Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Waterproofing Range - Asian Paints

Caricato da

gowthamDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Waterproofing Range - Asian Paints

Caricato da

gowthamCopyright:

Formati disponibili

SMARTCARE DAMP PROOF

Asian Paints SmartCare Damp Proof is a fiber reinforced elastomeric liquid applied water proofing

membrane. It is formulated with select elastomeric and resilient acrylic polymers and reinforcing polyester

fibers. Upon curing, it forms a thick, seamless, durable membrane thus offering ultimate waterproofing.

FEATURES & BENEFITS CHEMICAL & PHYSICAL PARAMETERS

• Waterproofing: Protection of up to7 • Form: Ready to use viscous liquid

bars hydrostatic pressure

• Mix density: 1.26

• Crack bridging: Unmatched crack bridging ability due

to elastomeric properties • Application temperature: 5oC to 35oC

• Mechanical strength: Reinforced with glass fibers for

superior abrasion resistance

• Adhesion: Strong adhesion to masonry substrates

• High sheen: Brilliant white colour and thick coat

results in high levels of heat reflectance

• Anti carbonation: Reduces carbon dioxide and

chloride ion diffusion thus protecting re-bars against

corrosion

• Use & maintenance: Single pack, easy to apply and

simple re-coating

PCC M20 Screed to Slope

Loosely laid Geotextile Film

Second coat of Damp Proof

First coat of Damp Proof + Joint

and Corner Tapes for ‘L’ shaped

joints and corners

Damp Proof Self Priming Coat

Roof Slab

TECHNICAL PARAMETERS

PROPERTY TYPICAL VALUE

Appearance Viscous liquid

Color White

Specific Gravity 1.25

Water Resistance 10

Alkali Resistance 8

Viscosity Sormer 122-134 KU

Solids by Wt,% 54.6-60.4

Tensile Strength 2.82

Elongation 220

Adhesion to Dry Concrete 5.47

CBA, mm 1 mm (Horizontal)

Water Vapour Permeance 4.41

Anti Carbonation, R Value (@ 207 DFT) 275

CERTIFICATIONS

STANDARD DESCRIPTION TESTING LAB

DIN 1048 Positive Hydrostatic pressure ConTech

ASTM C 1549 Solar Reflectance TUV

SMARTCARE DAMP SHEATH

Asian Paints SmartCare Damp Sheath Exterior is a waterproofing coating for exterior horizontal surfaces

like terraces, chajjas and also a waterproofing basecoat for Asian Paints Exterior Emulsion coatings for

vertical walls.

FEATURES & BENEFITS CHEMICAL & PHYSICAL PARAMETERS

• Water proofing: Best-in-class waterproofing of up to 3 • Form: Ready to use viscous liquid

bars of positive waterproofing pressure on vertical

surfaces and 5 bars of positive waterproofing pressure • Mix density: 1.26

on horizontal surfaces

• Application temperature: 5oC to 35oC

• Adhesion: Superior adhesion on all masonry and

cementitious surfaces

• Flexibility: Best-in-class flexibility with 150%

elongation on horizontal surfaces

• Crack Bridging: Superior crack bridging ability (CBA)

of up to 0.5mm on horizontal surfaces

• Warranty: 3 Years waterproofing warranty

• Application: Single product for both vertical and

horizontal application

• Use: Easy to apply

Damp Sheath

Damp Sheath Self-priming Coat

Roof Slab / Vertical Wall

CERTIFICATIONS

STANDARD DESCRIPTION TESTING LAB

ASNZ 4548 Crack Bridging Ability Veritas

RILEM RILEM Water Absorption Veritas

DIN 1048 Hydrostatic pressure +ve side ConTech

BS EN 1062 Part 6 Carbon Dioxide Diffusion (R Value) Taywood (Vinci Construction Lab, UK)

ASTM C 1549 - 09 Solar Réflectance TUV SUD (PSB Singapore)

SMARTCARE EPDM MEMBRANE

SmartCare EPDM Membrane is a preformed elastomeric waterproofing membrane made up of high quality

EPDM rubber. This membrane exhibits high tensile strength, elongation, tear strength and is also resistant to

weathering, heat ageing, ozone, UV rays, acids, alkalis & oxygenated solvents. SmartCare EPDM Membranes

demonstrates much higher elongation after ageing as compared to other types of membranes and hence

provides long service life.

FEATURES & BENEFITS CHEMICAL & PHYSICAL PARAMETERS

• Long service life • Colour: Black Colour textile finish rubber sheets

• High tensile and tear strength • Dimensions: 1.2 x 20 m Rolls, Tolerance +/- 10%

• Resistant to ozone, weathering, heat ageing, • Approval/standards: ASTM D 4637 & ASTM D 6134

ultra-violet, acids, alkalis & oxygenated solvents

• Shelf life: The shelf life is 24 months under specified

• High Elongation - More than 400 % storage conditions

• Zero maintenance cost provided, it is fixed as per the

recommendation

• Additional dead load – Negligible

PCC M20 Screed (To Slope)

Loosely laid Geotextile Film

SmartCare EPDM Membrane

SmartCare Rubber Adhesive

Roof Slab

TECHNICAL PARAMETERS

PROPERTY TESTING METHOD STANDARD VALUES TYPICAL VALUES

Chemical Base EPDM

Thickness mm ASTM 3767 1.3 ± 10%

Unit Weight kg/m2 1.42

Tensile Strength, MPa ASTM D 412 Min 9.0 Min 10 MPa

Elongation at Break (L/T)% ASTM D 412 Min 300.0 Min 400

Tear Strength (lbs/ inches) ASTM D 624 Min 26.27 Min 35

Adhesion Strength, (N/mm) ASTM D 903 Min 9

Hydrostatic Water Pressure, Bars DIN 1048 No Leakage Passes 7

Shore 'A' Hardness ASTM D 2240 Min 60

Elastic Recovery ASTM D 412 Min 90

CERTIFICATIONS

STANDARD TESTING LAB

NTH ASTM D 4637-08

SMARTCARE APP MODIFIED BITUMINOUS

MEMBRANE WITH MINERAL TOP (3MM, 4MM)

Asian Paints SmartCare Waterproofing Membrane is a five-layered system with APP modified polyester fleece

reinforced bituminous membrane for superior waterproofing. This membrane exhibits excellent tensile

strength, tear strength, puncture resistance and dimensional stability. The torch side of the membrane is

covered with polyethylene film for protection of the membrane.

FEATURES & BENEFITS CHEMICAL & PHYSICAL PARAMETERS

• Excellent flexibility • APP modified bituminous, polyester fleece reinforced,

mineral finish

• Cost effective and durable in comparison to

conventional low end waterproofing systems • ASTM Standard: ASTM D 6222-08

• Excellent water tightness if applied as per

recommended system and application

• Good temperature resistance to cold and warm

temperatures

• High tensile strength, tear and puncture resistance

PCC M20 Screed (To Slope)

Loosely laid Geotextile Film

SmartCare APP Membrane

(3mm - 4mm, by torching)

EPDM Membrane

SmartCare Bitumen Primer

Roof Slab

TECHNICAL PARAMETERS

PROPERTY TYPICAL VALUES

Sample Description 3mm MT 4mm MT

Top Face Mineral Finish Mineral Finish

Thickness, mm 3 4

Unit Weight, Kg/m2 Min 3.5 Min 4.8

Tensile Strength (N/5cm), Longitudinal 600 600

Tensile Strength (N/5cm), Transverse 550 550

% Elongation at Break, Longitudinal 30 30

% Elongation at Break, Transverse 30 30

Tear Strength, Longitudinal 350 350

Tear Strength, Transverse 320 320

Low Temp Flexibility, 0OC No Cracking No Cracking

Softening Point (OC) > 150 > 150

Compound Stability at 110OC No Flow No Flow

Dimensional Stability No change No change

Resistant to Water Pressure No Leakage No Leakage

% Water Absorption Max 3 Max 3

Lap Joint Strength, Longitudinal 600 600

Lap Joint Strength, Transverse 550 550

SMARTCARE PU MAGNUM

PU Magnum is one-component polyurethane, waterproofing liquid membrane, offering: Mechanical,

chemical, thermal, UV and weather resistance properties, as it is based on pure, elastomeric, hydrophobic,

polyurethane resins.

FEATURES & BENEFITS

• A uniform, elastic, waterproof, vaporpermeable

sealing layer, without forming seams or joints

• Applicability even on irregular substrates

• An affordable and reliable solution for waterproofing

• Availability in white

• It is certified with the CE marking as a coating for

surface protection of concrete, according to

EN 1504-2

SmartCare PU Magnum

SmartCare Epoxy Primer

Roof Slab

TECHNICAL PARAMETERS

PROPERTY TYPICAL VALUES

Form Pre-polymer polyurethane

Colors White, black

Density 1.44 kg/l

Viscosity 5,500 ± 500 mPa·sec (at

+230C)

Elongation at Break (ASTM D 412) 750 ± 50%

Tensile Strength (ASTM D412) 4.0 N/mm2

Hardness According to SHORE A 80 ± 2

Water Impermeability 5 atm (DIN 1048)

Solar Reflectance (SR) (ASTM E903-96) 84%

Infrared Emittance (ASTM C1371-04a) 0, 9

Solar Reflectance Index (SRI) (ASTM E1980-0) 106

Capillary Aabsorption (EN 1062-3, requirement of EN 1504-2: w < 0.1) 0.01 kg/m2·h0.5

Permeability to Co2 (EN 1062-6) Sd > 50 m

Water Vapor Permeability (permeable, EN ISO 7783-2, Class I < 5m) Sd = 0.82 m

Adhesion (EN 1542,requirement for exible systems without traf cking:0.8 N/mm2) > 2.0 N/mm2

Artificial Weathering (EN 1062-11,after 2000h) Pass (no blistering, cracking or,

flaking)

Reaction to Fire (EN 13501-1) (EN 13501-1)

Temperature Resistance from -300C to +900C

SMARTCARE EPOXY TRIBLOCK

Asian Paints Epoxy Tri Block is an epoxy cementitious coating for positive side waterproofing of cementitioUs

water retaining structures.

FEATURES & BENEFITS

• Good adhesion over smooth as well as cementitious

surfaces

• Positive side waterproofing

• Food grade certification, lit for storing portable water

• Microbial resistant coating

• 2 year warranty for cementitious water retaining

structure

Epoxy Tri Block

PCC Screed M20

Prof Damp Block 2K Layer

Tank Slab

TECHNICAL PARAMETERS

PROPERTY RESULTS

Nature Three componant

Mixing Ratio, by weight (Base:Hardner:Filler:Water) 17:18:65:20

Consistency Free flowing smooth paste

Pot Life at 30oC, Minutes 60 minutes

Surface Drying time at 30oC, Minutes 22 minutes

Inter-coat Periods at 30oC, Hours 4 - 5 hours

Positive Hydrostatic Pressure DIN 1048 No water penetration found up till 4 bars

Adhesion Strength a sper ASTM D 4541: 02in (N/mm2) 3 Mpa

Food Grade Certification Certified safe by CFTRI Mysore (Govt. Lab) to

store potable water

CERTIFICATIONS

STANDARD DESCRIPTION TESTING LAB

USFDA 175:300 Global Migration CFTRI

Potrebbero piacerti anche

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingDa EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNessuna valutazione finora

- Waterproofing & DrainageDocumento3 pagineWaterproofing & DrainageDwiagus SaputraNessuna valutazione finora

- What Are The Methods of Concrete Crack RepairDocumento10 pagineWhat Are The Methods of Concrete Crack RepairsadanandNessuna valutazione finora

- Data Sheet - APE SEALKOTE - Waterproof - Latex Bitumen EmulsionDocumento2 pagineData Sheet - APE SEALKOTE - Waterproof - Latex Bitumen EmulsionMochamad BhadawiNessuna valutazione finora

- Concrete Repair M.SDocumento10 pagineConcrete Repair M.Shossam eldin sobhyNessuna valutazione finora

- Waterproofing System For Building Standard in Vietnam CondtionDocumento18 pagineWaterproofing System For Building Standard in Vietnam CondtionNguyễn Việt LongNessuna valutazione finora

- Modern WaterproofingDocumento17 pagineModern WaterproofingDileepa DissanayakeNessuna valutazione finora

- Injection Grouting For Concrete Crack Repair - Its Types and MaterialsDocumento3 pagineInjection Grouting For Concrete Crack Repair - Its Types and MaterialsNaveen BansalNessuna valutazione finora

- Typical Sections - Editable (Autosaved)Documento157 pagineTypical Sections - Editable (Autosaved)sandeepNessuna valutazione finora

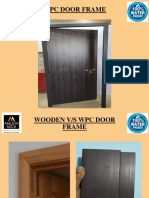

- Door Frame Presentation Mail VersionDocumento18 pagineDoor Frame Presentation Mail Versionrishi gupta100% (1)

- Methodology (Anti Termite Treatment Pre Con)Documento3 pagineMethodology (Anti Termite Treatment Pre Con)Rohit MallaiyaNessuna valutazione finora

- Specification For ConcreteDocumento3 pagineSpecification For Concretenazeer_mohdNessuna valutazione finora

- Injection SystemDocumento8 pagineInjection SystemMohammed Alkhateeb100% (1)

- Structural Cracks in BeamDocumento2 pagineStructural Cracks in Beamswapnil gandhiNessuna valutazione finora

- Conbextra UHSDocumento2 pagineConbextra UHSabhay_joshi20020% (1)

- Tufbond - Injection - Resins Oman Crack RepairDocumento2 pagineTufbond - Injection - Resins Oman Crack RepairWilfredoEnghoyNessuna valutazione finora

- MS For Lift Pit Water ProofingDocumento18 pagineMS For Lift Pit Water ProofingaruanNessuna valutazione finora

- Water Proofing Manual: BasementDocumento5 pagineWater Proofing Manual: Basementannayya.chandrashekar Civil EngineerNessuna valutazione finora

- Research AluformDocumento7 pagineResearch AluformPartth JayyNessuna valutazione finora

- Drfixit Torchshield PDFDocumento4 pagineDrfixit Torchshield PDFshashiNessuna valutazione finora

- Self Compacting Concrete - An Indian ScenarioDocumento9 pagineSelf Compacting Concrete - An Indian ScenariorajamaneeckemNessuna valutazione finora

- General Building BrochureDocumento20 pagineGeneral Building BrochurePratim SenguptaNessuna valutazione finora

- Sika SwellDocumento4 pagineSika SwellZivadin LukicNessuna valutazione finora

- TDS Fosroc Polyurea WH 200 IndiaDocumento4 pagineTDS Fosroc Polyurea WH 200 Indiaprem prakash mishraNessuna valutazione finora

- Work Method StatementDocumento8 pagineWork Method StatementsivagaaneshNessuna valutazione finora

- Sik A Green Streak Presentation 2Documento34 pagineSik A Green Streak Presentation 2hahaerNessuna valutazione finora

- Polyalk WPDocumento2 paginePolyalk WPkalyanqaqc100% (1)

- Sika Injection SystemsDocumento16 pagineSika Injection SystemsvertigoNessuna valutazione finora

- Cebex 100Documento2 pagineCebex 100Riyan Aditya NugrohoNessuna valutazione finora

- Fast FlexDocumento3 pagineFast FlexManoj Kumar SinghNessuna valutazione finora

- 2.2 Concrete FailureDocumento64 pagine2.2 Concrete Failuremuhammad harrisNessuna valutazione finora

- Expansion Joint Waterproofing Specs - SD Combiflex SG v2Documento5 pagineExpansion Joint Waterproofing Specs - SD Combiflex SG v2VIJAYTECH CONSULTANTS PVT. LTD.Nessuna valutazione finora

- Hyper Coat PU - 40Documento6 pagineHyper Coat PU - 40Nimra EmanNessuna valutazione finora

- PT Slab BrochureDocumento9 paginePT Slab BrochureAnonymous UebIaD8A8CNessuna valutazione finora

- Supercast PVC WaterstopDocumento4 pagineSupercast PVC WaterstopArun KumarNessuna valutazione finora

- Design of M100 Grade ACI MethodDocumento3 pagineDesign of M100 Grade ACI MethodGaurav PatilNessuna valutazione finora

- GlassDocumento23 pagineGlasssamatha100% (1)

- Common Defects in PlasterDocumento2 pagineCommon Defects in PlasterHatta RizqNessuna valutazione finora

- Water Proofing MethodologyDocumento6 pagineWater Proofing Methodologykartick adhikaryNessuna valutazione finora

- CT PPTS - 1Documento333 pagineCT PPTS - 1tahir khanNessuna valutazione finora

- S# Item C Waterproofing On SurfacesDocumento8 pagineS# Item C Waterproofing On SurfacesDeepa Junnarkar Degwekar100% (1)

- Sikadur Combiflex SG System 201008 LowDocumento8 pagineSikadur Combiflex SG System 201008 LowSebastian CiprianNessuna valutazione finora

- Liquid WaterproofingDocumento9 pagineLiquid Waterproofingjuli_radNessuna valutazione finora

- Sika Tilling SystemsDocumento32 pagineSika Tilling SystemsEduardo Rojas100% (1)

- Water Proofing of Terrace: Specification: Part1: Sealing of Pipe InsertsDocumento3 pagineWater Proofing of Terrace: Specification: Part1: Sealing of Pipe InsertsJayashree nNessuna valutazione finora

- Polymer Modified Mortars and CementDocumento9 paginePolymer Modified Mortars and CementKunwar Apoorv Singh Parihar100% (1)

- Guide To CuringDocumento1 paginaGuide To CuringTamer Gamil0% (1)

- AAC Blocks Construction Tips PDFDocumento7 pagineAAC Blocks Construction Tips PDFBharath Reddy ChinthiReddyNessuna valutazione finora

- Routing and Sealing of Cracks ConcreteDocumento2 pagineRouting and Sealing of Cracks ConcretePrageeth Nalaka ArambegedaraNessuna valutazione finora

- Construction and Building Materials: Saarthak Surana, Radhakrishna G. Pillai, Manu SanthanamDocumento10 pagineConstruction and Building Materials: Saarthak Surana, Radhakrishna G. Pillai, Manu SanthanamPaul BenNessuna valutazione finora

- Concrete TechnologyDocumento36 pagineConcrete Technologyshalu R FNessuna valutazione finora

- W.P.T. - Penetron ChemicalsDocumento30 pagineW.P.T. - Penetron ChemicalsguptasonsonNessuna valutazione finora

- Methods Used For Curing of ConcreteDocumento3 pagineMethods Used For Curing of ConcreteAjayNessuna valutazione finora

- The Masterbuilder - July 2012 - Concrete SpecialDocumento290 pagineThe Masterbuilder - July 2012 - Concrete SpecialChaitanya Raj GoyalNessuna valutazione finora

- DR Fixit Waterproofing ReckonerDocumento40 pagineDR Fixit Waterproofing ReckonerSusheel TalrejaNessuna valutazione finora

- Vulkem NEM - Data SheetDocumento2 pagineVulkem NEM - Data SheetRobertNessuna valutazione finora

- Membranes For The OversiteDocumento2 pagineMembranes For The OversiteRolando CostaNessuna valutazione finora

- Dow Corning AllGuard Silicone Elastomeric CoatingDocumento4 pagineDow Corning AllGuard Silicone Elastomeric Coatinggpax42Nessuna valutazione finora

- Fosroc Nitoproof WB PrimerDocumento3 pagineFosroc Nitoproof WB PrimermailingreenlifeNessuna valutazione finora

- Baement Waterproofing With Integrated Control and Injection Backup SystemDocumento128 pagineBaement Waterproofing With Integrated Control and Injection Backup SystemNadeem Hassoon100% (1)

- Attachment PDFDocumento2 pagineAttachment PDFYunita RamadhantiNessuna valutazione finora

- Mactor Report - Taller de Prospectiva D 2Documento39 pagineMactor Report - Taller de Prospectiva D 2Giovani Alexis Saez VegaNessuna valutazione finora

- Predicting and Specifying The Perceived Colors of Reflective ObjectsDocumento10 paginePredicting and Specifying The Perceived Colors of Reflective ObjectsEpic WinNessuna valutazione finora

- Seminar On Wireless Charging of Mobile DevicesDocumento24 pagineSeminar On Wireless Charging of Mobile DevicesGourish Amonkar100% (1)

- 1 s2.0 S1359431199000496 Main PDFDocumento14 pagine1 s2.0 S1359431199000496 Main PDFWILLIAMCARABALINessuna valutazione finora

- Ghaneeizad (2013)Documento25 pagineGhaneeizad (2013)alang_businessNessuna valutazione finora

- The Interpretation of Incomplete Piezocone Dissipation TestsDocumento358 pagineThe Interpretation of Incomplete Piezocone Dissipation Testsmaroof nahinNessuna valutazione finora

- Experimental and Theoretical Study of Pool BoilingDocumento11 pagineExperimental and Theoretical Study of Pool Boilingvaibhav pawarNessuna valutazione finora

- CEG 4011 S15 TibbettsDocumento5 pagineCEG 4011 S15 TibbettsGeotekers ItenasNessuna valutazione finora

- The Artist and The Mathematician - Amir AczelDocumento170 pagineThe Artist and The Mathematician - Amir AczelKike García Manyari100% (2)

- Etoos Solid State PS SirDocumento27 pagineEtoos Solid State PS SirGyandeep KalitaNessuna valutazione finora

- AnatoFisio VestibularDocumento17 pagineAnatoFisio VestibularRocío YáñezNessuna valutazione finora

- Lecture 3-1: HFSS 3D Design Setup: Introduction To ANSYS HFSSDocumento40 pagineLecture 3-1: HFSS 3D Design Setup: Introduction To ANSYS HFSSRicardo MichelinNessuna valutazione finora

- Pcs 0626Documento11 paginePcs 0626Diêm Công ViệtNessuna valutazione finora

- Capacidad de ConductoresDocumento4 pagineCapacidad de ConductoresCämpänitä FentyNessuna valutazione finora

- 27-12-14 SR - Iit-Z (Iz) Co-Spark Jee Main (2011) Ptm-16 Q'paperDocumento23 pagine27-12-14 SR - Iit-Z (Iz) Co-Spark Jee Main (2011) Ptm-16 Q'paperazeemNessuna valutazione finora

- Manual PT90Documento68 pagineManual PT90Youssef Sarkis MobarakNessuna valutazione finora

- Simulation of The Production of Sulfuric Acid From A Sulfur-Burning Single-Absorption Contact Sulfuric Acid PlantDocumento5 pagineSimulation of The Production of Sulfuric Acid From A Sulfur-Burning Single-Absorption Contact Sulfuric Acid PlantainmnrhNessuna valutazione finora

- Physics of SoundDocumento33 paginePhysics of SoundijahsmkutNessuna valutazione finora

- Radial Distribution Function For Argon Calculations From Thermodynamic Properties andDocumento11 pagineRadial Distribution Function For Argon Calculations From Thermodynamic Properties andrafelNessuna valutazione finora

- Pengaruh Kandungan Frekuensi Gempa Terhadap Simpangan Dan Drift Ratio 2 Arah Struktur Bangunan Set-Back Bertingkat BanyakDocumento9 paginePengaruh Kandungan Frekuensi Gempa Terhadap Simpangan Dan Drift Ratio 2 Arah Struktur Bangunan Set-Back Bertingkat BanyakIvan MuhammadNessuna valutazione finora

- Linear Interpolation With ExcelDocumento4 pagineLinear Interpolation With ExcelLiu YangtzeNessuna valutazione finora

- JIS F 2023 Chain Stopper For Dia.34-36mm Anchor ChainDocumento7 pagineJIS F 2023 Chain Stopper For Dia.34-36mm Anchor ChainusnadiNessuna valutazione finora

- 2nd Year Math Guess PaperDocumento6 pagine2nd Year Math Guess PaperArmaan MalikNessuna valutazione finora

- Week 3 Earth Science FINALDocumento4 pagineWeek 3 Earth Science FINALMichael DelivaNessuna valutazione finora

- Engineering - Catalog - Screw Conveyor PDFDocumento64 pagineEngineering - Catalog - Screw Conveyor PDFanxaanNessuna valutazione finora

- Fiber Optic CatalogueDocumento25 pagineFiber Optic Catalogueapi-3815405100% (2)

- Vibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsDocumento44 pagineVibration Analysis, Control and Optimum Accelerometer Placement For Successful Vibrations TestsVyankatesh AshtekarNessuna valutazione finora

- N Different Books (N 3) Are Put at Random in A Shelf. Among These Books There Is A ParticularDocumento8 pagineN Different Books (N 3) Are Put at Random in A Shelf. Among These Books There Is A ParticularAnkit Gupta100% (1)