Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

344.2 Visual Examination: Para. 344.7

Caricato da

NDTInstructorTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

344.2 Visual Examination: Para. 344.7

Caricato da

NDTInstructorCopyright:

Formati disponibili

344.

2 Visual Examination

ð18Þ 344.2.1 Definition. Visual examination is the direct

observation of the external and internal portions of

components, joints, and other piping elements that are

readily accessible or can be exposed to view before,

during, or after manufacture, fabrication, assembly, erection, examination, or testing. This examination

includes

verification of Code and engineering design requirements

for materials, components, dimensions, joint preparation,

alignment, welding, bonding, brazing, bolting, threading,

or other joining method, supports, assembly, and erection.

ð18Þ 344.2.2 Method. Visual examination shall be

performed in accordance with ASME BPVC, Section V,

Article 9. Examination shall be by the direct visual technique. The use of a remote visual technique and

the acceptance criteria beyond the requirements of this Code shall

be a matter of agreement between contracting parties

prior to the start of fabrication.

Records of individual visual examinations are not

required except for those of in-process examinations

as specified in para. 344.7.

344.3 Magnetic Particle Examination

344.3.1 Method. Examination of castings is covered in

para. 302.3.3. Magnetic particle examination of welds and

of components other than castings shall be performed in

accordance with ASME BPVC, Section V, Article 7.

344.3.2 Acceptance Criteria. Magnetic particle indications are caused by the attraction of the test media

to

surface or near-surface discontinuities in the area

under test. However, all such indications are not necessarily imperfections, since excessive roughness,

magnetic

permeability variations, etc., may produce nonrelevant

indications. Inadvertent accumulation of particles not

related to magnetic attraction is classified as a false indication. Indications shall be verified as being

relevant,

nonrelevant, or false. Additional surface preparation

and/or other test methods may be used as needed to

verify the relevance of an indication.

An indication of an imperfection may be larger than the

imperfection that causes it; however, the size of the indication is the basis for acceptance evaluation. Only

indications that have any dimension greater than 1.5 mm (1∕16

in.) shall be considered relevant.

(a) Indications

Potrebbero piacerti anche

- Low Voltage Testing Manual SM4613 PDFDocumento83 pagineLow Voltage Testing Manual SM4613 PDFLaurence CastilloNessuna valutazione finora

- Fundamentals of Visual InspectionDocumento49 pagineFundamentals of Visual InspectionsusanwebNessuna valutazione finora

- Closure Weld RequirementsDocumento1 paginaClosure Weld RequirementsManzar Khan0% (1)

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Documento242 pagineNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Mutual Fund Insight Nov 2022Documento214 pagineMutual Fund Insight Nov 2022Sonic LabelsNessuna valutazione finora

- Design File: Carefully Evaluate Code RequirementsDocumento2 pagineDesign File: Carefully Evaluate Code RequirementslionluisNessuna valutazione finora

- Vision CertificateDocumento1 paginaVision CertificateNDTInstructorNessuna valutazione finora

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsDa EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNessuna valutazione finora

- Forging DefectsDocumento1 paginaForging DefectsNDTInstructor0% (1)

- Relevant Discontinuities Visual Testing (VT), (Ebook)Documento98 pagineRelevant Discontinuities Visual Testing (VT), (Ebook)abdoNessuna valutazione finora

- Rules On Evidence PDFDocumento35 pagineRules On Evidence PDFEuodia HodeshNessuna valutazione finora

- Weld AbilityDocumento34 pagineWeld AbilityGauthamSarangNessuna valutazione finora

- User'S Manual: June 2006 T.O. #33D7-22-32-1Documento194 pagineUser'S Manual: June 2006 T.O. #33D7-22-32-1Pierpaolo AparoNessuna valutazione finora

- Pharmaceutical Microbiology NewsletterDocumento12 paginePharmaceutical Microbiology NewsletterTim SandleNessuna valutazione finora

- Handbook 1 A29Documento31 pagineHandbook 1 A29srgokuNessuna valutazione finora

- Defects Hydrogen Cracks IdentificationDocumento5 pagineDefects Hydrogen Cracks Identificationarif maulanafNessuna valutazione finora

- Module3 - Welding ProcessesDocumento155 pagineModule3 - Welding ProcessesPurvesh NanavatiNessuna valutazione finora

- RT Interpretation-SignedDocumento7 pagineRT Interpretation-Signedhamdi hamdiNessuna valutazione finora

- PAUT Vs RadiographyDocumento1 paginaPAUT Vs RadiographyNDTInstructorNessuna valutazione finora

- Weld Radio GraphsDocumento30 pagineWeld Radio Graphsvenkatesh0% (1)

- Barangay Tanods and The Barangay Peace and OrderDocumento25 pagineBarangay Tanods and The Barangay Peace and OrderKarla Mir74% (42)

- WeldingDocumento21 pagineWeldingprabhatkumar_6657012Nessuna valutazione finora

- Solution of 5817 Standard PDFDocumento37 pagineSolution of 5817 Standard PDFRajesh KumarNessuna valutazione finora

- Ttransition JointsDocumento15 pagineTtransition JointsAdil HasanovNessuna valutazione finora

- Procedure Qualification Requirements For Flaw SizingDocumento2 pagineProcedure Qualification Requirements For Flaw SizingAngelTinocoNessuna valutazione finora

- Financial StatementDocumento8 pagineFinancial StatementDarwin Dionisio ClementeNessuna valutazione finora

- Twi - Welding Inspection - SteelsDocumento209 pagineTwi - Welding Inspection - Steelsenels77Nessuna valutazione finora

- Industrial radiography A Complete Guide - 2019 EditionDa EverandIndustrial radiography A Complete Guide - 2019 EditionNessuna valutazione finora

- Esab DublexDocumento8 pagineEsab DublexSuphi YükselNessuna valutazione finora

- Steel - of Any Shape, in Any DirectionDocumento20 pagineSteel - of Any Shape, in Any Directionpoludo10Nessuna valutazione finora

- 2005 Stainless SteelsDocumento76 pagine2005 Stainless SteelsAnonymous 98vSKYTaDgNessuna valutazione finora

- On Applied EthicsDocumento34 pagineOn Applied Ethicsamanpatel78667% (3)

- Welding InspectionDocumento15 pagineWelding InspectionSreedhar Patnaik.MNessuna valutazione finora

- EW 512 6 Nondestructive TestingDocumento37 pagineEW 512 6 Nondestructive TestingHarun HodžićNessuna valutazione finora

- ARTICLE - Destructive Testing Basics (2012)Documento4 pagineARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajNessuna valutazione finora

- Lecture 7 Intergranular CorrosionDocumento18 pagineLecture 7 Intergranular Corrosionprakush01975225403Nessuna valutazione finora

- ARTICLE - Advancements in The Hardness Testing of Welds (2010)Documento3 pagineARTICLE - Advancements in The Hardness Testing of Welds (2010)Sangameswaran RamarajNessuna valutazione finora

- Welding - Joint - Symbols ISO 2553Documento32 pagineWelding - Joint - Symbols ISO 2553Silvio ZappinoNessuna valutazione finora

- ARTICLE - Considerations When Selecting An NDE Method (2010)Documento2 pagineARTICLE - Considerations When Selecting An NDE Method (2010)Sangameswaran RamarajNessuna valutazione finora

- TWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanyDocumento3 pagineTWI - FAQ - Can One Company Use Welding Procedures Qualified by Another CompanytuanNessuna valutazione finora

- Module 4 Weld Geometry and Welding Symbols-1Documento87 pagineModule 4 Weld Geometry and Welding Symbols-1Miki Jaksic100% (1)

- Weld Defects FlimDocumento21 pagineWeld Defects FlimvenkateshNessuna valutazione finora

- What Is Peening?: Frequently Asked QuestionsDocumento2 pagineWhat Is Peening?: Frequently Asked QuestionstuanNessuna valutazione finora

- Causes and Cures of Common Welding TroublesDocumento1 paginaCauses and Cures of Common Welding TroublesRathnakrajaNessuna valutazione finora

- Study On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationDocumento7 pagineStudy On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationManuel CarreñoNessuna valutazione finora

- Steel - Lack of FusionDocumento6 pagineSteel - Lack of FusionJose ContrerasNessuna valutazione finora

- Aws Cwi Some Question 2 PDFDocumento49 pagineAws Cwi Some Question 2 PDFninatenaNessuna valutazione finora

- Helling Katalog NDTDocumento43 pagineHelling Katalog NDTjeyaselvanmNessuna valutazione finora

- Welding SymbolsDocumento14 pagineWelding SymbolsSaif UllahNessuna valutazione finora

- RFI Radiographic Film Interpretation 30 - October - 2020Documento7 pagineRFI Radiographic Film Interpretation 30 - October - 2020SUNIL BABURAO GAVADENessuna valutazione finora

- ConsumablesDocumento28 pagineConsumablesadeoye_okunoyeNessuna valutazione finora

- Ie-Ndt Iqi En462-1 WireDocumento2 pagineIe-Ndt Iqi En462-1 Wiresamkarthik47Nessuna valutazione finora

- Get WRC Bulletin 506 Half Bead Temper BeadDocumento1 paginaGet WRC Bulletin 506 Half Bead Temper BeadMichael Sanders0% (1)

- Effect of Heat Treatment On The Mechanical Properties and Microstructure of Welded Abrasion Resistant Steel Ar200 PDFDocumento119 pagineEffect of Heat Treatment On The Mechanical Properties and Microstructure of Welded Abrasion Resistant Steel Ar200 PDFBurag HamparyanNessuna valutazione finora

- Tungsten Inert Gas (TIG or GTA) Welding: Job Knowledge 6Documento2 pagineTungsten Inert Gas (TIG or GTA) Welding: Job Knowledge 6tuanNessuna valutazione finora

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingDocumento1 paginaWelder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingReza100% (1)

- Senior Welding Inspection: Weld Procedures Course Reference WIS 10Documento21 pagineSenior Welding Inspection: Weld Procedures Course Reference WIS 10Harkynollar HarkyntehyeNessuna valutazione finora

- Ultrasonic Arrays For Non-Destructive Evaluation - A ReviewDocumento17 pagineUltrasonic Arrays For Non-Destructive Evaluation - A ReviewThatazita MenezesNessuna valutazione finora

- UT Outline Training LV IIIDocumento4 pagineUT Outline Training LV IIITrung Tinh HoNessuna valutazione finora

- ASME Section IX Code Edition 2017 Summary of Changes: Working Together For A Safer WorldDocumento38 pagineASME Section IX Code Edition 2017 Summary of Changes: Working Together For A Safer WorldWagner ClaudioNessuna valutazione finora

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDocumento7 pagineMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimNessuna valutazione finora

- Using Welding Inspection ToolsDocumento9 pagineUsing Welding Inspection ToolsVinoth RajendraNessuna valutazione finora

- 2018 Handling and Storage Recommendations - EN - Rev1!02!2018Documento4 pagine2018 Handling and Storage Recommendations - EN - Rev1!02!2018David Hortas CasasNessuna valutazione finora

- PT Level 2 SlidesDocumento68 paginePT Level 2 SlidesMuhammad ZariqNessuna valutazione finora

- Asme B31.3Documento2 pagineAsme B31.3Juan ortega castellarNessuna valutazione finora

- Pages From ASME - B31 - 3 - UnlockedDocumento8 paginePages From ASME - B31 - 3 - UnlockedJose Juan GasparNessuna valutazione finora

- Visual TestingDocumento48 pagineVisual Testingoulfa2013Nessuna valutazione finora

- VDA - New MSA - VDA - QMC - YPrint - 2024Documento45 pagineVDA - New MSA - VDA - QMC - YPrint - 2024Quality System SMGNessuna valutazione finora

- PFI ES-27-1994 - Visual Examination - The Purpose, Meaning and Limitation of The TermDocumento4 paginePFI ES-27-1994 - Visual Examination - The Purpose, Meaning and Limitation of The TermThao NguyenNessuna valutazione finora

- Procedure For Visual Examination Per Tech Pub T9074-AS-GIB-010/271Documento14 pagineProcedure For Visual Examination Per Tech Pub T9074-AS-GIB-010/271EdAlmNessuna valutazione finora

- TunisiaDocumento4 pagineTunisiaNDTInstructorNessuna valutazione finora

- Job Description NDTDocumento4 pagineJob Description NDTNDTInstructorNessuna valutazione finora

- NigieriaDocumento12 pagineNigieriaNDTInstructorNessuna valutazione finora

- Color Vision TestDocumento1 paginaColor Vision TestNDTInstructorNessuna valutazione finora

- Color Vision TestDocumento1 paginaColor Vision TestNDTInstructorNessuna valutazione finora

- H300 Introduction (Si Units) : Para. 304.3.3Documento2 pagineH300 Introduction (Si Units) : Para. 304.3.3NDTInstructorNessuna valutazione finora

- Piping 3Documento1 paginaPiping 3NDTInstructorNessuna valutazione finora

- A309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2Documento1 paginaA309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2NDTInstructorNessuna valutazione finora

- Piping 4Documento1 paginaPiping 4NDTInstructorNessuna valutazione finora

- (A) Elastic Behavior. The Assumption That DisplaceDocumento1 pagina(A) Elastic Behavior. The Assumption That DisplaceNDTInstructorNessuna valutazione finora

- Piping 4Documento1 paginaPiping 4NDTInstructorNessuna valutazione finora

- Api 580Documento1 paginaApi 580NDTInstructorNessuna valutazione finora

- MTDocumento1 paginaMTNDTInstructorNessuna valutazione finora

- Tank Inspection SolutionDocumento7 pagineTank Inspection SolutionNDTInstructorNessuna valutazione finora

- General TankDocumento2 pagineGeneral TankNDTInstructorNessuna valutazione finora

- Inspections and Audits For Boilers and Pressure VesselsDocumento2 pagineInspections and Audits For Boilers and Pressure VesselsNDTInstructorNessuna valutazione finora

- Shell Settlement EvaluationDocumento1 paginaShell Settlement EvaluationNDTInstructorNessuna valutazione finora

- Optimized Performance For Wall Thickness and LiftoffDocumento1 paginaOptimized Performance For Wall Thickness and LiftoffNDTInstructorNessuna valutazione finora

- Olympus Multiscan Ms 5800 Er1uDocumento2 pagineOlympus Multiscan Ms 5800 Er1uNDTInstructorNessuna valutazione finora

- Eddify Lyft Presentation DocumentDocumento4 pagineEddify Lyft Presentation DocumentBernardo FariasNessuna valutazione finora

- Procedure CFVDocumento13 pagineProcedure CFVNDTInstructorNessuna valutazione finora

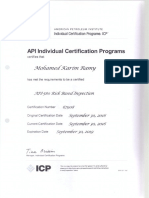

- API Individual Certification Programs: Mohamed Karim RamyDocumento1 paginaAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNessuna valutazione finora

- API Individual Certification Programs: Mohamed Karim RamyDocumento1 paginaAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNessuna valutazione finora

- Job Hazard AnalysisDocumento5 pagineJob Hazard AnalysisNDTInstructorNessuna valutazione finora

- Solutionstainlesssteelweldinspection 170124181624Documento13 pagineSolutionstainlesssteelweldinspection 170124181624NDTInstructorNessuna valutazione finora

- Resources and Courses: Moocs (Massive Open Online Courses)Documento8 pagineResources and Courses: Moocs (Massive Open Online Courses)Jump SkillNessuna valutazione finora

- NYLJtuesday BDocumento28 pagineNYLJtuesday BPhilip Scofield50% (2)

- Sec2 8 PDFDocumento3 pagineSec2 8 PDFpolistaNessuna valutazione finora

- Dunham Bush Midwall Split R410a InverterDocumento2 pagineDunham Bush Midwall Split R410a InverterAgnaldo Caetano100% (1)

- Relay Interface ModulesDocumento2 pagineRelay Interface Modulesmahdi aghamohamadiNessuna valutazione finora

- 1.6 Program AdministrationDocumento56 pagine1.6 Program Administration'JeoffreyLaycoNessuna valutazione finora

- Org ChartDocumento1 paginaOrg Chart2021-101781Nessuna valutazione finora

- Divider Block Accessory LTR HowdenDocumento4 pagineDivider Block Accessory LTR HowdenjasonNessuna valutazione finora

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocumento20 pagineAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenNessuna valutazione finora

- Relationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourDocumento16 pagineRelationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourToe ToeNessuna valutazione finora

- Analysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)Documento11 pagineAnalysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)AJHSSR JournalNessuna valutazione finora

- Rundown Rakernas & Seminar PABMI - Final-1Documento6 pagineRundown Rakernas & Seminar PABMI - Final-1MarthinNessuna valutazione finora

- EP2120 Internetworking/Internetteknik IK2218 Internets Protokoll Och Principer Homework Assignment 4Documento5 pagineEP2120 Internetworking/Internetteknik IK2218 Internets Protokoll Och Principer Homework Assignment 4doyaNessuna valutazione finora

- Tank Emission Calculation FormDocumento12 pagineTank Emission Calculation FormOmarTraficanteDelacasitosNessuna valutazione finora

- CC Anbcc FD 002 Enr0Documento5 pagineCC Anbcc FD 002 Enr0ssierroNessuna valutazione finora

- Dbms UPDATED MANUAL EWITDocumento75 pagineDbms UPDATED MANUAL EWITMadhukesh .kNessuna valutazione finora

- Charlemagne Command ListDocumento69 pagineCharlemagne Command ListBoardkingZeroNessuna valutazione finora

- Surge Arrester: Technical DataDocumento5 pagineSurge Arrester: Technical Datamaruf048Nessuna valutazione finora

- Sigma Valve 2-WayDocumento2 pagineSigma Valve 2-WayRahimNessuna valutazione finora

- China Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmDocumento40 pagineChina Ve01 With Tda93xx An17821 Stv9302a La78040 Ka5q0765-SmAmadou Fall100% (1)

- Sikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPDocumento15 pagineSikkim Manipal MBA 1 SEM MB0038-Management Process and Organization Behavior-MQPHemant MeenaNessuna valutazione finora

- Ap06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónDocumento9 pagineAp06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónJenny Lozano Charry50% (2)

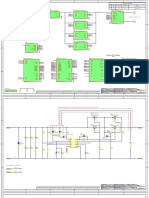

- Scheme Bidirectional DC-DC ConverterDocumento16 pagineScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaNessuna valutazione finora

- Grace Strux Beton PDFDocumento33 pagineGrace Strux Beton PDFmpilgirNessuna valutazione finora