Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Especificacion de Tubería

Caricato da

Cheko OoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Especificacion de Tubería

Caricato da

Cheko OoCopyright:

Formati disponibili

Piping Specification

Chilled and Cooling Water - Closed Systems

insulation

thickness

(closed

porous, insulation thickness

nominal outer nominal where (mineral fibre,

diameter diameter wall thickness pressure applicable) where applicable)

DN mm mm bar mm mm

6 10,2 2,00* 16 19 30

8 13,5 2,30* 16 19 30

10 17,2 2,30* 16 19 30

15 21,3 2,60* 16 19 30

20 26,9 2,60* 16 19 30

25 33,7 3,20* 16 19 30

32 42,4 3,20* 16 19 40

40 48,3 3,20* 16 19 40

50 60,3 3,60* 16 19 40

65 76,1 2,90 16 22 40

80 88,9 3,20 16 22 60

100 114,3 3,60 16 22 60

125 139,7 4,00 16 22 80

150 168,3 4,50 16 22 80

200 219,1 6,30 16 25 100

250 273,0 6,30 16 25 100

300 323,9 7,10 16 25 120

350 355,6 8,00 16 25 120

*=wall thickness suitable for threads

dimensions acc. DIN EN 10220

Piping: BLK seamless or welded

material: P235 (St 37.0) acc. EN 10216-1 or EN 10217-1

Flanges: according EN 1092-1

type 11 (welding neck flange)

form B (raised face)

PN 16

material: steel (black)

no rubber gaskets

Painting:

primer : anti corrosion paint

top coat: green RAL 6032 (only at non-insulated pipes)

Insulation:

cooling water pipes: no insulation

chilled water pipes: flexible foamed material (closed porous), e.g. ARMAFLEX,

NB: insulation thickness can be reduced acc. actual dew point

pipes between heating/cooling units and production line:

mineral fibre with metal sheet covering

Color identification rings:

chilled water pipes: white

Pipe code: WCS/WCR, WPS/WPR

Piping Specification 1/12 document no. 381200 - Rev.03

Piping Specification

Treated Water Systems and Open Cooling Water Systems

insulation

thickness

(closed

porous,

nominal outer nominal where

diameter diameter wall thickness pressure applicable)

DN mm mm bar mm

6 10,2 2,00* 10 19

8 13,5 2,30* 10 19

10 17,2 2,30* 10 19

15 21,3 2,60* 10 19

20 26,9 2,60* 10 19

25 33,7 3,20* 10 19

32 42,4 1,60 10 19

40 48,3 1,60 10 19

50 60,3 1,60 10 19

65 76,1 2,00 10 22

80 88,9 2,00 10 22

100 114,3 2,00 10 22

125 139,7 2,00 10 22

150 168,3 2,00 10 22

200 219,1 2,60 10 25

250 273,0 2,60 10 25

300 323,9 3,20 10 25

350 355,6 3,20 10 25

400 406,4 3,20 10 25

450 457,0 3,60 10 25

*=wall thickness suitable for threads

dimensions acc. EN ISO 1127

Piping: SST seamless or welded

material: stainless steel TP304L (1.4301)) acc. EN 10216-5 or EN 10217-7

Flanges: according EN 1092-4

type 02 (loose flange) with type 33 (unturned welding flange)

PN 10

material: aluminium

no rubber gaskets

Insulation:

tower water (WTS-WTR): no insulation

treated water (W): no insulation

pipes for waterbath flexible foamed material (closed porous),

(open system) e.g. ARMAFLEX

Color identification rings:

tower water: green RAL6032

treated water: green RAL6032 + white

Pipe code: W treated water

WTS/WTR open cooling water systems

Piping Specification 2/12 document no. 381200 - Rev.03

Piping Specification

Steam, Condensate and Hot Water Systems

nominal outer nominal insulation

diameter diameter wall thickness pressure thickness

DN mm mm bar mm

15 21,3 2,00 40 40

20 26,9 2,30 40 40

25 33,7 2,60 40 40

32 42,4 2,60 40 50

40 48,3 2,60 40 50

50 60,3 2,90 40 60

65 76,1 2,90 40 60

80 88,9 3,20 40 80

100 114,3 3,60 40 80

125 139,7 4,00 40 100

150 168,3 4,50 40 100

200 219,1 6,30 40 120

250 273,0 6,30 40 140

dimensions acc. DIN EN 10220

Piping: BLK seamless

material: P235GH (1.0345, St 35.8) acc. EN 10216-2 or EN 10217-2

certificate 3.1B acc. EN 10204 or similar

acc. local regulations for steam piping

actual steam /hot water pressure and

temperature has to be considered!

Flanges: according EN 1092-1

type 11 (welding neck flange)

form B (raised face)

actual steam /hot water pressure and

temperature has to be considered!

material: 245GH (1.0352) or 265GH (1.0425)

certificate 3.1B acc. EN 10204 or similar

gaskets: spiral wounded gaskets with graphite

(e.g.FLEXITALLIC)

Painting: primer : heat resistant anti corrosion paint

Insulation: mineral fibre with metal sheet covering

Color identification rings:

red RAL 3001

Pipe code: STE steam

CON condensate

WHS/WHR hot water

Piping Specification 3/12 document no. 381200 - Rev.03

Piping Specification

Thermal Oil Systems

nominal outer nominal insulation

diameter diameter wall thickness pressure thickness

DN mm mm bar mm

15 21,3 2,00 16 40

20 26,9 2,30 16 40

25 33,7 2,60 16 40

32 42,4 2,60 16 50

40 48,3 2,60 16 50

50 60,3 2,90 16 60

65 76,1 2,90 16 60

80 88,9 3,20 16 80

100 114,3 3,60 16 80

125 139,7 4,00 16 100

150 168,3 4,50 16 100

200 219,1 6,30 16 120

250 273,0 6,30 16 140

dimensions acc. DIN EN 10220

Piping: BLK seamless

material: P235GH (1.0345, St 35.8) acc. EN 10216-2 or EN 10217-2

certificate 3.1B acc. EN 10204 or similar

acc. local regulations for thermal oil piping

(max. temperature 300°C)

Flanges: according EN 1092-1

type 11 (welding neck flange)

form B (raised face)

PN 16

material: 245GH (1.0352) or 265GH (1.0425)

certificate 3.1B acc. EN 10204 or similar

gaskets: spiral wounded gaskets with graphite

(e.g.FLEXITALLIC)

Painting: primer : heat resistant anti corrosion paint

Insulation: mineral fibre with metal sheet covering

Color identification rings:

brown RAL 8002

Pipe code: OTS/OTR, OPS/OPR

Piping Specification 4/12 document no. 381200 - Rev.03

Piping Specification

Thermal Oil System for Chain Cooling

nominal outer nominal insulation

diameter diameter wall thickness pressure thickness

DN mm mm bar mm

15 21,3 2,00 16 30

20 26,9 2,30 16 30

25 33,7 2,60 16 30

32 42,4 2,60 16 30

40 48,3 2,60 16 30

50 60,3 2,90 16 30

65 76,1 2,90 16 30

80 88,9 3,20 16 30

dimensions acc. DIN EN 10220

Piping: BLK seamless

material: P235GH (1.0345, St 35.8) acc. EN 10216-2 or EN 10217-2

certificate 3.1B acc. EN 10204 or similar

acc. local regulations for thermal oil piping

(max. temperature 150°C)

Flanges: according EN 1092-1

type 11 (welding neck flange)

form B (raised face)

PN 16

material: 245GH (1.0352) or 265GH (1.0425)

certificate 3.1B acc. EN 10204 or similar

gaskets: spiral wounded gaskets with graphite

(e.g.FLEXITALLIC)

Painting: primer : heat resistant anti corrosion paint

Insulation: mineral fibre with metal sheet covering

Color identification rings:

brown RAL 8002

Pipe code: OPS-34/OPR-34

Piping Specification 5/12 document no. 381200 - Rev.03

Piping Specification

Light Fuel Oil Systems

nominal outer nominal

diameter diameter wall thickness pressure

DN mm mm bar

15 21,3 2,60* 16

20 26,9 2,60* 16

25 33,7 3,20* 16

32 42,4 3,20* 16

40 48,3 3,20* 16

50 60,3 3,60* 16

65 76,1 2,90 16

80 88,9 3,20 16

100 114,3 3,60 16

125 139,7 4,00 16

150 168,3 4,50 16

200 219,1 6,30 16

250 273,0 6,30 16

*=wall thickness suitable for threads

dimensions acc. DIN EN 10220

Piping: BLK seamless

material: P235 (St 37.0) acc. EN 10216-1 or EN 10217-1

certificate 3.1B acc. EN 10204 or similar

acc. local regulations for fuel oil piping

Flanges: according EN 1092-1

type 11 (welding neck flange)

form B (raised face)

PN 16

certificate 3.1B acc. EN 10204 or similar

Painting:

primer : anti corrosion paint

top coat: brown RAL 8002 + red RAL 3001

Pipe code: OFS/OFR

Piping Specification 6/12 document no. 381200 - Rev.03

Piping Specification

Compressed Air Systems

insulation

thickness

(mineral fibre,

nominal outer nominal where

diameter diameter wall thickness pressure applicable)

DN mm mm bar mm

6 10,2 2,00* 16 30

8 13,5 2,30* 16 30

10 17,2 2,30* 16 30

15 21,3 2,60* 16 30

20 26,9 2,60* 16 30

25 33,7 3,20* 16 30

32 42,4 3,20* 16 40

40 48,3 3,20* 16 40

50 60,3 3,60* 16 40

65 76,1 2,90 16 40

80 88,9 3,20 16 60

100 114,3 3,60 16 60

125 139,7 4,00 16 80

150 168,3 4,50 16 80

200 219,1 6,30 16 100

250 273,0 6,30 16 100

*=wall thickness suitable for threads

dimensions acc. DIN EN 10220

Piping: BLK seamless or welded

material: P235 (St 37.0) acc. EN 10216-1 or EN 10217-1

Flanges: according EN 1092-1

type 11 (welding neck flange)

form B (raised face)

PN 16

material: steel (black)

no rubber gaskets

Painting:

primer : anti corrosion paint

top coat: grey RAL 7004 (only at non-insulated pipes)

Insulation: mineral fibre with metal sheet covering

(only at pipes installed outside of building)

Pipe code: AC

Piping Specification 7/12 document no. 381200 - Rev.03

Piping Specification

Gas Systems

nominal outer nominal

diameter diameter wall thickness pressure

DN mm mm bar

15 21,3 2,00 16

20 26,9 2,30 16

25 33,7 2,60 16

32 42,4 2,60 16

40 48,3 2,60 16

50 60,3 2,90 16

65 76,1 2,90 16

80 88,9 3,20 16

100 114,3 3,60 16

125 139,7 4,00 16

150 168,3 4,50 16

200 219,1 6,30 16

250 273,0 6,30 16

dimensions acc. DIN EN 10220

Piping: BLK seamless or welded

material: P235 (St 37.0) acc. EN 10216-1 or EN 10217-1

certificate 3.1B acc. EN 10204 or similar

acc. local regulations for piping for

combustible liquids and gases

Flanges: according EN 1092-1

type 11 (welding neck flange)

form B (raised face)

PN 16

certificate 3.1B acc. EN 10204 or similar

Painting:

primer : anti corrosion paint

top coat: yellow RAL 1003

yellow RAL 1003 + red RAL 3001

(only for pipes between gas mixture station and burner)

Pipe code: NG or LPG (depending on gas type)

Piping Specification 8/12 document no. 381200 - Rev.03

Piping Specification

Fluff Conveying Systems

inner

nominal diameter (+/- nominal

diameter 2 mm) wall thickness pressure

DN mm mm bar

80 80,0 2,00 3

100 100,0 2,00 3

120 120,0 2,00 3

150 150,0 2,00 3

175 175,0 2,00 3

200 200,0 2,00 3

224 224,0 2,00 3

250 250,0 2,00 3

300 300,0 2,00 3

dimensions acc. JACOB

Piping: SST

material: stainless steel TP304L (1.4301)

bends: R=5xD

Flanges: U-shaped seal connection

acc JACOB or similar

material: clamps: galvanized steel

gaskets: EPDM, electrically conductive

Color identification rings:

grey RAL 7004 + white

Pipe code: RCF

Alternative: piping acc. specification for "Pressure Conveying Systems"

note: inner diameter has to be checked

(see corresponding drawing for pipework)

Piping Specification 9/12 document no. 381200 - Rev.03

Piping Specification

Exhaust Air Systems

inner

nominal diameter (+/- nominal

diameter 2 mm) wall thickness pressure

DN mm mm bar

80 80,0 2,00 3

100 100,0 2,00 3

120 120,0 2,00 3

150 150,0 2,00 3

175 175,0 2,00 3

200 200,0 2,00 3

224 224,0 2,00 3

250 250,0 2,00 3

300 300,0 2,00 3

dimensions acc. JACOB

Piping: GAL

material: galvanized steel

Flanges: U-shaped seal connection

acc JACOB or similar

material: clamps: galvanized steel

gaskets: NBR

Color identification rings:

grey RAL 7004

Pipe code: AEX

Piping Specification 10/12 document no. 381200 - Rev.03

Piping Specification

Pressure Conveying Systems

nominal outer nominal

diameter diameter wall thickness pressure

DN mm mm bar

50 60,3 2,60 16

65 76,1 2,60 16

80 88,9 2,60 16

100 114,3 2,60 16

125 139,7 2,90 16

150 168,3 2,90 16

200 219,1 2,90 16

dimensions acc. WB 95.0

Piping: AL/SST seamless

material: pipes: stainless steel

acc.company standard WB95.0

alternative: aluminium (only for BOPP-applications)

acc.company standard WB96.0

bends: stainless steel

acc. company standard WB97.0

Flanges: acc. company standard WB94.0

Color identification rings:

grey RAL 7004 + white

Pipe code: RCP

Piping Specification 11/12 document no. 381200 - Rev.03

Piping Specification

Conveying Air Systems

nominal outer nominal

diameter diameter wall thickness pressure

DN mm mm bar

65 76,1 2,00 10

80 88,9 2,00 10

100 114,3 2,00 10

125 139,7 2,00 10

150 168,3 2,00 10

200 219,1 2,60 10

dimensions acc. EN ISO 1127

Piping: SST seamless or welded

material: stainless steel TP304L (1.4301)) acc. EN 10216-5 or EN 10217-7

Flanges: according EN 1092-4

type 02 (loose flange)

with type 33 (unturned welding flange)

PN 10

material: aluminium

no rubber gaskets

Color identification rings:

grey RAL 7004

Pipe code: ACP

Piping Specification 12/12 document no. 381200 - Rev.03

Potrebbero piacerti anche

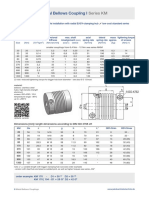

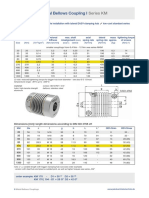

- Metal Bellows Coupling I Series KM Provides Simple Installation and Low CostDocumento1 paginaMetal Bellows Coupling I Series KM Provides Simple Installation and Low CostIsmael RiosNessuna valutazione finora

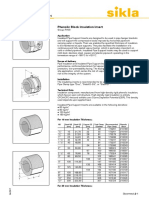

- Pipe Clamps & Accessories: Phenolic Block Insulation InsertDocumento4 paginePipe Clamps & Accessories: Phenolic Block Insulation Insertrahimi mohamadNessuna valutazione finora

- Z-Core Epoxy Resin Piping SystemSystem: Epoxy resin piping system up to 135°C and 10 barDocumento16 pagineZ-Core Epoxy Resin Piping SystemSystem: Epoxy resin piping system up to 135°C and 10 barjeovanNessuna valutazione finora

- 14 54 Namat Upvc DrainageDocumento22 pagine14 54 Namat Upvc DrainageImtiyaz KhanNessuna valutazione finora

- Metal Bellows Coupling I Series KM Provides Simple Installation and Low CostDocumento1 paginaMetal Bellows Coupling I Series KM Provides Simple Installation and Low CostAlexander DíazNessuna valutazione finora

- Data Sheet Acoustic Floor Mat 21 ENDocumento2 pagineData Sheet Acoustic Floor Mat 21 ENjonruaNessuna valutazione finora

- BS EN 1092 PN16 Flange Dimensions - Roy MechDocumento4 pagineBS EN 1092 PN16 Flange Dimensions - Roy MechpriyankaNessuna valutazione finora

- U-Bolts Acc. To Din 3570 System A: B.M.R.Bau-Montage-Rohrleitungsbau GMBHDocumento1 paginaU-Bolts Acc. To Din 3570 System A: B.M.R.Bau-Montage-Rohrleitungsbau GMBHLe HanNessuna valutazione finora

- Expansion of Safaniyah Civil Boq - UpdatedDocumento9 pagineExpansion of Safaniyah Civil Boq - UpdatedBhavanishankar ShettyNessuna valutazione finora

- Din 2577Documento2 pagineDin 2577zaharievNessuna valutazione finora

- Shrink Disc MAV 2208 Heavy Duty: FeaturesDocumento4 pagineShrink Disc MAV 2208 Heavy Duty: Featuresemrah nalbantNessuna valutazione finora

- Chain Din766 PDFDocumento5 pagineChain Din766 PDFMiguelRagas100% (1)

- Solution: PROBLEM 2.61Documento35 pagineSolution: PROBLEM 2.61Charbel Abou Khalil100% (1)

- Heco Product Sheet 6096 Stainless Steel U Clamps DIN 3570 Shape BDocumento2 pagineHeco Product Sheet 6096 Stainless Steel U Clamps DIN 3570 Shape Byulian.stanevNessuna valutazione finora

- Boundary Wall Estimation Coursed Rubble MasonryDocumento1 paginaBoundary Wall Estimation Coursed Rubble MasonryMohamed FarahNessuna valutazione finora

- Rab Resevoir Dan Rumah Pompa RevDocumento16 pagineRab Resevoir Dan Rumah Pompa RevSyahril AfiansyahNessuna valutazione finora

- Filtre NipluriDocumento1 paginaFiltre NipluristroiebogdanNessuna valutazione finora

- NRF 206 Pemex 2008 FDocumento17 pagineNRF 206 Pemex 2008 FJavier GarcíaNessuna valutazione finora

- Document No.: FFS - S/N 1829Documento5 pagineDocument No.: FFS - S/N 1829Matias MiroNessuna valutazione finora

- Heco Product Sheet 2207 Stainless Steel Plate Flanges DIN EN PN 10Documento4 pagineHeco Product Sheet 2207 Stainless Steel Plate Flanges DIN EN PN 10hafiz ashidqiNessuna valutazione finora

- Multilayer Pipes DatasheetDocumento10 pagineMultilayer Pipes Datasheetonga yaaNessuna valutazione finora

- 10 Datasheet 14825 Toothed Belt Pulleys T10 Profile - en PDFDocumento2 pagine10 Datasheet 14825 Toothed Belt Pulleys T10 Profile - en PDFEnko ŠatrovićNessuna valutazione finora

- 10 Datasheet 14825 Toothed Belt Pulleys T10 Profile - en PDFDocumento2 pagine10 Datasheet 14825 Toothed Belt Pulleys T10 Profile - en PDFAli AliNessuna valutazione finora

- EN-300 OSB1 - OSB2 - OSB3 - OSB4 - SpecsDocumento1 paginaEN-300 OSB1 - OSB2 - OSB3 - OSB4 - SpecsRodrigo CandeoNessuna valutazione finora

- Plomberie Support 1Documento16 paginePlomberie Support 1Rachid ChahmiNessuna valutazione finora

- Hose PDFDocumento1 paginaHose PDFankurNessuna valutazione finora

- Shallow, Rounded Buckets for Industry and AgricultureDocumento1 paginaShallow, Rounded Buckets for Industry and Agriculturemkiani2Nessuna valutazione finora

- Din 504Documento1 paginaDin 504Dule JovanovicNessuna valutazione finora

- Upvc Pressure CatalogueDocumento7 pagineUpvc Pressure CatalogueAmir ShahzadNessuna valutazione finora

- 1602 F 7944 Dbfaf BODocumento17 pagine1602 F 7944 Dbfaf BOArquiestructural EnginyersNessuna valutazione finora

- Sleeve Anchor Data Sheet - For SubmittalDocumento3 pagineSleeve Anchor Data Sheet - For SubmittalvtalexNessuna valutazione finora

- Aquarius+ UPVC Industrial Pipe & FittingsDocumento16 pagineAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNessuna valutazione finora

- Piping Class Rev. Ref. Piping Class Status: Basic DataDocumento8 paginePiping Class Rev. Ref. Piping Class Status: Basic DataMARCONessuna valutazione finora

- Cañeria Ac. C COST ASTM A53Documento2 pagineCañeria Ac. C COST ASTM A53alejandro inostrozaNessuna valutazione finora

- Kyodo Pipe Producs SpecificationDocumento3 pagineKyodo Pipe Producs SpecificationTengku MunzirNessuna valutazione finora

- Stat 315Documento3 pagineStat 315Sava KrsticNessuna valutazione finora

- Product Range - Pipes - : Load and Service Years Can Be Seen atDocumento4 pagineProduct Range - Pipes - : Load and Service Years Can Be Seen atConstantin CilibiuNessuna valutazione finora

- Caps DIN 2617 dimensions in mmDocumento2 pagineCaps DIN 2617 dimensions in mmBojan BučarNessuna valutazione finora

- On Choice: High Strength Steel!Documento1 paginaOn Choice: High Strength Steel!Zeljko StamatovicNessuna valutazione finora

- Henco TM 1.2.1 PDFDocumento1 paginaHenco TM 1.2.1 PDFAnonymous O0T8aZZNessuna valutazione finora

- Steel Tubes: Welded and SeamlessDocumento2 pagineSteel Tubes: Welded and Seamlessamit kumar sarkarNessuna valutazione finora

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Documento5 pagineTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745Nessuna valutazione finora

- Channels PFC PDFDocumento1 paginaChannels PFC PDFviswanathanNessuna valutazione finora

- British Parallel Flange Channels PFCDocumento1 paginaBritish Parallel Flange Channels PFCdarinnavilNessuna valutazione finora

- Piping Material Specification for Polymer ChipsDocumento8 paginePiping Material Specification for Polymer ChipsMARCONessuna valutazione finora

- REALLOCATION OF WATER LINES - MBARARA To Print 16-02-22Documento46 pagineREALLOCATION OF WATER LINES - MBARARA To Print 16-02-22Phillip KakuruNessuna valutazione finora

- ASME B31G Ejemplo2Documento2 pagineASME B31G Ejemplo2YURI EDGAR GIRALDO MACHADONessuna valutazione finora

- Flange Dim EN1092-1Documento18 pagineFlange Dim EN1092-1Santi Puente CosmesNessuna valutazione finora

- Lageweg 25 - 2222 AG Katwijk - The Netherlands - T +31 (0) 71 40 237 01 - Contact@vav - NL - WWW - Vav.nlDocumento3 pagineLageweg 25 - 2222 AG Katwijk - The Netherlands - T +31 (0) 71 40 237 01 - Contact@vav - NL - WWW - Vav.nlMarian ZatkoNessuna valutazione finora

- Carbon & Stainless Steel Pipe DimensionsDocumento4 pagineCarbon & Stainless Steel Pipe DimensionsM Zahran KhairyNessuna valutazione finora

- T210Documento4 pagineT210AmechNessuna valutazione finora

- ISO 10243.die SpringsDocumento12 pagineISO 10243.die SpringsКонстантин Косарев100% (1)

- Rangka & Pelat BetonDocumento4 pagineRangka & Pelat BetonWigih SantosoNessuna valutazione finora

- Wall Thickness Dnno: Profile Size Outside Diameter MM No. of Pipes Per Bundle No. of Pipes Per Ton (Average)Documento1 paginaWall Thickness Dnno: Profile Size Outside Diameter MM No. of Pipes Per Bundle No. of Pipes Per Ton (Average)Dilhara WickramaarachchiNessuna valutazione finora

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsDocumento4 pagineStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilNessuna valutazione finora

- Proyek BOT Sewa 7 Tahun: 4 Pekerjaan AtapDocumento2 pagineProyek BOT Sewa 7 Tahun: 4 Pekerjaan AtapAnonymous c7lIZyNessuna valutazione finora

- Flange Dim EN1092 1 BS4504 PDFDocumento18 pagineFlange Dim EN1092 1 BS4504 PDFSathykumar Murugesan100% (1)

- Centricast CL 1520 Data SheetDocumento6 pagineCentricast CL 1520 Data SheetOlmer Romero MendezNessuna valutazione finora

- Uma Material Schedule 4Documento1 paginaUma Material Schedule 4Emmanuel OtienoNessuna valutazione finora

- British Commercial Computer Digest: Pergamon Computer Data SeriesDa EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNessuna valutazione finora

- HHF-1000 Mud Pump ManualDocumento54 pagineHHF-1000 Mud Pump ManualMarutpal Mukherjee100% (7)

- Praher 2013 Pool CatalogueDocumento88 paginePraher 2013 Pool CatalogueProfessional LinesNessuna valutazione finora

- Nozzle LoadsDocumento7 pagineNozzle LoadsdivyamadhavanNessuna valutazione finora

- Manway Davits ZimmerlinCatalogDocumento64 pagineManway Davits ZimmerlinCatalogAnandKumarRavindranNessuna valutazione finora

- Expansion Joint ManualDocumento314 pagineExpansion Joint ManualAmina Taissa0% (1)

- Fig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFDocumento1 paginaFig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFmarchus09Nessuna valutazione finora

- Check ValveDocumento24 pagineCheck ValveshyamNessuna valutazione finora

- Brochure Alfagomma ChemichalDocumento14 pagineBrochure Alfagomma ChemichalZainuddin CIENessuna valutazione finora

- Indian Oil Corporation Limited Vendor EnquiryDocumento72 pagineIndian Oil Corporation Limited Vendor EnquiryANIMESH JAINNessuna valutazione finora

- A.3.7 JP152-300-DQP-05.81-90005-02 Pneumatic Pressure TestingDocumento12 pagineA.3.7 JP152-300-DQP-05.81-90005-02 Pneumatic Pressure TestingJabel Oil Services Technical DPTNessuna valutazione finora

- ASME StandardsDocumento8 pagineASME Standardsanappan100% (1)

- Cast Iron Ball Valve PN 16 Length DINDocumento8 pagineCast Iron Ball Valve PN 16 Length DINKarolNessuna valutazione finora

- PETRO TCS Ops Manual 700-20 25Documento56 paginePETRO TCS Ops Manual 700-20 25paulm3565Nessuna valutazione finora

- Materials: Pressure Parts and Applicable Service TemperaturesDocumento14 pagineMaterials: Pressure Parts and Applicable Service Temperaturesmohan babuNessuna valutazione finora

- (GRE) Installation Manual For MarineDocumento37 pagine(GRE) Installation Manual For MarineQuy RomNessuna valutazione finora

- Piping Material Classes Job SpecificationDocumento6 paginePiping Material Classes Job SpecificationGERAILLYNessuna valutazione finora

- Corrosion Mapping by UT & PADocumento24 pagineCorrosion Mapping by UT & PAInspection Engineer100% (2)

- 4 - Anchor - Bolts - Base - Plate - DD1-2 - Module 201BDocumento8 pagine4 - Anchor - Bolts - Base - Plate - DD1-2 - Module 201Btitir bagchiNessuna valutazione finora

- Y-Strainer: Flanged EndsDocumento2 pagineY-Strainer: Flanged Endsamir shokrNessuna valutazione finora

- STORAGE TANK SPECDocumento10 pagineSTORAGE TANK SPECpapathsheilaNessuna valutazione finora

- Anitha Piping CV PDFDocumento3 pagineAnitha Piping CV PDFRaja NavisNessuna valutazione finora

- ISV Product Summary SB-300.13 Rev00 - WebDocumento8 pagineISV Product Summary SB-300.13 Rev00 - WebLuis Gustavo HernandezNessuna valutazione finora

- Codeware, Inc.: Sarasota, FL, USADocumento20 pagineCodeware, Inc.: Sarasota, FL, USAVenkatesan ManikandanNessuna valutazione finora

- 34 Samss 711Documento26 pagine34 Samss 711Mohamed Ahmed MaherNessuna valutazione finora

- National Oil Corporation Packaged Reciprocating Compressor SpecificationDocumento26 pagineNational Oil Corporation Packaged Reciprocating Compressor SpecificationYousab JacobNessuna valutazione finora

- Contents:: Choke Valve Installation & Maintenance ManualDocumento10 pagineContents:: Choke Valve Installation & Maintenance Manualimam susantoNessuna valutazione finora

- Grinnell Emea Catalog 2013Documento284 pagineGrinnell Emea Catalog 2013ioan cristian cotorobaiNessuna valutazione finora

- Gorbel PDFDocumento42 pagineGorbel PDFWissam JarmakNessuna valutazione finora

- Flanges and Pipe Fitting ManufacturerDocumento12 pagineFlanges and Pipe Fitting Manufacturer9823458877Nessuna valutazione finora

- C57 19 01Documento17 pagineC57 19 01Carlos MolinaNessuna valutazione finora