Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter - E15: Site Testing and Commissioning

Caricato da

venkateshbitraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter - E15: Site Testing and Commissioning

Caricato da

venkateshbitraCopyright:

Formati disponibili

CHAPTER – E15 : SITE TESTING AND COMMISSIONING

1.00.00 INTRODUCTION

An indicative list of tests is given below. Contractor shall perform any additional

test based on specialties of the items as per the field QP/ instructions of the

equipment supplier or Employer without any extra cost to the Employer. The

Contractor shall arrange all instruments required for conducting these tests

alongwith calibration certificates and shall furnish the list of instruments to the

Employer for approval.

2.00.00 GENERAL CHECKS

a) Check for physical damage.

b) Visual examination of zinc coating/ plating

c) Check from name plate that all items are as per older/ specification.

d) Check tightness of all bolts, clamps and connecting terminals using toque

wrenches.

e) For oil filled equipment check for oil leakage, if any. Also check oil level and top

up.

f) Check ground connections for quality of weld and application of zinc rich paint

over weld joint of galvanized surfaces.

g) Check cleanliness of insulator and bushings.

h) All checks and tests specified by the manufactures in their drawings and manuals

as well as all tests specified in the relevant code of erection.

i) Check for surface finish of grading rings (corona control ring.)

j) Pressure test on all pneumatic lines at 1.5 times the rated pressure shall be

conducted.

3.00.00 CIRCUIT BREAKERS

a) Insulation resistance of each pole.

b) Check adjustments, if any, suggested by manufacturer.

c) Breaker closing and tripping time.

d) Slow and power closing operation and opening

e) Trip free and anti pumping operation.

f) Minimum pick up volts of coils

g) Contact resistance

h) Functional checking of compressed air plant and all accessories

i) Functional checking of control circuits, interlocks, tripping through protective

relays and auto-reclose operation.

j) Insulation resistance of control circuits, motor etc.

k) Resistance of closing and tripping coils.

4.00.00 ISOLATORS

a) Insulation resistance of each pole

b) Manual and electrical operation on interlocks

c) Insulation resistance of control circuits and motors.

d) Ground connections

e) Contact resistance

f) Proper alignment to minimise the vibration to the extreme possible during

operation.

REDG PART - II Page E15 – 1/2

SWYD. PACKAGE Spec. No CS-0000-572-2

g) Measurement of operating torque for isolator and Earth switch

h) Resistance of operating and interlocking coils.

5.00.00 CURRENT TRANSFORMERS

a) Insulation Resistance Test

b) Polarity test.

c) Ratio identification test-checking of all ratios on all cores by primary injection of

current.

d) Dielectric test of oil (wherever applicable)

e) Magnetizing characteristics test.

6.00.00 VOLTAGE TRANSFORMERS

a) Insulation resistance test

b) Polarity test

c) Ratio test

d) Dielectric test of oil (if applicable)

7.00.00 SURGE ARRESTER

a) Grading leakage current

b) Resistance of ground connection.

8.00.00 PHASING OUT

The phasing out of all supplies in the station system shall be carried out.

9.00.00 STATION EARTHING

a) Check soil resistivity

b) Check continuity of grid wires

c) Check earth resistance of the entire grid as well as various sections of the same.

d) Check for weld joint and application of zinc rich paint on galvanised surface.

e) Dip test on earth conductor prior to use.

10.00.00 CONDUCTOR STRINGING AND POWER CONNECTORS

a) Physical check for finish

b) Electrical clearance check

c) Testing of torque by torque by torque wrenches on all bus power connectors and

other accessories.

d) Milli volt drop test on all power connectors.

e) Sag and tension check on conductors.

11.00.00 INSULATORS

Visual examination for finish damage, creepage distance, etc.

REDG PART - II Page E15 – 2/2

SWYD. PACKAGE Spec. No CS-0000-572-2

Potrebbero piacerti anche

- SOP TemplateDocumento2 pagineSOP TemplateAnkur Dhir100% (1)

- B767 Flightdeck and AvionicsDocumento142 pagineB767 Flightdeck and Avionicsoscar89% (19)

- Information Sheet 3.1.1 Ensuring Proper Handling of Measuring InstrumentDocumento13 pagineInformation Sheet 3.1.1 Ensuring Proper Handling of Measuring Instrumentapi-196541959Nessuna valutazione finora

- Eil - Elect - Spec - VCB & Control Panel SpecificationDocumento7 pagineEil - Elect - Spec - VCB & Control Panel SpecificationDamodharan ChandranNessuna valutazione finora

- ABB - Across The Line Cont ActorsDocumento136 pagineABB - Across The Line Cont ActorsdnaviauxNessuna valutazione finora

- Knowledge is "Real Power": Introduction to Power QualityDa EverandKnowledge is "Real Power": Introduction to Power QualityNessuna valutazione finora

- Vs1 en 150dpiDocumento13 pagineVs1 en 150dpiPatrik PulungNessuna valutazione finora

- FAT Procedures: 1-ObjectiveDocumento6 pagineFAT Procedures: 1-ObjectiveMohammad YaseeenNessuna valutazione finora

- Ametek Electronic SpeedoDocumento2 pagineAmetek Electronic SpeedoHarlinton descalzi100% (1)

- Submittal 16080.003.A - NETA Test FormsDocumento34 pagineSubmittal 16080.003.A - NETA Test Formsirish sedilllNessuna valutazione finora

- L&T Queries-1Documento8 pagineL&T Queries-1venkateshbitraNessuna valutazione finora

- Transformer Type TestDocumento7 pagineTransformer Type TestvenkateshbitraNessuna valutazione finora

- VZ E Product Catalogue Sept2011Documento16 pagineVZ E Product Catalogue Sept2011anand.bala100% (1)

- Doosan Forklift b15 20t 2 Testing and Adjusting System OperationDocumento10 pagineDoosan Forklift b15 20t 2 Testing and Adjusting System Operationmaria100% (44)

- CER Example Registry: Professional Development ProgramDocumento13 pagineCER Example Registry: Professional Development ProgramPradyut TiwariNessuna valutazione finora

- General Low Voltage Cable Supply Connection GuidelineDocumento2 pagineGeneral Low Voltage Cable Supply Connection GuidelineDFNessuna valutazione finora

- Section-Iii: Technical SpecificationDocumento35 pagineSection-Iii: Technical SpecificationVarun BhardwajNessuna valutazione finora

- Final Hand Book 2-2 2013-14Documento66 pagineFinal Hand Book 2-2 2013-14sunilkumareceNessuna valutazione finora

- Ecuaciones para Curva de Conductores y MotoresDocumento6 pagineEcuaciones para Curva de Conductores y MotoresCarlos Lovera Rodriguez100% (1)

- Combine TRDocumento8 pagineCombine TRAchmad ZulkifliNessuna valutazione finora

- Role: - Engineer's Responsibilities:: Career Episode OneDocumento2 pagineRole: - Engineer's Responsibilities:: Career Episode OnemariaNessuna valutazione finora

- 21 6Documento19 pagine21 6Francisco M. RamosNessuna valutazione finora

- 7pa22 23 Catalog Sip E7hungDocumento3 pagine7pa22 23 Catalog Sip E7hungHung VuNessuna valutazione finora

- 2-Panel Component Training ProgramDocumento10 pagine2-Panel Component Training ProgramRAMADASTAGIRI NayakantiNessuna valutazione finora

- Generac - Gen Insulation ClassDocumento4 pagineGenerac - Gen Insulation Class6609503100% (1)

- EHV - Grounding TransformerDocumento23 pagineEHV - Grounding Transformerm kh100% (1)

- Fuji Tips and Tricks PDFDocumento26 pagineFuji Tips and Tricks PDFĐiền Nguyễn100% (2)

- Codigos de Error Samsung PDFDocumento18 pagineCodigos de Error Samsung PDFOscar LinoNessuna valutazione finora

- CDR Report Sample For Electrical EngineersDocumento4 pagineCDR Report Sample For Electrical EngineersstephengatesNessuna valutazione finora

- Spec EarthingDocumento10 pagineSpec EarthingDolyNessuna valutazione finora

- Qualification of TBEA Tianjin Transformers PDFDocumento6 pagineQualification of TBEA Tianjin Transformers PDFtranthienphongNessuna valutazione finora

- Electrical Specification Division 16, Section 16116Documento4 pagineElectrical Specification Division 16, Section 16116eng_asayedNessuna valutazione finora

- IC200MDL740Documento2 pagineIC200MDL740s_waqarNessuna valutazione finora

- Questions From Relay and Protection SchemeDocumento2 pagineQuestions From Relay and Protection SchemeChandan ChetriNessuna valutazione finora

- Saudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 ElectDocumento7 pagineSaudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 Electkarthi51289Nessuna valutazione finora

- R8005C MvawDocumento20 pagineR8005C MvawRinda_RaynaNessuna valutazione finora

- Building Electrical Inspection ChecklistDocumento2 pagineBuilding Electrical Inspection Checklistkhrayzie bhoneNessuna valutazione finora

- Electrical Engineering Safety Final ExamDocumento2 pagineElectrical Engineering Safety Final ExamMarielle LopezNessuna valutazione finora

- EXP-11 Study of LED Blinking in TMS 320 2812 KitDocumento5 pagineEXP-11 Study of LED Blinking in TMS 320 2812 KitParthiban BalaramanNessuna valutazione finora

- EE201 Power Amplifier Project ReportDocumento1 paginaEE201 Power Amplifier Project ReportbadaitimurNessuna valutazione finora

- Frequency RelayDocumento2 pagineFrequency RelayAkhilesh JindalNessuna valutazione finora

- Communication Training ReportDocumento33 pagineCommunication Training ReportkakagoNessuna valutazione finora

- CDR Questionnaire Form: of The Project I.E. How The Objectives of The Project Was Accomplished in Brief.)Documento2 pagineCDR Questionnaire Form: of The Project I.E. How The Objectives of The Project Was Accomplished in Brief.)NASEER AHMAD100% (1)

- Substation ManpowerDocumento11 pagineSubstation Manpowernagendra mishraNessuna valutazione finora

- Maintenance of TransformerDocumento8 pagineMaintenance of TransformeranilsinghteslaNessuna valutazione finora

- RCCBDocumento16 pagineRCCBHarnoor Singh AhluwaliaNessuna valutazione finora

- Flexi-MoU-CTS - Industrial Electrician - MSUDocumento48 pagineFlexi-MoU-CTS - Industrial Electrician - MSUkuber singhNessuna valutazione finora

- m2x3c I500c en M C Manual GBDocumento88 paginem2x3c I500c en M C Manual GBdinakaran2020Nessuna valutazione finora

- E14-S02 - 1 Design Requirement For Unit SubstationDocumento13 pagineE14-S02 - 1 Design Requirement For Unit SubstationMuhammad IrfanNessuna valutazione finora

- 2021 May Intake Advert Revised 4Documento2 pagine2021 May Intake Advert Revised 4douglas0% (1)

- Fire Pump DiagramDocumento1 paginaFire Pump DiagrammarvinNessuna valutazione finora

- Electrical Codes PDFDocumento16 pagineElectrical Codes PDFcosmin1991Nessuna valutazione finora

- Digital Differential Relaying Scheme For Teed Circuits Based On Voltage and Current Signal ComparisonDocumento10 pagineDigital Differential Relaying Scheme For Teed Circuits Based On Voltage and Current Signal ComparisonKumar DhirajNessuna valutazione finora

- Reference LettersDocumento1 paginaReference LetterscustomwriterNessuna valutazione finora

- S-AAA-CAB-GEN (Rev.0-2011)Documento35 pagineS-AAA-CAB-GEN (Rev.0-2011)Karuppu SamyNessuna valutazione finora

- TLB ServiceDocumento5 pagineTLB ServiceHugh O'Brien GwazeNessuna valutazione finora

- Control System & PLC Old Qns PaperDocumento4 pagineControl System & PLC Old Qns PaperJaya Rajesh RaajNessuna valutazione finora

- Wave Let TransformDocumento6 pagineWave Let Transformnirmal_inboxNessuna valutazione finora

- Entes CatalogueDocumento154 pagineEntes CatalogueShvan NajeebNessuna valutazione finora

- E09-X02 - 0 Medium Voltage Motor Control Center Data SheetDocumento3 pagineE09-X02 - 0 Medium Voltage Motor Control Center Data SheetMuhammad IrfanNessuna valutazione finora

- CL-NG-6460-002-038 Checklist For 110kV and 115kV and 132kV XLPE Cables Rev00Documento3 pagineCL-NG-6460-002-038 Checklist For 110kV and 115kV and 132kV XLPE Cables Rev00WajahatNessuna valutazione finora

- User Manual: Installation Fiberoptic Repeater OZD Profi 12M ..Documento72 pagineUser Manual: Installation Fiberoptic Repeater OZD Profi 12M ..Augusto Peruffo RodriguesNessuna valutazione finora

- A2 Installation Manual PDFDocumento27 pagineA2 Installation Manual PDFEko SuwarsonoNessuna valutazione finora

- Abbreviations PowergridDocumento100 pagineAbbreviations PowergridJayant Kumar Das100% (1)

- EV Charging Infrastructure A Complete Guide - 2020 EditionDa EverandEV Charging Infrastructure A Complete Guide - 2020 EditionNessuna valutazione finora

- Electrical Systems TestingDocumento6 pagineElectrical Systems Testingsyedfahadraza627Nessuna valutazione finora

- Goi PDFDocumento34 pagineGoi PDFvenkateshbitraNessuna valutazione finora

- IEC 61850 To TSPDCLDocumento52 pagineIEC 61850 To TSPDCLvenkateshbitraNessuna valutazione finora

- 3530 405 Pvi H 205 02Documento12 pagine3530 405 Pvi H 205 02venkateshbitraNessuna valutazione finora

- Major Works Done, Activities and AchievementsDocumento1 paginaMajor Works Done, Activities and AchievementsvenkateshbitraNessuna valutazione finora

- Itr2 - 2019 - PR2 JPDocumento89 pagineItr2 - 2019 - PR2 JPvenkateshbitraNessuna valutazione finora

- Sessions Main AuditoriumDocumento6 pagineSessions Main AuditoriumvenkateshbitraNessuna valutazione finora

- xxxxxxxx7353 2019-11-22 131895 PDFDocumento1 paginaxxxxxxxx7353 2019-11-22 131895 PDFvenkateshbitraNessuna valutazione finora

- CG Lux Lighting Software DownloadDocumento2 pagineCG Lux Lighting Software DownloadvenkateshbitraNessuna valutazione finora

- CPRI Clarification On 12.5MVA Impulse Test PDFDocumento2 pagineCPRI Clarification On 12.5MVA Impulse Test PDFvenkateshbitraNessuna valutazione finora

- Chapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorDocumento10 pagineChapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorvenkateshbitraNessuna valutazione finora

- Authorised For Receive PTWDocumento13 pagineAuthorised For Receive PTWvenkateshbitraNessuna valutazione finora

- Indian Standard: Application Guide For Electrical Relays For Ac SystemsDocumento16 pagineIndian Standard: Application Guide For Electrical Relays For Ac SystemsvenkateshbitraNessuna valutazione finora

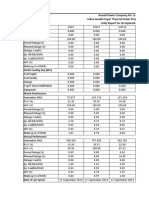

- Wind Speed-M/s KV Level Short Circuit Level - Ka Conduc Tor - Quad/tw in Normal Tension/ PH Phase To Phase Spacing Spacer SpanDocumento3 pagineWind Speed-M/s KV Level Short Circuit Level - Ka Conduc Tor - Quad/tw in Normal Tension/ PH Phase To Phase Spacing Spacer SpanvenkateshbitraNessuna valutazione finora

- Annex 6Documento2 pagineAnnex 6venkateshbitraNessuna valutazione finora

- Chapter - E 4: Surge Arrestors GeneralDocumento5 pagineChapter - E 4: Surge Arrestors GeneralvenkateshbitraNessuna valutazione finora

- Day PerformanceDocumento5 pagineDay PerformancevenkateshbitraNessuna valutazione finora

- 155 CHPDocumento5 pagine155 CHPvenkateshbitraNessuna valutazione finora

- NTPC Limited (Corporate Medical Cell)Documento1 paginaNTPC Limited (Corporate Medical Cell)venkateshbitraNessuna valutazione finora

- 162 - AHP Buxar-EPC: Package Id Loa Date Proje CT Engg Compln DateDocumento5 pagine162 - AHP Buxar-EPC: Package Id Loa Date Proje CT Engg Compln DatevenkateshbitraNessuna valutazione finora

- Metal Oxide Varistors: ElectronicsDocumento5 pagineMetal Oxide Varistors: ElectronicscarlosgnNessuna valutazione finora

- HyundaiDocumento3 pagineHyundaiМанук ЗурначянNessuna valutazione finora

- ProjectorDocumento6 pagineProjectorriteshsingh1983Nessuna valutazione finora

- TD10008Documento5 pagineTD10008ELKIN JESUS SUAREZ CALVONessuna valutazione finora

- ITT American Electric Contempo Post Top Series 45-46-145-146 Spec Sheet 4-80Documento8 pagineITT American Electric Contempo Post Top Series 45-46-145-146 Spec Sheet 4-80Alan MastersNessuna valutazione finora

- Partes Manual MP C 307 RicohDocumento262 paginePartes Manual MP C 307 RicohFernando GuarínNessuna valutazione finora

- TVS Radeon BSVI WIRINGDocumento4 pagineTVS Radeon BSVI WIRINGstarlinwooNessuna valutazione finora

- Temtron LinecardDocumento2 pagineTemtron LinecardAthosSchiavoneNessuna valutazione finora

- 2021 SEA HomeApplianceCatalogDocumento127 pagine2021 SEA HomeApplianceCatalogCiprian SorinNessuna valutazione finora

- ProductrayhanDocumento10 pagineProductrayhanMuhammad Rayhan FirdausNessuna valutazione finora

- Stock As On .10.2019Documento26 pagineStock As On .10.2019Bibhuti JhaNessuna valutazione finora

- SyncroFlo Vert In-LineDocumento2 pagineSyncroFlo Vert In-LineJaime RodriguezNessuna valutazione finora

- Pec, Ee Laws, Codes & EthicsDocumento18 paginePec, Ee Laws, Codes & EthicsJoshua GerarmanNessuna valutazione finora

- ServiceEnclosure2018 enDocumento2 pagineServiceEnclosure2018 endheyab farajNessuna valutazione finora

- UntitledDocumento4 pagineUntitledMateusz HeinNessuna valutazione finora

- Water-Cooled Chillers: Air ConditioningDocumento5 pagineWater-Cooled Chillers: Air ConditioningHasib KhanNessuna valutazione finora

- WateringSparesManual 2022Documento38 pagineWateringSparesManual 2022Paul HarrisNessuna valutazione finora

- FC 4.1.31 - Crawler Crane Checklist FormDocumento2 pagineFC 4.1.31 - Crawler Crane Checklist Formkhrayzie bhoneNessuna valutazione finora

- List of Prohibited Articles in Your Cabin BaggageDocumento2 pagineList of Prohibited Articles in Your Cabin Baggagesteven wijayaNessuna valutazione finora

- Air-Cooled Screw Chillers: Installation, Operation and Maintenance InstructionsDocumento56 pagineAir-Cooled Screw Chillers: Installation, Operation and Maintenance InstructionsAhmadNessuna valutazione finora

- First List of MaterialDocumento9 pagineFirst List of MaterialKasarachi AmadiNessuna valutazione finora

- Data Ruangan Intensive (071020)Documento31 pagineData Ruangan Intensive (071020)Andrew WarankiranNessuna valutazione finora

- Bme QPDocumento1 paginaBme QPAlex VincentNessuna valutazione finora