Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

G Codes

Caricato da

Jose Luis Hernandez0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

98 visualizzazioni4 pagineCódigos G para Control Numérico de máquinas Herramientas

Titolo originale

g codes

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCódigos G para Control Numérico de máquinas Herramientas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

98 visualizzazioni4 pagineG Codes

Caricato da

Jose Luis HernandezCódigos G para Control Numérico de máquinas Herramientas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

G and M Codes, CNC Machining Reference Chart - 4 Hire Tek

If you see this message in your browser instead of buttons, then Java is disabled.

Please enable or use links at bottom of page.

Standard CNC G Codes - Vertical and Horizontal Mills

Commonly Used "G" Codes - CNC Mill

G00 - Rapid Positioning G52 - Local Coordinate Setting

G01 - Feedrate Positioning G53 - Machine Coordinate Setting

G02 - Arc Clockwise G54 - Workpiece Coordinate Setting #1

G03 - Arc Counterclockwise G55 - Workpiece Coordinate Setting #2

G04 - Dwell G56 - Workpiece Coordinate Setting #3

G05 - High Speed Machining G57 - Workpiece Coordinate Setting #4

G07 - Imanaginary Axis Designation G58 - Workpiece Coordinate Setting #5

G09 - Exact Stop Check G59 - Workpiece Coordinate Setting #6

G10 - Program Parameter Input G60 - Single Direction Positioning

G11 - Program Peramater Input Cancel G62 - Automatic Corner Override

G12 - Circle Cutting CW G63 - Tapping Mode

G13 - Circle Cutting CCW G64 - Cutting Mode

G17 - X - Y Plane G65 - Custom Macro Call (Simple)

G18 - X - Z Plane G66 - Custom Macro Call (Modal)

G19 - Y - Z Plane G67 - Custom Macro Call Cancel (Modal)

G20 - Input in Inch Units G68 - Coordinate System Rotation ON

G21 - Input in Metric G69 - Coordinate System Rotation OFF

G22 - Stored Stroke Limit ON G70 - Input in Inch Units

G23 - stored Stroke Limit OFF G71 - Input in Metric Units

G27 - Reference Point Return Check G73 - High Speed Peck Drilling Cycle

G28 - Automatic Return to Reference Point G74 - Left Hand Tapping Cycle

G29 - Automatic Return from Reference Point G76 - Fine Boring Cycle

G30 - Return to 2nd, 3rd or 4th Reference Point G80 - Canned Cycle Cancel

G31 - Skip Function G81 - Drilling Cycle (Canned)

http://www.4hiretek.com/gmcodes.html (1 de 4) [14/06/2009 02:41:19 p.m.]

G and M Codes, CNC Machining Reference Chart - 4 Hire Tek

G33 - Thread Cutting G82 - Counter Boring Cycle (Canned)

G34 - Bolt Hole Circle (Canned Cycle) G83 - Peck Drilling Cycle (Canned)

G35 - Line at Angle (Canned Cycle) G84 - Right Hand Tapping Cycle (Canned)

G36 - Arc (Canned Cycle) G85 - Boring Cycle (Canned)

G40 - Cutter Compensation Cancel G87 - Back Boring Cycle (Canned)

G41 - Cutter Compensation Left G90 - Absolute Positioning

G42 - Cutter Compensation Right G91 - Incremental Positioning

G43 - Tool Length Compensation (Plus) G92 - Reposition Origin Point

G44 - Tool Length Compensation (Minus) G94 - Feed Per Minute

G45 - Tool Offset Increase G95 - Feed Per Revolution

G46 - Tool Offset Decrease G96 - Constant Surface Speed Contrpl

G49 - Tool Length Compensation Cancel G97 - Constant Surface Speed Control Cancel

G50 - Scaling OFF G98 - Set Initial Plane (Default)

G51 - Scaling ON G99 - Return to Rapid Plane

Standard CNC G Codes - Lathes

Commonly Used "G" Codes - CNC Lathe

G00 - Rapid Positioning G57 - Workpiece Coordinate Setting #4

G01 - Feedrate Positioning G58 - Workpiece Coordinate Setting #5

G02 - Arc Clockwise G59 - Workpiece Coordinate Setting #6

G03 - Arc Counterclockwise G61 - Exact Stop Check Mode

G04 - Dwell G62 - Automatic Corner Override

G07 - Feedrate Sine Curve Control G63 - Tapping Mode

G10 - Data Setting G64 - Cutting Mode

G11 - Data Setting Cancel G65 - User Macro Call

G17 - X - Y Plane G66 - User Macro Call (Modal)

G18 - X - Z Plane G67 - User Macro Call Cancel (Modal)

G19 - Y - Z Plane G70 - Finishing Cycle

G20 - Inch Units G71 - Turning Cycle

G21 - Metric Units G72 - Facing Cycle

G22 - Stored Stroke Check ON G73 - Pattern Repeat

G23 - Stored Stroke Check OFF G74 - Drilling Cycle

G27 - Reference Point Return Check G75 - Grooving Cycle

G28 - Automatic Zero Return G76 - Threading Cycle

G29 - Return from Zero Position G80 - Canned Cycle Cancel

G30 - 2nd Reference Point Return G83 - Face Drilling Cycle

G31 - Skip Function G84 - Face Tapping Cycle

G32 - Thread Cutting G86 - Face Boring Cycle

G36 - Automatic Tool Compensation G90 - Absolute Positioning

http://www.4hiretek.com/gmcodes.html (2 de 4) [14/06/2009 02:41:19 p.m.]

G and M Codes, CNC Machining Reference Chart - 4 Hire Tek

G40 - Tool Compensation Cancel G91 - Incremental Positioning

G41 - Tool Compensation Left G92 - OD Thread Cutting Cycle

G42 - Tool Compensation Right G94 - Face Turning Cycle

G46 - Automatic Tool Compensation G96 - Constant Speed Control

G50 - Coordinate System Setting G97 - Constant Speed Control Cancel

G52 - Local Coordinate System Setting G98 - Feedrate Per Time

G53 - Machine Coordinate System Setting G99 - Feedrate Per Revolution

G54 - Workpiece Coordinate Setting #1 G107 - Cylindrical Interpolation

G55 - Workpiece Coordinate Setting #2 G112 - Polar Coordinate Interpolation

G56 - Workpiece Coordinate Setting #3 G113 - Polar Coordinate Interpolation Cancel

Standard CNC M Codes - Mills and Lathes

Commonly Used "M" Codes - Mill & Lathe

Mill Lathe

M00 - Program Stop M00 - Program Stop

M01 - Optional Stop M01 - Optional Program Stop

M02 - Program End M02 - Program End

M03 - Spindle Clockwise M03 - Spindle Clockwise

M04 - Spindle Counter Clockwise M04 - Spindle Counter Clockwise

M05 - Spindle Stop M05 - Spindle Stop

M06 - Tool Change

M07 - Thru Spindle Coolant ON M07 - Flood Coolant #1 On

M08 - Flood Coolant ON M08 - Flood Coolant #2 On

M09 - Coolant Off (all coolant) M09 - Coolant Off

M10 - Table Pallet Clamp

M11 - Table Pallet Unclamp

M12 - Shower Coolant On

M14 - Spindle Air Blow On

M15 - Spindle Air Blow Off

M16 - Air Blast / Tool Changer

M18 - Air Blast Off

M19 - Spindle Orientation

M29 - Rigid Tapping

M30 - End Program M30 - End Progarm

M60 - Pallet Change

M61 - Load Pallet #1

M62 - Load Pallet #2

M98 - Sub Program Call M98 - Sub Program Call

http://www.4hiretek.com/gmcodes.html (3 de 4) [14/06/2009 02:41:19 p.m.]

G and M Codes, CNC Machining Reference Chart - 4 Hire Tek

M99 - Sub Program Cancel M99 - Sub Program Cancel

Contact G&M Tap & Drill

Home Services Faq. Privacy Parts

Us Codes Chart Chart

4 Hire Tek, Personalized & Affordable CNC Contract Programming

Copyright © 2001 - 2009, 4 Hire Tek All rights Reserved. !!!

http://www.4hiretek.com/gmcodes.html (4 de 4) [14/06/2009 02:41:19 p.m.]

Potrebbero piacerti anche

- Sae DynamometerDocumento10 pagineSae DynamometerJose Luis HernandezNessuna valutazione finora

- Lecture of CNC ProgramDocumento29 pagineLecture of CNC ProgramMargam Kiran KumarNessuna valutazione finora

- Iron Carbon DiagramDocumento10 pagineIron Carbon DiagramVinod100% (1)

- Basic Heat TreatmentDocumento12 pagineBasic Heat Treatmentpramod_goswamiNessuna valutazione finora

- Carbon SteelDocumento5 pagineCarbon Steelhayder1920Nessuna valutazione finora

- To Find Chord of A Windmill Rotor Blade As A Function of Radius RDocumento6 pagineTo Find Chord of A Windmill Rotor Blade As A Function of Radius RTuchitoNessuna valutazione finora

- Diseño de Álabes EólicosDocumento64 pagineDiseño de Álabes EólicosJose Luis HernandezNessuna valutazione finora

- Diseño de Álabes EólicosDocumento64 pagineDiseño de Álabes EólicosJose Luis HernandezNessuna valutazione finora

- Talk The Four TasselsDocumento4 pagineTalk The Four TasselsJose Luis HernandezNessuna valutazione finora

- Cálculo de EngranajesDocumento18 pagineCálculo de EngranajesJose Luis HernandezNessuna valutazione finora

- Bomba EólicaDocumento1 paginaBomba EólicaJose Luis HernandezNessuna valutazione finora

- Informe Bus de Facultad IngDocumento3 pagineInforme Bus de Facultad IngJose Luis HernandezNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- CNC Operator Web-Based Tutorial 545Documento20 pagineCNC Operator Web-Based Tutorial 545api-274441692Nessuna valutazione finora

- SSAB Machining Strenx 2017Documento28 pagineSSAB Machining Strenx 2017RogerNessuna valutazione finora

- CNC Turning Machine Programming and OperationDocumento17 pagineCNC Turning Machine Programming and OperationioshhNessuna valutazione finora

- MS Bolts & Nuts Weight PDFDocumento10 pagineMS Bolts & Nuts Weight PDFerkamlakar223429% (7)

- Proj-Ppt-Manufacturing of Steam Turbine BladeDocumento12 pagineProj-Ppt-Manufacturing of Steam Turbine BladegopikrishnandotpillaNessuna valutazione finora

- Melin Catalog 2005Documento122 pagineMelin Catalog 2005Sujata KulkarniNessuna valutazione finora

- Whitworth BSW BSF PDFDocumento2 pagineWhitworth BSW BSF PDFLaural MarshallNessuna valutazione finora

- Fixtures For NCDocumento13 pagineFixtures For NCMaha RajanNessuna valutazione finora

- Machining of MetalsDocumento22 pagineMachining of MetalsFiq IskandarNessuna valutazione finora

- PPR Pipe CutterDocumento1 paginaPPR Pipe CutterkuraimundNessuna valutazione finora

- SHEET METAL DUST PAN REPORTDocumento4 pagineSHEET METAL DUST PAN REPORTPrashant Sah60% (5)

- CNC Machine & Automation Questions Bank 1Documento69 pagineCNC Machine & Automation Questions Bank 1SACHIN SINGH 36Nessuna valutazione finora

- Machining and Machine Tools: Lecture NotesDocumento33 pagineMachining and Machine Tools: Lecture NotesNishchay pratapNessuna valutazione finora

- Brochure Reamers Type UDocumento3 pagineBrochure Reamers Type UPatrizio MassaroNessuna valutazione finora

- Sop - Drill MachineDocumento2 pagineSop - Drill MachineprojectssuyashcorpNessuna valutazione finora

- MD Set 2 AnsDocumento100 pagineMD Set 2 AnsJom BautistaNessuna valutazione finora

- HW-emoto Rotary Table High QualityDocumento14 pagineHW-emoto Rotary Table High QualityDenis TkachukNessuna valutazione finora

- What Is Milling ProcessDocumento4 pagineWhat Is Milling ProcessRonnick De La TongaNessuna valutazione finora

- Pious I T Report 2Documento41 paginePious I T Report 2Anfield Faithful100% (1)

- EMCO F1 ManualDocumento308 pagineEMCO F1 ManualClinton Koo100% (1)

- Doosan Puma MX Series PDFDocumento68 pagineDoosan Puma MX Series PDFGuillermo RamirezNessuna valutazione finora

- Thread Specifications GuideDocumento30 pagineThread Specifications GuidesoparlNessuna valutazione finora

- Fanuc CodeDocumento11 pagineFanuc CoderlwersalNessuna valutazione finora

- Drilling MachineDocumento7 pagineDrilling MachineTanish VermaNessuna valutazione finora

- Difference between jigs and fixtures for machiningDocumento2 pagineDifference between jigs and fixtures for machiningsandeep100% (1)

- BSP Threads PDFDocumento1 paginaBSP Threads PDFmihaidelianNessuna valutazione finora

- Study On Capstan Lathe and Copying LatheDocumento6 pagineStudy On Capstan Lathe and Copying Lathechandan kumarNessuna valutazione finora

- Diamut Pietra General Catalog ENGDocumento54 pagineDiamut Pietra General Catalog ENGВалера ЧечеткинNessuna valutazione finora

- Information Sheet 2.1-2docxDocumento8 pagineInformation Sheet 2.1-2docxErnesto CabuyadaoNessuna valutazione finora

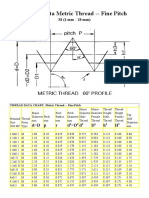

- Metric Fine ThreadDocumento3 pagineMetric Fine ThreadBrendan CreanerNessuna valutazione finora