Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Step Description Controls: Hazard

Caricato da

Mainak KhanraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Step Description Controls: Hazard

Caricato da

Mainak KhanraCopyright:

Formati disponibili

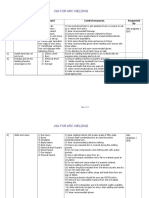

JSA 1 -WELDING/MECH

Step Description Hazard Controls

a) Use mechanical hoist or get assistance fro

a) Strain/sprain from heavy and/or

to set-up/ adjust workpiece--b) Wear recom

awkward workpiece--b) Foot injury from

footwear. Ensure workpiece is securely clam

dropping workpiece--c) Trip/fall in area

Set up fixture--c) Clean/clear work area/surfaces of

around Arc Welding workstation--d)

1 workpiece on tools/materials. Remove dust/debris.--d) W

Damage to workpiece from incorrect set-

fixture should be clean and secure to fixture--e) We

up--e) Hand/finger laceration from edge of

recommended gloves when handling workpi

workpiece--f) Hand/finger contusion from

sharp edges--f) Use correct tool and wear re

tool slippage while tightening fixture

gloves

Install

Ensure Arc Welding machine power to arc is

2 electrode rod Electric shock/burn from electrode rod

de-energized when changing electrical rod

into torch

Energize and a) Ensure welding machine is properly groun

set Arc should be insulated from live electrical parts

a) Electrical shock/burn from contact with

Welding Inspect and replace cables, plugs and leads

3 electrode rod holder--b) Damage to

Machine signs of defects. Wear recommended glove

workpiece from incorrect amperage/current

amperage/ clothing.--b) Refer to Op Sheet and/or Shop

current correct amperage/current--

a) Consult Op Sheet and/or Shop Order for c

rate--b) Practice caution around compressed

a) Damage to workpiece from incorrect gas

Turn on gas Protect gas cylinders from excessive heat, m

4 flow rate--b) Bodily injury from explosion of

and set flow shocks and arcs. Ensure cylinder is insulate

compressed gas cylinder--

so it will not fall. Do not use a compressed

that appears to be damaged and/or defectiv

a) Wear welding helmet with proper grade o

Ensure flash curtains/barriers are used to pr

bystanders/observers--b) Wear recommende

a) Eye injury from welding flash and/or

clothing. Ensure any exposed skin is covere

spatter--b) Burns from welding spatter,

welding process. Do not wear metal jewelry

UV/infrared radiation and/or electrical

with cuffs and/or pockets. Stay a safe dista

contact--c) Inhalation of welding fumes or

arc--c) Use local exhaust ventilation and a fa

asphyxiation from displaced oxygen--d)

good air circulation--d) Do not weld workpie

Weld Bodily injury from condition or type of

5 properly cleaned--e) Ensure welding machin

workpiece workpiece being welded--e) Electrical shock

grounded. Welder should be insulated from

hazard--f) Hearing loss from chronic

parts and dry. Do not weld when wet. Insp

exposure to noisy machinery--g) Fire due

replace cables, plugs and leads that show an

to combustible material in welding area--h)

defect.--f) Wear hearing protection--g) Rem

Hand/finger contact burn from hot

combustible material from the immediate we

electrode rod

Keep a fire extinguisher readily available.--h

electrode rod gets too short, stop welding a

a new electrode rod. Wear recommended g

Ensure Arc Welding machine power to arc is

a) Electrical shock/burn or electrical contact

de-energized. When not in use electrode ro

Complete with conducting objects, flammable liquids

6 removed from holder and holder should be p

welding and/or compressed gas cylinders due to

cannot make electrical contact with conduct

energized electrode rod holder

flammable liquids and/or compressed gas cy

a) Strain/sprain from heavy and/or a) Use mechanical hoist or get assistance fro

Remove awkward workpiece--b) Foot injury from to transport workpiece--b) Wear recommend

workpiece dropping workpiece--c) Trip/fall in area Ensure workpiece is securely clamped to fixt

7 from fixture around Arc Welding workstation--d) Clean/clear work area/surfaces of unused to

and transport Hand/finger laceration from edge of Remove dust/debris regularly--d) Wear reco

to inspection workpiece--e) Hand/finger contusion from gloves when handling workpieces with sharp

tool slippage Use correct tool and wear recommended glo

JSA 2-EXCAVATION/CIVIL

Step Description Hazard Controls

Job foreman attains and understands drawin

underground structures in the excavation loc

including sewers, oily water and storm wate

If underground utilities, footings, or

service water, potable water, electrical, prod

Attain foundations are not identified they may be

and/or natural gas mains, pipelines, etc., fou

underground damaged during excavation, causing

footings and share this information with all e

1 drawings and property damage, personal injury, or

job during pre-job planning and toolbox mee

excavation accidentally shutting down vital plant

ensure excavations will not damage under-g

permit processes causing potential shut down of

or lines or affect the stability of any surroun

unit or units.

vessels, or structures

• Fill out Excavation permit, If Blind Dig (Aug

driving) Get necessary signatures on permit.

If machinery is not set up with enough

clearance to nearby piping, plant

equipment , structures, overhead obstacles

the equipment may strike the equipment

causing personal injury, damage to

equipment, and possible unit upset. This

may cause plant interruptions, shut downs,

explosion, injury or death

• Walk down job before entering work area

• If the area around the machinery is not

Set up equipment. Use Tape measure and drawings

properly barricaded to keep other people

2 machinery for Height hazards and swing radius hazards are

and equipment out of the area, personal

Excavation • Use proper barricading to assure others ca

injury or equipment damage may occur.If

work area without permission

equipment in the immediate area that

causes vibrations is being used, the

excavation may cave in and damage

equipment or injury to personnel working

inside the excavation

• If Equipment is not in good condition it

may breakdown, causing property damage

or possible leaks of hydraulic fluid

• If operator and designated

Swamper/Signal person are not qualified, it

can lead to hitting known underground

hazards, known overhead and swing radius

hazards.

• If people stand too close to the edge of

an excavation, they can fall resulting in

personal injury.

• If people are working in the excavation,

the excavation may present hazards with

confined spaces.• If spoil pile is not placed

far enough away from the excavation there

is a potential for it to fall into the

excavation and hit or engulf people.

• If soils from the excavation are

Begin contaminated and they are not handled

3

Excavation correctly it could lead to contamination of

other areas, personnel, and potentially

cleanup costs, and or fines by local, state,

or federal agencies.

• Water accumulation in excavation if not

removed may make the excavation

unstable and increases the potential for

workers to slip and fall as well as

electrocution hazards from energized

sources

• For excavations more than 5 feet refer to

confined space JSA/Procedure.

• Excavation equipment may produce

exposures exceeding 95 decibels (dBA),

which may result in hearing damage if not

adequately protected.

No one will be permitted to stand next to a

Load

being loaded. Drivers may remain in their ca

soil/excavated

4 • Load soil/excavated material into truck overhead protection (cab) exists.

material into

• No one shall be under a suspended load o

truck

radius of the excavator/backhoe bucket.

• Slips, trips and falls Inspect work/staging area.

5 Secure tools

• Security • Lock equipment. Lock away tools

Potrebbero piacerti anche

- Arc WeldingDocumento2 pagineArc WeldingYoga PradiptaNessuna valutazione finora

- Safe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety AnalysisDocumento2 pagineSafe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety Analysisrazed86Nessuna valutazione finora

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDa EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNessuna valutazione finora

- 71 Arc Welding - JOB PROCEDUREDocumento3 pagine71 Arc Welding - JOB PROCEDUREAdilMunirNessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- 71 Arc Welding - Job Procedure - 2Documento3 pagine71 Arc Welding - Job Procedure - 2Angga EHSKOINNessuna valutazione finora

- JHA Welding Arc and Cutting (Hotwork)Documento2 pagineJHA Welding Arc and Cutting (Hotwork)Popo EaldamaNessuna valutazione finora

- Jsa For Arc WeldingDocumento3 pagineJsa For Arc Weldingtnssbhaskar100% (5)

- Job Safety Analysis For: Hcu & Lobs Revamp ProjectDocumento6 pagineJob Safety Analysis For: Hcu & Lobs Revamp ProjectShilpiengg SafetyNessuna valutazione finora

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocumento5 pagineJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNessuna valutazione finora

- JSA FabricationDocumento3 pagineJSA FabricationSwaroop CherryNessuna valutazione finora

- S LB502DC ManualDocumento104 pagineS LB502DC ManualhrisiyanamNessuna valutazione finora

- ArcWeld Varias PDFDocumento84 pagineArcWeld Varias PDFSistemcan Productivo100% (4)

- New G 2300 Manual 03Documento12 pagineNew G 2300 Manual 03Jasmine VaaltynNessuna valutazione finora

- Power Shovel Operation: Surface Metal and Nonmetal MinesDocumento16 paginePower Shovel Operation: Surface Metal and Nonmetal MinesHowk RiosNessuna valutazione finora

- Job Safety Analysis JSADocumento5 pagineJob Safety Analysis JSASuleman FaizNessuna valutazione finora

- Black & Decker Electronic Screwdriver ManualDocumento21 pagineBlack & Decker Electronic Screwdriver ManualDianawithloveNessuna valutazione finora

- Original Instructions: BS305/BS340Documento28 pagineOriginal Instructions: BS305/BS340carl12Nessuna valutazione finora

- 02JHA On Welding and Gas CuttingDocumento8 pagine02JHA On Welding and Gas CuttingPiyush SinghNessuna valutazione finora

- Job Hazard Analysis ON Erection of High Mast Lighting SystemDocumento5 pagineJob Hazard Analysis ON Erection of High Mast Lighting SystemKiran Bhatt100% (3)

- Jig Saw Porter Cable ManualDocumento44 pagineJig Saw Porter Cable ManualjunkNessuna valutazione finora

- Manual Sierra Circular 1014Documento32 pagineManual Sierra Circular 1014w6110Nessuna valutazione finora

- Serra Mármore - DeWALT - DW860 - Manual de InstruçõesDocumento28 pagineSerra Mármore - DeWALT - DW860 - Manual de Instruçõesmazzalimania0% (1)

- Manual SkilDocumento2 pagineManual SkilRicardo CortesNessuna valutazione finora

- JHA ConcretePlacingOperationDocumento3 pagineJHA ConcretePlacingOperationAnonymous XJ9663C6N4Nessuna valutazione finora

- Festool RO 150 E ManualDocumento21 pagineFestool RO 150 E ManualpatriciaNessuna valutazione finora

- JSA - Sheet FixingDocumento5 pagineJSA - Sheet FixingSwaroop CherryNessuna valutazione finora

- Safe Procedure For Hand DrillDocumento3 pagineSafe Procedure For Hand Drillfatyn farhanaNessuna valutazione finora

- STGS7115-B3 Mini Esmeriladoramanualusuario-29505070 PDFDocumento14 pagineSTGS7115-B3 Mini Esmeriladoramanualusuario-29505070 PDFHydro Energy GroupNessuna valutazione finora

- Arch WeldingDocumento16 pagineArch WeldingDarren OscarNessuna valutazione finora

- 1910.255 Resistance WeldingDocumento2 pagine1910.255 Resistance WeldingAlfredo VSNessuna valutazione finora

- CALADORA C119bCUWxDSDocumento24 pagineCALADORA C119bCUWxDSRazacalaNessuna valutazione finora

- RoverDocumento36 pagineRovertanosidagenNessuna valutazione finora

- Quick Installation Guide: Attention!Documento2 pagineQuick Installation Guide: Attention!Leo NunesNessuna valutazione finora

- PC 250 MTDocumento36 paginePC 250 MTTerrmosTerrmosNessuna valutazione finora

- 188524-01, DW502 DW504 La - EngDocumento9 pagine188524-01, DW502 DW504 La - EngCilvio LewlawskyjNessuna valutazione finora

- DeWalt DWE6401DS Disc Sander Instruction ManualDocumento40 pagineDeWalt DWE6401DS Disc Sander Instruction ManualOnagro XNessuna valutazione finora

- STGS6100: English FrenchDocumento32 pagineSTGS6100: English FrenchMohd Fitrie H.A.SNessuna valutazione finora

- GX200 Operator Service ManualDocumento12 pagineGX200 Operator Service ManualKenia Fdez AlvaradoNessuna valutazione finora

- Owner's Manual: The Equipment Is Approved by Following Car Manufacturers (China)Documento29 pagineOwner's Manual: The Equipment Is Approved by Following Car Manufacturers (China)Emanuel AlarcónNessuna valutazione finora

- dcs380-dcs381 XeDocumento16 paginedcs380-dcs381 XeLucio SuarezNessuna valutazione finora

- B45 ManualDocumento28 pagineB45 ManualBlouBul2Nessuna valutazione finora

- Shuttering in Foundation HSE ProfessionalsDocumento1 paginaShuttering in Foundation HSE Professionalsalaa_2305Nessuna valutazione finora

- Electrical Safety Quiz 2018 KEYDocumento4 pagineElectrical Safety Quiz 2018 KEYMeowwwewNessuna valutazione finora

- Black and Decker Mouse Sander ms600bDocumento32 pagineBlack and Decker Mouse Sander ms600bd sNessuna valutazione finora

- Angle GrinderDocumento1 paginaAngle GrinderAshraf Bin Abdul KadirNessuna valutazione finora

- Technical Notice VERTEX 1Documento16 pagineTechnical Notice VERTEX 1j.mejia07pNessuna valutazione finora

- Automotive Relay Users Guide: Please Use The Check SheetDocumento24 pagineAutomotive Relay Users Guide: Please Use The Check SheetVladimir PanuchNessuna valutazione finora

- Instruction Manual Guide D'Utilisation Manual de InstruccionesDocumento56 pagineInstruction Manual Guide D'Utilisation Manual de InstruccionesLuis Fernando Giraldo OspinaNessuna valutazione finora

- Dewalt d25601 Manual de UsuarioDocumento39 pagineDewalt d25601 Manual de UsuarioLUIS GERARDO URREA JIMENEZNessuna valutazione finora

- 130 Metal-Inert Gas (MIG) WeldingDocumento2 pagine130 Metal-Inert Gas (MIG) Weldinglara cross100% (1)

- Shield-Arc 400AS-50: IMA 554CDocumento24 pagineShield-Arc 400AS-50: IMA 554Cdidik prayitnoNessuna valutazione finora

- Manual Atornillador DewaltDocumento21 pagineManual Atornillador DewaltSoler Ruiz S.L. CUINSOL ™Nessuna valutazione finora

- stgs6100 stgt6100 t1 TWDocumento20 paginestgs6100 stgt6100 t1 TWjamesfletcherNessuna valutazione finora

- Triton Dust Bag 1Documento27 pagineTriton Dust Bag 1j_abendstern4688Nessuna valutazione finora

- G450 SDocumento20 pagineG450 Salberto100% (1)

- Syllabus Industry Tools, Tower Climbing and Rescue ENER-1020Documento11 pagineSyllabus Industry Tools, Tower Climbing and Rescue ENER-1020RasLDKNessuna valutazione finora

- Sho AssignmentDocumento10 pagineSho AssignmentnourNessuna valutazione finora

- Oil and Gas: Sector ProfileDocumento21 pagineOil and Gas: Sector ProfileKalpitNessuna valutazione finora

- Fundamentals of Automobile EngineeringDocumento18 pagineFundamentals of Automobile EngineeringLogeshwari RameshNessuna valutazione finora

- MersingDocumento28 pagineMersingSiti NurHafeezahNessuna valutazione finora

- China Airlines v. ChiokDocumento2 pagineChina Airlines v. ChiokVince MontealtoNessuna valutazione finora

- Supply Chain Management Practices in Printing Industry: University of Hyderabad, Hyderabad 500046, IndiaDocumento7 pagineSupply Chain Management Practices in Printing Industry: University of Hyderabad, Hyderabad 500046, IndiasaifrahmanNessuna valutazione finora

- Marking of HFL, DLDocumento23 pagineMarking of HFL, DLShubam Mota75% (4)

- Are You Measuring The Right Metrics To Optimize Logistic ProcessesDocumento5 pagineAre You Measuring The Right Metrics To Optimize Logistic ProcessespriqazxswNessuna valutazione finora

- Harbour Dock AND Tunnel Engineering: by R. SrinivasanDocumento4 pagineHarbour Dock AND Tunnel Engineering: by R. SrinivasanShubham DhummaNessuna valutazione finora

- USSBS Report 55, The Effects of Air Attack On Japanese Urban Economy, Summary Report, 1947, OCRDocumento90 pagineUSSBS Report 55, The Effects of Air Attack On Japanese Urban Economy, Summary Report, 1947, OCRJapanAirRaids100% (1)

- EastDocumento386 pagineEastMarco FigueroaNessuna valutazione finora

- Cooling System Report (Automotive Tech.)Documento5 pagineCooling System Report (Automotive Tech.)Mohamed AhmedNessuna valutazione finora

- Amalie GreasesDocumento2 pagineAmalie GreasesDavid PomaNessuna valutazione finora

- 5140c BrochureDocumento8 pagine5140c BrochurealexNessuna valutazione finora

- Wartsila LNG Bunkering (Drip Tray)Documento17 pagineWartsila LNG Bunkering (Drip Tray)Naufal MuflihNessuna valutazione finora

- 3 Rules For Hip TowingDocumento3 pagine3 Rules For Hip TowingDoug GouldNessuna valutazione finora

- Concrete Construction EquipmentDocumento25 pagineConcrete Construction EquipmentAYUSH PARAJULINessuna valutazione finora

- 06-07 AV6 Transmission SwapDocumento6 pagine06-07 AV6 Transmission SwapAnonymous v00MDljCQ100% (3)

- Fumigation of Cargo On Board Ships: The Invisible KillerDocumento7 pagineFumigation of Cargo On Board Ships: The Invisible KillerAnakin SkywalkerNessuna valutazione finora

- Speed Triple 1050 2010 UkDocumento108 pagineSpeed Triple 1050 2010 UkNattyBlessNessuna valutazione finora

- Tesla Model S PDFDocumento14 pagineTesla Model S PDFMargareth CailingNessuna valutazione finora

- Marine Application Handbook Propulsion 47708454 - ENDocumento124 pagineMarine Application Handbook Propulsion 47708454 - ENRodrigo Alves100% (2)

- Đề Thi Cuối Kỳ - Pre IELTS (L+R+W) (Update 03.2021)Documento9 pagineĐề Thi Cuối Kỳ - Pre IELTS (L+R+W) (Update 03.2021)Huy HoàngNessuna valutazione finora

- Technical Note - TN 024: 2017: Ambient Environmental ConditionsDocumento33 pagineTechnical Note - TN 024: 2017: Ambient Environmental Conditions_ARCUL_Nessuna valutazione finora

- Drum Handling EquDocumento20 pagineDrum Handling EquMohd HattaNessuna valutazione finora

- New Verna Owner's Manual - Full Version PDFDocumento411 pagineNew Verna Owner's Manual - Full Version PDFArnab GhoshNessuna valutazione finora

- Parking Policy (CWP - 17296 of 2011)Documento4 pagineParking Policy (CWP - 17296 of 2011)Devendra VermaNessuna valutazione finora

- TML Ir Ar 2018 19 PDFDocumento406 pagineTML Ir Ar 2018 19 PDFHarsh TimbadiaNessuna valutazione finora

- Rio Tinto Iron OreDocumento68 pagineRio Tinto Iron Orehatschi1Nessuna valutazione finora

- DVCA - 18022017 - Ver01.1 BOTTOMDocumento1 paginaDVCA - 18022017 - Ver01.1 BOTTOMcesvenegasNessuna valutazione finora

- Prepositions Raymond MurphyDocumento4 paginePrepositions Raymond Murphyj.t.LL100% (3)