Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Elliptical Head Design Tool

Caricato da

Sudjono BroDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Elliptical Head Design Tool

Caricato da

Sudjono BroCopyright:

Formati disponibili

1

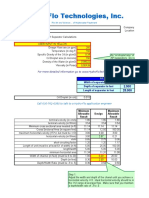

2 Pressure Vessel Engineering Ltd.

3 Finite Element Analysis ASME Code Calculations

4 Canadian Vessel Registration Vessel Modeling and Drafting

5

6 Elliptical Head Design Tool ver E4.01 Page 1 of 1

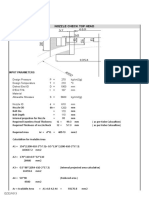

7 Elliptical Head Description

8 Dimensions:

9 24.000 Do [in] - outside diameter of head

10 0.188 tb [in] - thickness before forming

11 0.159 tf [in] - thickness after forming (note 1)

12 0.010 Corr [in] - corrosion allowance

13 2.000 Skirt [in] - straight skirt length

14 Material and Conditions:

15 SA-240 304 Material

16 20,000 S [psi] - allowable stress

17 1.00 E - head longitudinal efficiency

18 50.0 P [psi] - interior pressure

19 Calculated Properties:

20 note 1: Suggested thickness after forming Approx. head weight based on steel, lbs = 43.56

21 0.125 in Approx. head volume including skirt, cuft = 1.52

22 Variables:

23 nt [in] = tf-Corr ~~ thickness with corrosion allowance removed 0.159-0.01 = 0.149

24 D [in] = Do-2*nt ~~ ID with corrosion allowance removed 24-2*0.149 = 23.701

25 h [in] = D/4 ~~ inside crown height 23.701/4 = 5.925

26 ho [in] = h+nt 5.925+0.149 = 6.075

27 D/2h = D/(2*h) 23.701/(2*5.925) = 2.000

28 Do/2ho = Do/(2*ho) 24/(2*6.075) = 1.975

29 Ro [in]= Kzero*Do 0.889*24 = 21.334

30 Required Thickness: App. 1-4(c), UG-37(a)(1)

31 App1-4(f) = tf/(Kone*D) 0.159/(0.9*23.701) = 0.0075

32 App1-4(f)Calc = if(AND(0.0005=<App1-4(f),App1-4(f)<0.002),"Calculation Required","Calculation not required")

33 App. 1-4(f) Calculation Not Required

34 Treq [in] = (P*D*K)/(2*S*E-0.2*P)+Corr ~~ required minimum thickness

35 (50*23.701*1)/(2*20000*1-0.2*50)+0.01 = 0.040

36 CheckTreq = Treq<=tf 0.04<=0.159 = Acceptable

37 Maximum Pressure: App. 1-4(c), UG-37(a)(1)

38 Pmax [psi] = (2*S*E*nt)/(K*D+0.2*nt) ~~ maximum allowed design pressure

39 (2*20000*1*0.149)/(1*23.701+0.2*0.149) = 251.8

40 CheckPMax = Pmax >= P 251.8 >= 50 = Acceptable

41 App. 1-4(f) calculation is not included on this sheet

42 The UG-16(b) minimum thickness requirement has not been taken into consideration here.

43 Nozzles may be subject to a smaller required thickness depending on location in the head.

44 Only the knuckle required thickness is calculated on this sheet

45 Heads may be subject to stress relief if large elongation occurs - UCS-79(d), UNF-79(d), UHA-44(d)

46 Use the Weld Efficiency program to calculate E

47 This sheet cannot be used to check for allowable exterior pressure loads.

48 This sheet is for educational use only - use at your own risk.

49 Pressure Vessel Engineering Ltd.

50 120 Randall Drive, Suite B

51 Waterloo, Ontario, Canada, N2V 1C6

52 www.pveng.com (519) 880-9808

Potrebbero piacerti anche

- MD He Tema Asme v0.1Documento31 pagineMD He Tema Asme v0.1Sharon Lambert100% (1)

- 50 MT EOT Crane Specification for Magnet Fabrication BuildingDocumento24 pagine50 MT EOT Crane Specification for Magnet Fabrication BuildingSudjono BroNessuna valutazione finora

- 50 MT EOT Crane Specification for Magnet Fabrication BuildingDocumento24 pagine50 MT EOT Crane Specification for Magnet Fabrication BuildingSudjono BroNessuna valutazione finora

- Manual: Installation, Operation & MaintenanceDocumento86 pagineManual: Installation, Operation & MaintenanceNhân NgọcNessuna valutazione finora

- Horizontal Cylindrical Tank Volume and Level CalculatorDocumento5 pagineHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNessuna valutazione finora

- Memoria ASME-Pressure-Vessel-DesignDocumento143 pagineMemoria ASME-Pressure-Vessel-DesignJuan MendozaNessuna valutazione finora

- Flange Pad CalcsDocumento4 pagineFlange Pad CalcstomNessuna valutazione finora

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Documento35 pagineDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNessuna valutazione finora

- Specification For Piping MaterialDocumento49 pagineSpecification For Piping MaterialSudjono Bro100% (1)

- API SizingDocumento13 pagineAPI SizingJayesh SanganiNessuna valutazione finora

- Air Cooled ExchangerDocumento4 pagineAir Cooled Exchangermayurjannu100% (1)

- Studding Flange Calculations Gasket SelectionDocumento6 pagineStudding Flange Calculations Gasket SelectionDarshan PanchalNessuna valutazione finora

- Pressure Vessel Assessment SpreadsheetDocumento3 paginePressure Vessel Assessment SpreadsheetrawirabbatNessuna valutazione finora

- Nissan Skyline RB Engine Oil Control ModsDocumento1 paginaNissan Skyline RB Engine Oil Control Modsbyrnesvictim100% (1)

- F&D Head Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaF&D Head Design Tool: Pressure Vessel Engineering LTDMauricio KookcNessuna valutazione finora

- Calculation of Heat and Mass BalanceDocumento16 pagineCalculation of Heat and Mass BalanceHEMANTNessuna valutazione finora

- Electroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneDocumento48 pagineElectroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneShweta KateNessuna valutazione finora

- Weir Plate or Baffle Plate CalculationDocumento2 pagineWeir Plate or Baffle Plate CalculationamaNessuna valutazione finora

- Somatic Psychology Linda Hartley Review PDFDocumento8 pagineSomatic Psychology Linda Hartley Review PDFAndres SanabriaNessuna valutazione finora

- Tank Volume CalculationDocumento9 pagineTank Volume CalculationMangesh MandgeNessuna valutazione finora

- Exercise 1 and 2 - Revised2Documento5 pagineExercise 1 and 2 - Revised2Vivekka Olivia JohnNessuna valutazione finora

- Specification For Painting & CoatingDocumento19 pagineSpecification For Painting & CoatingSudjono BroNessuna valutazione finora

- Tank CalculationDocumento3 pagineTank CalculationSudjono BroNessuna valutazione finora

- Specification For Sea Water Lift PumpsDocumento20 pagineSpecification For Sea Water Lift PumpsSudjono BroNessuna valutazione finora

- Nozzle and ReinforcementDocumento23 pagineNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Astm D 2113-14Documento20 pagineAstm D 2113-14aswathy annie vargheseNessuna valutazione finora

- Design Procedure For Aes He PDFDocumento30 pagineDesign Procedure For Aes He PDFRyan Goh Chuang HongNessuna valutazione finora

- Studding Outlet Calculation - PV Elite 2016Documento8 pagineStudding Outlet Calculation - PV Elite 2016Liu YangtzeNessuna valutazione finora

- Nozzle Check Top Head: Input ParametersDocumento2 pagineNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocumento1 paginaK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNessuna valutazione finora

- Chartering Terms ExplainedDocumento49 pagineChartering Terms Explainedbrett1856Nessuna valutazione finora

- Half Coil For VersselDocumento1 paginaHalf Coil For VersselhuangjlNessuna valutazione finora

- Heat Exchanger DesignDocumento7 pagineHeat Exchanger Designsiva sankarNessuna valutazione finora

- Piping Material IdentificationDocumento21 paginePiping Material IdentificationSudjono BroNessuna valutazione finora

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocumento10 pagineFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNessuna valutazione finora

- Skirt Support Analysis Per en 13445Documento13 pagineSkirt Support Analysis Per en 13445karthik1amarNessuna valutazione finora

- Flat HeadsDocumento11 pagineFlat HeadsToniNessuna valutazione finora

- Aes DesignDocumento97 pagineAes DesigndineshsirasatNessuna valutazione finora

- Design Calculations For Pressure ShellDocumento33 pagineDesign Calculations For Pressure ShellGeorge GeorgianNessuna valutazione finora

- Asme Sec 8 Div 1 - App 1-10Documento11 pagineAsme Sec 8 Div 1 - App 1-10BibinBabuNessuna valutazione finora

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocumento2 pagineDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Nessuna valutazione finora

- 8KL FERMENTER DESIGN CALCULATIONSDocumento3 pagine8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryNessuna valutazione finora

- Dish End Weight CalculationDocumento5 pagineDish End Weight CalculationAniket royNessuna valutazione finora

- Buffer Vessel Data SheetDocumento4 pagineBuffer Vessel Data SheetUmair A. KhanNessuna valutazione finora

- Superheated Steam Condensate TankDocumento4 pagineSuperheated Steam Condensate TankGanesh BhardwajNessuna valutazione finora

- Burner specification document summaryDocumento6 pagineBurner specification document summaryHafiz Muhammad AbubakarNessuna valutazione finora

- Base Ring Fillet Size CalculationDocumento4 pagineBase Ring Fillet Size Calculationmiteshpatel191Nessuna valutazione finora

- Pipe Shell Design ToolDocumento1 paginaPipe Shell Design Toolep_alfiNessuna valutazione finora

- Vessel Weight CheckDocumento8 pagineVessel Weight ChecknileshNessuna valutazione finora

- Master CalculationsDocumento37 pagineMaster Calculationsb89502164Nessuna valutazione finora

- TD HE THE v2020.00Documento43 pagineTD HE THE v2020.00Claudia BonocoreNessuna valutazione finora

- Plastics as a Building Material GuideDocumento24 paginePlastics as a Building Material GuideVinod Nair100% (1)

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocumento30 pagineJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Volume Calculation For Pressure Vessel TankDocumento2 pagineVolume Calculation For Pressure Vessel Tanksai srikarNessuna valutazione finora

- Vdocuments - MX Rectangular Tank CalculationDocumento34 pagineVdocuments - MX Rectangular Tank CalculationAtilla TekinNessuna valutazione finora

- TubesheetDocumento8 pagineTubesheetVaibhavNessuna valutazione finora

- Tailing LugDocumento2 pagineTailing Lugjagannadha varmaNessuna valutazione finora

- Cone Development CalcDocumento2 pagineCone Development CalcbabuNessuna valutazione finora

- First Periodical Mapeh 9Documento5 pagineFirst Periodical Mapeh 9Juvy Singian100% (1)

- Cone Development CalculationsDocumento5 pagineCone Development CalculationssaudimanNessuna valutazione finora

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocumento53 pagineA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNessuna valutazione finora

- Tank Insulation CalculatorDocumento6 pagineTank Insulation CalculatorArvieRagasaNessuna valutazione finora

- Davit With ElbowDocumento2 pagineDavit With Elbownitin400Nessuna valutazione finora

- Ligament Efficiency and Thickness of The Support PlateDocumento10 pagineLigament Efficiency and Thickness of The Support PlatePankajDhobleNessuna valutazione finora

- Shears Cysts of The Oral and Maxillofacial Regions, 5th Edition (Paul Speight)Documento382 pagineShears Cysts of The Oral and Maxillofacial Regions, 5th Edition (Paul Speight)Miriam Tovar OgazonNessuna valutazione finora

- Calculation Sheet: Design CodeDocumento1 paginaCalculation Sheet: Design CodeCak AndiNessuna valutazione finora

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocumento1 paginaElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNessuna valutazione finora

- U-V-673 - Manual Flange and GussetDocumento8 pagineU-V-673 - Manual Flange and GussetDarshan PanchalNessuna valutazione finora

- Abus Overhead Cranes InfoDocumento12 pagineAbus Overhead Cranes Infoamachmouchi100% (1)

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Documento42 pagine8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Specification For Air Compressors and Air Dryer PackagesDocumento21 pagineSpecification For Air Compressors and Air Dryer PackagesSudjono BroNessuna valutazione finora

- Sea Water Data SheetDocumento17 pagineSea Water Data SheetSudjono BroNessuna valutazione finora

- Half Pipe Coil AgitatedDocumento1 paginaHalf Pipe Coil AgitatedNITINNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolssierroNessuna valutazione finora

- CalBOM - Formed ConicalDocumento5 pagineCalBOM - Formed ConicalRey FiedacanNessuna valutazione finora

- IBR - 1950 - Reg. 366Documento2 pagineIBR - 1950 - Reg. 366Vijay ParmarNessuna valutazione finora

- 7 PDFDocumento26 pagine7 PDFargaNessuna valutazione finora

- PDS Air CompressorDocumento1 paginaPDS Air Compressordhavalesh1Nessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolSudjono BroNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design Toolbai tap hoa vo coNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design Toolnaveen_86Nessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolJaveed KhanNessuna valutazione finora

- 300 - F&D Head Design Tool Ver E4.01Documento1 pagina300 - F&D Head Design Tool Ver E4.01Mo ZeroNessuna valutazione finora

- SikaDocumento8 pagineSikaPrakashNessuna valutazione finora

- Nominal Dimensions, Mass and Sectional Properties of Hot Rolled Equal Leg AnglesDocumento1 paginaNominal Dimensions, Mass and Sectional Properties of Hot Rolled Equal Leg AnglesVeeru RamisettyNessuna valutazione finora

- Tech WipoDocumento5.375 pagineTech Wipohoàng đình sơnNessuna valutazione finora

- Resd Load CalcDocumento5 pagineResd Load CalcOre Ulil DesuNessuna valutazione finora

- BCA Energy Performance Points CalculatorDocumento95 pagineBCA Energy Performance Points CalculatorCik BedahNessuna valutazione finora

- Offshore Soil Boring Log for Banggai Ammonia PlantDocumento8 pagineOffshore Soil Boring Log for Banggai Ammonia PlantSudjono BroNessuna valutazione finora

- Water Filter Expectancy CalculatorDocumento4 pagineWater Filter Expectancy CalculatorSudjono BroNessuna valutazione finora

- High Performance Steel Properties and ApplicationsDocumento38 pagineHigh Performance Steel Properties and ApplicationsigormetaldataNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolSudjono BroNessuna valutazione finora

- Conveyor Design Draft PDFDocumento42 pagineConveyor Design Draft PDFxuanben209Nessuna valutazione finora

- 1 - Silo Zeppelin PDFDocumento46 pagine1 - Silo Zeppelin PDFSudjono BroNessuna valutazione finora

- Emulsion Breaker Injection Pump Package Datasheet PDFDocumento1 paginaEmulsion Breaker Injection Pump Package Datasheet PDFSudjono BroNessuna valutazione finora

- High Performance Steel Properties and ApplicationsDocumento38 pagineHigh Performance Steel Properties and ApplicationsigormetaldataNessuna valutazione finora

- High Performance Steel Properties and ApplicationsDocumento38 pagineHigh Performance Steel Properties and ApplicationsigormetaldataNessuna valutazione finora

- Error Code Captiva P700Documento4 pagineError Code Captiva P700Sudjono BroNessuna valutazione finora

- Wipp RH Psar DOE/WIPP-03-3174: January 22, 2003Documento36 pagineWipp RH Psar DOE/WIPP-03-3174: January 22, 2003Sudjono BroNessuna valutazione finora

- PDF If I Break 15 Portia Moore CompressDocumento61 paginePDF If I Break 15 Portia Moore CompressAlbenis RodríguezNessuna valutazione finora

- Central Sterile ServiceDocumento75 pagineCentral Sterile ServiceSUBHENDU SIKDAR100% (1)

- A New Empirical System For Rock Slope Stability Analysis PDFDocumento10 pagineA New Empirical System For Rock Slope Stability Analysis PDFJessie LeeNessuna valutazione finora

- Ceng3181-Transport Engineering: Haramaya Institute of Technology Department of Civil EngineeringDocumento31 pagineCeng3181-Transport Engineering: Haramaya Institute of Technology Department of Civil EngineeringMuaz HararNessuna valutazione finora

- Mitsubishi: Technical Service BulletinDocumento11 pagineMitsubishi: Technical Service BulletinKonstantinNessuna valutazione finora

- Bharat Heavy Electricals LimitedDocumento19 pagineBharat Heavy Electricals LimitedChandreshDharDubeyNessuna valutazione finora

- Silo Surface Area CalculationDocumento3 pagineSilo Surface Area CalculationVIC EngineersNessuna valutazione finora

- Divine Mercy Sunday 2014Documento2 pagineDivine Mercy Sunday 2014Ssekabira DavidNessuna valutazione finora

- MCA-12 Web DesigningDocumento204 pagineMCA-12 Web DesigningLittaNessuna valutazione finora

- Heat Transfer Through Extended SurfacesDocumento16 pagineHeat Transfer Through Extended SurfaceschawarepNessuna valutazione finora

- The Box Above Contains Words That Pertain To The Computer or The Computer Itself. Below Are The Operational Definitions of The WordsDocumento4 pagineThe Box Above Contains Words That Pertain To The Computer or The Computer Itself. Below Are The Operational Definitions of The WordsMarkie Dela CruzNessuna valutazione finora

- Columbus United Methodist Church: in This IssueDocumento11 pagineColumbus United Methodist Church: in This IssueColumbusUMCNessuna valutazione finora

- Single Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDocumento30 pagineSingle Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDeepak GuptaNessuna valutazione finora

- K.P.Mondal & Sons: Quality Assurance PlanDocumento1 paginaK.P.Mondal & Sons: Quality Assurance PlanTanmoy DuttaNessuna valutazione finora

- 51-11-15-001-Data Recording of Allowable Damage and Repairs-A320Documento6 pagine51-11-15-001-Data Recording of Allowable Damage and Repairs-A320FredNessuna valutazione finora

- Air Preparation Products: Parker Pneumatic Section EDocumento11 pagineAir Preparation Products: Parker Pneumatic Section EPartsGopher.comNessuna valutazione finora

- PID and Feedback Compensation Design for Control SystemsDocumento32 paginePID and Feedback Compensation Design for Control SystemsNikhil PanikkarNessuna valutazione finora

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocumento10 pagineSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingBradyNessuna valutazione finora

- Modeling Relationships in Scatter PlotsDocumento45 pagineModeling Relationships in Scatter PlotsSiddarth Kalyan100% (1)