Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pump House Sop

Caricato da

Code NameDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pump House Sop

Caricato da

Code NameCopyright:

Formati disponibili

1.

Introduction

Raw water pump facility consists of the following equipment:

(1) Intake basin

(2) Raw water pumps: Centrifugal pump

Specification

(a) Installation Number : 5 pumps

(b) Capacity : 550L/sec x 17mH

(3) Pipes and valves

Butterfly valve (Manual/ Mortalized), non-return valve

(4) Drain pumps

Specification

(a) Installation Number : 2 pumps

(b) Capacity : 1.18L/min

(5) Crane

Raw water from the intake is led into the intake basin through raw water pipe. Raw

water in the intake basin is discharged by the raw water pumps and transferred to

distribution basin though a raw water pipe.

2. Features of process

2-1. Function of process

Function of the raw water facility is to transfer the raw water into the distribution basin

with the required quantity.

2-2. Impacts of process

For the correct starting of water treatment process, the raw water flow rate shall be used

for the calculation of chemical requirement. Chemical devices shall be adjusted so that

they can supply the proper dosing amount determined by the chemist in laboratory.

2-3 Relations between other processes

2-3-1. Raw water intake

Raw water intake is a preceding step of the raw water supply. Raw water is flown into

the intake basin by gravity. Water level and water quality in the intake basin will be

almost the same as the water level and water quality of canal.

2-3-2. Distribution basin

The distribution basin is located after the raw water pump facility. The required quantity

of the raw water should be fed from the raw water pump to the distribution basin under

controlled condition and required quantities.

3. Criteria for operation

3-1. Schedule for pump operation

Raw water pumps should be operated according to the operation schedule. Usually,

some pumps will operate 24 hours. And then stand-by pumps operate according to the

water demand. Summary for the operation schedule is as shown in following table.

According to the following contents, daily operation record should be managed.

Period Operation Schedule

General

(Operation Main pump should be change every week.

Frequency)

1. Check for operation current

2, Check for operation pressure

3. Check for Abnormal noise, temperature, vibration &

Daily etc,

4. Check for operation Time (From start to stop)

5. Check for daily total operation hour

6. Check for daily total production water amount

3-2. Preparation to start operating the pump (In case that the vacuum pump is

used)

Prior to start a pump, air in the casing of the pump should be evacuated by vacuum

pump. After water is filled in the pump casing, a pump will be able to start. Vacuum

pressure indicator requires minus 0.3 bar or more to start a pump.

3-3. Proper working number of raw water pump

Required number of raw water pumps should be operated according to the water

demand.

3-4.Indication of discharge pressure gauge of pump

Proper indication for pressure gauge: Lower limit ----- bar

Upper limit ----- bar

* Pressure value should be checked at the site. Plant manager should notice it to

operators.

3-5.Indication of operation current of pump

Proper indication of operation current: Lower limit ----- A

Upper limit ----- A

* Rated current for pumps should be checked at the site. Plant manager should notice it to

operators.

3-6.Indication of production amount of the well

Proper production water amount: Lower limit ----- m3/day

Upper limit ----- m3/day

* Production water amount from the well should be checked at the site. Plant manager

should notice it to operators.

4. Operation under normal condition

4-1. Startup and shutdown procedures

4-1-1. Pre-start check

Pumps should be checked according to following procedure before start.

(1) Water level in the intake basin

Water level should be sufficient for operating pump.

(2) Valves on suction pipeline

Valves in suction pipeline should be opened fully.

(3) Valves on discharge pipeline

Valves in discharge pipeline should be closed.

(4) Valve for air evacuation by vacuum pump (in case that the vacuum pump is used.)

Valve for air evacuation by vacuum pump should be opened fully.

(5) Electrical switch board

Power should be supplied.

4-1-2. Startup

(1) Operate the vacuum pump (in case that the vacuum pump is used.)

Vacuum pressure indicator should require minus 0.3 bar or more.

(2) Close the valve for air evacuation and stop the vacuum pump

Water is discharged at the end of air evacuation pipe, valve should be closed.

(3) Operate the raw water pump by the switch-on control at the control panel

(4) Open the discharge valve

(5) Check the discharge pressure

(6) Check the operation current

(7) Check the abnormal noise, vibration, temperature arise and water leakage

(8) Adjust the tightening of gland packing, if any

4-1-3. Shutdown

(1) Close the discharge valve

(2) Stop the raw water pump by the switch-off control at the control panel

4-2. Monitoring and visual check during operation

Monitoring and visual check of the intake area is very important activity. It should be

conducted at least 3 times a day. If unusual condition is found, corrective action should

be immediately conducted especially in case of vibration, unusual noise and decrease

discharge amount.

5. Operation under unusual condition

5-1 Expected troubles and trouble shooting

Clogging in the suction pipe or the discharge pipe

Discharge pressure is not enough (high or low)

Discharge quantity is not enough

The water level in the intake basin is not enough

Mechanical trouble of the pump

6. Report and record

6-1. Record

Record for the raw water pump operation should include the following:

6-1-1. Record of pump operation

Operation hours of each pump

Operation condition

Discharge pressure, quantity, electrical current, etc.

Water level in the raw water basin

Unusual condition of pump

6-1-2. Record of vacuum pump operation

Operation hours of each pump

Operation condition

Vacuum pressure, electrical current, etc.

6-2 Report

Reports for operation of raw water intake should include the following:

6-2-1. Unusual condition in operation

Unusual condition, corrective action conducted and recovery time should be reported.

6-2-2. Monthly report

Operation hours of each pump

Recommendation on operation

6-2-3. Annual report

Operation hours of each pump

Recommendation on operation

Potrebbero piacerti anche

- Standard Operating Procedure of Chiller MachineDocumento1 paginaStandard Operating Procedure of Chiller MachineBishwas PoudelNessuna valutazione finora

- Boiler Operating ProcedureDocumento3 pagineBoiler Operating ProcedureSathish KumarNessuna valutazione finora

- SOP For Compressor (Instrumentation & Service)Documento2 pagineSOP For Compressor (Instrumentation & Service)santosh jsNessuna valutazione finora

- HSD Unloading Standard Operating ProcedureDocumento4 pagineHSD Unloading Standard Operating ProcedureMD Shahadat Hossan100% (1)

- Work Permit Safety Standard Training PackDocumento24 pagineWork Permit Safety Standard Training PackAtma Prakash Sinha100% (1)

- SOP of Automatic Water Sprinkler SystemDocumento1 paginaSOP of Automatic Water Sprinkler SystemShahnawaz KazmiNessuna valutazione finora

- Method For Cleaning Concrete TankDocumento3 pagineMethod For Cleaning Concrete TankSpecial MahooNessuna valutazione finora

- SOP-Pumps 20161031Documento4 pagineSOP-Pumps 20161031SubburajMechNessuna valutazione finora

- Automobile Air Condition System Using Exahust GasDocumento19 pagineAutomobile Air Condition System Using Exahust GasEr. Ramji TripathiNessuna valutazione finora

- Quality Assuarance - Sop For Cleaning of Sparkler FilterDocumento5 pagineQuality Assuarance - Sop For Cleaning of Sparkler FilterKrishna PalNessuna valutazione finora

- Method of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryDocumento5 pagineMethod of Statement For SPI366 Pump Sump Cleaning Without Confined Space EntryKarpana Devi LetchumananNessuna valutazione finora

- Front Loader Maintenance PlanDocumento2 pagineFront Loader Maintenance PlanScribdTranslationsNessuna valutazione finora

- ETP UpgradationDocumento7 pagineETP UpgradationYogesh DhekaleNessuna valutazione finora

- Air - Noise 2aDocumento16 pagineAir - Noise 2aOmaya TariqNessuna valutazione finora

- Electrical Safety in Industry & Home-11-12-08Documento18 pagineElectrical Safety in Industry & Home-11-12-08narasimhamurthy414Nessuna valutazione finora

- Osha Niosh Heat Illness InfosheetDocumento3 pagineOsha Niosh Heat Illness InfosheetUsman RajputNessuna valutazione finora

- Introduction To Power Plants and BoilersDocumento47 pagineIntroduction To Power Plants and Boilersl8o8r8d8s8i8v8Nessuna valutazione finora

- Maintenance Schedule For Fire Alarm Addressable SystemDocumento2 pagineMaintenance Schedule For Fire Alarm Addressable SystemRobert LuggardNessuna valutazione finora

- Line and Equipment Opening / Oil Draining ProcedureDocumento4 pagineLine and Equipment Opening / Oil Draining ProcedureRASHEED YUSUFNessuna valutazione finora

- Types of DryersDocumento14 pagineTypes of DryersChintan ModiNessuna valutazione finora

- Pipe Strain Check ProcedureDocumento1 paginaPipe Strain Check Procedurekamal arabNessuna valutazione finora

- Orbinox VG08 Knife Gate ValveDocumento8 pagineOrbinox VG08 Knife Gate ValveYorkistNessuna valutazione finora

- The Different Types of Orifice Plates AreDocumento2 pagineThe Different Types of Orifice Plates AresnehalNessuna valutazione finora

- Hot Work PermitDocumento17 pagineHot Work Permituday0% (1)

- Filling & Decanting SOP'sDocumento4 pagineFilling & Decanting SOP'sMian Abdul RehmanNessuna valutazione finora

- Procedure For Agriculture InspectionDocumento2 pagineProcedure For Agriculture InspectionPariksha AryaNessuna valutazione finora

- Multi Gas Detector RAEDocumento4 pagineMulti Gas Detector RAESurya Kusuma WNessuna valutazione finora

- Wet Riser SpecificationDocumento4 pagineWet Riser SpecificationshihabnittNessuna valutazione finora

- NMA Portable Gas Detection Standard - 803Documento7 pagineNMA Portable Gas Detection Standard - 803Divine MelodyNessuna valutazione finora

- PM Text As Per Bcel-002Documento4 paginePM Text As Per Bcel-002Jay Rameshbhai ParikhNessuna valutazione finora

- HVAC Duct Work Installation Method StatementDocumento7 pagineHVAC Duct Work Installation Method StatementNeguib FarahNessuna valutazione finora

- Foam InductorDocumento6 pagineFoam InductorDipanjan Chakrabarti100% (1)

- Confined SpaceDocumento7 pagineConfined SpacearajanchabhadNessuna valutazione finora

- SOP - U1400 - Road Tanker Pump Filling CO2 TankDocumento3 pagineSOP - U1400 - Road Tanker Pump Filling CO2 TankDan nathaniel gonzalesNessuna valutazione finora

- Fire Water TankDocumento1 paginaFire Water TankAnonymous yCpjZF1rF100% (1)

- Vacuum Truck Plant Pre-Acceptance ChecklistDocumento3 pagineVacuum Truck Plant Pre-Acceptance Checklistحماية منتجNessuna valutazione finora

- Refrigerant Recovery and Recharge of A Room Air Conditioner 170280VDocumento9 pagineRefrigerant Recovery and Recharge of A Room Air Conditioner 170280VMathiNessuna valutazione finora

- Chapter 1: Boilers and ComponentsDocumento12 pagineChapter 1: Boilers and ComponentseugeneNessuna valutazione finora

- Plunger Pump Service Manual: Installation and Start-Up InformationDocumento6 paginePlunger Pump Service Manual: Installation and Start-Up InformationDark CenobiteNessuna valutazione finora

- ATTACH 3 LOG SHEET UpdatedDocumento12 pagineATTACH 3 LOG SHEET UpdatedHedi Ben MohamedNessuna valutazione finora

- Sop For Total Power Failure.Documento4 pagineSop For Total Power Failure.anon_251342212Nessuna valutazione finora

- Third Party Equipment ChecklistDocumento5 pagineThird Party Equipment ChecklistMARIO LEALNessuna valutazione finora

- Checklist For Pressure Testing Safely 2Documento2 pagineChecklist For Pressure Testing Safely 2Jonathan CambaNessuna valutazione finora

- Inspection On EconomiserDocumento2 pagineInspection On Economiserkrishna50% (2)

- Rotating Equipment SafetyDocumento34 pagineRotating Equipment SafetySuchismita Bhattacharya Bhaumik0% (1)

- PPE Disposal SOPDocumento2 paginePPE Disposal SOPAmit MakwanaNessuna valutazione finora

- Pressure Systems - Safety and YouDocumento8 paginePressure Systems - Safety and YouadammzjinNessuna valutazione finora

- Earth Compactor Daily Check ListDocumento2 pagineEarth Compactor Daily Check ListpjosesmNessuna valutazione finora

- Leak Testing of Valves: Sr. N. Attribute API-598 MSS-SP61 ANSI-FCI70.2 ISODocumento1 paginaLeak Testing of Valves: Sr. N. Attribute API-598 MSS-SP61 ANSI-FCI70.2 ISODurga Prasad SharmaNessuna valutazione finora

- WINEWISE-Water Management ChecklistDocumento3 pagineWINEWISE-Water Management ChecklistCCR100% (1)

- Sop STPDocumento5 pagineSop STPModi JayNessuna valutazione finora

- Tamil Nadu Factories Rules 1950Documento18 pagineTamil Nadu Factories Rules 1950Sindarth RaveendrakrishnanNessuna valutazione finora

- Cadet Boiler Installation ManualDocumento92 pagineCadet Boiler Installation ManualAnonymous pkqcrsfmF100% (1)

- Fm200 System Test Report Formats Index SL - No Description Document No. A Erection Control Forms For FM200 SystemDocumento2 pagineFm200 System Test Report Formats Index SL - No Description Document No. A Erection Control Forms For FM200 SystemAneesh ConstantineNessuna valutazione finora

- LUFT AHU Installation Startup MaintananceDocumento38 pagineLUFT AHU Installation Startup MaintananceUğur DarcanNessuna valutazione finora

- Power Plant Maintenance 3.0Documento25 paginePower Plant Maintenance 3.0MariusDragoescuNessuna valutazione finora

- HSS - User Manual For 25tph RO Water SystemDocumento26 pagineHSS - User Manual For 25tph RO Water SystemJuan Ramos EstelaNessuna valutazione finora

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocumento3 pagineTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocumento3 pagineTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhNessuna valutazione finora

- Operation Principal of Sewage Treatmentplant and Point of MDocumento12 pagineOperation Principal of Sewage Treatmentplant and Point of MKo Gyi BakaNessuna valutazione finora

- PSI RecommendationsDocumento2 paginePSI RecommendationsCode NameNessuna valutazione finora

- Ba 2019Documento117 pagineBa 2019Code NameNessuna valutazione finora

- REP All LubricationManagementpdf GL All RephubDocumento8 pagineREP All LubricationManagementpdf GL All RephubCode NameNessuna valutazione finora

- Failure List Hierarchy - Mechanical: Blower: Centrifugal Failure: BlceDocumento118 pagineFailure List Hierarchy - Mechanical: Blower: Centrifugal Failure: BlceCode NameNessuna valutazione finora

- Heat Exchanger Spiral Tech SpecificationDocumento20 pagineHeat Exchanger Spiral Tech SpecificationCode NameNessuna valutazione finora

- Explaination:: Flash DistillationDocumento9 pagineExplaination:: Flash DistillationKaleemNessuna valutazione finora

- Cap 03 Mecanica Dos Fluidos Fox Mcdonald 8a Edicao SolutionDocumento166 pagineCap 03 Mecanica Dos Fluidos Fox Mcdonald 8a Edicao SolutionAlice LimaNessuna valutazione finora

- Daily Drilling Monitoring Report Bibiyana-18Documento2 pagineDaily Drilling Monitoring Report Bibiyana-18shuvo134Nessuna valutazione finora

- Okicat07 EsabDocumento18 pagineOkicat07 EsabchosilimitedNessuna valutazione finora

- ASHRAE - Factsheet Refrigerant - 200424Documento6 pagineASHRAE - Factsheet Refrigerant - 200424Hiei ArshavinNessuna valutazione finora

- Expt 1 (Fluidshit)Documento3 pagineExpt 1 (Fluidshit)Trisha MariehNessuna valutazione finora

- Gas Power Cycles: Mehmet KanogluDocumento29 pagineGas Power Cycles: Mehmet KanogluFiras Abu talebNessuna valutazione finora

- (A) Same As That of A' (B) One-Fourth As That of A' (C) Twice As That of A' (D) Four Times As That of A'Documento6 pagine(A) Same As That of A' (B) One-Fourth As That of A' (C) Twice As That of A' (D) Four Times As That of A'Aduchelab AdamsonuniversityNessuna valutazione finora

- Data Sheet VA521 enDocumento2 pagineData Sheet VA521 enuiUaNessuna valutazione finora

- OPRA Turbines Brochure (English)Documento8 pagineOPRA Turbines Brochure (English)HyungTae JangNessuna valutazione finora

- 8663 1694 8663 1681 Ps 1678PREZENTARE-SERIA-AS-EV-GEMAK-RO-EN PDFDocumento6 pagine8663 1694 8663 1681 Ps 1678PREZENTARE-SERIA-AS-EV-GEMAK-RO-EN PDFcld72Nessuna valutazione finora

- Stratification: Earth's Atmosphere Lower 4 Layers of The Atmosphere in 3 Dimensions As Seen Diagonally FromDocumento7 pagineStratification: Earth's Atmosphere Lower 4 Layers of The Atmosphere in 3 Dimensions As Seen Diagonally FromJordan MosesNessuna valutazione finora

- Air Driven Hydraulic PumpsDocumento32 pagineAir Driven Hydraulic Pumpsdejanr111Nessuna valutazione finora

- Quiz 1Documento5 pagineQuiz 1bbbbbNessuna valutazione finora

- Compresor QGS 10 - 15 Instruction ManualDocumento38 pagineCompresor QGS 10 - 15 Instruction ManualosvabribNessuna valutazione finora

- Low Pressure Filter: Spin-On CartridgesDocumento10 pagineLow Pressure Filter: Spin-On CartridgesIgorNessuna valutazione finora

- MEEG 630, Intermediate Fluid Mechanics: R U R If A Pressure GradientDocumento2 pagineMEEG 630, Intermediate Fluid Mechanics: R U R If A Pressure GradientAditya KumarNessuna valutazione finora

- STD 113Documento44 pagineSTD 113Arun KumarNessuna valutazione finora

- Catalogo de Parker SporlanDocumento64 pagineCatalogo de Parker SporlanTuphacNessuna valutazione finora

- Iclx PDFDocumento28 pagineIclx PDF王耀田Nessuna valutazione finora

- Chevron Pump ManualDocumento401 pagineChevron Pump Manualsiva242245100% (2)

- CHE 311 HEAT TRANSFER TablesDocumento24 pagineCHE 311 HEAT TRANSFER TablesJack O'MeraNessuna valutazione finora

- 7013 Pressure Regulator DataDocumento4 pagine7013 Pressure Regulator DataNasredine AlainNessuna valutazione finora

- Atlascopco Oil DatasheetDocumento2 pagineAtlascopco Oil DatasheetAmirmasoudNessuna valutazione finora

- Acid Gas AmineDocumento22 pagineAcid Gas AmineZaenal BahriNessuna valutazione finora

- Baro Mano WorksheetDocumento12 pagineBaro Mano WorksheetashokNessuna valutazione finora

- Mfiv-II Mechanically Controlled Isolation Valve PsDocumento2 pagineMfiv-II Mechanically Controlled Isolation Valve PsalainestorNessuna valutazione finora

- BSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)Documento8 pagineBSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)LudiNessuna valutazione finora

- (Phd124) Uitm Pp/Fakulti Farmasi Questions On Chapter 8 - Phase EquilibriumDocumento3 pagine(Phd124) Uitm Pp/Fakulti Farmasi Questions On Chapter 8 - Phase EquilibriumIZZAN IZALIA MAHZANNessuna valutazione finora

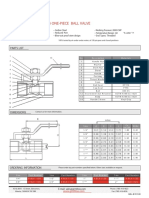

- G-104 One-Piece Ball Valve: Parts ListDocumento1 paginaG-104 One-Piece Ball Valve: Parts ListEnrique AssmannNessuna valutazione finora