Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flamebar Info Sheet

Caricato da

Lato43Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flamebar Info Sheet

Caricato da

Lato43Copyright:

Formati disponibili

Highly effective economical range of water based flame

retardant solutions designed to improve safety on a wide range

of materials.Tested to British Standards BS476 parts 6&7,

BS5867 part 2 1980, BS3119/3120, BS5852 and BS5665.

PRODUCTS FLAME RETARDANTS

Natural Fabrics and materials • cotton • linen • muslin • rayon • wool

• silk • feathers • leather

Synthetic Fabrics • polyester • nylon • acrylics • dralon • suede

FLAMEBAR PE6

• polycotton • silk & artificial silk (rayon) flowers • carpets

• wall coverings • curtains foam • stage curtains • drapes & scenery

Dried Natural • flowers & plants • dried grasses • dried leaves

Wood Products • insulation board • cork • heavyweight cardboard

• industrial belting • stage wood props • exhibition boards • sawdust •

FLAMEBAR N5

wood fibre • shavings • wood nuggets • peat • bark vacuum impregnation

of wood • straw

Natural Materials - an economical solution • cotton • hessian • rope • sisal

FLAMEBAR S3 • woven cotton tapes & belts • canvas welding screens • tarpaulins •

lighter weight cardboard

FLAMEBAR S1WA2 Lightweight natural materials • cotton etc • muslin • paper

FLAMEBAR ACE6 Polyester artificial flowers • plants and tree foliage

Available in 25 litre or 5 litre containers and 1 litre trigger sprays.

GENERAL INFORMATION ON FLAMEBAR SOLUTIONS

Test

We recommend that a small sample is tested before application to main substrate, to check suitability and application rate. Dry and

test with match or suitable flame.

Concentration

Flamebar solutions are supplied ready for use.

Dry

In a warm ventilated atmosphere drying will be quicker, but be aware that drying too quickly can cause white marking on surface.

A cool iron may be used.

Treatment

Will withstand dry cleaning solvents but needs re-application after washing or other exposure to water. It is long

lasting in dry conditions.

British Standards

Flamebar flame retardants have been tested on a wide variety of materials to British Standard levels as listed on fire certificate data

sheet.These include BS5867 part 2 1980 flammability of furnishing standard mainly for fabrics and building regulation standard

BS476 part 7 surface spread of flame.These are mainly on wood and allied products.

Flame Retardancy

It is not possible to produce a non ignitable finish on all materials.The level varies, but the most effective treatments are on

absorbent materials like cotton and other natural fibres; wood, straw, cardboard and paper products etc. Synthetic materials are

more difficult to treat with most plastics being extremely difficult to upgrade this way. Finishes like scotchguard stain proofing

present difficulties of penetration. Increased penetration is normally possible by adding wetting agent or raising the temperature of

the solution. The purpose is to obtain the best flame retardancy possible with the particular material applying the most suitable

flame retardant.This is to make the material more difficult to ignite, to slow any flame spread down to a minimum and prevent

smouldering. In this way, in case of fire, it helps along with other measures to provide a time delay for people to evacuate the area

safely.

Health and Safety

Flamebar solutions are not harmful when used as directed. Observe normal safety precautions limiting exposure to a minimum by

providing ventilation and using gloves, goggles, and mask for extended spraying. Refer to Health and Safety Sheet Before use.

HOW TO APPLY FLAMEBAR SOLUTIONS

INSTRUCTIONS

Apply by spraying or dipping.Test samples first for suitability and level of treatment. Check appearance when dry and fire retardancy

with a flame. Normally solutions are used as supplied but in certain cases may need to be diluted.Test samples.

SPRAYING

Use trigger spray, garden type pump up sprayer or airless spray. Spray uniformly from about 12”-16” on clean, dry material. One

treatment may be sufficient but repeat after drying if required. Excess may cause some stiffening.Two light sprayings are preferable

to one heavy application. Adopt instructions for application to wood and paper products, boards, wall coverings and foam.Wash all

equipment after use with clean water.

DIPPING

Use plastic or stainless steel container. Ascertain concentration required by test. Soak clean material in solution until wet out

(1-2 minutes).Wring out evenly, preferably through hand or power wringer leaving in about 75% of the original weight of fabric.

Dry, avoiding excess localised heat, a cool iron may be used, do not dip velvet or pile fabrics (Must be sprayed).

Application for ACE 6 Only.

Wet out all foliage in ACE 6 in shallow plastic tray, normally 2 or 3 minutes treatment. Remove and shake off excess solution.

Separate and dry naturally with good circulation avoiding excess heat. Spray lightly after drying if required.

COVERAGE

Depends on absorbency and thickness of the material but approximations are:

Heavy weight/medium wt. fabric 4-6 square metre per litre

Light weight fabric 7-9 square metre per litre

Wood Products 4-6 square metre per litre

Paper/thin card 10 square metre per litre

NOTES

Performance: Correctly treated items exhibit good flame retardancy with no smouldering or afterglow, but some items like synthetics which are non

absorbent are more difficult to treat.The treatment is long lasting in dry conditions. It withstands dry cleaning but reapply after washing. Good fast

colours are normally not affected. Protect mirrors, metals, decorative and polished surfaces.Wash with clean water.

P.O. Box 78 • Croydon Road • Beckenham • Kent BR3 4BL • UK

Technical Enquiries: (020) 8658 2299 • Facsimile (020) 8658 8672

Sales Line: 0845 601 2905 • Sales Fax: 0800 0854 663

E-mail: sales@bollom.com • Website: www.bollomfireprotection.co.uk

Potrebbero piacerti anche

- Paper and Board Based Packaging MaterialsDocumento33 paginePaper and Board Based Packaging MaterialsdimendraNessuna valutazione finora

- Paper and Paper Based Packaging MaterialsDocumento25 paginePaper and Paper Based Packaging MaterialsPremnathNessuna valutazione finora

- 6 DW 32 Exterior ExttimbapreservativeDocumento5 pagine6 DW 32 Exterior Exttimbapreservativeyoxan25808Nessuna valutazione finora

- Applying Water-Based Interior FinishDocumento3 pagineApplying Water-Based Interior FinishldvierteNessuna valutazione finora

- Camouflage Matt EnamelsDocumento3 pagineCamouflage Matt EnamelsIqra AngelsNessuna valutazione finora

- Fiberboard Manufacture FinalDocumento22 pagineFiberboard Manufacture Finalyeng botzNessuna valutazione finora

- BM 1Documento13 pagineBM 120 - 65 perla saisreeNessuna valutazione finora

- Types of Yarns & Application& PropertiesDocumento3 pagineTypes of Yarns & Application& PropertiesPushkarNessuna valutazione finora

- Polished PlasterDocumento3 paginePolished PlasterZubair IrshadNessuna valutazione finora

- PC-5 Neoprene CoatingDocumento2 paginePC-5 Neoprene Coatingbello imamNessuna valutazione finora

- Cold Mounting EnglishpdfDocumento6 pagineCold Mounting EnglishpdfJorge BonillaNessuna valutazione finora

- Unit 3 Timber and Timber ProductsDocumento52 pagineUnit 3 Timber and Timber ProductsAnamika MuralidharanNessuna valutazione finora

- Cordial Adhesive PresenationDocumento42 pagineCordial Adhesive Presenationomermeric bilginNessuna valutazione finora

- Technical Data Sheet: Blackfriar Wood DyeDocumento2 pagineTechnical Data Sheet: Blackfriar Wood DyeFrancisco Javier Bandarra BandarraNessuna valutazione finora

- Bamboo Processing Furniture Manual PDFDocumento62 pagineBamboo Processing Furniture Manual PDFsstibis90% (10)

- LookupDocumento3 pagineLookupenzooo2009Nessuna valutazione finora

- Plastic Lumber ReportDocumento6 paginePlastic Lumber ReportsonakshiNessuna valutazione finora

- Finishes Finishing TechniquesDocumento34 pagineFinishes Finishing TechniquesDhairya BhattNessuna valutazione finora

- BM 11Documento13 pagineBM 1120 - 65 perla saisreeNessuna valutazione finora

- Nourison Wool Warranty-PAGE 10Documento14 pagineNourison Wool Warranty-PAGE 10adelalgNessuna valutazione finora

- Hydro-Gloss: Technical Data SheetDocumento2 pagineHydro-Gloss: Technical Data SheetNippon Paint PakistanNessuna valutazione finora

- Break-Through! V56-410 Series: General Description Application Information (Continued)Documento2 pagineBreak-Through! V56-410 Series: General Description Application Information (Continued)chrisNessuna valutazione finora

- Photo and Service InfoDocumento11 paginePhoto and Service InfoSOHAM KODENessuna valutazione finora

- Nippon Hydro-Finish 2022.04Documento2 pagineNippon Hydro-Finish 2022.04Richard LeongNessuna valutazione finora

- Royale High Gloss Enamel - 4926Documento3 pagineRoyale High Gloss Enamel - 4926PraveenNessuna valutazione finora

- Hydro Gloss Solid WoodDocumento2 pagineHydro Gloss Solid WoodphilipNessuna valutazione finora

- Seminar, 30 Mins, Sterilization PackagingDocumento32 pagineSeminar, 30 Mins, Sterilization PackagingArdyNessuna valutazione finora

- STARBOND UL-30-36 Waterproofing CoatDocumento2 pagineSTARBOND UL-30-36 Waterproofing CoatabmopalhvacNessuna valutazione finora

- Nahar Colour & Chemical Premium Wood Stain: Product ApplicationDocumento3 pagineNahar Colour & Chemical Premium Wood Stain: Product ApplicationManish AbotiNessuna valutazione finora

- Vinilex 5400 Wall SealerDocumento2 pagineVinilex 5400 Wall SealerEzuan AdamNessuna valutazione finora

- BCT CompilationDocumento19 pagineBCT CompilationPRACHI JAINNessuna valutazione finora

- 2 Packaging MaterialsDocumento87 pagine2 Packaging MaterialsMonty KushwahaNessuna valutazione finora

- Sadolin Quick Drying Wood Preserver Technical Data SheetDocumento2 pagineSadolin Quick Drying Wood Preserver Technical Data SheetelcivilengNessuna valutazione finora

- Thermal Insulation MaterialsDocumento33 pagineThermal Insulation MaterialsVishal GuptaNessuna valutazione finora

- Packaging of Food in Paperboard Containers - 2020Documento40 paginePackaging of Food in Paperboard Containers - 2020fernandoluisNessuna valutazione finora

- Euro Caberboard MSDSDocumento7 pagineEuro Caberboard MSDSOsa Ewaen GregoryNessuna valutazione finora

- Demidekk Decking & Garden Stain Colour CardDocumento4 pagineDemidekk Decking & Garden Stain Colour CardkormatekNessuna valutazione finora

- Paper RecyclingDocumento17 paginePaper RecyclingtoluwaniNessuna valutazione finora

- 12X88 10130DSC12X88 Gori 88 TR TDS (En) #3109Documento4 pagine12X88 10130DSC12X88 Gori 88 TR TDS (En) #3109Ajith SomaratneNessuna valutazione finora

- Denture Base PolymersDocumento20 pagineDenture Base PolymersZain KolachiNessuna valutazione finora

- Non WovenDocumento16 pagineNon WovenMuhammad RizwanNessuna valutazione finora

- HayparoofDocumento2 pagineHayparoofHisham BerrasaliNessuna valutazione finora

- 12X44 10130DSC12X44 Gori 44 Facades TDS (En) #1554Documento4 pagine12X44 10130DSC12X44 Gori 44 Facades TDS (En) #1554Ajith SomaratneNessuna valutazione finora

- Hydro FinishDocumento2 pagineHydro FinishphilipNessuna valutazione finora

- Selection of Right Cladding Material For PolyhouseDocumento45 pagineSelection of Right Cladding Material For Polyhousepink girlNessuna valutazione finora

- 1 DT 2.6 Prep Corro3 MetaletchprimerDocumento4 pagine1 DT 2.6 Prep Corro3 Metaletchprimeryoxan25808Nessuna valutazione finora

- Xylan 80-018-g6706 Black - BeDocumento2 pagineXylan 80-018-g6706 Black - BeSYED MAZHARNessuna valutazione finora

- Nippon Paint Coating Solution For Exterior SurfacesDocumento2 pagineNippon Paint Coating Solution For Exterior SurfacesNippon Paint Total Coating and Construction SolutionsNessuna valutazione finora

- RUBBER NewDocumento10 pagineRUBBER NewAleem AhmedNessuna valutazione finora

- Odour-Less Premium All-In-1: Technical Data SheetDocumento2 pagineOdour-Less Premium All-In-1: Technical Data SheetSiti Hajar KhalidNessuna valutazione finora

- 13X44 10130DSC13X44 Gori 44+ TDS (En) #3105Documento3 pagine13X44 10130DSC13X44 Gori 44+ TDS (En) #3105Ajith SomaratneNessuna valutazione finora

- Hyperdesmo - Fr-Kit: Fire Retardant, Polyurethane Liquid Membrane For Waterproofing & ProtectionDocumento4 pagineHyperdesmo - Fr-Kit: Fire Retardant, Polyurethane Liquid Membrane For Waterproofing & ProtectionGizem D.Nessuna valutazione finora

- PDS Hempalin Enamel52140 en-GBDocumento2 paginePDS Hempalin Enamel52140 en-GBKhyle Laurenz DuroNessuna valutazione finora

- Resistance Materials Presentation AssignmentDocumento15 pagineResistance Materials Presentation Assignmentradksianga299Nessuna valutazione finora

- Gori 88 Technical Data SheetDocumento5 pagineGori 88 Technical Data SheetABHISHEK ROUTNessuna valutazione finora

- PC 1752 - Asian Bituminous CoatingsDocumento3 paginePC 1752 - Asian Bituminous CoatingsRamesh BabuNessuna valutazione finora

- Wellcoat VarnishDocumento2 pagineWellcoat VarnishMahmoud FlefilNessuna valutazione finora

- Synthetic Fibres2Documento78 pagineSynthetic Fibres2nitishkohliNessuna valutazione finora

- Anti Stick Acrylic Clear Coat: Technical Data SheetDocumento2 pagineAnti Stick Acrylic Clear Coat: Technical Data SheetJeh Tat WongNessuna valutazione finora

- Family Handyman Handy Hints, Volume 2Da EverandFamily Handyman Handy Hints, Volume 2Family HandymanNessuna valutazione finora

- Mercruiser GearcasecomponentsDocumento42 pagineMercruiser GearcasecomponentswguenonNessuna valutazione finora

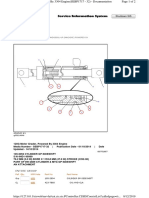

- Shutdown SIS: Motor Grader 120G Motor Grader 4Hd 120G Motor Grader 4HD00001-UP (MACHINE) POWERED BY 3304 EngineDocumento2 pagineShutdown SIS: Motor Grader 120G Motor Grader 4Hd 120G Motor Grader 4HD00001-UP (MACHINE) POWERED BY 3304 EngineStevenNessuna valutazione finora

- Experimental Study of Cuttings Transport in Directional WellsDocumento14 pagineExperimental Study of Cuttings Transport in Directional WellsFabian Andrey DiazNessuna valutazione finora

- HS22186Documento4 pagineHS22186daviNessuna valutazione finora

- POCLP010101 Wood PelletsDocumento1 paginaPOCLP010101 Wood PelletsPratiwi CocoNessuna valutazione finora

- ISRA University FormDocumento4 pagineISRA University Formpure14Nessuna valutazione finora

- Wilf Book FlyerDocumento4 pagineWilf Book FlyerEduardo Manuel Chávarry VelaNessuna valutazione finora

- Differential Pressure Switch RH3Documento2 pagineDifferential Pressure Switch RH3Jairo ColeccionistaNessuna valutazione finora

- Assignment SurveyDocumento4 pagineAssignment Surveyfatin_fazlina_1Nessuna valutazione finora

- C1506 16bDocumento4 pagineC1506 16bmasoud132Nessuna valutazione finora

- Revit LookupDocumento6 pagineRevit Lookupjuand_121Nessuna valutazione finora

- My Restaurant API DocumentDocumento60 pagineMy Restaurant API DocumentJosé FranciscoNessuna valutazione finora

- Y y Y Y Y: Design of Machinery 86Documento1 paginaY y Y Y Y: Design of Machinery 86Star GlacierNessuna valutazione finora

- Oyo Busines ModelDocumento1 paginaOyo Busines ModelVikash KumarNessuna valutazione finora

- MB 0244 2e - Fi X30HL B 34001Documento5 pagineMB 0244 2e - Fi X30HL B 34001raiNessuna valutazione finora

- Soichiro HondaDocumento5 pagineSoichiro HondaVeronika YsNessuna valutazione finora

- Applications of Genetic Algorithm in Water Resources Management and OptimizationDocumento11 pagineApplications of Genetic Algorithm in Water Resources Management and OptimizationGarima TyagiNessuna valutazione finora

- Rehau Awadukt Thermo: Ground-Air Heat Exchanger System For Controlled VentilationDocumento36 pagineRehau Awadukt Thermo: Ground-Air Heat Exchanger System For Controlled VentilationLeon_68Nessuna valutazione finora

- Aggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinDocumento15 pagineAggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinKushal BhatiaNessuna valutazione finora

- Sewa bill-AED 559Documento1 paginaSewa bill-AED 559muhdazarNessuna valutazione finora

- Why JSON in PostgreSQL Is AwesomeDocumento7 pagineWhy JSON in PostgreSQL Is AwesomeTeo TokisNessuna valutazione finora

- 4 Power TransmissionDocumento27 pagine4 Power TransmissionMehmetNessuna valutazione finora

- lTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelDocumento42 paginelTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelGrupo CardogalNessuna valutazione finora

- Sts Lesson 6Documento13 pagineSts Lesson 6Ivy Joy BelzaNessuna valutazione finora

- Anothr System Definition FacilityDocumento90 pagineAnothr System Definition FacilityllllllluisNessuna valutazione finora

- Chapter Application PortfolioDocumento51 pagineChapter Application PortfolioShahla AsNessuna valutazione finora

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldDocumento8 pagineTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungNessuna valutazione finora

- What Is JavaScriptDocumento10 pagineWhat Is JavaScriptKhalinux AnonimoNessuna valutazione finora

- Getting Familiar With Microsoft Word 2007 For WindowsDocumento3 pagineGetting Familiar With Microsoft Word 2007 For WindowsRaymel HernandezNessuna valutazione finora

- Airtag Wallet Keyword Search-2Documento15 pagineAirtag Wallet Keyword Search-2Azhar ShakeelNessuna valutazione finora