Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

P-Diagram - Project Marcel Transmission System

Caricato da

kumarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

P-Diagram - Project Marcel Transmission System

Caricato da

kumarCopyright:

Formati disponibili

P-Diagram - Project Marcel Transmission System

Noise Factors

Potential

1. Piece to piece variation 2. Other systems 3. Customer usage/duty cycle Causes

Case variation Case and Bearings Overloaded

-center variation Speed Sensor Aftermarket changes / Performance modifications

Fork variation Primary drive / clutch Poor service practices

Drum variation Secondary Drive Poor quality oil

Lubricant quality External Shift Linkage Oil change freq.

Speed Sensor Engine Lubrication system Abusive shifting

Bearing plate variation Hydraulic Clutch Low oil

Gear variation Cover System Extreme duty cycle in high heat

Assembly Process Variation Exhaust

Frame variation

Torque on fasteners

4. Deterioration/degredation over time 5. Environment

Self generated debris Poor road conditions

Gear wear / Dog and teeth wear Spacer wear Contamination

Fork Wear Seal / Gasket wear Air and temp changes

Bearing wear Oil degradation

Shaft wear Design Thrust surface wear

Function

Clamp Load loss

(Detail)

Shifter componenet fatigue

Fatigue failures

Input Ideal function (musts)

Engine RPM and torque Transmission System Transfer power from engine to rear wheel

Gear selection / shift input Meet noise regulation requirements (NVH) Design

Rear wheel input on coast Reduce speed from engine to rear wheel Function

Clutch drag torque Can not effect current emissions performance

Heat and vibration from engine Error states No measurable decrease in shift quality

Secondary drive belt tension Does not transfer power from engine to rear wheel Must meet Durability requirements

Vibration Energy Does not meet noise regulations requirements Provide a clean signal to the vehicle speed sensor

Vehicle inputs - Strain, twist, vibration Fails to reduce speed from engine to rear wheel Must maintain clearance to other engine components

Effects current emissions performance Must interface with vehicle frame system

Control factors Change in shift quality Must interfece with engine management system

Does not meet durability requirements Must interface with external shifter linkages

Emissions Regulations Does not provide a clean signal to the vehicle speed sensor Must interface with starter system

NVH Passby Regulations Interference with other engine components Must interface with engine lube system

- EEC 97/24/Ch. 9 - Europe Does not interface with other vehicle components Must interface with secondary drive system

- Australia ADR 39/00 Design Does not provide electrical ground Must interface with primary drive system

- Japan MOT articles 30 & 31 Controls poor rider ergonimics must interface with evaporative emisions system

- Korean EPA Notice 91-26 excessive social noise Must provide acceptable ground for electrical system

- Mexican Noise Emission Standard NOM-082-ECOL-1994 poor handling characteristics Must maintain acceptable rider interface ergonomics

- USA F76a – 40 CFR Ch. 1 (7-1-86 Ed.) does not meet assemblability requirements Must have approiate gear ratios for vehicle applications

Launch timing-MW MY05 Big Twin MY06 damage during shipping Must meet styling requirements

Homologation requirements cannot operate in required ambient temps Must meet current cosmetic zoning reqs.

Failure

Jed Program deliverables Must meet social noise reqs.

Modes

Must deliver acceptable handling characteristics

Design meets the needs of the shipping duty cycle

Potrebbero piacerti anche

- 1P Tractor 6B Cab EngDocumento2 pagine1P Tractor 6B Cab EngHendry PardedeNessuna valutazione finora

- 793F T4 Commissioning - Check - ListDocumento3 pagine793F T4 Commissioning - Check - ListErlen PolancoNessuna valutazione finora

- Diesel Generator Set X2.5 Series Engine: 15 kVA-27 kVA 50 HZ 10.8 kW-20 KW 60 HZDocumento4 pagineDiesel Generator Set X2.5 Series Engine: 15 kVA-27 kVA 50 HZ 10.8 kW-20 KW 60 HZJose VarelaNessuna valutazione finora

- Century Generator EspecificacionesDocumento4 pagineCentury Generator EspecificacionesSebastianVargasNessuna valutazione finora

- 6090HFM85 C AuxDocumento2 pagine6090HFM85 C AuxLupin GonzalezNessuna valutazione finora

- Diesel Generator Set X1.3 Series Engine: 7.5 kVA - 11 kVA 50 HZDocumento4 pagineDiesel Generator Set X1.3 Series Engine: 7.5 kVA - 11 kVA 50 HZthainarimeNessuna valutazione finora

- Diesel Generator Set QSB7 Series Engine: 160 kVA - 220 kVA 50 HZ 135 KW - 200 KW 60 HZDocumento4 pagineDiesel Generator Set QSB7 Series Engine: 160 kVA - 220 kVA 50 HZ 135 KW - 200 KW 60 HZthainarimeNessuna valutazione finora

- Kirloskar: Diesel Generating Sets KG200W / KG200WSDocumento4 pagineKirloskar: Diesel Generating Sets KG200W / KG200WSnam phạm100% (1)

- Specifi Cations: C32 Acert™ Locomotive EngineDocumento5 pagineSpecifi Cations: C32 Acert™ Locomotive EngineIssa DRAMANENessuna valutazione finora

- Diesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ 409 KW - 500 KW 60 HZDocumento4 pagineDiesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ 409 KW - 500 KW 60 HZthetam218kjjNessuna valutazione finora

- Diesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ 409 KW - 500 KW 60 HZDocumento4 pagineDiesel Generator Set QSX15 Series Engine: 364 kVA - 500 kVA 50 HZ 409 KW - 500 KW 60 HZRoohullah Mehdi BhuttoNessuna valutazione finora

- CM20170823 27892 17513Documento5 pagineCM20170823 27892 17513jacobvimalaNessuna valutazione finora

- Powertech ™ 6090afm85 Diesel Engine: Marine Propulsion Engine SpecificationsDocumento2 paginePowertech ™ 6090afm85 Diesel Engine: Marine Propulsion Engine SpecificationsjohnnyNessuna valutazione finora

- Mma 152 MotorDocumento101 pagineMma 152 Motoraviacion gnaNessuna valutazione finora

- Rental Power 70 KW: Specification SheetDocumento4 pagineRental Power 70 KW: Specification SheetDulguunkherlen BudkhandNessuna valutazione finora

- PowerTech M 4024T Diesel Engine - Generator Drive Engine SpecificationsDocumento2 paginePowerTech M 4024T Diesel Engine - Generator Drive Engine SpecificationsRamon Pujol PerramonNessuna valutazione finora

- A. Genset.2Documento2 pagineA. Genset.2menggandakanNessuna valutazione finora

- Workshop Rebuild John DeereDocumento2 pagineWorkshop Rebuild John DeereKevin TtitoNessuna valutazione finora

- Natural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWDocumento4 pagineNatural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWJohn YangNessuna valutazione finora

- HTTPSWWW - Deere.co - Ukassetspdfscommonindustriesengines and Drivetrainspecsheets6068TF250 C PDFDocumento2 pagineHTTPSWWW - Deere.co - Ukassetspdfscommonindustriesengines and Drivetrainspecsheets6068TF250 C PDFThe EndNessuna valutazione finora

- KG125W KG125WSDocumento4 pagineKG125W KG125WSSatish SharmaNessuna valutazione finora

- Powertech ™ 4045Tfm75 Diesel Engine: Marine Propulsion Engine SpecificationsDocumento2 paginePowertech ™ 4045Tfm75 Diesel Engine: Marine Propulsion Engine SpecificationsDAVIDNessuna valutazione finora

- Diesel Generator Sets: FeaturesDocumento5 pagineDiesel Generator Sets: FeaturesFarrukh SharfiNessuna valutazione finora

- Especificaciones Tecnicas Mortores 6069 Jhon Deere MarinosDocumento2 pagineEspecificaciones Tecnicas Mortores 6069 Jhon Deere MarinosLeonardo ViilalobosNessuna valutazione finora

- Cummins C33D5 - Specification SheetDocumento4 pagineCummins C33D5 - Specification SheetmunhNessuna valutazione finora

- Spec Sheet - 17Documento4 pagineSpec Sheet - 17MP Vasu RajuNessuna valutazione finora

- 150 KW Planta C150D6e-1Documento4 pagine150 KW Planta C150D6e-1Tonathiu MartinezNessuna valutazione finora

- Diesel Generator Set X2.5 Series Engine: 15 kVA - 28 kVA 50 HZ 10.8 KW - 20 KW 60 HZDocumento4 pagineDiesel Generator Set X2.5 Series Engine: 15 kVA - 28 kVA 50 HZ 10.8 KW - 20 KW 60 HZabera alemayehuNessuna valutazione finora

- SS26-CPGK - Hoja de Especificacion C20D6Documento4 pagineSS26-CPGK - Hoja de Especificacion C20D6johanNessuna valutazione finora

- 6135HFM85 C AuxDocumento2 pagine6135HFM85 C AuxAdrian NazareNessuna valutazione finora

- SS22 CPGKDocumento4 pagineSS22 CPGKArtemio Garcia BarrientosNessuna valutazione finora

- QSL9 Series PDFDocumento4 pagineQSL9 Series PDFAnonymous 3RS6JNcNessuna valutazione finora

- Natural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWDocumento4 pagineNatural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWJose Leandro Del ZarNessuna valutazione finora

- Planta Elect. Cat 3512Documento5 paginePlanta Elect. Cat 3512MauricioNessuna valutazione finora

- Cummins GensetDocumento4 pagineCummins GensetBenny S PutraNessuna valutazione finora

- Generator LogDocumento4 pagineGenerator LogFELIXENGIPLASCOMNessuna valutazione finora

- gEN C185D635 Ficha TecnicaDocumento5 paginegEN C185D635 Ficha TecnicaIldebrando Montaño MedinaNessuna valutazione finora

- John Deere 4045tfm50 - CDocumento2 pagineJohn Deere 4045tfm50 - CArthur SchoutNessuna valutazione finora

- C300D6RDocumento4 pagineC300D6RMANUEL AZAÑERONessuna valutazione finora

- Powertech ™ 6068Tfm76 Diesel Engine: Marine Generator Drive Engine SpecificationsDocumento2 paginePowertech ™ 6068Tfm76 Diesel Engine: Marine Generator Drive Engine SpecificationsDAVIDNessuna valutazione finora

- Diesel Generator Set QSB5 Series Engine: 35-80 KW 60 HZDocumento4 pagineDiesel Generator Set QSB5 Series Engine: 35-80 KW 60 HZIgnacio TabuadaNessuna valutazione finora

- Power Tech 4045 PDFDocumento2 paginePower Tech 4045 PDFmario reinaNessuna valutazione finora

- Powertech ™ 6068Hf120 Diesel Engine: Generator Drive Engine SpecificationsDocumento2 paginePowertech ™ 6068Hf120 Diesel Engine: Generator Drive Engine SpecificationsRaul Fletcher0% (1)

- Cummins 175 DSGAD - QSB7Documento4 pagineCummins 175 DSGAD - QSB7pank4r4Nessuna valutazione finora

- Gas Engine DataDocumento10 pagineGas Engine Datarendy simanjuntakNessuna valutazione finora

- SDocumento4 pagineSDenisNessuna valutazione finora

- EMERS-5888-EN Model QSZ13Documento5 pagineEMERS-5888-EN Model QSZ13Sandi Siburian100% (1)

- SS26-CPGK Specification SheetDocumento4 pagineSS26-CPGK Specification SheetmnezamiNessuna valutazione finora

- Lehe20255 02Documento4 pagineLehe20255 02Brian RomanoNessuna valutazione finora

- Parts CatalogueDocumento160 pagineParts CatalogueRobert Utrecht Hutapea100% (1)

- 3512 - 1100KW 1250KW - 1375kva 1563kva - 380V 13800V (2018) (Lehe1246-01)Documento5 pagine3512 - 1100KW 1250KW - 1375kva 1563kva - 380V 13800V (2018) (Lehe1246-01)Darren R. FlorNessuna valutazione finora

- Generator HTMLDocumento5 pagineGenerator HTMLInstrumentistas de Turno ARCO MezclasNessuna valutazione finora

- Nas 5829 enDocumento4 pagineNas 5829 enmnezamiNessuna valutazione finora

- ECM Template InformationDocumento4 pagineECM Template InformationBosko KalicaninNessuna valutazione finora

- Cat G3512E: Natural Gas Generator SetsDocumento7 pagineCat G3512E: Natural Gas Generator SetsD.M. KaiumNessuna valutazione finora

- SS26-CPGK 0Documento8 pagineSS26-CPGK 0mnezamiNessuna valutazione finora

- Powertech ™ 4045Tfm50 Diesel Engine: Marine Propulsion Engine SpecificationsDocumento2 paginePowertech ™ 4045Tfm50 Diesel Engine: Marine Propulsion Engine SpecificationsDAVIDNessuna valutazione finora

- RS425 TerexDocumento2 pagineRS425 TerexMAQUINARIA 2022Nessuna valutazione finora

- Diesel Generator Sets: FeaturesDocumento5 pagineDiesel Generator Sets: FeaturesBilel Ben SlamaNessuna valutazione finora

- Design FMEA UltraDocumento49 pagineDesign FMEA UltrakumarNessuna valutazione finora

- Design FMEA UltraDocumento49 pagineDesign FMEA UltrakumarNessuna valutazione finora

- Wikipedia Gallon (US) : 'Cube''Documento13 pagineWikipedia Gallon (US) : 'Cube''kumarNessuna valutazione finora

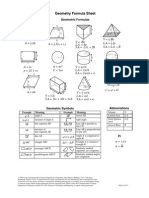

- Geometry Formula SheetDocumento1 paginaGeometry Formula SheetArun KumarNessuna valutazione finora

- Ce 1252 - Strength of Materials: Two Mark Question & AnswersDocumento21 pagineCe 1252 - Strength of Materials: Two Mark Question & AnswerskumarNessuna valutazione finora

- Ce 1252 - Strength of Materials: Two Mark Question & AnswersDocumento21 pagineCe 1252 - Strength of Materials: Two Mark Question & AnswerskumarNessuna valutazione finora

- Ce 1252 - Strength of Materials: Two Mark Question & AnswersDocumento21 pagineCe 1252 - Strength of Materials: Two Mark Question & AnswerskumarNessuna valutazione finora

- Geometry Formula SheetDocumento1 paginaGeometry Formula SheetArun KumarNessuna valutazione finora

- 4.4 Tractor Instrument PanelDocumento7 pagine4.4 Tractor Instrument Panelkumar100% (1)

- Mechanics of MaterialsDocumento30 pagineMechanics of MaterialskumarNessuna valutazione finora

- Kids Math - Angles Glossary and TermsDocumento7 pagineKids Math - Angles Glossary and Termssathish11407144Nessuna valutazione finora

- Firewater Hydraulic Study Report Detailed Engineering Design Oml-24 Crude Storage Tanks and De-Watering ProjectDocumento22 pagineFirewater Hydraulic Study Report Detailed Engineering Design Oml-24 Crude Storage Tanks and De-Watering ProjectPatrick AyanNessuna valutazione finora

- Nikuradse's ExperimentDocumento50 pagineNikuradse's ExperimentAli BahuNessuna valutazione finora

- Mass and Thermal Balance During Composting of A Poultry Manure-Wood Shavings Mixture at Different Aeration RatesDocumento9 pagineMass and Thermal Balance During Composting of A Poultry Manure-Wood Shavings Mixture at Different Aeration RatesPrashant RamNessuna valutazione finora

- Lab Report On AdsorptionDocumento12 pagineLab Report On AdsorptionElizabeth Polancos BruaNessuna valutazione finora

- 1990 - A New Approach To Highefficiency Multibandgap Solar Cells PDFDocumento5 pagine1990 - A New Approach To Highefficiency Multibandgap Solar Cells PDFdarleydomingosNessuna valutazione finora

- Several Problems of The Polish Physics Olympiad: Waldemar GorzkowskiDocumento4 pagineSeveral Problems of The Polish Physics Olympiad: Waldemar GorzkowskiVikram SaurabhNessuna valutazione finora

- 2017 Tubing InformationDocumento28 pagine2017 Tubing InformationSatyabrat GaanNessuna valutazione finora

- Electronics and Communication Engineering CurriculamDocumento6 pagineElectronics and Communication Engineering Curriculamraghucp141Nessuna valutazione finora

- Design of A New Low Cost ROV VehicleDocumento6 pagineDesign of A New Low Cost ROV VehicleMuhammad Yasar JavaidNessuna valutazione finora

- Study On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderDocumento4 pagineStudy On Mechanical Properties of Concrete On Partial Replacement of Fine Aggregate With Copper Slag and Granite PowderIJIRST100% (1)

- Rockwell Round Correction ChartsDocumento2 pagineRockwell Round Correction Chartsdarwin_huaNessuna valutazione finora

- Thermal Calculation of Heat Exchangers With Simplified Consideration of Axial Wall Heat ConductionDocumento7 pagineThermal Calculation of Heat Exchangers With Simplified Consideration of Axial Wall Heat ConductionA.M.P.P. GUNARATHNANessuna valutazione finora

- Thermodynamics Definition, Formulas, Laws and Equations - PhysicsDocumento7 pagineThermodynamics Definition, Formulas, Laws and Equations - PhysicsRamaKrishnanGNessuna valutazione finora

- Speech About Go GreenDocumento4 pagineSpeech About Go GreenMuhammadArifAzw100% (1)

- Avionics Unit 1Documento25 pagineAvionics Unit 1Raahini IzanaNessuna valutazione finora

- RodinDocumento27 pagineRodinThe Dead Alewives WatchtowerNessuna valutazione finora

- How To Calculate The NPSH of Pump in HYSYSDocumento3 pagineHow To Calculate The NPSH of Pump in HYSYSAnonymous jqevOeP7100% (3)

- ClabDocumento123 pagineClabScribd UserNessuna valutazione finora

- SETTLING VELOCITY 2.1 - Calculations of Sedimentation Velocity and Hindered Settling Rate of ParticlesDocumento74 pagineSETTLING VELOCITY 2.1 - Calculations of Sedimentation Velocity and Hindered Settling Rate of ParticlesSonu Singh100% (4)

- Hydrologic CycleDocumento35 pagineHydrologic CycleFachri JahriNessuna valutazione finora

- Scs 210 AmDocumento6 pagineScs 210 AmAntonio CabelloNessuna valutazione finora

- Laboratory Report - EvaporationDocumento14 pagineLaboratory Report - EvaporationWayne Tandingan0% (1)

- OxF125 SignedDocumento6 pagineOxF125 SignedJOSE ABADNessuna valutazione finora

- aSTM A 751 PDFDocumento5 pagineaSTM A 751 PDFTheOne YasirNessuna valutazione finora

- Laboratory Experimental Testing of InertersDocumento6 pagineLaboratory Experimental Testing of Inertersนิติพล ไชยวงศ์Nessuna valutazione finora

- Chapter - 4 - Design of Footings-2-Isolated FootingDocumento10 pagineChapter - 4 - Design of Footings-2-Isolated FootingAdisalem BelayNessuna valutazione finora

- Laine Tall 2013Documento11 pagineLaine Tall 2013Fadel Muhammad Arraiza FarhanNessuna valutazione finora

- Light NcertDocumento55 pagineLight NcertDani MathewNessuna valutazione finora

- Physics: Paper 2Documento16 paginePhysics: Paper 2Mhmd AlrashedNessuna valutazione finora