Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Crystallization

Caricato da

bala saiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Crystallization

Caricato da

bala saiCopyright:

Formati disponibili

C. SRINIVASAKANNAN et al., A Study on Crystallization of Oxalic Acid …, Chem. Biochem. Eng. Q.

16 (3) 125–129 (2002) 125

A Study on Crystallization of Oxalic Acid in Batch Cooling Crystallizer

C. Srinivasakannan*, R. Vasanthakumar, K. Iyappan, and P. G. Rao Profesional paper

Chemical Engineering Division, Central Leather Research Institute, Received: December 19, 2001

Chennai 600 020, India Accepted: April 25, 2002

A study on batch cooling crystallizer, to assess the effects of various cooling modes

on the crystal size distribution, is attempted for oxalic acid. The linear cooling mode is

found to give narrow crystal size distribution and higher crystal size as compared to con-

trolled cooling modes. The effect of various operating quantities such as the seed ratio,

type of agitator, agitation rates, are carried out with linear cooling mode. The increase in

seed ratio is found to reduce the mean crystal size. For turbine type agitator, increase in

the agitation rate beyond 140 rpm is found to widen the crystal size distribution and

lower the mean crystal size, where as for anchor type agitator, agitation rate beyond 100

rpm is found to decrease mean crystal size.

Key Words:

Batch crystallization, oxalic acid, crystal size distribution.

Introduction cooling control, since uncontrolled cooling leads to

poor quality product.3 This is caused by the forma-

Batch cooling crystallizers are commonly used

tion of large number of crystal nuclei, which cannot

in the production of fine chemicals, pharmaceuti-

grow to the desired size, if the cooling rate in the

cals and bio-chemicals. Crystallization from solu-

tion is an industrially important unit operation due initial stages of the process is too high.4 In order to

to its ability to provide high purity separation. get large crystals the temperature should be reduced

Batch processes are preferred, if the production rate slowly in the early stages of the process and more

is low or the equipment must be used to produce rapidly as the temperature of the solution de-

several different products. Batch cooling crystalli- creases.3,4 When the batch crystallizer is refriger-

zers present the advantage of being simple, flexible, ated with coolant of constant flow rate and tempera-

require less investment and, generally, involve less ture leads to wide size distribution and small size

process development.1 However as compared to crystals.9

continuous process the batch process yield poor The earlier research on batch crystallizers were

quality product with smaller crystal size. mostly focused on the control of cooling rate and

The crystal size distribution is an important seed ratios in order to maintain supersaturation

quantity in the production of high quality product within the so-called metastable zone to control crys-

and for determining the efficiency of downstream tal size distribution.2,4–8 Jagadesh et al.,9 have high-

operations, such as filtration and washing, reaction lighted the use of natural cooling mode, as it does

with other chemicals, transportation and storage of not require any temperature control. Sufficient

crystals. If the crystals are to be marketed as a final seeding can arrest the formation of fresh nuclei, re-

product, customer’s acceptance requires individual sulting from the high levels of supersaturation cre-

crystals to be strong, non-aggregated, uniform in ated under natural cooling mode. A decrease in

size and non-caking in the package. For these rea- supersaturation levels with increase in the seed ratio

sons, crystal size distribution must be under control simulating conditions of controlled cooling, was re-

and it is the prime objective in the design and oper- ported. Further a bimodal type of crystal size distri-

ation of crystallizer. A uniform and narrow crystal bution observed in all cooling modes was elimi-

size distribution with a large mean crystal size is of- nated at higher seed ratio. The seed ratio required

ten desired. for attaining uni-modal crystal size distribution is

In a batch cooling crystallizer, solution is much lower as compared to seed ratio required for

cooled for achieving the supersaturation essential attaining ideal growth curve. Although increase in

for crystallization.2 Crystallizers often incorporate seed ratio leads to attaining ideal growth curve, due

to mass balance constraint, the mean crystal size re-

duces rapidly. Moreover the use of high seed ratio,

*Corresponding author. to control supersaturation and to attain ideal growth

Present Address: Lecturer, School of Chemical Engineering, Univer-

sity Sains Malaysia, 14300 Nibong Tebal, Pulau Penang, Malaysia. curve, leads to higher loads on the downstream pro-

Email: chkannan@eng.usm.my cessing, thereby increasing the processing cost.

126 C. SRINIVASAKANNAN et al., A Study on Crystallization of Oxalic Acid …, Chem. Biochem. Eng. Q. 16 (3) 125–129 (2002)

Since the control of cooling rate is quite easy with in the control unit refers to the temperature in the

use of modern process control, the present study at- crystallizer bath and accordingly manipulates the

tempts to study the effect of different cooling temperature of coolant to achieve the required tem-

modes on crystal size distribution for a uni-modal perature. Based on the solubility data (Table.1) a

crystal size distribution of oxalic acid. The effects saturated solution of oxalic acid is prepared at a

of various operating quantities on crystal size distri- temperature of 60 °C by dissolving required amount

bution for the best identified cooling mode, has of oxalic acid in three liters of distilled water. After

been studied. dissolving the stirrer speed is adjusted to the desired

level. The experiments are started by cooling the

solution at different cooling rates as required for the

Experimental experiment. The seeds are added to the crystallizer

under supersaturated conditions at required seed ra-

Experiments are carried out in a five liter jack- tio. Seed ratio is defined as the mass of seeds taken

eted crystallizer made of stainless steel 316 Grade, to the theoretical yield of crystals taken from solu-

with mild steel jacket for heating and cooling pur- bility curve by cooling from 60 to 10 °C. Prelimi-

pose. The schematic diagram of the experimental nary experiments are conducted to ensure that

set up is shown in Figure 1. The crystallizer con- uni-modal crystal size distribution is obtained at

sists of agitator (1), baffles (2), jacket (3), jacket the seed ratio used in the present study. The total

fluid inlet (4), jacket fluid outlet (5), and outlet suspension is withdrawn at the end of the experi-

valve (6). The diameter of the crystallizer is 180 ment, filtered in a Buckner funnel under vacuum.

mm with a height of 240 mm. The experimental set The product is dried in an air oven and subjected to

up comprises of a circulation bath with provision to sieve analysis. The crystal size distribution is ob-

either cool to –50 °C or heat to 250 °C. Six blade tained and the mean size is calculated. The experi-

pitched turbine and anchor agitators are used in the ments are conducted covering different temperature

present study. The agitator is placed 20 mm from profiles as shown in Figure 2. The details of various

the bottom of the crystallizer. The diameter of tur- quantities covered in the present study are detailed

bine as well as anchor agitator is 90 mm. Two baf- in Table 2.

fles of 23 mm are installed opposite to each other to

avoid vortex formation and for better mixing only

in the case of turbine agitator.

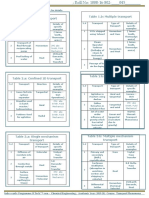

T a b l e 1 Solubility Data for Oxalic Acid – Water System

Temperature °C g of oxalic acid / 100 g of water

0 3.0

10 6.0

20 9.5

30 14.5

40 21.6

60 44.3

80 84.4

T a b l e 2 Details of qualitities and their range covered in

the present study

Quantities Range Unit

Six Blade turbine,

Type of Agitators

Anchor

F i g . 1 Schematic diagram of experimental setup Temperature 60 to 10 °C

(1) Agitator, (2) Baffles, (3) Jacket, (4) Jacket

fluid inlet, (5) Jacket fluid outlet, (6) Outlet valve. Seed Ratio 1, 3

Batch time 130, 300 min.

Desired temperature in the crystallizer is Agitator speed 100, 140, 180 rpm

achieved by setting appropriate temperature in the

Seed size 80 mm

control unit of circulation bath. Temperature sensor

C. SRINIVASAKANNAN et al., A Study on Crystallization of Oxalic Acid …, Chem. Biochem. Eng. Q. 16 (3) 125–129 (2002) 127

Results and discussion

In order to assess the crystallization character-

istics of crystallizer, experiments are carried out

with linear cooling mode and different controlled

cooling modes. The effect of operating quantities

such as agitation rates, type of agitator and seed ra-

tio, are performed for the best identified cooling

mode.

Figure 2 shows different cooling modes adop-

ted for experimentation. Curve controlled cooling

mode A, corresponds to slower cooling rate during

the initial stages and faster cooling in the later

stages. Curve controlled cooling mode B corre-

sponds to faster cooling rate during the initial stages F i g . 3 Effect of different cooling modes on crystal size

and slower cooling during the later stages. Curve distribution

linear cooling mode corresponds to constant rate of

cooling from the beginning to end. However all the

experiments are carried out for 300 minutes. Curve wider crystal size distribution and lower mean size.

controlled cooling mode C corresponds to the case On the other hand in the case of linear cooling

in which final temperature of the magma is reached mode the small amount of nucleation that sets in

at much faster rate as compared to other cooling during the initial stages of cooling has ample time

modes. The final temperature of 10 °C is attained to grow resulting in a narrow size distribution and

with in 130 minutes. higher mean size.

The crystal size distribution due to controlled

cooling mode B is inferior to the linear cooling

mode and controlled cooling mode A (Fig. 3). This

may be due to high levels of supersaturation in the

initial stages, which leads to higher initial nucle-

ation, leading to lower mean crystal size and wider

crystal size distribution.

It can be observed from Figure 3 that the crys-

tal size distribution due to controlled cooling mode

C is inferior as compared to other cooling modes.

Since the rate of cooling in controlled cooling mode

C, as compared to other cooling modes is much

faster leading to exposure of the seeded crystal to

much higher levels of supersaturation, results in

high amounts of initial nucleation and leads to

wider size distribution and low mean crystal size.

F i g . 2 Plot of crystallizer temperature with respect to

The effects of operating quantities such as the

time observed for various cooling modes

seed ratio, type of agitator, agitation rate, are car-

ried out following linear cooling mode with 300

The different temperature profiles correspond minutes crystallization duration.

to different levels of supersaturation during various Figure 4 shows a reduction in the mean crystal

stages of crystallization. Figure 3 compares the size with the increase in seed ratio, although, there

crystal size distribution of all the above different is no significant change in the crystal size distribu-

modes of cooling. It can be observed, that a narrow tion. The reduction in mean size of the crystals is

crystal size distribution and higher mean size is ob- due to the mass balance constraint. With the in-

tained for linear cooling mode, as compared to con- crease in number of seed crystals, the solute is dis-

trolled cooling mode A. This is contrary to the be- tributed on higher number of seeds, and hence the

lief, as the supersaturation levels are maintained size increase is limited. The increase in seed ratio

lower during the initial stages in controlled cooling on one hand reduces the initial nucleation in linear

mode A, as compared to linear cooling mode. This cooling profile and on the other hand promotes

may be due to the secondary nucleation, which sets growth of the seeded crystals, on the other hand due

in at later stages of cooling due to higher levels of to mass balance constraints the size enlargement is

supersaturation, has lesser time to grow resulting in limited.

128 C. SRINIVASAKANNAN et al., A Study on Crystallization of Oxalic Acid …, Chem. Biochem. Eng. Q. 16 (3) 125–129 (2002)

F i g . 4 Effect of seed concentration on crystal size distri-

bution F i g . 6 Effect of different Agitation rate with turbine agi-

tator on crystal size distribution

Figure 5 compares the crystal size distribution

for turbine agitator and anchor agitator at 140 rpm.

A higher mean crystal size and narrow crystal size

distribution is obtained for turbine type agitator as

compared to anchor type agitator. It could be, be-

cause of the intense mixing in anchor agitator, as

compared to turbine agitator leading to formation of

secondary nucleation due to attrition, contributing

to fresh nuclei, results in lower mean size and wider

crystal size distribution.

F i g . 7 Effect of different Agitation rate with Anchor agi-

tator on crystal size distribution

agitator, 100 rpm is sufficient to keep the solids in

suspension without aiding formation of fresh nuclei

due to attrition.

F i g . 5 Effect of type of Agitator on crystal size distribu- Conclusions

tion

A detailed study in batch cooling crystallizer

covering different cooling modes is carried out and

It can be evidenced from figure 6 that a higher it is found that a linear temperature profile with 300

mean crystal size and narrow crystal size distribu- minutes cooling cycle is found to provide narrow

tion is obtained at 140 rpm as compared to 180 rpm crystal size distribution and higher mean crystal

with turbine type agitator. At 180 rpm the mixing is size. The effects of various quantities such as the

more intense leading to formation of fresh nucle- seed ratio, type of agitator, agitation rate are as-

ation due to attrition resulting in poorer product sessed under linear cooling mode. The increase in

quality. Similarly figure 7 shows a higher mean seed ratio is found to decrease the mean crystal size

crystal size at 100 rpm as compared to 140 rpm for due to mass balance constraints. The turbine agita-

anchor agitator. In the case of anchor agitator since tor is found to have narrow crystal size distribution

the mixing is observed to be better than the turbine and higher mean crystal size at 140 rpm as com-

C. SRINIVASAKANNAN et al., A Study on Crystallization of Oxalic Acid …, Chem. Biochem. Eng. Q. 16 (3) 125–129 (2002) 129

pared to anchor agitator. This is attributed to the in- dc – crystal diameter, mm

tense mixing with anchor agitator, which leads to t – time, h

secondary nucleation due to attrition. Similarly 140 T – temperature, °C

rpm is found to give higher mean size and narrow

size distribution as compared to 180 rpm with tur-

bine agitator. With anchor agitator 100 rpm is found References

to give higher mean crystal size as compared to 140

1. Tavare, N. S., Rohani, S., Garside, J., Can. J. Chem. Eng.

rpm. An agitation rate of 100 rpm is sufficient to 68 (1990) 260

keep the solids in suspension with anchor agitator, 2. Jones, A. G., Chem. Engg. Sci. 29 (1974) 1075.

whereas 140 rpm is required in the case of turbine 3. Mullin, J. W., Crystallization, Butterworths. London 1972.

agitator. 4. Mullin, J. W., Nyvlt, J., Chem. Engg. Sci. 26 (1971) 369.

5. Jones, A. G., Mullin J. W., Chem. Engg. Sci. 29 (1974)105.

6. Ajinkya, M. B., Ray, W. H., Chem. Eng. Comm. 1 (1974)

List of Symbols 181.

SR – Seed Ratio, ms/mth 7. Morari, M., Chem. Engg. Comm. 4 (1980) 167.

m – mass of crystal 8. Jones, A. G., Akers, S. R. G., Budz., Cryst. Res. Tech. 21

(1986) 1383.

ms – mass of sead crystals 9. Jagadesh, D., Kubota, N., Yokata, M., Doski N., Sato, A., J.

mth – theoretical mass of crystal Chem. Engg. Japan. 32 (1999) 514.

Potrebbero piacerti anche

- Atec Manual ElectronicDocumento73 pagineAtec Manual ElectronicMinaSaeed67% (3)

- Finite-Difference Model for Out-of-Container Pasteurization of Pickled CucumbersDocumento7 pagineFinite-Difference Model for Out-of-Container Pasteurization of Pickled CucumbersRoberto Tello UrreloNessuna valutazione finora

- When Glass meets Pharma: Insights about glass as primary packaging materialDa EverandWhen Glass meets Pharma: Insights about glass as primary packaging materialNessuna valutazione finora

- Food Analysis: S. Suzanne NielsenDocumento644 pagineFood Analysis: S. Suzanne Nielsenathanasios_syrakis100% (3)

- BiomagnetismDocumento30 pagineBiomagnetismapi-19937584100% (4)

- Crystallization Equipment TypesDocumento9 pagineCrystallization Equipment TypesJonnah Faye MojaresNessuna valutazione finora

- Crystallization Equipment (Crystallizers) : Swenson-Walker CrystallizerDocumento5 pagineCrystallization Equipment (Crystallizers) : Swenson-Walker CrystallizerJustin Paul CongeNessuna valutazione finora

- CrystallizersDocumento7 pagineCrystallizersMiguel Ackah-YensuNessuna valutazione finora

- Crystallize RDocumento11 pagineCrystallize RIan De La CruzNessuna valutazione finora

- Crystallizer SelectionDocumento8 pagineCrystallizer SelectionKTINE08Nessuna valutazione finora

- Alat KristalisasiDocumento13 pagineAlat KristalisasiseriolaNessuna valutazione finora

- Industrial CrystallizationDocumento54 pagineIndustrial Crystallizationma junallie pomperadaNessuna valutazione finora

- A Clearer View of CrystallizersDocumento5 pagineA Clearer View of Crystallizersfawmer61Nessuna valutazione finora

- Rystallization: Instructor: Zafar ShakoorDocumento41 pagineRystallization: Instructor: Zafar ShakoorMALIK ZARYABBABARNessuna valutazione finora

- Clearer View of CrystilizerDocumento5 pagineClearer View of CrystilizerChem.EnggNessuna valutazione finora

- Selection of Anti-Caking Agents Through Crystallization InhibitionDocumento6 pagineSelection of Anti-Caking Agents Through Crystallization InhibitionAsmita AtreNessuna valutazione finora

- جورنال عراقى (جامعة تكريت) PDFDocumento10 pagineجورنال عراقى (جامعة تكريت) PDFchecolonoskiNessuna valutazione finora

- MSMPR Crystallization Equipment OverviewDocumento1 paginaMSMPR Crystallization Equipment OverviewChem.EnggNessuna valutazione finora

- CrystallizersDocumento5 pagineCrystallizersSharissePapasNessuna valutazione finora

- Swenson CrystallizationDocumento12 pagineSwenson Crystallization陳盈佃Nessuna valutazione finora

- Seeding EffectDocumento6 pagineSeeding EffectjokonudiNessuna valutazione finora

- Effect of Temperature On The Wide Angle XDocumento5 pagineEffect of Temperature On The Wide Angle XJia TianNessuna valutazione finora

- Cristalizacion EnfriamientoDocumento9 pagineCristalizacion EnfriamientoHector Joel Chaname RodriguezNessuna valutazione finora

- Zeng Ve ArkDocumento8 pagineZeng Ve ArkMert GüngörNessuna valutazione finora

- Tran 2007Documento10 pagineTran 2007Ngọc LànhNessuna valutazione finora

- PSD Glutamato MonosodicoDocumento7 paginePSD Glutamato MonosodicoJulian LizcanoNessuna valutazione finora

- Batch Tank CrystallizationDocumento12 pagineBatch Tank CrystallizationShoaib PathanNessuna valutazione finora

- 5 PBDocumento8 pagine5 PBNurfaidah Ayu ApriliantiNessuna valutazione finora

- Experiment 4Documento13 pagineExperiment 4Renu SekaranNessuna valutazione finora

- 3 - Cristallisation of Cuso4Documento3 pagine3 - Cristallisation of Cuso4Chintan ModiNessuna valutazione finora

- Determination of Copper and ZincDocumento9 pagineDetermination of Copper and Zincraheema tahirNessuna valutazione finora

- Continuous Fluidized Bed Drying With and Without Internals: Kinetic ModelDocumento8 pagineContinuous Fluidized Bed Drying With and Without Internals: Kinetic ModelavgpaulNessuna valutazione finora

- GRP (E) HRM AssignDocumento10 pagineGRP (E) HRM AssignHuzefa JouharNessuna valutazione finora

- Study of Corrosion Rate in Water Treatment Plant in OilfieldDocumento12 pagineStudy of Corrosion Rate in Water Treatment Plant in OilfieldJose Barret0Nessuna valutazione finora

- Batch Vacuum: Crystallization ApparatusDocumento3 pagineBatch Vacuum: Crystallization ApparatusHarris IjazNessuna valutazione finora

- A Convection Chamber For Measuring Ice Crystal Growth DynamicsDocumento12 pagineA Convection Chamber For Measuring Ice Crystal Growth DynamicsAhmed ElmasryNessuna valutazione finora

- ATR-FTIR For Determining Optimal Cooling Curves For Batch Crystallisation of Succinic AcidDocumento4 pagineATR-FTIR For Determining Optimal Cooling Curves For Batch Crystallisation of Succinic AcidEilise IrelandNessuna valutazione finora

- Efecto Del K-CarrageninaDocumento6 pagineEfecto Del K-CarrageninaWiny Yucra ChaqquereNessuna valutazione finora

- Material Preparation and Crystal Growth TechniquesDocumento4 pagineMaterial Preparation and Crystal Growth TechniquesPoovithaNessuna valutazione finora

- 2018 IRI - 1 s2.0 S0011224017305655 MainDocumento7 pagine2018 IRI - 1 s2.0 S0011224017305655 MainRobert DowneyNessuna valutazione finora

- CLC Ram SemenDocumento8 pagineCLC Ram Semensaifulmangopo123Nessuna valutazione finora

- CVC Manual Rev.0Documento38 pagineCVC Manual Rev.0Kaith GallegoNessuna valutazione finora

- Zhang2017 PDFDocumento7 pagineZhang2017 PDFEsther N. NinaNessuna valutazione finora

- An Investigation of The Effects On Agglomeration of Changing The Speed of A Mechanical MixerDocumento6 pagineAn Investigation of The Effects On Agglomeration of Changing The Speed of A Mechanical MixerSalman AshfaqNessuna valutazione finora

- 20ff PDFDocumento8 pagine20ff PDFCaio Fazzioli Tavares100% (1)

- Cryogenic GrindingDocumento5 pagineCryogenic GrindingBenimon NesNessuna valutazione finora

- Partial Drying of Cut Pears To Improve Freeze-Thaw Texture-Bolin1993Documento4 paginePartial Drying of Cut Pears To Improve Freeze-Thaw Texture-Bolin1993NEFTALI VAZQUEZ ESPINOSANessuna valutazione finora

- Crystallization MaterialDocumento31 pagineCrystallization Materialjaladi gunaNessuna valutazione finora

- Equipment For CrystallizationDocumento6 pagineEquipment For CrystallizationOmkar MudkannaNessuna valutazione finora

- CrystallizationDocumento29 pagineCrystallizationYawar QureshiNessuna valutazione finora

- Effects of Dry Heat and Saturated Steam On The Physical Properties of ChitosanDocumento6 pagineEffects of Dry Heat and Saturated Steam On The Physical Properties of ChitosanJan ChadaratNessuna valutazione finora

- Ultra Purification of Ionic Liquids by Melt CrystallizationDocumento9 pagineUltra Purification of Ionic Liquids by Melt CrystallizationrenifajNessuna valutazione finora

- Crystallizers and Their ControlDocumento34 pagineCrystallizers and Their ControlVinitaVartakNessuna valutazione finora

- A Case Study of A Successful Matrix Acid Stimulation Treatment in Horizontal Wells Using A New Diversion Surfactant in Saudi ArabiaDocumento9 pagineA Case Study of A Successful Matrix Acid Stimulation Treatment in Horizontal Wells Using A New Diversion Surfactant in Saudi Arabiamsmsoft90Nessuna valutazione finora

- Melt CrystallizationDocumento10 pagineMelt CrystallizationBryan DallaraNessuna valutazione finora

- CrystallizationDocumento6 pagineCrystallizationPulok HasanNessuna valutazione finora

- Modulus: Effect On The Elastic of High-Density Polyethylene Differing Thermal TreatmentsDocumento4 pagineModulus: Effect On The Elastic of High-Density Polyethylene Differing Thermal Treatmentsapi-3733260Nessuna valutazione finora

- Solution Crystallization052012 GEA-METSODocumento20 pagineSolution Crystallization052012 GEA-METSOelon_cardosoNessuna valutazione finora

- Recrystallisation of Paracetamol Vol 1.1Documento4 pagineRecrystallisation of Paracetamol Vol 1.1h9g886qdnpNessuna valutazione finora

- A Model For Predicting The Size Distribution of Product From A Granulating DrumDocumento9 pagineA Model For Predicting The Size Distribution of Product From A Granulating DrumJaenni KimNessuna valutazione finora

- Crystallization PDFDocumento7 pagineCrystallization PDFMallick Zeyshan Tariq100% (1)

- Standard methods for the examination of water and sewageDa EverandStandard methods for the examination of water and sewageNessuna valutazione finora

- Calculated Values of DEQ Variables: POLYMATH ReportDocumento1 paginaCalculated Values of DEQ Variables: POLYMATH Reportbala saiNessuna valutazione finora

- Table5 11Documento1 paginaTable5 11bala saiNessuna valutazione finora

- Shear Thickening of Cornstarch Suspensions: Articles You May Be Interested inDocumento18 pagineShear Thickening of Cornstarch Suspensions: Articles You May Be Interested inbala saiNessuna valutazione finora

- Engineering Economics1Documento64 pagineEngineering Economics1bala saiNessuna valutazione finora

- Lecture 3Documento42 pagineLecture 3bala saiNessuna valutazione finora

- Ped Unit 4Documento45 paginePed Unit 4bala saiNessuna valutazione finora

- 2.1 Estimation of Diffusion CoefficientsDocumento21 pagine2.1 Estimation of Diffusion Coefficientsbala saiNessuna valutazione finora

- Table2 2&2 3Documento2 pagineTable2 2&2 3bala saiNessuna valutazione finora

- Lecture 1Documento11 pagineLecture 1bala saiNessuna valutazione finora

- Gate Mathematics: MAI) 4SDocumento258 pagineGate Mathematics: MAI) 4SManivannan VadiveluNessuna valutazione finora

- CN5040 Advanced Transport Homework 1Documento1 paginaCN5040 Advanced Transport Homework 1bala saiNessuna valutazione finora

- Ped Unit 4Documento45 paginePed Unit 4bala saiNessuna valutazione finora

- CrystallizationDocumento6 pagineCrystallizationbala saiNessuna valutazione finora

- STHE BtechDocumento48 pagineSTHE Btechbala saiNessuna valutazione finora

- Ped Unit 4Documento45 paginePed Unit 4bala saiNessuna valutazione finora

- Canada UnivDocumento1 paginaCanada Univbala saiNessuna valutazione finora

- STHE BtechDocumento48 pagineSTHE Btechbala saiNessuna valutazione finora

- New Doc 2019-10-24 21.43.02 PDFDocumento5 pagineNew Doc 2019-10-24 21.43.02 PDFbala saiNessuna valutazione finora

- New Doc 2019-10-24 21.43.02 PDFDocumento5 pagineNew Doc 2019-10-24 21.43.02 PDFbala saiNessuna valutazione finora

- Question PapersDocumento32 pagineQuestion Papersbala saiNessuna valutazione finora

- MtoDocumento45 pagineMtobala saiNessuna valutazione finora

- 09 Jarvinen FuelCycleSep CrystPrec12-08fin 3-2-09Documento14 pagine09 Jarvinen FuelCycleSep CrystPrec12-08fin 3-2-09HoHo WindyantoNessuna valutazione finora

- New Doc 2019-10-24 21.43.02 PDFDocumento5 pagineNew Doc 2019-10-24 21.43.02 PDFbala saiNessuna valutazione finora

- MTO Assignment AdsorptionDocumento4 pagineMTO Assignment Adsorptionbala saiNessuna valutazione finora

- Transport phenomena document titleDocumento1 paginaTransport phenomena document titlebala saiNessuna valutazione finora

- PmsDocumento49 paginePmsbala saiNessuna valutazione finora

- Table 1.a: Single Transport Table 1.b: Multiple Transport: (MC Abe Smith, Fulid Mechanics)Documento1 paginaTable 1.a: Single Transport Table 1.b: Multiple Transport: (MC Abe Smith, Fulid Mechanics)bala saiNessuna valutazione finora

- Handbook On Energy Conscious Buildings PDFDocumento397 pagineHandbook On Energy Conscious Buildings PDFbala saiNessuna valutazione finora

- Wellbore Stability AnalysisDocumento148 pagineWellbore Stability Analysishagh1234Nessuna valutazione finora

- Energy Transfer in Turbomachines ExplainedDocumento4 pagineEnergy Transfer in Turbomachines Explainedsachintyagi1Nessuna valutazione finora

- Chapter 12: Vibrations and Waves: 12.1 Simple Harmonic MotionDocumento5 pagineChapter 12: Vibrations and Waves: 12.1 Simple Harmonic MotionSteven SuNessuna valutazione finora

- Physics II Problems PDFDocumento1 paginaPhysics II Problems PDFBOSS BOSSNessuna valutazione finora

- The Preparation of Magnetic Nanoparticles For Applications in BiomedicineDocumento17 pagineThe Preparation of Magnetic Nanoparticles For Applications in BiomedicineMadavat Prem Pai LópezNessuna valutazione finora

- Chemistry 2013 June - P2 PDFDocumento20 pagineChemistry 2013 June - P2 PDFBinu PereraNessuna valutazione finora

- Concepts of Modern Physics Beiser 6th EditionDocumento246 pagineConcepts of Modern Physics Beiser 6th EditionAlex Martínez100% (2)

- The Mechanics of The Atom - by Max BornDocumento346 pagineThe Mechanics of The Atom - by Max Bornahsbon100% (2)

- Nobel Lecture The Double HeterostructureDocumento16 pagineNobel Lecture The Double Heterostructuremglez2012Nessuna valutazione finora

- Selected Topics in Structronic and Mechatronic Systems (Stability, Vibration and Control of Systems, Series B, 3)Documento457 pagineSelected Topics in Structronic and Mechatronic Systems (Stability, Vibration and Control of Systems, Series B, 3)Devang SNessuna valutazione finora

- Fundamentals of Metallurgy by Seshadri SeetharamanDocumento1 paginaFundamentals of Metallurgy by Seshadri SeetharamanAmanda Ariesta ApriliaNessuna valutazione finora

- Aqa 84031 W MS Jun13 PDFDocumento18 pagineAqa 84031 W MS Jun13 PDFdadajee420Nessuna valutazione finora

- Exercise EC4Documento23 pagineExercise EC4babel_stanNessuna valutazione finora

- AC Circuit Problems and SolutionsDocumento4 pagineAC Circuit Problems and SolutionsGarlapati Srinivasa RaoNessuna valutazione finora

- Nucleophilic Substitution Reactions of Alkyl HalidesDocumento36 pagineNucleophilic Substitution Reactions of Alkyl HalidesmaulidyaNessuna valutazione finora

- Keyin MaterialsDocumento17 pagineKeyin MaterialsH.GorenNessuna valutazione finora

- Math 53 Samplex FinalsDocumento16 pagineMath 53 Samplex Finalskate_acamaNessuna valutazione finora

- IrDocumento13 pagineIrumesh123patilNessuna valutazione finora

- MicrobiologyDocumento82 pagineMicrobiologyAbhishek SinghNessuna valutazione finora

- Books Doubtnut Question BankDocumento472 pagineBooks Doubtnut Question Bankkeerthana vNessuna valutazione finora

- CLS Aipmt 18 19 XII Phy Study Package 5 SET 2 Chapter 1Documento36 pagineCLS Aipmt 18 19 XII Phy Study Package 5 SET 2 Chapter 1Adil Ahmed83% (12)

- Precalculus Unit 6 Vectors NotesDocumento30 paginePrecalculus Unit 6 Vectors Notesapi-287816312100% (1)

- Dcmotors601 0241Documento42 pagineDcmotors601 0241Afrida Fazira MNessuna valutazione finora

- TriodeDocumento7 pagineTriodeAnonymous E4Rbo2sNessuna valutazione finora

- Allen DLP Major-3eng QDocumento24 pagineAllen DLP Major-3eng Qrk467111Nessuna valutazione finora

- Thermodynamics FundamentalsDocumento84 pagineThermodynamics FundamentalsKC Paguinto100% (1)

- Principles of Finned Tube Heat Exchanger Design For Enhanced Heat TransferDocumento20 paginePrinciples of Finned Tube Heat Exchanger Design For Enhanced Heat Transferunknown8787Nessuna valutazione finora

- Couette Flow of Micropolar Fluids: Theory GoverningDocumento6 pagineCouette Flow of Micropolar Fluids: Theory GoverningSrinivas JangiliNessuna valutazione finora