Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Inspection and Test Plan: Contract No

Caricato da

Ahmed Samir SalimTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Inspection and Test Plan: Contract No

Caricato da

Ahmed Samir SalimCopyright:

Formati disponibili

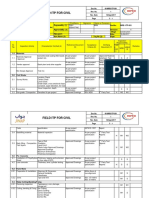

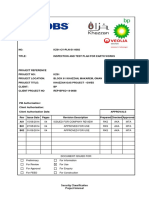

CONTRACT NO

PETROJET

Dahshour /Abo El-Gharadig 24''/262.5 KM Gas PL REV 0

DOC NO. PTJ-KPC-DA-019-PROC

Concrete work procedure DATE 22/10/2012

INSPECTION AND TEST PLAN

Concrete work procedure

Document No.PTJ-KPC-DA-019-PROC

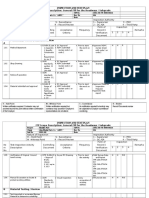

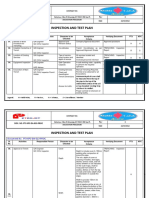

Sl. Character Responsible Acceptance Verifying

Activities PTJ KPC

No. to be Checked Person Criteria Document

Approved procedure & Approved for construction Work procedure for

1 Document review Procedure approval QC CiviI Inspector ,QA Engineer R R

drawings concreteing work

Material

Material mill certificates

2 selection,approval&review QC CiviI Inspector ,QA Engineer As per AFC drawing. Sample approval report H W

and test certificates

of test certificates

1-CONCRETE POURING

the testing results of

REPORT 2-

3 Mix design and trial mixes concrete strength to be CIVIL QC Inspector As per AFC drawing. H W

COMPRESSION TEST ON

checked

CONCRETE CUBES

Legend: H = Hold Point, R = Review, W = Witness, S = Surveillance / Monitor

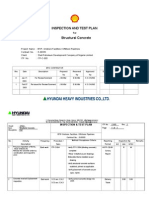

CONTRACT NO

PETROJET

Dahshour /Abo El-Gharadig 24''/262.5 KM Gas PL REV 0

DOC NO.PTJ-KPC-DA-019-PROC

Concrete work procedure DATE 22/10/2012

INSPECTION AND TEST PLAN

Concrete work procedure

Document No.PTJ-KPC-DA-019-PROC

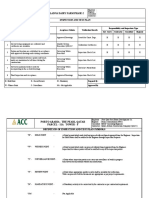

Sl. Character Responsible Acceptance Verifying

Activities PTJ KPC

No. to be Checked Person Criteria Document

1- All formwork shall be made from clean marine

waterproof plywood with white wood used for the frame of

formworks.

2- Formwork shall be sufficiently tight to prevent leakage

of cement slurry while concreting.

3- Form work will be adequately propped, braced and tied

Dimentions,tightness,

in position to ensure that it retains its shape and position INSPECTION RECORD

4 Formwork and spacers location,orientation and QC Civil inspector H S

before, during and after concreting. FOR CONCRETE WORKS

cleaness 4- Formwork will remain in place until the concrete has

hardened sufficiently to resist damages from the removal

operation which in this case in a minimum of 24 hours after

placing of concrete.

5- as per requirments of project specs and approved

procedure

1- Fabrication & Deformation of steel will be done at

Reinforcement steel fabrication shop at site or at external

factories approved by KPC.

2- Assembled reinforcement will be erected manually or

Steel reinforcement wire wire mesh type , cover , INSPECTION RECORD

5 QC Civil inspector using crane / suitable lifting equipment (If necessary). H S

mesh lap distance and fixation. 3- The spacer blocks will be prepared near Reinforcement

FOR CONCRETE WORKS

yard at site and casted from the same mix as the

surrounding concrete.

1- INSPECTION RECORD

Inspection prior to concrete Formwork , reinforcement FOR CONCRETE WORKS

6 QC Civil inspector approved for construction work procedure 2- POST – POUR H W

pouring and spacers final check

INSPECTION RECORD FORM

Concrete will be placed as nearly as practicable to its final

position and care taken to avoid segregation of concrete,

concrete pouring & displacement of reinforcement, formwork or embedded CONCRETE POURING

7 Concrete QC Civil inspector Items, maxi free fall for concrete shall not exceed 1.5m.

H W

compaction and curing REPORT

Temperature of concrete at the time of placement shall be

measured and recorded each pour card.

1-COMPRESSION TEST ON

CONCRETE CUBES 2-

8 Concrete test Tests for concrete QC Civil inspector AFC drawing. H S

CONCRETE POURING

REPORT

Prepared by: Approved by :

Petrojet KPC

QC Engineer Ref. Indicator

Legend: H = Hold Point, R = Review, W = Witness, S = Surveillance / Monitor

Potrebbero piacerti anche

- ITP-ALU Doors & Windows & Glazing WorksDocumento2 pagineITP-ALU Doors & Windows & Glazing WorksYash Sharma100% (1)

- Cb2 Q Zen 05 60211 Itp For Earth Work - Rev.bDocumento6 pagineCb2 Q Zen 05 60211 Itp For Earth Work - Rev.bAnonymous wIPMQ5rhNessuna valutazione finora

- Quality Induction Training-No 1Documento22 pagineQuality Induction Training-No 1Kannan Murugesan100% (1)

- QC Check Sheets (Overview)Documento6 pagineQC Check Sheets (Overview)ricosanojuanNessuna valutazione finora

- Itp - Building WorksDocumento15 pagineItp - Building WorksVasilica BArbarasaNessuna valutazione finora

- ITP For Civil WorksDocumento15 pagineITP For Civil WorksNoor A Qasim100% (8)

- ITP CIVIL WORK-Rev-1Documento6 pagineITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- Project Quality Control PlanBBBDocumento21 pagineProject Quality Control PlanBBBVO DINH TRI100% (1)

- Quality InductionDocumento15 pagineQuality InductionaleemmurtazaNessuna valutazione finora

- Field ITP Civil Rev-8after Lump-Sump.Documento17 pagineField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- NCR-017-final - ClosedDocumento46 pagineNCR-017-final - ClosedANIL PLAMOOTTILNessuna valutazione finora

- M Storm Drainage System IC M SDS 00Documento2 pagineM Storm Drainage System IC M SDS 00achusanachuNessuna valutazione finora

- Procedure For Erection of Pipings and StructuresDocumento10 pagineProcedure For Erection of Pipings and StructuresraviNessuna valutazione finora

- 5.1.1. Construction of Access Road and Structure PadsDocumento7 pagine5.1.1. Construction of Access Road and Structure PadsALI ASGHARNessuna valutazione finora

- Soil Compaction Test ReportDocumento7 pagineSoil Compaction Test ReportAkash SharmaNessuna valutazione finora

- Quality Inspection FormDocumento3 pagineQuality Inspection FormTesfuNessuna valutazione finora

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocumento53 pagineA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNessuna valutazione finora

- ITP C 005 (Structural Concrete)Documento4 pagineITP C 005 (Structural Concrete)segun ajibolaNessuna valutazione finora

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDocumento81 pagine30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonNessuna valutazione finora

- Itp Civil WorkDocumento9 pagineItp Civil WorkChristian Albert Sinaga RumajarNessuna valutazione finora

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDocumento20 pagine04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraNessuna valutazione finora

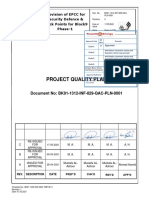

- Project Quality Plan: Document No: BK91-1312-INF-829-QAC-PLN-0001Documento53 pagineProject Quality Plan: Document No: BK91-1312-INF-829-QAC-PLN-0001Berry UmpolaNessuna valutazione finora

- ITP - General Fill For The Roads - SampleDocumento12 pagineITP - General Fill For The Roads - SamplezubairNessuna valutazione finora

- Saudi Technical LTD: Qa / QC Department Organization ChartDocumento1 paginaSaudi Technical LTD: Qa / QC Department Organization Chartzahid_497Nessuna valutazione finora

- Nawaz Khan - Civil InspectorDocumento4 pagineNawaz Khan - Civil InspectormlNessuna valutazione finora

- Method Statement - EXCAVATION AND BACKFILLING 560-S28 (Code-2)Documento9 pagineMethod Statement - EXCAVATION AND BACKFILLING 560-S28 (Code-2)MGNessuna valutazione finora

- Al Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & WiresDocumento5 pagineAl Ain Stadium & Mixed Use Development Phase 1.1: Inspection & Test Plan For Installation & Termination of Cables & Wiresmidhun muraliNessuna valutazione finora

- Typical QAPDocumento4 pagineTypical QAPhemantmech09Nessuna valutazione finora

- Inspection Test Plan For ISBL 1Documento59 pagineInspection Test Plan For ISBL 1Sharat SahaNessuna valutazione finora

- Construction Project Quality Plan (PQP)Documento15 pagineConstruction Project Quality Plan (PQP)MohamedNessuna valutazione finora

- Itp - Inspection and Testing Plan (Creation and Management)Documento10 pagineItp - Inspection and Testing Plan (Creation and Management)Luffy11100% (1)

- QA-QC Control P1Ch16Documento8 pagineQA-QC Control P1Ch16jasolanoroNessuna valutazione finora

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Documento4 pagineFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocumento3 pagineProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNessuna valutazione finora

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocumento9 pagineRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNessuna valutazione finora

- Installation of LV Cables: Inspection and Test Plan ForDocumento1 paginaInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNessuna valutazione finora

- Method PileDocumento3 pagineMethod Pileavisek_basu100% (1)

- MS Site and FenceDocumento11 pagineMS Site and FenceSahabzada AamirNessuna valutazione finora

- Method Statement FOR Painting Works: Revision RecordDocumento16 pagineMethod Statement FOR Painting Works: Revision RecordrajatNessuna valutazione finora

- Request For Inspection: QC Rfi No.Documento1 paginaRequest For Inspection: QC Rfi No.KarthikNessuna valutazione finora

- Inspection and Testing PlanDocumento7 pagineInspection and Testing PlanStephen David Gozun50% (2)

- Concrete Work: (Please Provide Detail of Repair Activities E.G)Documento2 pagineConcrete Work: (Please Provide Detail of Repair Activities E.G)Eze NonsoNessuna valutazione finora

- Waterproofing (Cementitious+HDPE)Documento12 pagineWaterproofing (Cementitious+HDPE)masahinNessuna valutazione finora

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocumento2 pagineKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNessuna valutazione finora

- METHOD STATEMENT FOR Backfilling - Rev 0Documento5 pagineMETHOD STATEMENT FOR Backfilling - Rev 0Osama MZNessuna valutazione finora

- ITP - Concrete WorksDocumento17 pagineITP - Concrete WorksVasilica BArbarasa100% (2)

- Civil Quality Control Plan EarthworksDocumento3 pagineCivil Quality Control Plan Earthworksroekyat hendrawanNessuna valutazione finora

- QCP - BuildingsDocumento4 pagineQCP - BuildingsMitendra Kumar ChauhanNessuna valutazione finora

- Inspection and Test Plan-Concrete Protection C008Documento2 pagineInspection and Test Plan-Concrete Protection C008FurqanNessuna valutazione finora

- Saudi Oger Ltd. (Project Name) : PlasteringDocumento1 paginaSaudi Oger Ltd. (Project Name) : PlasteringAnthony AngelesNessuna valutazione finora

- ITP For Steel Structure1Documento3 pagineITP For Steel Structure1吴兴泊Nessuna valutazione finora

- ITP EverythingDocumento5 pagineITP EverythingAkram SayeedNessuna valutazione finora

- Quality Requirements For Subcontractor: Project ProcedureDocumento15 pagineQuality Requirements For Subcontractor: Project ProcedureDindo QuintanNessuna valutazione finora

- Aramco ChecklistDocumento1 paginaAramco ChecklistTayyab AchakzaiNessuna valutazione finora

- Rapp-7&8 Construction of Main Plant Civil Work-Package-I: List of Approved Qaps/ ItpsDocumento2 pagineRapp-7&8 Construction of Main Plant Civil Work-Package-I: List of Approved Qaps/ ItpsAkansh JainNessuna valutazione finora

- 04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTADocumento4 pagine04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTAjay2kay5793Nessuna valutazione finora

- ExcavationDocumento1 paginaExcavationkumarakash122392Nessuna valutazione finora

- QC Example Resume.01Documento4 pagineQC Example Resume.01Guru SankarNessuna valutazione finora

- 11-Qa - QC ProcedureDocumento18 pagine11-Qa - QC Procedureerwin hidayat100% (1)

- Inspection and Test Plan: Contract NoDocumento2 pagineInspection and Test Plan: Contract NoAhmed Samir SalimNessuna valutazione finora

- Internal & External Plaster Works Method Statement For Areas (1P70, 1N53 & 1F52Documento14 pagineInternal & External Plaster Works Method Statement For Areas (1P70, 1N53 & 1F52Ahmed Samir SalimNessuna valutazione finora

- Lose Fat BodyfatblasterDocumento1 paginaLose Fat BodyfatblasterAhmed Samir SalimNessuna valutazione finora

- Null 25Documento3 pagineNull 25Ahmed Samir SalimNessuna valutazione finora

- Calorie, Macro, and Portion Guide: Personalized Nutrition Report ForDocumento18 pagineCalorie, Macro, and Portion Guide: Personalized Nutrition Report ForMaría José Rivero100% (1)

- Scale 1: 5 Scale 1: 5: Drawing No .: 079254P-1N53-TNK-DTL-0402Documento1 paginaScale 1: 5 Scale 1: 5: Drawing No .: 079254P-1N53-TNK-DTL-0402Ahmed Samir SalimNessuna valutazione finora

- Growin Arms30daysDocumento1 paginaGrowin Arms30daysRemiNessuna valutazione finora

- Mix DesignDocumento10 pagineMix DesignMary Emalaine SerranoNessuna valutazione finora

- Astm D1785-2012Documento11 pagineAstm D1785-2012mavericklf1100% (1)

- Field Manual ROADDocumento315 pagineField Manual ROADJose Espejo Vasquez100% (1)

- Safety Data Sheet: Epcon C8 ResinDocumento3 pagineSafety Data Sheet: Epcon C8 ResinAhmed Samir SalimNessuna valutazione finora

- Epcon C8: Steel Reinforcement Fixings For Reinforced ConcreteDocumento3 pagineEpcon C8: Steel Reinforcement Fixings For Reinforced ConcreteAhmed Samir SalimNessuna valutazione finora

- Reinforcing Detailing of R.C.C MembersDocumento47 pagineReinforcing Detailing of R.C.C MembersAmey ShettiNessuna valutazione finora

- Proposed Methodology For Measurement, Survey and Assessment of Vertical Deformation of StructuresDocumento27 pagineProposed Methodology For Measurement, Survey and Assessment of Vertical Deformation of StructuresAhmed Samir SalimNessuna valutazione finora

- Concrete Mix DesignDocumento6 pagineConcrete Mix DesignKarnalPreethNessuna valutazione finora

- Miscellaneous Material PDFDocumento3 pagineMiscellaneous Material PDFAhmed Samir SalimNessuna valutazione finora

- ConcreteDocumento4 pagineConcretegeonikoNessuna valutazione finora

- ACI Method ExampleDocumento2 pagineACI Method ExampleSam Ang KeoNessuna valutazione finora

- Concrete Mix Plant Bis 4925.2004Documento14 pagineConcrete Mix Plant Bis 4925.2004DilipKumarDaddalaNessuna valutazione finora

- 70 RiprapDocumento7 pagine70 RiprapRonald Cario SeguinNessuna valutazione finora

- Riprap PDFDocumento5 pagineRiprap PDFGonzalo Diz LoisNessuna valutazione finora

- 311 5R-02Documento6 pagine311 5R-02farhadamNessuna valutazione finora

- 01 - Method Statement For Excavation Work222Documento9 pagine01 - Method Statement For Excavation Work222Ahmed Samir SalimNessuna valutazione finora

- 01 - Method Statement For Excavation WorkhhhjkDocumento10 pagine01 - Method Statement For Excavation WorkhhhjkAhmed Samir SalimNessuna valutazione finora

- Rock Riprap Design Methods and Their Applicability To Long-Term Protection of Uranium Mill Tailings ImpoundmentsDocumento98 pagineRock Riprap Design Methods and Their Applicability To Long-Term Protection of Uranium Mill Tailings ImpoundmentsAhmed Samir SalimNessuna valutazione finora

- Miscellaneous Material PDFDocumento3 pagineMiscellaneous Material PDFAhmed Samir SalimNessuna valutazione finora

- Inspection and Test Plan: Etro ETDocumento1 paginaInspection and Test Plan: Etro ETAhmed Samir SalimNessuna valutazione finora

- المقص فى حديد تسليح السلم PDFDocumento6 pagineالمقص فى حديد تسليح السلم PDFAhmed Samir SalimNessuna valutazione finora

- Inspection and Test Plan: Contract NoDocumento2 pagineInspection and Test Plan: Contract NoAhmed Samir SalimNessuna valutazione finora

- ITP For TrenchingDocumento4 pagineITP For TrenchingAhmed Samir SalimNessuna valutazione finora

- Inspection and Test Plan: Contract NoDocumento2 pagineInspection and Test Plan: Contract NoAhmed Samir SalimNessuna valutazione finora

- List of Common FormulasDocumento3 pagineList of Common FormulasJun YoutubeNessuna valutazione finora

- Insulation SpecificationDocumento25 pagineInsulation SpecificationRaaj ChandranNessuna valutazione finora

- Bioresource Technology: Suhas, V.K. Gupta, P.J.M. Carrott, Randhir Singh, Monika Chaudhary, Sarita KushwahaDocumento11 pagineBioresource Technology: Suhas, V.K. Gupta, P.J.M. Carrott, Randhir Singh, Monika Chaudhary, Sarita KushwahaDavid Hoktua Siregar siregarNessuna valutazione finora

- Belt Conveyor DesignDocumento21 pagineBelt Conveyor DesignAjith100% (1)

- Subject Code Theory of Metal CuttingDocumento2 pagineSubject Code Theory of Metal CuttingShimada TadaNessuna valutazione finora

- Pasqual Cavaliere - Shaft Furnaces and Beehive Charcoal Kilns - A History of Smelting in The Far West, 1863-1900Documento4 paginePasqual Cavaliere - Shaft Furnaces and Beehive Charcoal Kilns - A History of Smelting in The Far West, 1863-1900HamidBarekatainNessuna valutazione finora

- Joint Free Slabs On Grade An Innovative Approach WorkingDocumento6 pagineJoint Free Slabs On Grade An Innovative Approach Workingmehdi_hoseineeNessuna valutazione finora

- Diesel Usado AnfoDocumento8 pagineDiesel Usado AnfochoqolloNessuna valutazione finora

- FRD17Documento3 pagineFRD17Raul FloresNessuna valutazione finora

- Lab 1Documento7 pagineLab 1Gagan GautamNessuna valutazione finora

- Technical Data UltraproofDocumento2 pagineTechnical Data UltraproofSidik ArzachelNessuna valutazione finora

- ASTM Carbon Alloy Pipe and TubingDocumento1 paginaASTM Carbon Alloy Pipe and TubingServando LozanoNessuna valutazione finora

- 44 DW-309MoLPDocumento1 pagina44 DW-309MoLPamit singhNessuna valutazione finora

- Gcse Ocr DT FlashcardsDocumento8 pagineGcse Ocr DT Flashcardsapi-256027312Nessuna valutazione finora

- Hexadrain Brickslot OverviewDocumento2 pagineHexadrain Brickslot Overviewloren4_rengifo3044Nessuna valutazione finora

- Haldimann Structural Use of Glass Book PDFDocumento221 pagineHaldimann Structural Use of Glass Book PDFDAVID LOPES DOS SANTOSNessuna valutazione finora

- Patent EthanolDocumento11 paginePatent EthanolAZIMI KURNIAWANNessuna valutazione finora

- Estimate-Csg For Slab and Walls Per Square MetersDocumento2 pagineEstimate-Csg For Slab and Walls Per Square MetersRoland CepedaNessuna valutazione finora

- Crits Notes On Water and Ion Exchange PDFDocumento55 pagineCrits Notes On Water and Ion Exchange PDFAlfredo HernandezNessuna valutazione finora

- U.S. Department of Transportation: Laboratory Test Procedure FOR Fmvss 116 Motor Vehicle Brake FluidsDocumento5 pagineU.S. Department of Transportation: Laboratory Test Procedure FOR Fmvss 116 Motor Vehicle Brake FluidsMuhammad RNessuna valutazione finora

- Catalogue Pressure GaugeDocumento2 pagineCatalogue Pressure GaugeSupriyaRongNessuna valutazione finora

- Teardrop (TF2) : Specification SheetDocumento2 pagineTeardrop (TF2) : Specification SheetMichael AzamarNessuna valutazione finora

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersDocumento68 pagineVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- Science Course III: Enhanced Oil Recovery: Starter PackDocumento15 pagineScience Course III: Enhanced Oil Recovery: Starter PackJames SampurnaNessuna valutazione finora

- G-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration NonwovensDocumento1 paginaG-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration Nonwovensfer17165Nessuna valutazione finora

- Telecom Cost Template - New Site Transmission WorkDocumento26 pagineTelecom Cost Template - New Site Transmission WorkRanel EspinosaNessuna valutazione finora

- Cov Fast Stainless Steel Cat - 3rd Ed - Jun 09Documento116 pagineCov Fast Stainless Steel Cat - 3rd Ed - Jun 09jaffliangNessuna valutazione finora

- Experiment Observation Inference: Analysis of Simple Salt-AnionsDocumento8 pagineExperiment Observation Inference: Analysis of Simple Salt-AnionsMayank BhartiNessuna valutazione finora

- Synthesis of Dibenzalacetone: Tobias Langenegger Tobiasla@student - Ethz.ch 05-918-362 D-Biol (Chem.)Documento6 pagineSynthesis of Dibenzalacetone: Tobias Langenegger Tobiasla@student - Ethz.ch 05-918-362 D-Biol (Chem.)Júlio Gabriel Queiroz dos SantosNessuna valutazione finora

- Balluff Chemical ResistanceDocumento17 pagineBalluff Chemical ResistanceHéctor Eduardo Hernández LópezNessuna valutazione finora