Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

07

Caricato da

mohammedalathwaryCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

07

Caricato da

mohammedalathwaryCopyright:

Formati disponibili

FRENIC-Lift Series Inverters

for Elevating Machinery

Tetsuya Nomura

Hiroaki Kato

1. Introduction Fig.1 External view of FRENIC-Lift series

In elevator industry, system is transitioning from

geared elevators that use standard induction motors to

gearless elevators that use synchronous motors. Gear-

less elevators has already got the majority of new

construction starts in Japan, and demand for their use

is also increasing in rapidly growing markets in China

and Europe. Inverters that drive gearless elevators

are required to be small, thin, to have high overload Multi-function keypad

capacity, and to deliver high performance and high (option)

functionality.

In consideration of these circumstances, Fuji Elec-

tric has newly developed FRENIC-Lift series inverters

designed specifically for elevator machinery. This

paper introduces the features of FRENIC-Lift series.

2. FRENIC-Lift Specifications and Features

Fig.2 Speed vs. torque characteristics (at low speed)

FRENIC-Lift series was developed to provide pow-

erful and high-performance inverters as well as easy-

to-use. Input voltage is 3-phase 400 V, and output 7.5 r/min 7.5 r/min

capacity ranges from 5.5 to 22 kW. Figure 1 shows

external appearance of 11 kW model. Functionality is Maximum

enhanced with the provision of many custom functions torque increases

for elevator machinery, including the well-established Speed ripple

decreases

vector control with speed sensor.

Torque (%)

Torque (%)

2.1 Hardware configuration for powerful and optimized

elevator machinery

2.1.1 High overload capacity

Since maximum torque is needed during accelera-

tion and deceleration for elevator-related applications, Motor speed

an ample overload capability is important. Moreover, (r/min)

Motor speed

required load inertia (at the motor shaft) of recently (r/min)

popularized gearless elevator is larger than that of

geared elevator, and a larger torque is needed during FRENIC5000G11UD FRENIC-Lift

acceleration and deceleration.

With FRENIC-Lift, specified thermal design based

on operating pattern of elevator and lower generated load capacity of previous model (FRENIC5000G11UD).

loss due to the use of next-generation insulated gate Consequently, FRENIC-Lift series is well suited

bipolar transistor (IGBT) chip enabled the realization for applications for which prior models could not be

of 200 % – 10 s overload capacity. This value is used due to their limited overload capacity such as

significant improvement from the 150 % – 10 s over- relatively high-speed elevators and gearless elevators

FRENIC-Lift Series Inverters for Elevating Machinery 33

Fig.3 Control block diagram

FRENIC-Lift Flux pattern generator Y Synchronous motor

0

Analog N Mechanical

speed ø /I brake

command Automatic

current PWM

Ramp controller

regulator inverter M

Automatic

Speed speed Vibration (ACR)

+

Multi-step command regulator suppression τ /I

speed selector (ASR) + observer PG

command

Imbalanced + Y

Current

load

limiter

0

compensator + Slip N +

Internal monitor

compensator +

Synchronous motor

CAN Speed detector

communication

bus Torque bias

selector

2F

1F

User controller

Load detection signal

having large load inertia (at the motor shaft). Fig.4 Speed response characteristics

Figure 2 shows speed vs. torque characteristics at

low speed. Compared to FRENIC5000G11UD, it can 10

be seen that FRENIC-Lift has larger torque and lower

speed ripple, and is thereby capable of powerful and 0

Gain (dB)

stable operation. - 3 dB

2.1.2 Internal encoder interface and braking circuit FRENIC-Lift

-10

Encoder interface and braking circuit are provided

FRENIC5000G11UD

as standard equipment. As a result, it is attachable to

-20

the small space compared with previous models. 10 100 1,000

2.1.3 Safety function Frequency (Hz)

Safety function is provided whereby, regardless of

operating state, when dedicated control input (EN

terminal) is turned OFF, inverter output is cutoff Fig.5 Car vibration (vertical)

immediately and motor drive is stopped reliably. The

process by which drive output is cutoff in response to 0.1

Elevator conditions: 1.75 m/s, 1000 kg

Vertical acceleration (m/s2)

this function is implemented by hardware, which

0.10 m/s2 no load, traveling downward

operates much faster than software processing. Addi- 0.05

tionally, since output cutoff circuit is equipped with

functions for stopping the motor drive reliably even in 0

the case of partial malfunction and for delivering

information outside about the malfunction, it realized - 0.05

enhanced safety feature.

- 0.1

0 5 10 15 20 25

2.2 High-level control performance Time (s)

2.2.1 Greater riding comfort by improved control

response

With FRENIC-Lift, control response has been 2.2.2 Reduced rollback when brake is released

improved significantly with use of higher-speed auto- Unless elevator provides torque compensation in

matic current regulator (ACR). Figure 3 shows a block response to load imbalance between weight of car (with

diagram of FRENIC-Lift control system, and Fig. 4 load) and counterweight, rollback will occur when

shows speed response characteristics of FRENIC-Lift mechanical brake is released.

and the FRENIC5000G11UD. Typically, a signal from load detector attached to

With improved control response of FRENIC-Lift, elevator car has been used to calculate necessary

elevator car vibration (vertical) has been reduced amount of torque to inverter so as to reduce the

compared to previous models, and a vibration charac- occurrence of rollback when the mechanical brake is

teristic less than 0.10 m /s2 (p-p) was achieved in actual released. FRENIC-Lift, however, is equipped with

gearless elevator (See Fig. 5). imbalanced load compensator to calculate and provide

34 Vol. 52 No. 1 FUJI ELECTRIC REVIEW

Fig.6 Reduced rollback when mechanical brake is release Fig.7 Torque characteristics during battery operation

25 r/min

Motor speed

(42 r/min/div)

Torque (%)

Torque current

Motor speed (r/min)

(50 % /div)

Motor acceleration

(0.875 m /s2 /div)

Less mechanical shock at startup

Motor current

(45.3 A /div)

1 s/div

Elevator conditions : 1.75 m /s, 1,000 kg, FRENIC-Lift 48 V DC

Uncompensated Compensated

rated load, traveling upward

2.3.2 Optimization of operating cycle

necessary amount of torque compensation. Generally, just prior to landing elevator (the car is

Figure 6 shows characteristic data of imbalanced approaching loading position), it travels at a low-speed

load compensator. Data on the left is “uncompensated” known as creep speed to reach the landing position

and data on the right is “compensated.” The phenome- accurately. However, FRENIC-Lift is equipped with

non of rollback when mechanical brake is released can creepless operation function that operates when the

be checked with vibration of motor acceleration. Com- elevator is landing. When receives a positioning signal

pensated data shows no fluctuation in motor accelera- as an external command, this creepless operation

tion, and it can be seen that the imbalanced load function generates speed command pattern to move

compensator mitigates the phenomenon of rollback. the elevator from that time to just the specified

Because load detector is unnecessary with this distance, and then to stop the elevator. Therefor it can

function, elevator system can be simplified and reduce eliminate the need for creep speed operation.

its cost. When renewing an elevator, for example, This function enables optimized operating cycle of

imbalanced load compensator is very effective to an elevator.

realize smooth operation even in elevators not 2.3.3 Battery operation characteristics

equipped with load detector. Figure 7 shows speed vs. torque characteristics

2.2.3 Application for gearless elevators (option) during battery operation. The battery voltage is 48 V

For synchronous motors, an optional interface is DC. When in the braking mode, even during battery

available that supports “EnDat 2.1 serial interface operation, stable operation with at least 200 % torque

encoder” and “4-bit gray code and U V W 3-bit code is possible.

parallel interface encoders,” which are used often in Additionally, during battery operation, an uninter-

elevator industry. Additionally, offset tuning function ruptible power supply (UPS) or the like may be used as

of magnetic pole position is also provided to adjust the an auxiliary power input to inverter control circuit.

magnet pole position offset values automatically. Since UPS output voltage matches the voltage of the

As a result, set-up work for gearless elevator is power distribution system, it often differs from the

simplified. voltage at the motor power inputs (3-phase power

supply). For example, in the case where 3-phase power

2.3 Functions suited for elevator applications supply is 380 V and the power distribution system

2.3.1 Standard CAN bus interface voltage is single-phase 220 V, a voltage drop of more

Controller area network (CAN) bus is a highly than 40 % will occur at time of changeover to the UPS.

reliable network having a track record of many Fuji Electric’s general-purpose inverters only guaran-

successful applications. Moreover, due to low protocol tee proper operation for up to 15 % drop in power

overhead and high-speed communication capability of supply voltage. However with FRENIC-Lift, design of

CAN bus, high-speed response can be achieved that is the DC-DC converter load has been optimized to

approximately 10 times RS-485 communication perfor- guarantee proper operation during this type of wide

mance used in conventional general-purpose inverter. voltage variation. By reducing DC-DC converter load

Because CAN bus is provided as standard inter- during battery-powered operation, 400 V series invert-

face, inverter control can be realized via communica- er can allow 200 V control power input during a power

tion lines, and as a result, less wiring is possible. failure.

FRENIC-Lift Series Inverters for Elevating Machinery 35

Fig.8 Trace function tively severe environments such as inside an elevator

control console, machine room, or the like, a dust-

Historical trace

protecting fan is used to improve the capability of the

inverter against such environments.

2.4.3 Other functions

An elevator control system consists of user control-

ler, inverter and peripheral circuitry. FRENIC-Lift

series is system-oriented, and is equipped with many

convenient functions.

One of such function is providing door open-close

control signal. This signal equipped on inverter side

make it easy to control the elevator door when the

elevator has landed.

Another convenient function is selection of positive

or negative logic for each I / O signal. The decision of

whether each signal is normal ON, or abnormal ON,

depends on the type of control signal and the system

2.4 Ease of use design. With FRENIC-Lift, all I / O signal active logic

2.4.1 Trace function can be switched easily with the parameter settings.

Windows*1-compatible FRENIC loader enables

trace function that is capable of monitoring such 3. Future Outlook

waveforms as inverter’s internal reference speed and

reference torque, etc. 3.1 Global standard conformance

Trace function allows for real-time traces, which Fuji Electric intends to conform with EC directive

display the current state as a continuous waveform, (CE mark) required in the European markets, and the

and historical traces, which display waveforms before UL standards and cUL certification required in the

and after when trigger conditions are met (See Fig. 8). North American markets. Furthermore, although

Because this function allows parameters to be inverters are presently exempt, in consideration of the

adjusted during test runs, maintenance, waveform growing sense of environmental awareness in the

monitoring, and the like, operation efficiency is im- market, Fuji Electric is also making preparations to

proved and set-up time is reduced. facilitate conformance with RoHS directive*2.

2.4.2 Environment-friendly functions

Since elevators are public facility, the level of 3.2 Product series expansion

acoustic noise emitted from an inverter’s cooling fan In the future, Fuji Electric plans to develop a

when elevator is stopped, may be undesired in some large-capacity 400 V series and a 200 V series.

cases. With FRENIC-Lift, the conventional cooling fan

control has been improved such that, as long as the 4. Conclusion

inverter’s heat sink temperature does not rise, the

cooling fan will not operate. As a result, not only Features of FRENIC-Lift series inverters for eleva-

reduction of acoustic noise from the cooling fan, but tor machinery have been presented. Fuji Electric

also extension of service life of cooling fan is per- intends to continue to develop inverters that meet the

formed. needs of the market and to incorporate insights from

Additionally, since inverters are installed in rela- end users to create even better products in the future.

*1: Windows is a registered trademark of Microsoft Corp. in *2: RoHS directive is restriction on the use of certain

the US and other countries. hazardous substances in electric and electronic devices.

36 Vol. 52 No. 1 FUJI ELECTRIC REVIEW

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Easytronic Micro II (2012 Revision15) ControllerDocumento11 pagineEasytronic Micro II (2012 Revision15) Controllermohammedalathwary56% (9)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Industrial-Data-Communications (pg22) PDFDocumento285 pagineIndustrial-Data-Communications (pg22) PDFBruno Martins100% (2)

- GDKDocumento30 pagineGDKRobert Aguilar100% (4)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- GBA 26800 H IV OVF 20 Service - ToolDocumento31 pagineGBA 26800 H IV OVF 20 Service - ToolPeter80% (15)

- NICE3000 Synchronous Motor Adjusting Manual - PDF - PDFDocumento29 pagineNICE3000 Synchronous Motor Adjusting Manual - PDF - PDFJouny Wael100% (4)

- NICE3000 Synchronous Motor Adjusting Manual - PDF - PDFDocumento29 pagineNICE3000 Synchronous Motor Adjusting Manual - PDF - PDFJouny Wael100% (4)

- Smart Home Automation Using AndroidDocumento8 pagineSmart Home Automation Using Androidultimatekp144100% (1)

- Break SpecificationsDocumento1 paginaBreak SpecificationsmohammedalathwaryNessuna valutazione finora

- Page0023 PDFDocumento1 paginaPage0023 PDFmohammedalathwaryNessuna valutazione finora

- Chapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnDocumento1 paginaChapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnmohammedalathwaryNessuna valutazione finora

- Break Reless Chapter 1 IntroDocumento1 paginaBreak Reless Chapter 1 IntromohammedalathwaryNessuna valutazione finora

- OTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncDocumento10 pagineOTIS 506, 506SL, 510 UNITS: Precision Escalator Products, IncmohammedalathwaryNessuna valutazione finora

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDocumento7 pagineTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMaicol Rodolfo CaizaNessuna valutazione finora

- Sky301-V3 User ManualDocumento16 pagineSky301-V3 User Manualمحمدحماد100% (1)

- EWD-RL-J2 Elevator Weighing Device Introdtion Manual (V2.0) : DeclarationDocumento12 pagineEWD-RL-J2 Elevator Weighing Device Introdtion Manual (V2.0) : Declarationmohammedalathwary100% (4)

- Sec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186Documento1 paginaSec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186mohammedalathwaryNessuna valutazione finora

- VanderGraaf INSTALL-MANUAL PDFDocumento18 pagineVanderGraaf INSTALL-MANUAL PDFJonathan Omar Martinez HernandezNessuna valutazione finora

- Electronics Prom Programmer Series Ii User Manual MODELS 160 170 180 200Documento31 pagineElectronics Prom Programmer Series Ii User Manual MODELS 160 170 180 200mohammedalathwaryNessuna valutazione finora

- Sec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186Documento1 paginaSec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186mohammedalathwaryNessuna valutazione finora

- P Ja 51687 Av TF32 VDDocumento3 pagineP Ja 51687 Av TF32 VDrabreyNessuna valutazione finora

- De DP016Documento14 pagineDe DP016mohammedalathwaryNessuna valutazione finora

- Alhamdany Hospital: Partner Asansör FormDocumento1 paginaAlhamdany Hospital: Partner Asansör FormmohammedalathwaryNessuna valutazione finora

- HGL10 Operation Service ManualDocumento49 pagineHGL10 Operation Service ManualmohammedalathwaryNessuna valutazione finora

- Car Operating Panels & Landing Push Stations: Lift ComponetsDocumento1 paginaCar Operating Panels & Landing Push Stations: Lift ComponetsmohammedalathwaryNessuna valutazione finora

- Warnings: Device Usage and Operation SequenceDocumento9 pagineWarnings: Device Usage and Operation Sequencemohammedalathwary100% (1)

- Icsoftware Instructions Procedure Brief1.Get Into The Software 2.add Elevator Data 3.switch Card 4.write Owner CardDocumento5 pagineIcsoftware Instructions Procedure Brief1.Get Into The Software 2.add Elevator Data 3.switch Card 4.write Owner CardmohammedalathwaryNessuna valutazione finora

- SJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9Documento16 pagineSJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9mohammedalathwary100% (2)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Documento7 pagine标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Documento7 pagine标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- Manual For EncoderDocumento2 pagineManual For EncodermohammedalathwaryNessuna valutazione finora

- Emcp II Sensor CheckDocumento14 pagineEmcp II Sensor CheckAbdul Khaliq100% (1)

- Electrical QuestionsDocumento6 pagineElectrical QuestionsarupNessuna valutazione finora

- 2014-02 TestingCathodicProtectionSystems Slides 508Documento49 pagine2014-02 TestingCathodicProtectionSystems Slides 508shejin R.SNessuna valutazione finora

- Adoc - Pub SMP Kelas 9 Fisika Bab 2 Rangkaian Listrik Dan SumDocumento37 pagineAdoc - Pub SMP Kelas 9 Fisika Bab 2 Rangkaian Listrik Dan Sumno replayNessuna valutazione finora

- PLCYC1Documento4 paginePLCYC1skitz104Nessuna valutazione finora

- A Presentation On-: E-Paper TechnologyDocumento19 pagineA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruNessuna valutazione finora

- Service Manual: Serving The Physician Since 1937Documento72 pagineService Manual: Serving The Physician Since 1937JiThiN vPNessuna valutazione finora

- Design and Implementation of I2C Bus Protocol On Fpga Using Verilog For EepromDocumento5 pagineDesign and Implementation of I2C Bus Protocol On Fpga Using Verilog For EepromRohail AhmedNessuna valutazione finora

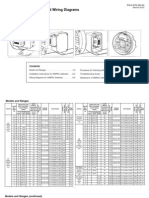

- Installation Instructions and Wiring Diagrams For All Models and RangesDocumento8 pagineInstallation Instructions and Wiring Diagrams For All Models and RangesMaria MusyNessuna valutazione finora

- Instrukcja Obslugi MODECOM Volcano Amirani ARGBDocumento2 pagineInstrukcja Obslugi MODECOM Volcano Amirani ARGBKarol KotekNessuna valutazione finora

- Manual Partes Millermatic 350Documento43 pagineManual Partes Millermatic 350Miguel Angel Pavon CarbonellNessuna valutazione finora

- Electronic Symbol - WikipediaDocumento11 pagineElectronic Symbol - WikipediaLevy Faria GiembinskyNessuna valutazione finora

- Equinox Lipo Cell Balancer-ManualDocumento6 pagineEquinox Lipo Cell Balancer-ManualKin TiriyasNessuna valutazione finora

- Ra-1900 Ii2 Qi 1-0-0Documento41 pagineRa-1900 Ii2 Qi 1-0-0Gustavo BessoneNessuna valutazione finora

- General Physics 2 ReviewerDocumento21 pagineGeneral Physics 2 ReviewervaljeanphantomNessuna valutazione finora

- Swimming Pool Lighting DesignDocumento2 pagineSwimming Pool Lighting DesignquletjavierNessuna valutazione finora

- CHAPTER VII Direct Current CircuitsDocumento28 pagineCHAPTER VII Direct Current CircuitsNandya GuvitaNessuna valutazione finora

- Delta Elevator Drive VFD-ED Series User ManualDocumento228 pagineDelta Elevator Drive VFD-ED Series User ManualMohammed HussenNessuna valutazione finora

- Universal Receiver: Wireless AccelerometerDocumento2 pagineUniversal Receiver: Wireless AccelerometerMarco SotoNessuna valutazione finora

- PHY-101 - Applied OpticsDocumento2 paginePHY-101 - Applied Opticspriyanshi mishraNessuna valutazione finora

- Camara Vivotek PZ7111Documento12 pagineCamara Vivotek PZ7111TecnoSmartNessuna valutazione finora

- Cbse 12th 2019 Physics Answer Key Solution 55 2 1 by Govt PDFDocumento21 pagineCbse 12th 2019 Physics Answer Key Solution 55 2 1 by Govt PDFbhabesh acharyaNessuna valutazione finora

- Physics 5054 P2 Complete Electricity Topical Past Paper (Only Questions)Documento183 paginePhysics 5054 P2 Complete Electricity Topical Past Paper (Only Questions)Manthan ChakrabortyNessuna valutazione finora

- Bizhub C652 C552 Theory of OperationDocumento400 pagineBizhub C652 C552 Theory of Operationtesla500Nessuna valutazione finora

- September 04 2022 NEET UG Re Exam Combined Solution Code W6 1Documento46 pagineSeptember 04 2022 NEET UG Re Exam Combined Solution Code W6 1Bishal ChowdhuryNessuna valutazione finora

- CSIO-PS1 ReportDocumento14 pagineCSIO-PS1 ReportRajan WaliyaNessuna valutazione finora

- Site MapDocumento1 paginaSite MapDavid MucollariNessuna valutazione finora

- Checking Data, I-CANDocumento3 pagineChecking Data, I-CANWaldek KozlowskiNessuna valutazione finora

- Virtual-Circuit Networks: Frame Relay and ATMDocumento24 pagineVirtual-Circuit Networks: Frame Relay and ATMdil_18100% (1)