAW

B. SWAT

C. NSAT

D. None of the above

19. What is the first step in welding steel plate in flat welding position?

A. Capping

B. Root pass

C. Hot pass

D. Chipping

20. How do you groove or bevel the steel plate?

A. By chipping

B. By hammering

C. By grinding

D. By marking

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

ANSWERS KEY

1. D 11. C

2. A 12. D

3. B 13. B

4. A 14. A

5. B 15. A

6. C 16. B

7. B 17. A

8. C 18. A

9. A 19. B

10. D 20. C

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

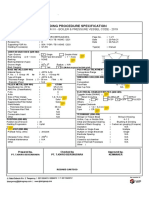

SESSION PLAN

Sector : METALS AND ENGINEER

Qualification Title : SHIELDED METAL ARC WELDING NC II

Unit of Competency : WELD METAL PLATES AND PIPES USING SMAW

Module Title : Welding Metal Plates and Pipes Using Smaw

Learning Outcomes:

LO1: Perform root pass LO2: Clean root pass LO3: Weld subsequent/ filling passes LO4: Perform capping

A. INTRODUCTION:

This module covers the knowledge, skills and attitude in performing welding on carbon steel plates and pipes using smaw.

B. LEARNING ACTIVITIES:

LO: 1

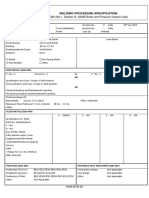

Learning Content Methods Presentation Practice Feedback Resources Time

Modular self- Check answer Information

Welding Procedure paced learning from the answer sheet 1.1-1

Specification and/or Read key 1.1-1

client specifications. Lecture information Answer Self- Task sheet 1.1-1 1 hour

Sheet1.1-1 Check 1.1-1 Apply

Watching video Performance Performance

clips Video tutorial Task sheet criteria checklist criteria checklist

1.1-1

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Safety procedure and Modular self- Read Answer self- Check answer information

requirements paced learning information check 1.1-2 from the Answer sheet 1.1-2

Sheet 1.1-2 key 1.1-2

Perform Task sheet 1.1-2

Lecture

safety Use performance Performance

procedure criteria checklist

criteria checklist

Defects and Repaired Modular self- Read Answer self- Check answer information

paced learning information check 1.1-3 from the answer sheet 1.1-3

sheet 1.1-3 key 1.1-3

Check weld in Task sheet 1.1-3

Lecture

Visual for Use performance Performance

defects criteria checklist

criteria checklist

Codes and Standard Modular self- Read Answer self- Check answer information

paced learning information check 1.1-4 from the answer sheet 1.1-4

sheet 1.1-4 key 1.1-4

Check weld Task sheet 1.1-4

Lecture

Website visual if Use performance

Internet information acceptable criteria checklist

Performance

criteria checklist

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

LO: 2

Check answer Information

Modular self- Answer self- form the answer sheet 1.2-1

defects and paced learning Read check 1.2-1 key 1.2-1 Task sheet 1.2-1

discontinuities information

Lecture/video sheet 1.2-1 Task clean Apply Use performance

clip root pass performance criteria checlist

criteria checklist

Read Information

Modular self-

Welding Procedure information sheet 1.2-2

paced learning

sheet 1.2-2 Answer self- Check answer from

Specification Lecture

check 1.2-2 the answer key 1.2-2

Website

Internet

information

LO: 3

Modular self- Read information Check answer Information

paced learning sheet 1.3-1 from the answer sheet 1.3-1/

Answer self-

key 1.3-1 Task sheet

lding Procedure check 1.3-1

Watching Video tutorial 1.3-1 /

Specification Apply assessment Use

Perform weld

criteria checklist performance

subsequent/

criteria

filling passes

checklist

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Modular self- Answer self- Information

learning check 1.3-2 sheet 1.3-2

Check answer

Read information from the answer

Lecture Check visual Task sheet

Defects and sheet 1.3-2 key 1.3-2

defects and 1.3-2

repaired

repair

Use assessment

Assessment

criteria checklist

criteria

checklist

Answer self – Check answer Information

check 1.3-3 from the answer sheet 1.3-3/

Modular self- Read information

key 1.3-3 Task sheet

Codes and paced learning sheet 1.3-3

Check visual 1.3-3 /

Standard

if acceptable Use assessment Assessment

Lecture

criteria checklist criteria

checklist

LO: 4

Modular self- Read information Answer self- Check answer Information

paced learning sheet 1.4-1 check 1.4-1 form the anwser sheet 1.4-1/

Welding Procedure key 1.4-1 Task sheet

Specification Video tutorial Perform 1.4-1

Watching

and/or client capping Performance

specifications. Use performance criteria

criteria checklist checklist

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Defects and Modular self- Read information Answer self- Check answer Information

repaired learning/ sheet 1.4-2 check 1.4-2 from the answer sheet 1.4-2

key 1.4-2

Lecture Check defects Task sheet

and repair Use performance 1.4-2

assessment

criteria checklist Performance

criteria

checklist

Codes and Modular self- Read information Answer self – Check answer Information

Standard paced learning sheet 1.4-3 check 1.4-3/ from the answer sheet 1.4-3

Check weld key 1.4-3

visual if Task sheet

acceptable Use performance 1.4-3

criteria checklist Performance

criteria

checklist

C. ASSESSMENT PLAN

Written Test

Performance Test

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Demonstration

D. TEACHER’S SELF-REFLECTION OF THE SESSION

Prepared by:

Romarico Mendiola Jr.

TRAINER

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

HOW TO USE THIS COMPETENCY- BASE

LEARNING MATERIALS

Welcome!

The unit of competency, " Weld Carbon Steel Plates And Pipes

Using Smaw , is one of the competencies of Shielded Metal Arc Welding NC

II, a course which comprises the knowledge, skills and attitudes required for

a S M A W trainee to possess.

The module ,Weld Carbon Steel Plates and Pipes Using Smaw ,

contains training materials and activities related to this unit covers skills ,

knowledge an attitudes required in Welding Carbon metal Plates and Pipes Using

Smaw process.

In this module, you are required to go through a series of learning

activities in order to complete each learning outcome. In each learning

outcome are Information Sheets, Self-Checks, Task Sheets and Job Sheets.

Follow and perform the activities on your own. If you have questions, do not

hesitate to ask for assistance from your facilitator.

Remember to:

Read information sheets and complete the self-checks. Suggested

references are included to supplement the materials provided in this module.

Perform the Task Sheets and Job Sheets until you are confident that your

outputs conform to the Performance Criteria Checklist that follows the

sheets.

Submit outputs of the Task Sheets and Job Sheets to your facilitator for

evaluation and recording in the Accomplishment Chart. Outputs shall

serve as your portfolio during the Institutional Competency Evaluation.

When you feel confident that you have had sufficient practice, ask your

trainer to evaluate you. The results of your assessment will be recorded in

your Progress Chart and Accomplishment Chart.

You must pass the Institutional Competency Evaluation for this

competency before moving to another competency. A Certificate of

Achievement will be awarded to you after passing the evaluation.

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

SMAW NC II

COMPETENCY-BASED LEARNING MATERIALS

List of Competencies

Code No. BASIC COMPETENCIES

500311105 Participate in Workplace Communication

500311106 Work in Team Environment

500311107 Practice career professionalism

500311108 Practice occupational health and safety procedures

Code No. COMMON COMPETENCIES

MEE722201 Apply Safety Practices

MEE721202 Interpret Drawings and Sketches

MEE721203 Perform Industry Calculations

MEE721204 Contribute to Quality System

MEE721205 Use Hand Tools

MEE721206 Prepare Weld Materials

MEE721207 Setup Welding Equipment

MEE721208 Fit up Weld Materials

MEE721209 Repair Welds

Code No. CORE COMPETENCIES

MEE7213 Weld Carbon Steel Plates and Pipes Using SMAW

06

Prepared by:

Romarico Mendiola Jr

Trainer

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Module Content

Qualification Title : SHIELDED METAL ARC WELDING NC II

Unit of Competency : Weld carbon plates and pipes using smaw

Module Title : Welding carbon plates and pipes using smaw

Nominal Duration : 194 Hours

Introduction

This unit covers the competencies required to select and use hand

and power tools to perform complex bench work operation.

LEARNING OUTCOMES:

Upon Completion of this module you MUST be able to:

LO1: Perform root pass

LO2: Clean root pass

LO3: Weld subsequent/ filling passes

LO4: Perform capping

Assessment Criteria:

Root pass is performed in accordance with WPS

and/or client specifications.

Task is performed in accordance with company or industry

requirement and safety procedure.

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Weld is visually checked for defects and repaired, as required

Weld is visually acceptable in accordance with applicable codes and

standards

Root pass is cleaned and free from defects and discontinuities

Task is performed in accordance with approved WPS

Subsequent/ filling passes is performed in accordance with

approved WPS

Capping is performed in accordance with WPS and/or client

specifications

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Leaning Outcome #1 Title : Perform Root Pass

Contents:

Explain the essentials of welding

Deposit weld beads on plate

Weld plates in root pass groove joints in flat, horizontal and

vertical positions

Weld plates in root pass groove joints in overhead positions

Weld pipe in root pass 1G, 2G, 5G and 6G positions

Assessment Criteria

Root pass is performed in accordance with WPS and/or client

specifications.

Task is performed inaccordance with company or industry

requirement and safety procedure.

Weld is visually checked for defects and repaired, as required.

Weld is visually acceptable in accordance with applicable codes

and standards

Content

Tools

Head shield/helmet Plier/tong

Ballpeen Hammer Try square

Files-half round Steel brush

Steel square 300 mm. long 300 mm.

long

Leather apron/jacket

Leather glove, long

Safety goggle, wide vision,

clear

Oxy-acetylene goggles

Chipping Hammer

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

Assessment Method:

1. direct observation of bench work

activities

2. written exam

3. oral short answer questions

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

RM Training Center

Tacloban City, Leyte

SHIELDED METAL ARC Developed November , 2019

WELDING NC II

Developed by:

Welding Steel Plates

And Pipe using Smaw ROMARICO MENDIOLA JR.

Potrebbero piacerti anche

- Specific Instruction SmawDocumento1 paginaSpecific Instruction SmawMay Esban100% (1)

- Welder Performace Qualification Report 2014..Documento132 pagineWelder Performace Qualification Report 2014..Kayra Riri ChirulNessuna valutazione finora

- Determining The Cost of WeldingDocumento22 pagineDetermining The Cost of WeldingSanjay J NNessuna valutazione finora

- Competency-Based Learning Material: Shielded Metal Arc Welding (SMAW) I.Learn Center PhilippinesDocumento39 pagineCompetency-Based Learning Material: Shielded Metal Arc Welding (SMAW) I.Learn Center PhilippinesRuel Daitol100% (3)

- Trainees Record BookDocumento10 pagineTrainees Record BookJaypee AturoNessuna valutazione finora

- Conduct Competency AssessmentDocumento3 pagineConduct Competency AssessmentMelita-Mely Baco PallarcoNessuna valutazione finora

- Aws A5 14 PDFDocumento7 pagineAws A5 14 PDFrezaNessuna valutazione finora

- Wps Format Asme Sec - IxDocumento2 pagineWps Format Asme Sec - IxDeepu ChandranNessuna valutazione finora

- Demonstration Checklist With Oral QuestioningDocumento2 pagineDemonstration Checklist With Oral QuestioningAlberto T. Toledo100% (2)

- Welding Duplex Stainless Steel Piping SpecDocumento44 pagineWelding Duplex Stainless Steel Piping SpecAlaa100% (1)

- d10 6-d10 6mPVDocumento6 pagined10 6-d10 6mPVDhanush Nair0% (1)

- CBLM - SMAW NC II - CORE PIPES NewDocumento207 pagineCBLM - SMAW NC II - CORE PIPES NewCharity GarrateNessuna valutazione finora

- SESSION PLAN in SMAW NC2Documento5 pagineSESSION PLAN in SMAW NC2justin may tuyorNessuna valutazione finora

- Learn Adult CharacteristicsDocumento6 pagineLearn Adult CharacteristicsJaizery Realubit OriñaNessuna valutazione finora

- Housekeeping Schedule SmawDocumento8 pagineHousekeeping Schedule SmawWc-mark ChuvachucHuNessuna valutazione finora

- Facilitate Learning Session (Steps)Documento1 paginaFacilitate Learning Session (Steps)Emmer100% (2)

- TESDA Welding Module on Cleaning Root PassesDocumento9 pagineTESDA Welding Module on Cleaning Root PassesMarilyn odtujan100% (1)

- Esab Welding Filler Metal Databook - Usa 2016Documento426 pagineEsab Welding Filler Metal Databook - Usa 2016Mahiro MacNessuna valutazione finora

- Metal - Brazing and Soldering - ProcessesDocumento8 pagineMetal - Brazing and Soldering - Processeshisham_eyes100% (1)

- SMAW Assessment ConductedDocumento3 pagineSMAW Assessment ConductedRuel Concepcion100% (1)

- Code of Welding Process Qualification-CHINADocumento71 pagineCode of Welding Process Qualification-CHINAParvee K Nakwal100% (1)

- Institutional Assessment (SMAW NC II)Documento11 pagineInstitutional Assessment (SMAW NC II)greatcenter registrarNessuna valutazione finora

- SMAW NC I CBLM CoreDocumento146 pagineSMAW NC I CBLM CoreSeniorito Louiesito100% (2)

- CBC SMAW NCII Feb. 9 2018Documento76 pagineCBC SMAW NCII Feb. 9 2018jayson platino100% (1)

- CBT Monitoring Tools GuideDocumento7 pagineCBT Monitoring Tools GuideMario Tan100% (3)

- 3 Facilitate Learning SessionDocumento10 pagine3 Facilitate Learning SessionMaica50% (2)

- NPA_EPAS NCII_Flexible Learning_Training PlanDocumento12 pagineNPA_EPAS NCII_Flexible Learning_Training PlanJhay Dee50% (2)

- Evidence Plan 2Documento30 pagineEvidence Plan 2cheenee dela cruz100% (1)

- Welding Lecture1 2Documento34 pagineWelding Lecture1 2Dr Abhijeet GangulyNessuna valutazione finora

- Evidence Plan: Machining NCII Turn Work Piece (Intermediate)Documento12 pagineEvidence Plan: Machining NCII Turn Work Piece (Intermediate)alice jane lagsa100% (1)

- Maintain Training Facilities (Complete Docs)Documento15 pagineMaintain Training Facilities (Complete Docs)kurapota0% (1)

- Core Smaw NC IDocumento13 pagineCore Smaw NC INICOSAT CollegesNessuna valutazione finora

- Parts of A Competency-Based Learning Material PackageDocumento19 pagineParts of A Competency-Based Learning Material PackageRoedfrey OrtizNessuna valutazione finora

- TRAINING PLAN For SMAW 1Documento16 pagineTRAINING PLAN For SMAW 1Mark Marasigan100% (10)

- Usability Designators FCAWDocumento5 pagineUsability Designators FCAWAnonymous dh6DITNessuna valutazione finora

- CBLM Set Up Welding Equipment NC 2 OCT. 2022Documento43 pagineCBLM Set Up Welding Equipment NC 2 OCT. 2022Mark KimhitaNessuna valutazione finora

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocumento3 pagineASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNessuna valutazione finora

- Maintain Training FacilitiesDocumento14 pagineMaintain Training Facilitiesrodel megollasNessuna valutazione finora

- Script FacilitatingDocumento4 pagineScript FacilitatingHisburn BermudezNessuna valutazione finora

- Standard Specification 3-26-4 Vessel Internals Low Chrome and Stainless SteelDocumento2 pagineStandard Specification 3-26-4 Vessel Internals Low Chrome and Stainless SteelSenthil KumarNessuna valutazione finora

- Rating Sheet For Demonstration With Oral QuestioningDocumento4 pagineRating Sheet For Demonstration With Oral QuestioningRinalyn G. CanetesNessuna valutazione finora

- Session Plan: Metals and Engineering Shield Metal Arc Welding (Smaw) NC Ii Participating in Workplace CommunicationDocumento5 pagineSession Plan: Metals and Engineering Shield Metal Arc Welding (Smaw) NC Ii Participating in Workplace CommunicationJesus Placedes100% (1)

- WPSDocumento2 pagineWPSAlam MD Sazid100% (1)

- Demonstration Checklist for Motorcycle Engine ServicingDocumento4 pagineDemonstration Checklist for Motorcycle Engine ServicingCelso Amoto0% (2)

- Smaw NC IiDocumento62 pagineSmaw NC IiMark Marasigan0% (1)

- Recieve and Respond To Workplace CommunicationDocumento57 pagineRecieve and Respond To Workplace CommunicationAlberto T. ToledoNessuna valutazione finora

- DON BOSCO BOYS HOME AND VOCATIONAL TRAINING CENTER MODULE ON DEMONSTRATE WORK VALUESDocumento14 pagineDON BOSCO BOYS HOME AND VOCATIONAL TRAINING CENTER MODULE ON DEMONSTRATE WORK VALUESCelso Amoto100% (1)

- Standard Specification 3-26-2: 1. GeneralDocumento2 pagineStandard Specification 3-26-2: 1. Generalhlagos123Nessuna valutazione finora

- Install Computer Systems Evidence PlanDocumento17 pagineInstall Computer Systems Evidence PlanRex Chambers LadaoNessuna valutazione finora

- COMMON 2 Interpret Drawing and Sketches FINALDocumento82 pagineCOMMON 2 Interpret Drawing and Sketches FINALJoyLyn Sarmiento AmitNessuna valutazione finora

- Contribute To Quality SystemDocumento13 pagineContribute To Quality SystemYang Cole100% (2)

- Evidence PlanDocumento6 pagineEvidence PlanEmmer100% (2)

- Maintain Training FacilitiesDocumento26 pagineMaintain Training FacilitiesJohn Emmanuel100% (1)

- CBLMDocumento50 pagineCBLMLowen Tabance Simbit100% (2)

- TM Smaw NC IiDocumento137 pagineTM Smaw NC IiSam Louis Lepiten100% (1)

- Don Bosco Boys Home Practices Housekeeping ProceduresDocumento18 pagineDon Bosco Boys Home Practices Housekeeping ProceduresCelso Amoto88% (8)

- Cblm-SmawDocumento43 pagineCblm-Smawrezhablo33% (3)

- Training Matrix Smaw NC IDocumento10 pagineTraining Matrix Smaw NC IEdward LyleNessuna valutazione finora

- CBLM-SMAW NC I Use Hand ToolsDocumento68 pagineCBLM-SMAW NC I Use Hand ToolsRichard Chaneco100% (1)

- CBLM Smaw Plates 1g-4gDocumento39 pagineCBLM Smaw Plates 1g-4gMarlon Ty Manalo85% (27)

- Session-Plan SMAW NC IDocumento4 pagineSession-Plan SMAW NC ICris Herra100% (6)

- Bs-En Iso 544 2003 PDFDocumento16 pagineBs-En Iso 544 2003 PDFPacoNessuna valutazione finora

- Essential Variables API 1104Documento4 pagineEssential Variables API 1104Madidj_2014Nessuna valutazione finora

- Smaw PTSDocumento19 pagineSmaw PTSGissele AbolucionNessuna valutazione finora

- Smaw NC IIDocumento42 pagineSmaw NC IILloyd Arnold Catabona100% (1)

- Maintain Training FacilitiesDocumento15 pagineMaintain Training FacilitiesrobNessuna valutazione finora

- Templates for Welding Qualification DocumentsDocumento124 pagineTemplates for Welding Qualification DocumentsJohn Wilner DirectoNessuna valutazione finora

- RATING SHEET FOR DEMONSTRATION SmawDocumento3 pagineRATING SHEET FOR DEMONSTRATION SmawLudivino Toto Ledesma Condalor100% (2)

- Supervise EditononDocumento37 pagineSupervise EditononDALISAY GINGCO67% (3)

- CALCULATION SKILLS FOR WELDING NCIIDocumento22 pagineCALCULATION SKILLS FOR WELDING NCIIYang Cole100% (1)

- SMAW Welding Task SheetDocumento2 pagineSMAW Welding Task SheetShallimar AlcarionNessuna valutazione finora

- Waste Segregation Methods for Electrical TrainingDocumento1 paginaWaste Segregation Methods for Electrical TrainingMay Esban100% (1)

- 2019-05-13 (PTS) Plan Training Session Questionnaire For Trainee CharacteristicsDocumento3 pagine2019-05-13 (PTS) Plan Training Session Questionnaire For Trainee CharacteristicsMich AltoNessuna valutazione finora

- Task Sheet Title: Enrolling Learners Performance ObjectiveDocumento2 pagineTask Sheet Title: Enrolling Learners Performance ObjectiveAileen Ligmayo0% (1)

- 2 Housekeeping ScheduleDocumento3 pagine2 Housekeeping ScheduleCeloSakiNessuna valutazione finora

- Electronic Products Assembly and Servicing NC Ii Assembly Electronic ProductsDocumento2 pagineElectronic Products Assembly and Servicing NC Ii Assembly Electronic ProductsJhobhel Christopher Galivo100% (2)

- CBLMDocumento60 pagineCBLMfelicity lincuna100% (2)

- Leyte National High School: Data Gathering Instrument For Trainee's CharacteristicsDocumento14 pagineLeyte National High School: Data Gathering Instrument For Trainee's CharacteristicsMacxzNessuna valutazione finora

- Promulgated Training Regulations As of March 2016Documento7 paginePromulgated Training Regulations As of March 2016Basal JonathanNessuna valutazione finora

- WPS Presentation on Welding Procedures Specification'sDocumento30 pagineWPS Presentation on Welding Procedures Specification'sMario TanNessuna valutazione finora

- SELF CHECK SupervisingDocumento4 pagineSELF CHECK SupervisingMario TanNessuna valutazione finora

- 1.1-6 Trainees' Current Competencies SampleDocumento14 pagine1.1-6 Trainees' Current Competencies SampleMario TanNessuna valutazione finora

- Aws D14.6.-2005Documento186 pagineAws D14.6.-2005ardfall17Nessuna valutazione finora

- CH 29-Fundamentals of WeldingDocumento39 pagineCH 29-Fundamentals of WeldingNasir MaqsoodNessuna valutazione finora

- Soldering & WeldingDocumento82 pagineSoldering & WeldingRachita Arora100% (1)

- Brazing & Soldering Today: Comparing High-Temperature Nickel Brazing Filler MetalsDocumento6 pagineBrazing & Soldering Today: Comparing High-Temperature Nickel Brazing Filler Metals2ndragendaNessuna valutazione finora

- Inconel 82 PDFDocumento1 paginaInconel 82 PDFMiguel MorenoNessuna valutazione finora

- TenderDocumento144 pagineTenderSanthosh BabuNessuna valutazione finora

- 320102cB SMAW-B - 1Documento32 pagine320102cB SMAW-B - 1Syaifur RohmanNessuna valutazione finora

- Aws A5.3 1999Documento26 pagineAws A5.3 1999Marco VeraNessuna valutazione finora

- Brazing:: 1 - Discuss The Details of Brazing, Soldering and Riveting Welding TechniquesDocumento8 pagineBrazing:: 1 - Discuss The Details of Brazing, Soldering and Riveting Welding Techniquessofyan samNessuna valutazione finora

- 49 Dstu en So 14343 2019 Zvaryuvaln Mater AliDocumento23 pagine49 Dstu en So 14343 2019 Zvaryuvaln Mater AliUDDOM CHHENGNessuna valutazione finora

- Sample Format: Sensitivity: LNT Construction Internal UseDocumento2 pagineSample Format: Sensitivity: LNT Construction Internal UseKarthikNessuna valutazione finora

- Ge3271 - Epl ManualDocumento63 pagineGe3271 - Epl Manualkavishmasr2006Nessuna valutazione finora

- Manufacturing Process: Chapter 5 Joining ProcessesDocumento53 pagineManufacturing Process: Chapter 5 Joining ProcesseshizanorhudaNessuna valutazione finora