Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tablas Aleaciones No Férreas

Caricato da

macalupu0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni7 paginetabla de aleaciones no ferreas

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentotabla de aleaciones no ferreas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni7 pagineTablas Aleaciones No Férreas

Caricato da

macaluputabla de aleaciones no ferreas

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

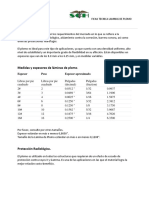

ALEACIONES DE ALUMINIO

Temper designation system for aluminun alloys

Aleaciones base cobre

UNS No Composición

Aleaciones para

forja

Cobres C10100- >99% Cu

C15760

Aleaciones de C16200- >96% Cu

altas en cobre C19600

Latones C20500- Cu-Zn

C28580

Latones al plomo C31200- Cu-Zn-Pb

C38590

Latones al estaño C40400- Cu-Zn-Sn-Pb

C49080

Bronces C50100- Cu-Sn-P

fosforados C52400

Cobres- C55180- Cu-P-Ag

fosforados y C55284

aleaciones cobre-

plata-fósforos

Bronces C53200- Cu-Sn-Pb-P

fosforados al C54800

plomo

Bronces al C60600- Cu-Al-Ni-Fe-Si-

aluminio C64400 Sn

Bronces al silicio C64700- Cu-Si-Sn

C66100

Otras aleaciones C66400- ...

cobre-zinc C69900

Cuproníqueles C70000- Cu-Ni-Fe

C79900

Cu-Ni-Zn C73200- Cu-Ni-Zn

C79900

Aleaciones moldeadas

Cobres C80100-C81100 >99% Cu

Aleaciones altas en cobre C81300-C82800 >94% Cu

Latones rojos y latones rojos al plomo C83300-C85800 Cu-Zn-Sn-Pb (75-89% Cu)

Latones amarillos y latones amarillos al plomo C85200-C85800 Cu-Zn-Sn-Pb (57-74% Cu)

Bronces al manganeso y Bronces al manganeso con plomo C86100-C86800 Cu-Zn-Mn-Fe-Pb

Bronces al silicio bronces, latones al silicio C87300-C87900 Cu-Zn-Si

Bronces al estaño y bronces estañados al plomo C90200-C94500 Cu-Sn-Zn-Pb

Bronces estañados al níquel C94700-C94900 Cu-Ni-Sn-Zn-Pb

Bronces al aluminio C95200-C95810 Cu-Al-Fe-Ni

Cuproníqueles C96200-C96800 Cu-Ni-Fe

Ni-Cu-Zn-Pb-Sn C97300-C97800 Cu-Ni-Zn-Pb-Sn

Cobres al plomo C98200-C98800 Cu-Pb

Aleaciones especiales C99300-C99750 ...

Copper-zinc alloys (brasses)

Composition, wt%

Copper Other

alloy No. Previous tradename Cu Pb Fe Zn named elements

C21000 Gilding, 95% 94.0-96.0(t) 0.03 0.05 bal ...

(t)

C22000 Commercial bronze, 90% 89.0-91.0 0.05 0.05 bal ...

(t)

C22600 86.0-89.0 0.05 0.05 bal ...

Jewelry bronze, 87 %

C23000 Red brass, 85% 84.0-86.0(t) 0.05 0.05 bal ...

(t)

C23030 ... 83.5-85.5 0.05 0.05 bal 0.20-0.40Si

(t)

C23400 ... 81.0-84.0 0.05 0.05 bal ...

(t)

C24000 Low brass, 80% 78.5-81.5 0.05 0.05 bal ...

(t)

C24080 ... 78.0-82.0 0.20 . . . bal 0.10Al

(u)

C26000 Cartridge brass, 70% 68.5-71.5 0.07 0.05 bal ...

(u)

C26130 ... 68.5-71.5 0.05 0.05 bal 0.02-0.08As

(u)

C26200 ... 67.0-70.0 0.07 0.05 bal ...

(u)

C26800 Yellow brass, 66% 64.0-68.5 0.15 0.05 bal ...

(u)

C27000 Yellow brass, 65% 63.0-68.5 0.10 0.07 bal ...

(u)

C27200 ... 62.0-65.0 0.07 0.07 bal ...

(u)

C27400 Yellow brass, 63% 61.0-64.0 0.10 0.05 bal ...

(u)

C28000 Muntz metal, 60% 59.0-63.0 0.30 0.07 bal ...

Compositions of copper tin alloy castings

UNS Other designations, Applicable Composition(b), wt%

N° descriptive names casting Other

(former SAE No.) processes(a) Cu Sn Pb Zn Ni Fe

C90200 242, 93-7-0-0 S, C, CL, 91.0- 6.0- 0.30 0.50 0.50(i) 0.20 0.20 Sb, 0.05 S,

PM, I, P 94.0 8.0 0.05 P(j), 0.005 Al,

0.005 Si

C90300 225, 88-8-0-4, Navy S, C, CL, 86.0- 7.5- 0.30 3.0- 1.0(i) 0.20 0.20 Sb, 0.05 S,

"G" bronze, (SAE 620) PM, I, P 89.0 9.0 5.0 0.05 P(j), 0.005 Al,

0.005 Si

C90500 210, 88-10-0-2, gun S, C, CL, 86.0- 9.0- 0.30 1.0- 1.0(i) 0.20 0.20 Sb, 0.05 S,

metal, (SAE 62) PM, I, P 89.0 11.0 3.0 0.05 P(j), 0.005 Al,

0.005 Si

C90700 205, 89-11, (SAE 65) S, C, CL, 88.0- 10.0- 0.50 0.50 0.50(i) 0.15 0.20 Sb, 0.05 S,

PM, I, P 90.0 12.0 0.30 P(j), 0.005 Al,

0.005 Si

C90710 ... S, C, CL, Bal 10.0- 0.25 0.05 0.10(i) 0.10 0.20 Sb, 0.05 S,

PM, I, P 12.0 0.05-1.2 P(j), 0.005

Al, 0.005 Si

C90800 ... S, C, CL, 85.0- 11.0- 0.25 0.25 0.50(i) 0.15 0.20 Sb, 0.05 S,

PM, I, P 89.0 13.0 0.30 P(j), 0.005 Al,

0.005 Si

C90810 ... S, C, CL, Bal 11.0- 0.25 0.30 0.50(i) 0.15 0.20 Sb, 0.05 S,

PM, I, P 13.0 0.15-0.8 P(j), 0.005

Al, 0.005 Si

C90900 199, 87-13-0-0 S, C, CL, 86.0- 12.0- 0.25 0.25 0.50(i) 0.15 0.20 Sb, 0.05 S,

PM, I, P 89.0 14.0 0.05 P(j), 0.005 Al,

0.005 Si

C91000 197, 85-14-0-1 S, C, CL, 84.0- 14.0- 0.20 1.5 0.80(i) 0.10 0.20 Sb, 0.05 S,

PM, I, P 86.0 16.0 0.05 P(j), 0.005 Al,

0.005 Si

C91100 84-16-0-0 S, C, CL, 82.0- 15.0- 0.25 0.25 0.50(i) 0.25 0.20 Sb, 0.05 S, 1.0

PM, I, P 85.0 17.0 P(j), 0.005 Al, 0.005

Si

C91300 194, 81-19 S, C, CL, 79.0- 18.0- 0.25 0.25 0.50(i) 0.25 0.20 Sb, 0.05 S, 1.0

PM, I, P 82.0 20.0 P(j), 0.005 Al, 0.005

Si

C91600 S, C, CL, 86.0- 9.7- 0.25 0.25 1.2- 0.20 0.20 Sb, 0.05 S,

205N, 88-10 -0-0- PM, I, P 89.0 10.8 2.0(i) 0.30 P(j), 0.005 Al,

1 , nickel gear bronze 0.005 Si

C91700 S, C, CL, 84.0- 11.3- 0.25 0.25 1.20- 0.20 0.20 Sb, 0.05 S,

86 -12-0-0-1 , PM, I, P 87.0 12.5 2.0(i) 0.30 P(j), 0.005 Al,

nickel gear bronze 0.005 Si

(a) Casting processes: S, sand; D, die; C, continuous; I, investment; PM, permanent

mold; CL, centrifugal;and P, plaster.

(b) Composition values are given as maximum percentages, unless shown as a range

or minimum.

Bal= Cu + sum of named elements, 99.5%min.

Designaciones de temperizado para aleaciones base cobre

Potrebbero piacerti anche

- Cobre y Sus AleacionesDocumento6 pagineCobre y Sus AleacionesDiego Fernando Pacheco SantosNessuna valutazione finora

- BronceDocumento51 pagineBronceJack Caceres100% (1)

- Tubos de Cobre ASTM B111Documento7 pagineTubos de Cobre ASTM B111SERVICIOS INTEGRALES OSDANessuna valutazione finora

- Tablas Aleaciones No Férreas2Documento6 pagineTablas Aleaciones No Férreas2Pablo Chumacero TimanáNessuna valutazione finora

- Cobre y Sus AleacionesDocumento27 pagineCobre y Sus Aleacionesesandremont02Nessuna valutazione finora

- Tema 11. Cobre y Sus Aleaciones PDFDocumento8 pagineTema 11. Cobre y Sus Aleaciones PDFCamilo GonzalezNessuna valutazione finora

- Tablas de EmisividadDocumento5 pagineTablas de EmisividadAndres0% (1)

- 6.2. - La Termografia Emisividad de Materiales.Documento5 pagine6.2. - La Termografia Emisividad de Materiales.Oscar PuenteNessuna valutazione finora

- WIZ 18S 3.2mm 504145Documento1 paginaWIZ 18S 3.2mm 504145MARIO ALBANessuna valutazione finora

- CobreDocumento2 pagineCobredarkvaroNessuna valutazione finora

- Tuberia de Laton 272Documento2 pagineTuberia de Laton 272Samuel GuedezNessuna valutazione finora

- Tablas Propiedades Fisicoquímicas FIQDocumento4 pagineTablas Propiedades Fisicoquímicas FIQJuan MNessuna valutazione finora

- Aluminio Extruido Aleaciones en PDFDocumento12 pagineAluminio Extruido Aleaciones en PDFAhmet HamamcıoğluNessuna valutazione finora

- Tablas Hollman PDFDocumento18 pagineTablas Hollman PDFNathalyaNessuna valutazione finora

- BronceDocumento74 pagineBronceEliana MejiaNessuna valutazione finora

- 2745 1999 PDFDocumento12 pagine2745 1999 PDFFreddy GallardoNessuna valutazione finora

- Fórmula #222 Esmaltes Crudos de Muy Baja Temperatura Sin PlomoDocumento4 pagineFórmula #222 Esmaltes Crudos de Muy Baja Temperatura Sin PlomoMariana Alejandra VargasNessuna valutazione finora

- Obtención Del CobreDocumento27 pagineObtención Del CobreNatán RodrigezNessuna valutazione finora

- Escoria PDFDocumento10 pagineEscoria PDFJorge ValenciaNessuna valutazione finora

- Aceros EcuadorDocumento20 pagineAceros EcuadorRicardo C.Nessuna valutazione finora

- Tubo de Cobre para Usos Electricos Propiedades ElectricasDocumento2 pagineTubo de Cobre para Usos Electricos Propiedades Electricasjanis lopezNessuna valutazione finora

- Tablas de Secciones y Tipos de Aleaciones para de Conductores Cobre y AluminioDocumento11 pagineTablas de Secciones y Tipos de Aleaciones para de Conductores Cobre y AluminioWalterNessuna valutazione finora

- AcerosDocumento21 pagineAcerosEduardo Mh GNessuna valutazione finora

- Presentación Unidad 3 - Aceros Estructura y PropiedadesDocumento40 paginePresentación Unidad 3 - Aceros Estructura y PropiedadesZuleiky NoriegaNessuna valutazione finora

- Tratamientos TermicosDocumento135 pagineTratamientos TermicosDanilo ILaquize AltamiranoNessuna valutazione finora

- Láminas de PlomoDocumento4 pagineLáminas de PlomoAna Paulino(/SCH)Nessuna valutazione finora

- Herrerias Barras Redondas 2744-1999Documento12 pagineHerrerias Barras Redondas 2744-1999Emilio EscalanteNessuna valutazione finora

- Ceritificado Soldadura 7018 PDFDocumento1 paginaCeritificado Soldadura 7018 PDFCentro de SaludNessuna valutazione finora

- Fundición de Cobre-Clase 9Documento114 pagineFundición de Cobre-Clase 9José Carlos Tiraccaya Garcia100% (1)

- Microscopia (Laton)Documento26 pagineMicroscopia (Laton)Fil Melchor ChavezNessuna valutazione finora

- WIZ 18S 3.2mm 504145Documento1 paginaWIZ 18S 3.2mm 504145Alfredo OrellanaNessuna valutazione finora

- Fundición de Cobre-Clase 9Documento114 pagineFundición de Cobre-Clase 9freddy.sucuytanaNessuna valutazione finora

- Laboratorio Calificado de Ingenieria de MaterialesDocumento12 pagineLaboratorio Calificado de Ingenieria de MaterialesAdriano MartinezNessuna valutazione finora

- Diagrama de Graville - SchaefflerDocumento6 pagineDiagrama de Graville - SchaefflerCarlos JavierNessuna valutazione finora

- Excavadora de Orugas - # A10996 DamperDocumento1 paginaExcavadora de Orugas - # A10996 DamperCarlos GutierrezNessuna valutazione finora

- WAX09C0317 WIZ 18S 3.2mm 504145Documento1 paginaWAX09C0317 WIZ 18S 3.2mm 504145Yeison MontañaNessuna valutazione finora

- Aleaciones-Del-Aluminio Trabajo para PresentarDocumento38 pagineAleaciones-Del-Aluminio Trabajo para PresentarJavier Nicolas Quintanilla FloresNessuna valutazione finora

- Clasificación de Los Electrodos Según La AWSDocumento5 pagineClasificación de Los Electrodos Según La AWSAlisar Atayupanqui ZarateNessuna valutazione finora

- WAX05B0204 WIZ 18S 2.4mm 504144Documento1 paginaWAX05B0204 WIZ 18S 2.4mm 504144Yeison MontañaNessuna valutazione finora

- Wax17d2721 WizDocumento1 paginaWax17d2721 Wizgracia78Nessuna valutazione finora

- Tablas CalorDocumento2 pagineTablas CalorGISELA DEAMBROGIONessuna valutazione finora

- Fleje de AluminioDocumento20 pagineFleje de AluminioSandra M. LopezNessuna valutazione finora

- WIZ 18S 4.0mm 504146Documento1 paginaWIZ 18S 4.0mm 504146Yeison MontañaNessuna valutazione finora

- Ejercicios Afino Metalurgia SecundariaDocumento2 pagineEjercicios Afino Metalurgia SecundariaCalis ThenicsNessuna valutazione finora

- Cobre PDFDocumento17 pagineCobre PDFSantiago VilaróNessuna valutazione finora

- A 000524742Documento14 pagineA 000524742PEDRONessuna valutazione finora

- Temperatura de Fusion de Metales PDFDocumento1 paginaTemperatura de Fusion de Metales PDFCarlos QF100% (2)

- To-00025 - # D9T (TWG00604) - MotDocumento1 paginaTo-00025 - # D9T (TWG00604) - MotPablo Cesar Portilla OrdoñezNessuna valutazione finora

- Aceros Grado MaquinariaDocumento11 pagineAceros Grado Maquinariaangel139Nessuna valutazione finora

- Uic 600Documento6 pagineUic 600hannibal2004685Nessuna valutazione finora

- Ecuación de Andrews Tratamientos Térmicos AC3Documento4 pagineEcuación de Andrews Tratamientos Térmicos AC3Rodrigo Alejandro García García100% (1)

- Material Practica 3Documento9 pagineMaterial Practica 3edgar lopezNessuna valutazione finora

- Tablas de Conductividad Termica - Acero-Aluminio - Transferencia de CalorDocumento3 pagineTablas de Conductividad Termica - Acero-Aluminio - Transferencia de CalorsuckerNessuna valutazione finora

- Horno de GráfitoDocumento20 pagineHorno de GráfitoJoaquín Yáñez BravoNessuna valutazione finora

- Cobre y Aleaciones de CobreDocumento33 pagineCobre y Aleaciones de CobreAnonymous pUyTGziy3L100% (1)

- Al Si 9 MN MGDocumento1 paginaAl Si 9 MN MGadrian carvajalNessuna valutazione finora

- Acero 1045 Ficha TecnicaDocumento2 pagineAcero 1045 Ficha Tecnicaa20095643Nessuna valutazione finora

- Manual Del Ingeniero Químico (Antonio Valiente, Jaime Noriega)Documento584 pagineManual Del Ingeniero Químico (Antonio Valiente, Jaime Noriega)Gerzain Carrillo100% (12)

- Aceros Ferrito PerlíticosDocumento2 pagineAceros Ferrito PerlíticosmacalupuNessuna valutazione finora

- Lab 6 ELDocumento7 pagineLab 6 ELmacalupuNessuna valutazione finora

- Resumen ICMDocumento2 pagineResumen ICMmacalupuNessuna valutazione finora

- Electronica PDFDocumento155 pagineElectronica PDFmacalupuNessuna valutazione finora

- AsimetriaDocumento48 pagineAsimetriaSandra ArciniegaNessuna valutazione finora

- Act, La Mayuscula 2023Documento2 pagineAct, La Mayuscula 2023Vilma Zeballos ZapataNessuna valutazione finora

- Arte y Cultura - Actividades - 2doDocumento4 pagineArte y Cultura - Actividades - 2doLOGAN INMORTAL SS100% (1)

- Monasterio de RipollDocumento12 pagineMonasterio de RipollAlejandro DoménechNessuna valutazione finora

- Tina Modotti y El Muralismo, Un Lenguaje ComúnDocumento15 pagineTina Modotti y El Muralismo, Un Lenguaje ComúndeimoshellraiserNessuna valutazione finora

- Presentación de Camila Aldave y Fernanda HigueraDocumento81 paginePresentación de Camila Aldave y Fernanda Higueraferchus higueraNessuna valutazione finora

- CajamarcaDocumento9 pagineCajamarcaNAJIB JADER ALANYA CONDENessuna valutazione finora

- El Lenguaje Clásico de La Arquitectura (TRABAJO DEF.)Documento5 pagineEl Lenguaje Clásico de La Arquitectura (TRABAJO DEF.)Julio Sánchez SantosNessuna valutazione finora

- 1 Ped de Cultura Material Del Mundo ClásicoDocumento8 pagine1 Ped de Cultura Material Del Mundo Clásicoantonio juaniNessuna valutazione finora

- Ensayo de Lenguaje MusicalDocumento5 pagineEnsayo de Lenguaje MusicalRomayra100% (1)

- Equipamiento Hostelero 107Documento84 pagineEquipamiento Hostelero 107Sueli SousaNessuna valutazione finora

- Periodo ArcaicoDocumento158 paginePeriodo Arcaicokelver100% (1)

- Análisis de Precios Unitarios ArquitecturaDocumento7 pagineAnálisis de Precios Unitarios ArquitecturaPaul Martinez SosaNessuna valutazione finora

- Tema 1Documento17 pagineTema 1Dani EsperillaNessuna valutazione finora

- Introduccion A La CuraduriaDocumento8 pagineIntroduccion A La CuraduriaPier TapiaNessuna valutazione finora

- Glosario de ElectivaDocumento11 pagineGlosario de ElectivaMarianNessuna valutazione finora

- Ficha 6, Manierismo PDFDocumento4 pagineFicha 6, Manierismo PDFPilar ForgueNessuna valutazione finora

- Arte Negro Prewsente en PosimpresionismoDocumento35 pagineArte Negro Prewsente en PosimpresionismoKim ArtaviaNessuna valutazione finora

- CivitDocumento5 pagineCivitsmontiverosNessuna valutazione finora

- Teora MusicalDocumento13 pagineTeora MusicalPaul Aguinaga Arancibia100% (1)

- Semana 15Documento6 pagineSemana 15Luz RiosNessuna valutazione finora

- Apuntes. Realismo y Pintura AcádemicaDocumento15 pagineApuntes. Realismo y Pintura AcádemicaFernanda Valiente BethencourtNessuna valutazione finora

- Diagrama de GanttDocumento8 pagineDiagrama de GanttAlexs Sander Mamani Quispe100% (1)

- Glosario Arte Universa1Documento8 pagineGlosario Arte Universa1Luz JoyaNessuna valutazione finora

- Características de Los Periodos HistóricosDocumento4 pagineCaracterísticas de Los Periodos Históricoszusy6030250% (2)

- Biografía de Arnoldo Ramírez AmayaDocumento2 pagineBiografía de Arnoldo Ramírez Amayasony100% (1)

- Ficha 08-III Trimestre-Artes 1 - 6 Al 17 de Junio 2022Documento6 pagineFicha 08-III Trimestre-Artes 1 - 6 Al 17 de Junio 2022Isabel PoolNessuna valutazione finora

- Pintores Claroscuristas Biografias 10 ResumidosDocumento12 paginePintores Claroscuristas Biografias 10 Resumidosgcalito20% (10)