Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Material Lab 9

Caricato da

AhmadCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Material Lab 9

Caricato da

AhmadCopyright:

Formati disponibili

MATERIALS LABORATORY 2006

Procedure

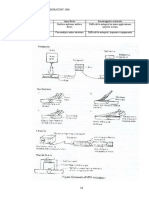

A servo-hydraulic or servo-mechanical testing machine is used. The specimen

of known dimensions are loaded in the machine and strained at a constant rate.

The load is measured by a load cell. The crosshead movement and/or strain are

recorded; for strain measurement an extensometer is used.

The X-Y plots are obtained. However the computer can also plot an

engineering stress-strain curve directly, using the appropriate conversion factors

and specimen area and gauge length. After the specimen is broken, the final

length and diameter are measured. The fracture type and the fracture surface are

investigated, in order to determine the fracture mode.

Results

1. Plot a load - elongation curve for each specimen.

2. Determine the engineering stress-strain curve and the true stress- true strain

curve.

3. Determine the 0.2% yield stress, UTS, % elongation, % reduction in area,

modulus of elasticity. Determine the mathematical expression for the true stress

true strain curve for the second material.

4. Identify the fracture mode, i.e. ductile or brittle and explain the reasons.

5. Find the mechanical properties of the tested material from Handbooks and

make comparisons. Or if the material is not known try to guess it with the help of

the mechanical properties.

Discussion

If the material is given compare your test results of strength and ductility with

book values. Why is there a significant difference? Answer questions listed

below.

Tensile Test Questions

1. Which modulus did you find from the initial portion of the stress-strain curve?

If did not use an extensometer but determined strain from the crosshead

movement, would the initial slope still allow you to determine an accurate

modulus? Explain.

2. Write the definition using symbols for shear modulus, bulk modulus and

Poisson's ratio. Write the equations relating these two modulus to Young's

modulus.

3. What is the approximate value of Poisson's ratio for metals? What is the

physical significance of Poisson's ratio, i.e. what does it represent resistance

to?

4. What is the area under the stress-strain curve equivalent to? What does the

area under the elastic portion of the stress-strain represent?

5. What % elongation and % reduction in area measures of?

6. Explain the different deformation mechanisms which are active in the different

regions of the tensile stress-strain curve. (elastic, yielding, strain hardening,

necking etc.)

References

1. Dieter, Mechanical Metallurgy, McGrawHill.

2. Dowling E.D.,Mechanical Behavior of Materials, Prentice-Hall.

3. KayalM S, Ensari C. and .Dikey F., Metalik Malzemelerin Mekanik Deneyleri,

NTÜ YayMnM.

10

Potrebbero piacerti anche

- Metal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringDa EverandMetal Fatigue Analysis Handbook: Practical Problem-solving Techniques for Computer-aided EngineeringValutazione: 3.5 su 5 stelle3.5/5 (5)

- Introduction To Materials TestingDocumento6 pagineIntroduction To Materials Testinggosaye desalegnNessuna valutazione finora

- Mechanical Properties of SteelDocumento27 pagineMechanical Properties of SteelMuhd Farhan Bin Ibrahim100% (1)

- Laws of MotionDocumento5 pagineLaws of Motionkatie4834Nessuna valutazione finora

- 3-Exp#03 Tensile TestDocumento7 pagine3-Exp#03 Tensile TestD7ooM_612Nessuna valutazione finora

- Tensile TestDocumento9 pagineTensile Testonkod1Nessuna valutazione finora

- Lab Manual 1Documento9 pagineLab Manual 1Hallowfied KawsarNessuna valutazione finora

- Tensile LabDocumento13 pagineTensile LabnevermoreNessuna valutazione finora

- Tensile TestDocumento15 pagineTensile TestLilac ClassNessuna valutazione finora

- Tutorial Manual 2021-22 - Sem-III - MOS - MITSOEDocumento97 pagineTutorial Manual 2021-22 - Sem-III - MOS - MITSOEJeetender MishraNessuna valutazione finora

- Engineering Materials Lab ManualDocumento69 pagineEngineering Materials Lab ManualyousifNessuna valutazione finora

- Identifying Unknown SamplesDocumento12 pagineIdentifying Unknown SamplesJason Paul RoqueNessuna valutazione finora

- Standard Tension TestDocumento12 pagineStandard Tension TestStephen Mirdo50% (2)

- MM207E | Materials Science | Lab2_Tensile Test | Mechanic LabDocumento4 pagineMM207E | Materials Science | Lab2_Tensile Test | Mechanic LabKerem Taha TekinNessuna valutazione finora

- Tensile Testing Lab SheetDocumento3 pagineTensile Testing Lab SheetHalaaNessuna valutazione finora

- 06-MS-ME - Mechanical Properties of MetalsDocumento51 pagine06-MS-ME - Mechanical Properties of Metalsfarah Al-zgoulNessuna valutazione finora

- Tensile Testing of Metals-II (Non-Ferrous Metals) MDDocumento3 pagineTensile Testing of Metals-II (Non-Ferrous Metals) MDH S Vishwanath Shastry0% (1)

- Polymer Lab Instron ProcedureDocumento8 paginePolymer Lab Instron ProcedureJulio GranadosNessuna valutazione finora

- Mechanical PropertiesDocumento57 pagineMechanical PropertiesElmedin Gluhic100% (1)

- Eng Lab ModuleDocumento58 pagineEng Lab ModuleFirzana AmiraNessuna valutazione finora

- Real O.V Tensile TestingDocumento14 pagineReal O.V Tensile TestingOshane ThomasNessuna valutazione finora

- Tensile Testing Concepts DefinitionsDocumento12 pagineTensile Testing Concepts Definitions04Musyaffa Nafis MNessuna valutazione finora

- Tensile Test Experiment Kirinyaga UniversityDocumento7 pagineTensile Test Experiment Kirinyaga Universitysteve gateriNessuna valutazione finora

- Solids and Structural MechanicsDocumento15 pagineSolids and Structural MechanicsBONFACE MUGUNANessuna valutazione finora

- Tensile Testing Concepts DefinitionsDocumento12 pagineTensile Testing Concepts DefinitionsPremNessuna valutazione finora

- Mos Lab Manual PDFDocumento34 pagineMos Lab Manual PDFs.rihanaNessuna valutazione finora

- 2016 Practical Guide PDFDocumento9 pagine2016 Practical Guide PDFPromiseDoringtenNkosiNessuna valutazione finora

- Tensile Testing Lab Determines Plastic PropertiesDocumento36 pagineTensile Testing Lab Determines Plastic PropertiesalkharfaneNessuna valutazione finora

- Tension LabDocumento4 pagineTension LabWilliamMermell100% (1)

- Ceg 201 Lab ReportdddDocumento21 pagineCeg 201 Lab ReportdddEmenike-Ukah Michael ChiedozieNessuna valutazione finora

- FM and SM Lab ManualDocumento87 pagineFM and SM Lab ManualGeorge OliverNessuna valutazione finora

- Experiment 1 - TENSION TEST OF MILD STEEL SPECIMENDocumento10 pagineExperiment 1 - TENSION TEST OF MILD STEEL SPECIMENSamiha Maysoon Nooria100% (1)

- Lab Report Tensile Group 5Documento12 pagineLab Report Tensile Group 5Danial AqilNessuna valutazione finora

- Tensile TestingDocumento4 pagineTensile TestingNaveed AfzalNessuna valutazione finora

- Mechanical Properties and Stress-Strain Diagram of Tensile Tested SteelDocumento13 pagineMechanical Properties and Stress-Strain Diagram of Tensile Tested Steelالشهاب ناروتوNessuna valutazione finora

- Som ExperimentsDocumento17 pagineSom ExperimentsAnudeex ShettyNessuna valutazione finora

- Tensile Testing: Mechanical Engineering LaboratoryDocumento7 pagineTensile Testing: Mechanical Engineering LaboratoryChandra Wahyu SetiawanNessuna valutazione finora

- Mechanical Properties of Metals, Wood and ConcreteDocumento2 pagineMechanical Properties of Metals, Wood and ConcreteritolabNessuna valutazione finora

- Tensile Report Group7Documento21 pagineTensile Report Group7muhd hariz100% (1)

- Stress-Strain Curve 3. Short Term Mechanical PropertiesDocumento183 pagineStress-Strain Curve 3. Short Term Mechanical PropertiesManprita BasumataryNessuna valutazione finora

- Universal Testing Machine Components and UsageDocumento17 pagineUniversal Testing Machine Components and UsageRABINDRA NATH NAYAKNessuna valutazione finora

- Stress-Strain Curve 3. Short Term Mechanical PropertiesDocumento183 pagineStress-Strain Curve 3. Short Term Mechanical PropertieskhagendrakryadavNessuna valutazione finora

- Experiment Name: Tensile Test of Steel: ObjectivesDocumento4 pagineExperiment Name: Tensile Test of Steel: ObjectivesKalikiri navyaNessuna valutazione finora

- Altinbas University Industrial Engineering Ie258 Manufacturing Process Lab. Tension, Bending, Compression and Torsion TestDocumento19 pagineAltinbas University Industrial Engineering Ie258 Manufacturing Process Lab. Tension, Bending, Compression and Torsion TestHusam JARRAR100% (1)

- SOM CivilDocumento7 pagineSOM CivilVikram RaoNessuna valutazione finora

- Chapter 03 Mechanical PropertiesDocumento8 pagineChapter 03 Mechanical PropertiesSumaya MahmoodNessuna valutazione finora

- Papua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenDocumento4 paginePapua New Guinea University of Technology CE 261-Engineering Materials Test 2 - Tensile Test of A Steel SpecimenIsrael PopeNessuna valutazione finora

- Lab#1 - Tensile Test HandoutDocumento7 pagineLab#1 - Tensile Test Handoutgrbxjgsh59Nessuna valutazione finora

- Tensile Testing Asm StandardDocumento13 pagineTensile Testing Asm StandardNinad PawarNessuna valutazione finora

- Mild Steel Tensile Test ResultsDocumento30 pagineMild Steel Tensile Test ResultsDipesh GugaleNessuna valutazione finora

- IJREI - Fabrication and Analysis of Spring Testing MachineDocumento6 pagineIJREI - Fabrication and Analysis of Spring Testing MachineIjrei JournalNessuna valutazione finora

- Kim, Chen, Kim - 2002 - Estimation Methods For Fatigue Properties of Steels Under Axial and Torsional LoadingDocumento11 pagineKim, Chen, Kim - 2002 - Estimation Methods For Fatigue Properties of Steels Under Axial and Torsional LoadingoffayevNessuna valutazione finora

- Tensile Test of Brass SpecimenDocumento7 pagineTensile Test of Brass SpecimenmanmathkNessuna valutazione finora

- Introduction To Mechanical Testing Module ADocumento27 pagineIntroduction To Mechanical Testing Module AmostafaNessuna valutazione finora

- Mechanical Properties PDFDocumento57 pagineMechanical Properties PDFvardhaNessuna valutazione finora

- Experiment 1Documento7 pagineExperiment 1waseemjuttNessuna valutazione finora

- Fatigue Properties of JIS H3300 C1220 Copper For Strain Life PredictionDocumento10 pagineFatigue Properties of JIS H3300 C1220 Copper For Strain Life PredictionnomecNessuna valutazione finora

- BME Mannual BT 203-1Documento41 pagineBME Mannual BT 203-1shivanshu tiwariNessuna valutazione finora

- Chapter 6 Mechanical Properties of Metals - With Practice QuestionsDocumento90 pagineChapter 6 Mechanical Properties of Metals - With Practice QuestionsSalman KhalilNessuna valutazione finora

- TensileTest-sheetDocumento7 pagineTensileTest-sheetKhubaib MalikNessuna valutazione finora

- Magnetic Particle:: The Following Steps Are Applied During The ExperimentDocumento1 paginaMagnetic Particle:: The Following Steps Are Applied During The ExperimentAhmadNessuna valutazione finora

- Material Lab-17Documento1 paginaMaterial Lab-17AhmadNessuna valutazione finora

- Material Lab-37Documento1 paginaMaterial Lab-37AhmadNessuna valutazione finora

- ML2006 Safety ProtocolsDocumento1 paginaML2006 Safety ProtocolsAhmadNessuna valutazione finora

- Material Lab-16Documento1 paginaMaterial Lab-16AhmadNessuna valutazione finora

- Material Lab-33 PDFDocumento1 paginaMaterial Lab-33 PDFAhmadNessuna valutazione finora

- Jominy Hardenability Test: ObjectiveDocumento1 paginaJominy Hardenability Test: ObjectiveAhmadNessuna valutazione finora

- Ultrasonic Inspection:: The Following Steps Should Be Applied During The ExperimentDocumento1 paginaUltrasonic Inspection:: The Following Steps Should Be Applied During The ExperimentAhmadNessuna valutazione finora

- Tensile Testing of Metals: ObjectiveDocumento1 paginaTensile Testing of Metals: ObjectiveAhmadNessuna valutazione finora

- Material Lab-33 PDFDocumento1 paginaMaterial Lab-33 PDFAhmadNessuna valutazione finora

- Material Lab-35Documento1 paginaMaterial Lab-35AhmadNessuna valutazione finora

- Material Lab-15Documento1 paginaMaterial Lab-15AhmadNessuna valutazione finora

- Study Metal StructureDocumento1 paginaStudy Metal StructureAhmadNessuna valutazione finora

- Visual Inspection:: Materials Laboratory 2006Documento1 paginaVisual Inspection:: Materials Laboratory 2006AhmadNessuna valutazione finora

- NDT Methods Guide for Materials Testing LabDocumento1 paginaNDT Methods Guide for Materials Testing LabAhmadNessuna valutazione finora

- Materials Lab 2006 ReportDocumento1 paginaMaterials Lab 2006 ReportAhmadNessuna valutazione finora

- Material Lab-11Documento1 paginaMaterial Lab-11AhmadNessuna valutazione finora

- Material Lab-14Documento1 paginaMaterial Lab-14AhmadNessuna valutazione finora

- Material Lab-12Documento1 paginaMaterial Lab-12AhmadNessuna valutazione finora

- Material Lab-5Documento1 paginaMaterial Lab-5AhmadNessuna valutazione finora

- Material Lab-16 PDFDocumento1 paginaMaterial Lab-16 PDFAhmadNessuna valutazione finora

- Material Lab-13Documento1 paginaMaterial Lab-13AhmadNessuna valutazione finora

- Material Lab 4Documento1 paginaMaterial Lab 4AhmadNessuna valutazione finora

- Material Lab 7Documento1 paginaMaterial Lab 7AhmadNessuna valutazione finora

- Checklist For Tensile Report: Materials Laboratory 2006Documento1 paginaChecklist For Tensile Report: Materials Laboratory 2006AhmadNessuna valutazione finora

- Material Lab 3Documento1 paginaMaterial Lab 3AhmadNessuna valutazione finora

- Material Lab 4Documento1 paginaMaterial Lab 4AhmadNessuna valutazione finora

- Materials Lab 2006 Attendance SheetDocumento1 paginaMaterials Lab 2006 Attendance SheetAhmadNessuna valutazione finora

- Material Lab 2Documento1 paginaMaterial Lab 2AhmadNessuna valutazione finora

- 2005-021 MotwaniDocumento6 pagine2005-021 Motwanialexander100% (1)

- Section 3,4: Bending Deformation, Strain and Stress in BeamsDocumento20 pagineSection 3,4: Bending Deformation, Strain and Stress in BeamsRasool AkhterianNessuna valutazione finora

- Definition and Purposes of ExplanationDocumento4 pagineDefinition and Purposes of ExplanationArka WiguaNessuna valutazione finora

- Underground sump reservoir specification and designDocumento30 pagineUnderground sump reservoir specification and designAnand SoniNessuna valutazione finora

- 20Mnv6 Hollow Bar: Iso Stocked Sizesiso ChartDocumento3 pagine20Mnv6 Hollow Bar: Iso Stocked Sizesiso ChartretrogradesNessuna valutazione finora

- Consider A Simple Steam-Turbine Engine With The Tu.Documento4 pagineConsider A Simple Steam-Turbine Engine With The Tu.Din TescoNessuna valutazione finora

- Lab 5 - Analysis of Deflection Under Transverse Loading (Simply Supported Beam)Documento8 pagineLab 5 - Analysis of Deflection Under Transverse Loading (Simply Supported Beam)Mohib ShareefNessuna valutazione finora

- Ryton PPS Design GuideDocumento24 pagineRyton PPS Design GuideAnonymous l2sT4aENessuna valutazione finora

- Measuring Devices (Sensors & Transducers)Documento16 pagineMeasuring Devices (Sensors & Transducers)mani.mit2005Nessuna valutazione finora

- CL141 Engineering Mechanics Laboratory Manual: First Year B.Tech. (CL/ME/EE)Documento64 pagineCL141 Engineering Mechanics Laboratory Manual: First Year B.Tech. (CL/ME/EE)Abdul RehmanNessuna valutazione finora

- Documents 5401 G 5Documento2 pagineDocuments 5401 G 5ductoan32Nessuna valutazione finora

- Piping Stress AnalysisDocumento36 paginePiping Stress AnalysisSugumar S100% (1)

- Achieving Perfect Plastification April - 2010Documento2 pagineAchieving Perfect Plastification April - 2010Anonymous nsmzJNLoNessuna valutazione finora

- Mardina A PDFDocumento4 pagineMardina A PDFAdib YusofNessuna valutazione finora

- DAB 2018 Componenets CatalogueDocumento20 pagineDAB 2018 Componenets CataloguegobilgobilNessuna valutazione finora

- Turbidimetry NotesDocumento2 pagineTurbidimetry NotesJessa MayNessuna valutazione finora

- Light - Emitting DiodesDocumento12 pagineLight - Emitting DiodesasadNessuna valutazione finora

- Fans and BlowersDocumento51 pagineFans and BlowersJohn Kennedy FernandesNessuna valutazione finora

- Failure analysis of bilge keels reveals stresses lead to cracksDocumento6 pagineFailure analysis of bilge keels reveals stresses lead to cracksBrizamar AguiarNessuna valutazione finora

- Fluid Flow OperationDocumento2 pagineFluid Flow OperationShubham imtsNessuna valutazione finora

- Surface Review & LettersDocumento12 pagineSurface Review & LettersSujoy ChakrabortyNessuna valutazione finora

- The Compressive Strehgth of Cement Mortr PDFDocumento3 pagineThe Compressive Strehgth of Cement Mortr PDFOsama ShukurNessuna valutazione finora

- Atmospheric, Oceanic and Terrestrial Processes (Lec3)Documento32 pagineAtmospheric, Oceanic and Terrestrial Processes (Lec3)kiedd_04100% (1)

- BayblendDocumento10 pagineBayblendGarry TaylorNessuna valutazione finora

- 3 04 LT Cooling SystemDocumento25 pagine3 04 LT Cooling Systemstopless_dalian685Nessuna valutazione finora

- Prelim Examination Set A Solutions PDFDocumento6 paginePrelim Examination Set A Solutions PDFOxy GenNessuna valutazione finora

- Prismatic and Surveyor Compass: Types, Components, Uses and AdjustmentDocumento6 paginePrismatic and Surveyor Compass: Types, Components, Uses and AdjustmentSaHil ShaRmaNessuna valutazione finora

- Design of Beam To Column SpliceDocumento1 paginaDesign of Beam To Column SpliceAndro RebuyasNessuna valutazione finora

- Lecture 11 - Multiple Reactions 2Documento14 pagineLecture 11 - Multiple Reactions 2Sabrina AzharNessuna valutazione finora