Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Effect of Salt Water in The Production of Concrete

Caricato da

John OtawhoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Effect of Salt Water in The Production of Concrete

Caricato da

John OtawhoCopyright:

Formati disponibili

EFFECT OF SALT WATER IN THE PRODUCTION

OF CONCRETE

E.M. Mbadikea , A.U. Elinwab

a

Civil Engineering Department, Michael Okpara University of Agriculture, Umudike,

Umuahia, Abia State. (Email: elvis mbadike@yahoo.co.uk)

b

Civil Engineering Department, Abubakar Tafawa Balewa University, Bauchi, Nigeria.

Abstract

In this research work, the effect of salt water in the production of concrete was

investigated. A total of ninety (90) concrete cubes were cast for compression

strength test i.e. forty five cubes were cast using fresh water and the other forty

five cubes were also cast using salt water. Similarly, a total of ninety (90) concrete

beams were cast for flexural strength test i.e. forty five beams were cast using fresh

water and the other forty five beams were also cast using salt water. The concrete

cubes and the beams were cured at 7,21,28,60 and 90 days respectively. The result

of the average compressive strength of concrete obtained using fresh water of mix

ratio (1 : 1.51 : 4.01), water cement ratio (0.47) ranges from 27.35-42.34N/mm2

while that of salt water ranges from 25.24-38.81N/mm2 for the hydration period of

7, 21, 28, 60 and 90 days. The flexural strength of concrete obtained using fresh

water of the same mix ratio and water cement ratio ranges from 6.60 - 11.20N/mm2

for 7, 21, 28, 60 and 90 days hydration period while that of salt water ranges from

5.98-11.04N/mm2 for the same hydration period. For the mix ratio (1 : 1.61 :

4.03) and water cement ratio (0.55), the average compressive strength of concrete

obtained using fresh and salt water ranges from 27.26 - 40.80N/mm2 and 24.68 -

39.13N/mm2 respectively while the flexural strength ranges from 6.55 - 11.13N/mm2

and 6.26 - 10.76N/mm2 for fresh and salt water respectively. For the mix ratio (1

: 1.66 : 4.24) and water cement ratio (0.50), the average compressive strength

of concrete obtained using fresh and salt water ranges from 25.05 - 38.13N/mm2

and 23.58 - 36.03N/mm2 respectively while the flexural strength ranges from 6.18

- 9.88N/mm2 and 6.15 - 10.39N/mm2 for fresh and salt water respectively. The

initial and final setting time of cement using fresh water is 50mins and 587mins

while that of salt water is 55mins and 605mins respectively.

Keywords: fresh water, salt water, compressive strength, flexural strength, setting time

1. Introduction inert, they introduce an important contribu-

tion to these major characteristics which make

Concrete is a mixture of cement, water and concrete the most favoured building material

aggregates in a given proportions. Aggregates [7]. Aggregates help to reduce shrinkage and

represent some 60-80% of the concrete vol- heat dissipation during hardening and also

ume. They are inert grains bound together by contribute to the increase in the mechanical

means of a binder which is cement. Although

Nigerian Journal of Technology Vol. 30, No. 2, June 2011.

106 E.M. MBADIKE and A.U. ELINWA

strength of concrete [14]. Cement generally 0.55. The third mixture was proportioned at

represent 12-14% of concrete weight. It plays 36N/mm2 , 290kg/m3 , 480kg/m3 , 1230kg/m3

an active part in the mixture by ensuring co- and 0.50 for target cube strength, cement

hesion between aggregate grains and, in do- content, fine aggregate content, coarse ag-

ing so, it introduces a decisive contribution gregate content and water cementitious ratio

to concrete mechanical strengths. During the respectively.

hardening process, it generates shrinkage and

heat dissipation phenomena which lead to ma- The salt water in this research was obtained

terial cracking [5]. Water occupies 6-8% of the from Ebonyi State while the fresh water was

composition of fresh concrete. It provides for obtained from bore hole. The fine aggregate

cement hydration and for the workability of used was clean river sand, free from deleteri-

the fresh concrete mixture. When in excess, ous substances with a specific gravity of 2.62

it determinately affects concrete porosity and and a bulk density of 1533kg/m3 . The coarse

mechanical strengths [6]. aggregate was obtained from a local supplier

with a maximum size of 20mm, specific grav-

Water used in this research work is brack

ity of 2.65 and bulk density of 1467kg/m3 .

water. Brack water is water that has more

Both aggregates conforms to BS 877 of 1967

salinity than fresh water, but not as much as

[3] and BS 3797 of 1964 [2] respectively for

sea water. The word ’brack’ comes from the

coarse and fine aggregates while the cement

Middle Dutch root “brack” meaning “Salten”

conforms to BS 12 of 1978 [1]. The cement

or “Salty”. Brackish water is also the primary

used is Ordinary Portland Cement. The con-

waste product of the salinity gradient power.

crete cubes were lubricated with oil before the

Salinity gradient or Osmotic power is the en-

mixed concrete was placed inside it in order to

ergy retrieved from the difference in salt con-

reduce friction between the concrete and the

centration between sea water and river water.

cubes.

Water is said to be salty if it contains chlorides

and sulphates [13]. When the concrete was properly mixed us-

ing the salt water and fresh water respectively,

2. Methodology the concrete cubes were filled to one third of

their height and compacted 120 times. The

The concrete cube size measuring cubes were later filled to two third of their

150×150×150mm in dimension was used. height and finally filled completely. In each of

The batching of the concrete moulds was the layer, the concrete cubes were compacted

by weight. The concrete was produced 120 times respectively. The concrete cubes

using salt water and fresh water respectively. were cast and cured for 7, 21, 28, 60 and 90

Three mixture proportions were considered days respectively. For each of the hydration

in this research work. The first mixture was period, three cubes were tested and the av-

proportioned for a target cube strength of erage compressive strength recorded. The to-

43N/mm2 and had a cementitious material tal number of concrete cubes cast was ninety

content of 340kg/m3 , a fine aggregate content (90) i.e. forty five cubes using salt water and

of 513kg/m3 , a coarse aggregate content of forty five cubes using fresh water. Similarly,

1387kg/m3 and a water cementitious ratio of the flexural strength was determined using a

0.47. The second mixture was proportioned beam mould of 150×150×600mm in dimen-

for a target cube strength of 39N/mm2 sion. The total number of beams cast was

and had a cementitious material content also ninety(90) i.e. forty five beams using salt

of 310N/mm3 , a fine aggregate content of water and forty five beams using fresh water.

498kg/m3 , a coarse aggregate content of The setting time was also determined using

1250kg/m3 and a water cementitious ratio of Vicat apparatus.

Nigerian Journal of Technology Vol. 30, No. 2. June 2011.

Effect of Salt Water in the Production of Concrete 107

3. Results and Discussion Table 1: Result of sieve analysis of fine aggregate.

Standard Mass of Mass of Percentage Percentage

sieve size sample sample retained passing

Table 1 shows the result of the sieve analysis retained

(g)

passing

(g)

(g) (g)

of fine aggregate used. The result shows that 8mm

5mm

0.00

11.60

250.00

238.40

0.00

4.64

100.00

95.36

the aggregate falls into zone 2 of calibration 2.36mm

1.18mm

44.20

32.90

194.20

161.30

17.68

13.16

77.68

64.52

graph. 600µm

300µm

77.05

56.25

84.25

28.00

30.82

22.50

33.70

11.20

Table 2 shows the result of the initial and fi- 150µm

Pan

15.90

12.10

12.10

0.00

6.36

4.84

4.84

0.00

nal setting time of cement using fresh and salt

water respectively. The initial setting time of

cement using fresh water is 50mins while the Table 2: Initial and final setting time of OPC/Fresh

final setting time is 587mins. The initial and water and OPC/Salt water.

Type of water Initial setting time Final setting time

final setting time of cement using salt water Fresh

(mins)

50

(mins)

587

is 55mins and 605mins. The higher the set- Salt 55 605

ting time, the lower the strength of concrete

produced. This is because salt water increases

the setting of cement which indicates that the spectively.

strength of concrete produced is reduced. Table 12-15 shows the result of the aver-

Table 3-6 shows the result of the average age compressive and flexural strength of con-

compressive and flexural strength of concrete crete obtained using fresh and salt water of

produced using fresh and salt water of mix mix ratio (1 : 1.66 : 4.24) and water ce-

ratio (1 : 1.51 : 4.01) and water cement ra- ment ratio of 0.50. The result of the aver-

tio of 0.47. The result of the average com- age compressive strength ranges from 25.05 -

pressive strength of concrete produced using 38.13N/mm2 and 23.58-36.03N/mm2 for fresh

fresh water ranges from 27.35-42.34N/mm2 and salt water respectively while the flexu-

while that of the salt water ranges from 25.24- ral strength ranges from 6.18-9.88N/mm2 and

38.81N/mm2 . 6.15-9.55N/mm2 for fresh and salt water re-

Similarly, the result of the average flexural spectively.

strength of concrete produced using fresh wa- The above results shows that there is a de-

ter of the same mix ratio and water cement ra- crease in the strength of concrete produced

tio ranges from 6.60 - 11.20N/mm while that when salt water is used. The decrease is due

of salt water ranges from 5.98-11.04N/mm2 . to the presence of chlorides and sulphates in

The result shows that the average compressive the salt water.

and flexural strength of concrete produced us-

ing fresh water is higher than that of the salt

water. Table 3: Result of compressive strength obtained us-

Table 7 shows the result of the physical and ing fresh water of mix ratio (1:1.51:4.01), water ce-

chemical analysis of fresh and salt water used ment ratio (0.47).

Cube size Age of Test Compressive Average

in this research work. Table 8-11 shows the (mm) cube

(days)

load

(kN)

strength

(N/mm2)

com-

pressive

result of the average compressive and flexural strength

(N/mm2 )

strength of concrete obtained using fresh and 150x150x150

150x150x150

7

7

700

550

31.11

24.44

27.35

salt water of mix ratio (1:1.61:4.03) and water 150x150x150

150x150x150

7

21

596

855

26.49

38.00 31.26

cement ratio of 0.55. The result of the aver- 150x150x150

150x150x150

21

21

604

651

26.84

28.93

age compressive strength ranges from 27.26- 150x150x150

150x150x150

28

28

950

760

42.22

33.78

35.70

40.80N/mm2 and 24.68-39.13N/mm2 for fresh 150x150x150

150x150x150

28

60

700

880

31.11

39.11 39.85

and salt water respectively while the flexural 150x150x150

150x150x150

60

60

1010

800

44.88

35.56

strength ranges from 6.55-11.13N/mm2 and 150x150x150

150x150x150

90

90

908

935

40.36

41.56

42.34

6.26-10.76N/mm2 for fresh and salt water re- 150x150x150 90 1015 45.11

Nigerian Journal of Technology Vol. 30, No. 2. June 2011.

108 E.M. MBADIKE and A.U. ELINWA

Table 4: Result of compressive strength obtained us-

ing salt water of mix ratio (1 : 1.51 : 4.01), water Table 7: Result of the physical and chemical analysis

cement ratio (0.47). of fresh and salt water.

Cube size Age of Test Compressive Average S/No Parameter Standard Sample of Sample of

(mm) cube load strength com- distilled bore hole salt water

(days) (kN) (N/mm2) pressive and water

strength deionized

(N/mm2 ) water

150x150x150 7 640 28.44 25.24 1 Colour 0.00 0.002 0.022

150x150x150 7 510 22.67 2 Odour Unobjection- Unobjection- Unobjection-

150x150x150 7 554 24.62 able able able

150x150x150 21 794 35.29 29.08 3 Taste Insipid Not de- Not de-

150x150x150 21 600 26.67 tected tected

150x150x150 21 569 25.29 4 pH 7.00 6.4 7.5

150x150x150 28 830 36.89 33.47 5 Temperature ( ) 28.00 28.00 28.00

150x150x150 28 705 31.33 6 Conductivity 0.00 0.24 410.00

150x150x150 28 724 32.18 7 Salinity (mg/l) 0.00 0.00 875.00

150x150x150 60 878 39.02 37.61 8 Total dissolved 0.00 21 1300

150x150x150 60 895 39.78 solid (mg/l)

150x150x150 60 766 34.04 9. Total suspended 0.00 0.04 59.00

150x150x150 90 950 42.02 38.81 solid (mg/l)

150x150x150 90 880 39.11 10 Turbidity 0.00 0.08 46.70

150x150x150 90 790 35.11 11 Dissolved oxygen 0.00 0.06 4.5

(mg/l)

12 Total hardness 0.00 5.20 20.90

CaC03 (mg/l)

13 Alkalinity (ppm) 0.00 1.04 4.01

14 Chemical oxygen 0.00 0.03 2.02

demand (mg/l)

15 Total petroleum 0.00 0.00 1.5

Table 5: Result of the flexural strength of concrete hydrocarbon

(mg/l)

obtained using fresh water of mix ratio (1 : 1.51 : 16 Total hydrocarbon 0.00 0.00 1.15

content (mg/l)

4.01), water cement ratio (0.47). 17 Biochemical oxy- 0.00 2.2 14

Cube size Age of Test Compressive Average gen demand (mg/l)

(mm) cube load strength com- 18 Nitrate ion (N02−

(days) (kN) (N/mm2) pressive 3 ) 0.00 0.002 0.186

mg/l

strength 19 Phosphate (mg/l) 0.00 0.08 0.20

(N/mm2 )

20 Phenols (mg/l) 0.00 0.00 0.51

150x150x150 7 40.50 7.20 6.60

21 Sulphate (mg/l) 0.00 6.7 180

150x150x150 7 35.10 6.24

22 Lead (mg/l) 0.00 ¡0.02 ¡0.01

150x150x150 7 35.80 6.36

23 Iron (mg/l) 0.00 0.04 0.42

150x150x150 21 43.60 7.75 7.85

24 Copper (mg/l) 0.00 0.34 0.61

150x150x150 21 40.00 7.11

150x150x150 21 48.80 8.68 25 Nickel (mg/l) 0.00 ¡0.002 0.90

150x150x150 28 50.00 8.89 9.09 26 Vanadium (mg/l) 0.00 0.96 ¡0.002

150x150x150 28 49.20 8.75 27 Zinc (mg/l) 0.00 ¡0.001 0.03

150x150x150 28 54.10 9.62 28 Cadmium (mg/l) 0.00 0.00 ¡0.001

150x150x150 60 52.60 9.35 10.21

150x150x150 60 59.10 10.51

150x150x150 60 60.50 10.76

150x150x150 90 60.90 10.83 11.20

150x150x150 90 66.70 11.86

150x150x150 90 61.30 10.90

Table 8: Result of the compressive strength of con-

Table 6: Result of the flexural strength of concrete crete obtained using fresh water of mix ratio (1 : 1.61

obtaining using salt water of mix ratio (1 : 1.51 : : 4.03), water cement ratio (0.55).

Cube size Age of Test Compressive Average

4.01), water cement ratio (0.47). (mm) cube load strength com-

Cube size Age of Test Compressive Average (days) (kN) (N/mm2) pressive

(mm) cube load strength com- strength

(days) (kN) (N/mm2) pressive (N/mm2 )

strength 150x150x150 7 660 29.33 27.26

(N/mm2 ) 150x150x150 7 670 29.78

150x150x150 7 33.00 5.87 5.98 150x150x150 7 510 22.67

150x150x150 7 33.80 6.01 150x150x150 21 744 33.01 29.67

150x150x150 7 34.10 6.06 150x150x150 21 690 30.67

150x150x150 21 38.80 6.90 6.91 150x150x150 21 570 25.33

150x150x150 21 37.60 6.68 150x150x150 28 700 31.11 31.88

150x150x150 21 40.20 7.15 150x150x150 28 682 30.31

150x150x150 28 45.00 8.00 8.08 150x150x150 28 770 34.22

150x150x150 28 48.90 8.69 150x150x150 60 767 34.09 34.92

150x150x150 28 42.50 7.56 150x150x150 60 696 30.93

150x150x150 60 52.40 9.32 9.65 150x150x150 60 894 39.73

150x150x150 60 50.70 9.01 150x150x150 90 889 39.51 40.80

150x150x150 60 59.70 10.61 150x150x150 90 960 42.69

150x150x150 90 59.90 10.65 11.04 150x150x150 90 905 40.22

150x150x150 90 63.55 11.30

150x150x150 90 62.86 11.18

Nigerian Journal of Technology Vol. 30, No. 2. June 2011.

Effect of Salt Water in the Production of Concrete 109

Table 9: Result of the compressive strength of con- Table 12: Result of the flexural strength of concrete

crete obtained using salt water of mix ratio (1 : 1.61 obtained using salt water of mix ratio (1:1.61:4.03),

: 4.03), water cement ratio (0.55). water cement ratio (0.55).

Cube size Age of Test Compressive Average Cube size Age of Test Compressive Average

(mm) cube load strength com- (mm) cube load strength com-

(days) (kN) (N/mm2) pressive (days) (kN) (N/mm2) pressive

strength strength

(N/mm2 ) (N/mm2 )

150x150x150 7 580 25.78 24.68 150x150x150 7 601.50 26.73 25.05

150x150x150 7 608 27.02 150x150x150 7 515.00 22.89

150x150x150 7 478 21.24 150x150x150 7 574.20 25.52

150x150x150 21 582 25.87 26.74 150x150x150 21 708.40 31.48 29.24

150x150x150 21 720 32.00 150x150x150 21 652.10 28.98

150x150x150 21 503 22.36 150x150x150 21 613.05 27.25

150x150x150 28 791 35.16 31.38 150x150x150 28 697.20 30.99 33.14

150x150x150 28 618 27.47 150x150x150 28 728.10 32.36

150x150x150 28 709 31.51 150x150x150 28 811.80 36.08

150x150x150 60 784 34.84 34.08 150x150x150 60 751.00 33.38 33.56

150x150x150 60 662 29.42 150x150x150 60 688.10 30.58

150x150x150 60 855 38.00 150x150x150 60 826.40 36.73

150x150x150 90 840 37.33 39.13 150x150x150 90 818.60 36.38 38.13

150x150x150 90 922 40.89 150x150x150 90 771.10 34.27

150x150x150 90 881.50 39.16 150x150x150 90 984.00 43.73

Table 10: Result of the flexural strength of concrete Table 13: Result of the compressive strength of

obtained using fresh water of mix ratio (1:1.61:4.03), concrete obtained using salt water of mix ratio

water cement ratio (0.55). (1:1.66:4.24), water cement ratio (0.50).

Cube size Age of Test Compressive Average Cube size Age of Test Compressive Average

(mm) cube load strength com- (mm) cube load strength com-

(days) (kN) (N/mm2) pressive (days) (kN) (N/mm2) pressive

strength strength

(N/mm2 ) (N/mm2 )

150x150x150 7 34.80 6.19 6.55 150x150x150 7 499.07 22.18 23.58

150x150x150 7 30.60 5.44 150x150x150 7 586.50 26.07

150x150x150 7 45.10 8.02 150x150x150 7 506.15 22.50

150x150x150 21 40.06 7.12 7.44 150x150x150 21 561.00 24.93 26.56

150x150x150 21 38.40 6.83 150x150x150 21 709.60 31.54

150x150x150 21 47.00 8.36 150x150x150 21 522.10 23.20

150x150x150 28 49.80 8.85 8.24 150x150x150 28 694.85 30.88 32.22

150x150x150 28 49.01 8.71 150x150x150 28 714.00 31.73

150x150x150 28 40.95 7.28 150x150x150 28 766.30 34.06

150x150x150 60 50.50 8.98 10.07 150x150x150 60 640.00 28.44 33.44

150x150x150 60 53.20 9.46 150x150x150 60 801.10 35.60

150x150x150 60 66.15 11.76 150x150x150 60 816.00 36.27

150x150x150 90 59.60 10.60 11.13 150x150x150 90 730.00 32.44 36.03

150x150x150 90 55.90 9.94 150x150x150 90 888.20 39.48

150x150x150 90 72.20 12.84 150x150x150 90 813.70 36.16

Table 11: Result of the flexural strength of concrete Table 14: Result of the flexural strength of concrete

obtained using salt water of mix ratio (1:1.61:4.03), obtained using fresh water of mix ratio (1:1.66:4.24),

water cement ratio (0.55). water cement ratio (0.50).

Cube size Age of Test Compressive Average Cube size Age of Test Compressive Average

(mm) cube load strength com- (mm) cube load strength com-

(days) (kN) (N/mm2) pressive (days) (kN) (N/mm2) pressive

strength strength

(N/mm2 ) (N/mm2 )

150x150x150 7 31.10 5.53 6.26 150x150x150 7 29.80 5.30 6.18

150x150x150 7 36.00 6.40 150x150x150 7 31.10 5.53

150x150x150 7 38.55 6.85 150x150x150 7 43.35 7.71

150x150x150 21 30.87 5.49 6.31 150x150x150 21 37.05 6.59 6.48

150x150x150 21 34.67 6.15 150x150x150 21 41.30 7.34

150x150x150 21 41.05 7.30 150x150x150 21 30.98 5.51

150x150x150 28 44.00 7.82 8.18 150x150x150 28 50.00 8.89 9.07

150x150x150 28 50.30 8.94 150x150x150 28 51.20 9.10

150x150x150 28 43.70 7.77 150x150x150 28 51.93 9.23

150x150x150 60 50.08 8.90 9.31 150x150x150 60 61.50 10.93 9.76

150x150x150 60 57.20 10.17 150x150x150 60 54.20 9.64

150x150x150 60 49.89 8.86 150x150x150 60 48.96 8.70

150x150x150 90 55.90 9.94 10.76 150x150x150 90 66.00 11.73 9.88

150x150x150 90 76.10 13.53 150x150x150 90 49.95 8.88

150x150x150 90 49.55 8.81 150x150x150 90 50.81 9.03

Nigerian Journal of Technology Vol. 30, No. 2. June 2011.

110 E.M. MBADIKE and A.U. ELINWA

Table 15: Result of the flexural strength of concrete 4. ACI Committee 212. Admixture for Con-

obtained using salt water of mix ratio (1:1.66:4.24), crete. Journal of American Concrete Insti-

water cement ratio (0.50). tute, vol. 60, 2002, pp 11.

Cube size Age of Test Compressive Average

(mm) cube load strength com-

(days) (kN) (N/mm2) pressive 5. Malhotra V.M. A Global Review with Em-

strength

(N/mm2 ) phasis on Durability and Innovative Con-

150x150x150 7 30.00 5.33 6.15

150x150x150 7 36.18 6.43

crete. Journal of American Concrete Insti-

150x150x150

150x150x150

7

21

37.55

33.60

6.68

5.97 7.33

tute, Vol. 30, 1988, pp. 120- 130.

150x150x150 21 53.05 9.43

150x150x150 21 37.00 6.58

150x150x150 28 46.10 8.20 8.39 6. Neville A.M. and Brooks J. Concrete Tech-

150x150x150 28 58.00 10.31

150x150x150 28 37.45 6.66

nology, 3rd Edition, Pearson Publishers, In-

150x150x150

150x150x150

60

60

53.63

51.10

9.53

9.08

9.00 dia, 1995.

150x150x150 60 46.98 8.35

150x150x150 90 58.30 10.36 9.55

150x150x150 90 50.00 8.89 7. Neville A.M. Properties of Concrete, 4th

150x150x150 90 52.86 9.40

Edition, Pitman Publishing Company Ltd.,

New York, 1995.

4. Conclusion and Recommendations 8. Desai J.B. and Digbe R.S. The Influence of

Salt Water on the Compressive Strength of

The conclusion of the study can be summa- Concrete. India Concrete Journal, vol. 56,

rized as follows: 1980, pp 200-208.

a. The strength development in the con-

9. Chatterji A.K. Effect of Salt Water on the

crete produced increases with the increase in

Flexural Strength of Concrete. Journal of

the hydration period.

Scientific Industrial Research, vol. 18, 2000,

b. The higher the setting time, the lower pp. 301-340.

the strength of concrete produced

c. The use of salt water in concrete pro- 10. Ding Z. and Zhang D. Influence of Salt Wa-

duction will reduce the strength of concrete ter on the Setting Time of Ordinary Port-

produced to approximately 8%. land Cement. China Concrete Cement Pro-

d. Curing is very necessary in concrete in duction, Vol 12, 1999, pp 10-11.

order to ensure the complete hydration of ce- 11. Agunwamba J.C. Water Engineering Sys-

ment tems. Revised Edition by De-Adroit Inno-

e. The strength development in concrete vation, Enugu, Nigeria, 2008.

depends on the percentage chemical compo-

12. British Standard Code Structural Use of

sition of cement.

Concrete. Part 1, Code of Practice for De-

f. The presence of chlorides and sulphates

sign and Construction 2004.

in salt water reduces strength of concrete.

13. Tchobanoglous G., Burton F.L. and Stensel

H.D. Waste Water Engineering and Treat-

References ment. 4th Edition, McGraw Hill Company

Ltd., England, 2003.

1. BS 12. Specification for Ordinary and Rapid

Hardening Portland Cement. London, 1978, 14. He C. Makovicky, Osbaeck B. Measurement

pp 38. of Acid Soluble Silica in Salt Water. Journal

of Applied Sciences, vol 8, 1998, pp 160-172.

2. BS 3797. Lightweight Aggregate for Con-

crete. London, 1964, PP 8. 15. Surana M.S. and Joshi S.N. The Measure-

ment of Alkali Soluble Silica by Spectropho-

3. BS 877. Foamed or Expanded Blast Fur- tometric Method, ACI Journal, Vol. 10,

nace Slag Lightweight Aggregate for Con- 1990, pp 81-83.

crete. London, 1967, pp8.

Nigerian Journal of Technology Vol. 30, No. 2. June 2011.

Potrebbero piacerti anche

- Professional CV FormatDocumento2 pagineProfessional CV FormatShawn ParkerNessuna valutazione finora

- Concrete Mix Design ProcedureDocumento7 pagineConcrete Mix Design ProcedureJaime Manalili Landingin0% (1)

- Macmillan English Grammar in Context Advanced PDFDocumento3 pagineMacmillan English Grammar in Context Advanced PDFAnonymous l1MDLhBFXNessuna valutazione finora

- For Calibration List - OrginalDocumento62 pagineFor Calibration List - Orginaluttam khatriNessuna valutazione finora

- Click and Learn How To Get Free TikTok FansDocumento4 pagineClick and Learn How To Get Free TikTok FansFreedmanMcFadden9Nessuna valutazione finora

- Study On Properties of Cellular Light Weight ConcreteDocumento19 pagineStudy On Properties of Cellular Light Weight ConcreteDivya VahinipathiNessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Effect of Cement Content and Size of Coarse Aggregate On The Strength of Brick Aggregate ConcreteDocumento5 pagineEffect of Cement Content and Size of Coarse Aggregate On The Strength of Brick Aggregate ConcreteVikash TiwariNessuna valutazione finora

- Curing Methods and Their Effects On TheDocumento4 pagineCuring Methods and Their Effects On Theshiraz ahmedNessuna valutazione finora

- Characteristic Study of Concrete by Replacing Glass Cullet and Ceramic Tiles Over Conventional AggregatesDocumento4 pagineCharacteristic Study of Concrete by Replacing Glass Cullet and Ceramic Tiles Over Conventional AggregatesD S VijayanNessuna valutazione finora

- Robo Sand (2) - 2Documento21 pagineRobo Sand (2) - 2Shaik ShareefNessuna valutazione finora

- Study of Compressive Strengths of Laterite-Cement Mixes As A Building MaterialDocumento7 pagineStudy of Compressive Strengths of Laterite-Cement Mixes As A Building MaterialArjun KumarNessuna valutazione finora

- Utilisation of Waste Marble Dust As Fine AggregateDocumento7 pagineUtilisation of Waste Marble Dust As Fine AggregatePoporok SantiagoNessuna valutazione finora

- Experimental Investigation On Partial Replacement of Sand by Pond Ash and Coarse Aggregate by Steel FibreDocumento19 pagineExperimental Investigation On Partial Replacement of Sand by Pond Ash and Coarse Aggregate by Steel FibreAbhinav ChaharNessuna valutazione finora

- Evaluation of Compressive Strength and Water Absorption of Styrene Butadiene Rubber (SBR) Latex Modified ConcreteDocumento5 pagineEvaluation of Compressive Strength and Water Absorption of Styrene Butadiene Rubber (SBR) Latex Modified ConcreteIJMERNessuna valutazione finora

- Proportions and Quantities: Strength Reduction, When Using Air-EntrainDocumento6 pagineProportions and Quantities: Strength Reduction, When Using Air-EntrainLuyanda SilangweNessuna valutazione finora

- A Review On Mix Design For Pervious Concrete: Salunkhepatil S.S., Patil O.D., Dhemare A. M., Jadhav S.A., Bhirud S.VDocumento6 pagineA Review On Mix Design For Pervious Concrete: Salunkhepatil S.S., Patil O.D., Dhemare A. M., Jadhav S.A., Bhirud S.VLokesh KNessuna valutazione finora

- Nahushananda Chakravarthy H.GDocumento11 pagineNahushananda Chakravarthy H.GGlobal Research and Development ServicesNessuna valutazione finora

- Experiment No. 11 Fabricating Concrete Specimen For Tests: Referenced StandardDocumento5 pagineExperiment No. 11 Fabricating Concrete Specimen For Tests: Referenced StandardRenNessuna valutazione finora

- International Journal of Engineering Research and DevelopmentDocumento7 pagineInternational Journal of Engineering Research and DevelopmentIJERDNessuna valutazione finora

- There Will Be Threethree For Threewith Used, Another Another Three Samplethree Will Be Obtained The S Subjected Exposed ExposureDocumento5 pagineThere Will Be Threethree For Threewith Used, Another Another Three Samplethree Will Be Obtained The S Subjected Exposed ExposureJomar TerbioNessuna valutazione finora

- Flow Behavior and Strength For y Ash Blended Cement Paste and MortarDocumento8 pagineFlow Behavior and Strength For y Ash Blended Cement Paste and MortarZuhair NadeemNessuna valutazione finora

- HIgh Strength High-Performance Concrete For Marine EnvironmentDocumento8 pagineHIgh Strength High-Performance Concrete For Marine EnvironmentdsmnnangNessuna valutazione finora

- Replacement of Fine Aggregate by Mixture of Ceramic and Surkhi Powder in Concrete IJERTV6IS040780Documento9 pagineReplacement of Fine Aggregate by Mixture of Ceramic and Surkhi Powder in Concrete IJERTV6IS040780Abdullah Al-MamunNessuna valutazione finora

- Cc-Mix DesignDocumento37 pagineCc-Mix DesignManoj Kumar SinghNessuna valutazione finora

- 001 Concrete ConstructionDocumento10 pagine001 Concrete ConstructionKimMinJae26Nessuna valutazione finora

- Ecological Tranformation Urban Lake 12-12-17 ADocumento22 pagineEcological Tranformation Urban Lake 12-12-17 Agk mNessuna valutazione finora

- Compressive and Flexural Strength TestinDocumento16 pagineCompressive and Flexural Strength TestinRani HendrikusNessuna valutazione finora

- 43-C.S. Poon Fly Ash Reactivity - 2Documento9 pagine43-C.S. Poon Fly Ash Reactivity - 2Ali SherNessuna valutazione finora

- Effect of Moisture Content On The Moulding Properties of River Niger Sand Using Tudun-Wada Clay As A BinderDocumento5 pagineEffect of Moisture Content On The Moulding Properties of River Niger Sand Using Tudun-Wada Clay As A Binderstudy pointNessuna valutazione finora

- Concrete Mix DesignDocumento4 pagineConcrete Mix DesignZakir AliNessuna valutazione finora

- International Journal of Chemtech Research: R. Malathy, N. Karuppasamy, S.BaranidharanDocumento9 pagineInternational Journal of Chemtech Research: R. Malathy, N. Karuppasamy, S.BaranidharanAhmedNessuna valutazione finora

- Partillay Replacement of Sand by Artifical Sand in Ferrocement Used in Road ConstructionDocumento28 paginePartillay Replacement of Sand by Artifical Sand in Ferrocement Used in Road ConstructionNagaraj GuptaNessuna valutazione finora

- Effect of Primary Treated Waste Water in Concrete MixDocumento5 pagineEffect of Primary Treated Waste Water in Concrete MixAmihan SantosNessuna valutazione finora

- Estimating The Original Cement Content and Water Cement Ratio of Portland Cement by Background Electron MicrosDocumento14 pagineEstimating The Original Cement Content and Water Cement Ratio of Portland Cement by Background Electron MicrosRobertMaddenNessuna valutazione finora

- Strenghts: Water Absorption of Concrete 1.24% Water Absorption of Water-Hyacinth Incorporated Concrete 1.15%Documento3 pagineStrenghts: Water Absorption of Concrete 1.24% Water Absorption of Water-Hyacinth Incorporated Concrete 1.15%Kimberly Wealth Meonada MagnayeNessuna valutazione finora

- Development of Correlation Between Different Properties of Pervious ConcreteDocumento12 pagineDevelopment of Correlation Between Different Properties of Pervious ConcreteTJPRC PublicationsNessuna valutazione finora

- Bleeding of Fresh Concrete Containing Cement SupplDocumento7 pagineBleeding of Fresh Concrete Containing Cement SupplCatnis Tom100% (1)

- Robo Sand (2) - 3Documento20 pagineRobo Sand (2) - 3Shaik ShareefNessuna valutazione finora

- Comparative Study On The Strength of Lightweight Foamed Concrete Prepared Using Different ReagentsDocumento3 pagineComparative Study On The Strength of Lightweight Foamed Concrete Prepared Using Different ReagentsReethika SNessuna valutazione finora

- Art:10 1007/BF02472722Documento8 pagineArt:10 1007/BF02472722Tarek ChikerNessuna valutazione finora

- Utilization of Aggregate Quarry Waste in Construction IndustryDocumento7 pagineUtilization of Aggregate Quarry Waste in Construction IndustryJanine Rose MendozaNessuna valutazione finora

- Chloride Ion Penetration Into Mortar Containing Ceramic Waste AggregateDocumento7 pagineChloride Ion Penetration Into Mortar Containing Ceramic Waste AggregateViníciusNessuna valutazione finora

- Arma 2018 306Documento8 pagineArma 2018 306JhormanNessuna valutazione finora

- The Mechanical Behaviour of Historic Masonry Structures: R. Hayen, K. Van Balen and D. Van GemertDocumento10 pagineThe Mechanical Behaviour of Historic Masonry Structures: R. Hayen, K. Van Balen and D. Van GemertPedro SilvaNessuna valutazione finora

- Effect of Specimen Size and Shape On The Compressive Strength of High Strength ConcreteDocumento10 pagineEffect of Specimen Size and Shape On The Compressive Strength of High Strength ConcreteNikita DigheNessuna valutazione finora

- Structural Strength Characteristics of Cement-Cassava Peel Ash Blended ConcreteDocumento11 pagineStructural Strength Characteristics of Cement-Cassava Peel Ash Blended ConcreteMUSTAPHA SHEHU ABUBAKARNessuna valutazione finora

- Second Review - Batch 03-1Documento16 pagineSecond Review - Batch 03-119114 GovindNessuna valutazione finora

- Review of Water Quality For Use in Concrete 201101024Documento10 pagineReview of Water Quality For Use in Concrete 201101024Fausto Da GamaNessuna valutazione finora

- Fence Panel Concrete Test ReportDocumento27 pagineFence Panel Concrete Test ReportDessalegn GaminiNessuna valutazione finora

- In Fluence of The Manufacturing Process On The Performance of Low Clinker, Calcined Clay-Limestone Portland CementDocumento7 pagineIn Fluence of The Manufacturing Process On The Performance of Low Clinker, Calcined Clay-Limestone Portland CementVictor RodrigoNessuna valutazione finora

- Research Article: The Compressive Strength of High-Performance Concrete and Ultrahigh-PerformanceDocumento8 pagineResearch Article: The Compressive Strength of High-Performance Concrete and Ultrahigh-PerformanceJaka Suranto & PartnersNessuna valutazione finora

- Construction and Building Materials: Valeria Corinaldesi, Giacomo Moriconi, Tarun R. NaikDocumento5 pagineConstruction and Building Materials: Valeria Corinaldesi, Giacomo Moriconi, Tarun R. NaikShekharNessuna valutazione finora

- Mechanical Properties of Soil-Cement Interlocking BlocksDocumento24 pagineMechanical Properties of Soil-Cement Interlocking BlocksMahsa Chavoshi80% (5)

- Research Article: Effect of W/C Ratio On Durability and Porosity in Cement Mortar With Constant Cement AmountDocumento12 pagineResearch Article: Effect of W/C Ratio On Durability and Porosity in Cement Mortar With Constant Cement AmountSteffani Sanchez AngelesNessuna valutazione finora

- Mixingofconcretewitheffects 151014102053 Lva1 App6892 PDFDocumento37 pagineMixingofconcretewitheffects 151014102053 Lva1 App6892 PDFChandresh ReddyNessuna valutazione finora

- Elixir 93201639468 39471 Published1Documento5 pagineElixir 93201639468 39471 Published1Shuvro ChakravortyNessuna valutazione finora

- A Comparative Study On The Properties of Pervious Concrete For Pavements Using FlyashDocumento4 pagineA Comparative Study On The Properties of Pervious Concrete For Pavements Using FlyashiaetsdiaetsdNessuna valutazione finora

- Effect of Salt Water On Mechanical Properties of Conventional and Pervious ConcreteDocumento4 pagineEffect of Salt Water On Mechanical Properties of Conventional and Pervious ConcreteNatarajan SaravananNessuna valutazione finora

- Shubham Agrawal ProjectDocumento18 pagineShubham Agrawal Projectkamlesh kumawatNessuna valutazione finora

- Fracture in DesignDocumento4 pagineFracture in DesignSivakumar MvnNessuna valutazione finora

- Optimisation of Building Material To Achieve Specific StrenghtDocumento44 pagineOptimisation of Building Material To Achieve Specific StrenghtVinayak ChaturvediNessuna valutazione finora

- Multi Scale Experimental Study of Concrete Rheology: From Water Scale To Gravel ScaleDocumento11 pagineMulti Scale Experimental Study of Concrete Rheology: From Water Scale To Gravel ScaleTarek ChikerNessuna valutazione finora

- Evaluation of The Performance of Normal Concrete Produced by Marble Waste IJERTV11IS030037Documento6 pagineEvaluation of The Performance of Normal Concrete Produced by Marble Waste IJERTV11IS030037fayaz9063230250Nessuna valutazione finora

- Catalogo Agom Expansion Joints ENG Rev.02Documento8 pagineCatalogo Agom Expansion Joints ENG Rev.02John OtawhoNessuna valutazione finora

- Pray For Our Leaders Prayer Guide PDFDocumento3 paginePray For Our Leaders Prayer Guide PDFJohn OtawhoNessuna valutazione finora

- Mutual Funds at A Glance: Fund Type Investment Objective Asset Allocation Minimum Investment Amount Income DistributionDocumento1 paginaMutual Funds at A Glance: Fund Type Investment Objective Asset Allocation Minimum Investment Amount Income DistributionJohn OtawhoNessuna valutazione finora

- The New Generation: A AX X 0 01 1 P Plla Atte e B Be Ea Arriin NG G T Te Esstte ErrDocumento2 pagineThe New Generation: A AX X 0 01 1 P Plla Atte e B Be Ea Arriin NG G T Te Esstte ErrJohn OtawhoNessuna valutazione finora

- Nim-Nysc Induction CourseDocumento55 pagineNim-Nysc Induction CourseJohn OtawhoNessuna valutazione finora

- Kitchen CabinetDocumento1 paginaKitchen CabinetJohn OtawhoNessuna valutazione finora

- Planet3 PDFDocumento1 paginaPlanet3 PDFJohn OtawhoNessuna valutazione finora

- April 2019 Diet Time TableDocumento3 pagineApril 2019 Diet Time TableJohn OtawhoNessuna valutazione finora

- Coren Proposer Form Updated PDFDocumento1 paginaCoren Proposer Form Updated PDFJohn OtawhoNessuna valutazione finora

- Plan PDFDocumento1 paginaPlan PDFJohn OtawhoNessuna valutazione finora

- The Nigerian Society of EngineersDocumento4 pagineThe Nigerian Society of EngineersJohn OtawhoNessuna valutazione finora

- KU Scholarship 2019 For International Students Application FormDocumento6 pagineKU Scholarship 2019 For International Students Application FormJohn OtawhoNessuna valutazione finora

- Build PlanDocumento1 paginaBuild PlanJohn OtawhoNessuna valutazione finora

- KEDA Quotation of 2 3 4 Inch Mini Gold DredgerDocumento3 pagineKEDA Quotation of 2 3 4 Inch Mini Gold DredgerShane CapstickNessuna valutazione finora

- Unit 9 Computer NetworksDocumento8 pagineUnit 9 Computer NetworksDaniel BellNessuna valutazione finora

- Hi 8586pdiDocumento9 pagineHi 8586pdiDunkMeNessuna valutazione finora

- Refrence List Middle EastDocumento7 pagineRefrence List Middle EastazeemNessuna valutazione finora

- ALV List and ALV GridDocumento6 pagineALV List and ALV Gridlavi2Nessuna valutazione finora

- TOR of The Feasibility Study of Crop RecommendationDocumento6 pagineTOR of The Feasibility Study of Crop RecommendationGangadhar ChaudharyNessuna valutazione finora

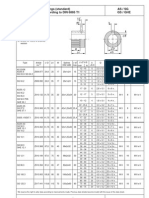

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Documento1 paginaAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeNessuna valutazione finora

- Seminar ReportDocumento27 pagineSeminar ReportnitinNessuna valutazione finora

- Rajiv Verma CVDocumento3 pagineRajiv Verma CVrajivNessuna valutazione finora

- List of RDSO Coaching DrawingsDocumento21 pagineList of RDSO Coaching DrawingsShubhav Manav0% (2)

- TELEC-Dwg-Al Khater Plastic FactoryDocumento8 pagineTELEC-Dwg-Al Khater Plastic FactoryRENJITH K NAIRNessuna valutazione finora

- Automotive Engg. & TechnologyDocumento15 pagineAutomotive Engg. & TechnologysayuuishotNessuna valutazione finora

- Studyguide PDFDocumento97 pagineStudyguide PDFraqibappNessuna valutazione finora

- 1-18 Easy Fix Double Glazing Counter Price ListDocumento16 pagine1-18 Easy Fix Double Glazing Counter Price ListChris PaceyNessuna valutazione finora

- Lowel LightsDocumento80 pagineLowel LightsSaulo Valley100% (1)

- Lesson 1 DataDocumento4 pagineLesson 1 Dataapi-435318918Nessuna valutazione finora

- PPG en-US P162.OutputDocumento4 paginePPG en-US P162.OutputChemical EngineerNessuna valutazione finora

- Retail Generation ZDocumento24 pagineRetail Generation ZSomanNessuna valutazione finora

- Horizontal Cylindrical Steam Autoclave: Main FeaturesDocumento2 pagineHorizontal Cylindrical Steam Autoclave: Main FeaturesMahroelNessuna valutazione finora

- Philips HeartStart MRX EMS BrochureDocumento12 paginePhilips HeartStart MRX EMS BrochureEnerspect Medical Solutions100% (1)

- 01-25 OB Bbs 3 Year Preboard 2076Documento1 pagina01-25 OB Bbs 3 Year Preboard 2076Reestam SD100% (1)

- Lampiran BDocumento3 pagineLampiran BIqbhal WanaharaNessuna valutazione finora

- Um0244 01 GBDocumento84 pagineUm0244 01 GBnetharafernando1Nessuna valutazione finora

- SFP Module PDFDocumento2 pagineSFP Module PDFMario PatarroyoNessuna valutazione finora

- Cambridge Ordinary LevelDocumento4 pagineCambridge Ordinary LevelHaziq AfzalNessuna valutazione finora

- Security Issues in Modern Automotive Systems: Patrick NischDocumento6 pagineSecurity Issues in Modern Automotive Systems: Patrick NischEdson PatrícioNessuna valutazione finora