Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Electric Terex Cedarapids

Caricato da

AdamCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Electric Terex Cedarapids

Caricato da

AdamCopyright:

Formati disponibili

PAVER

TECHNICAL MANUAL

300 Series & 411

Electrical Section

Technical Manual

A Terex Company

Table of Contents

Grayhound 300 Series/CR411

Component Location Maps ......................................................................................... 1 - 10

Engine Starting System .................................................................................................... 11

Charging System .............................................................................................................. 12

Throttle & Fuel .......................................................................................................... 13 - 14

Engine Start & Fuel - Elite Engine ................................................................................... 15

Horn .................................................................................................................................. 16

Gauges .............................................................................................................................. 17

Lights ................................................................................................................................ 18

Brakes ............................................................................................................................... 19

Travel/Pave (P2) System CR361 ...................................................................................... 20

Front Wheel Assist CR351/CR411 .................................................................................. 21

Travel Control CR351/CR411 .................................................................................. 22 - 24

Travel Control & Steer Assist - Rubber Tire Pavers 1999 & After........................... 25 - 27

Travel Control Adj. Procedure-3 Pot Controller Grayhound Tire Pavers ................. 28 - 29

Travel Control Adj. Procedure-3 Pot Controller Grayhound Track Pavers .............. 30 - 32

Travel Control Adj. Procedure-4 Pot Controller Grayhound Tire Pavers ................. 33 - 34

Differential Lock CR351/CR411...................................................................................... 35

Steer Assist CR351/CR411 ....................................................................................... 36 - 37

LH Travel Speed Control CR361 .............................................................................. 38 - 39

RH Travel Speed Control CR361 .............................................................................. 40 - 41

Travel Control Adj. Procedure-4 Pot Controller Grayhound Track Pavers .............. 42 - 44

Susmic 10 Dual Path Control Calibration Procedures............................................... 45 - 49

Hopper .............................................................................................................................. 50

Truck Hitch (Optional) ..................................................................................................... 51

Frame Raise CR351/CR411 ............................................................................................. 52

LH Flow Gate ................................................................................................................... 53

RH Flow Gate ................................................................................................................... 54

Material Flow Indicators 1999 & Before .................................................................. 55 - 56

Material Flow Indicators 1999 & After ..................................................................... 57 - 58

Screed Lift ........................................................................................................................ 59

Screed Assist .................................................................................................................... 60

Power Main Crown ........................................................................................................... 61

Vibrators ........................................................................................................................... 62

300 Series & CR411 Electrical Troubleshooting i 22478 (11/00)

Technical Manual

A Terex Company

Table of Contents

Grayhound 300 Series/CR411

LH Hydraulic Strike-Off Extend ...................................................................................... 63

RH Hydraulic Strike-Off Extend ...................................................................................... 64

LH Hydraulic Strike-Off Slope ........................................................................................ 65

RH Hydraulic Strike-Off Slope ........................................................................................ 66

LH Match Height .............................................................................................................. 67

RH Match Height ............................................................................................................. 68

LH Main Burner #1 .......................................................................................................... 69

RH Main Burner #2 .......................................................................................................... 70

LH Ext. Burner #3 ............................................................................................................ 71

RH Ext. Burner #4 ............................................................................................................ 72

Rear Frame Compensator Adjustment ............................................................................. 73

Remote Oil Cooler Motors ............................................................................................... 74

300 Series & CR411 Electrical Troubleshooting ii 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map Fastach 8 & 10

1 ........... Screed burner fan and glow plug

2 ........... Controls for glow plugs, fans and horn

3 ........... Burner and spray down control valves

300 Series & CR411 Electrical Troubleshooting 1 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map Fastach II

Cedarapids

EXTEND

FEED

STOP

OVER

RIDE

SLOPE

HEIGHT

MATCH

BERM

TOWPOINT

MAN

MAN

SETUP

AUTO

HORN

Cedarapids

EXTEND

FEED

STOP

OVER

RIDE

SLOPE

E

TEMPERATUR

RH MAIN CONTROL

HEIGHT RH EXT HEAT OUTLET

MATCH LH MAIN HEAT

OUTLET

LH EXT HEAT

HEAT

HEAT

BERM GENERATOR

ON

ON

OFF

OFF

TOWPOINT

MAN

MAN

SETUP

AUTO

HORN

HORN

CROWN

INCREASE

E

DECREAS

1 ........... Screed Heater Control Panel

2 ........... Screed Generator

300 Series & CR411 Electrical Troubleshooting 2 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map Stretch 16 & 18

2 3

1 ........... Screed burner fan and glow plug

2 ........... Controls for glow plugs, fans and horn

3 ........... Burner and spray down control valves

300 Series & CR411 Electrical Troubleshooting 3 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map

Grayhound 300 Series/CR411

Earlier Version

DIN Connector Travel Controller

Low Threshold

Reverse

Maximum Pot

Forward

Maximum Pot

Manual Override

DIN Connector

Current Version

Travel Controller

MINIMUM Forward Pot

MINIMUM Reverse Pot

MAXIMUM Forward Pot

MAXIMUM Reverse Pot

300 Series & CR411 Electrical Troubleshooting 4 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map

Grayhound 300 Series/CR411

L2 L4

L1 L3

L5 L6

Front

Bulkhead

L17

L9

L12

L8

L7

L16

L11

L13

L10 Rear

Bulkhead

L14

L15

L1 ......... Slope sensor

L2 ......... Front wheel assist

L3 ......... LH pull point solenoid

L4 ......... Truck hitch solenoid

L5 ......... LH material flow gate

L6 ......... RH material flow gate

L7 ......... Main electrical junction box

L8 ......... Hopper wing solenoid

L9 ......... RH pull point solenoid

L10 ....... Screed lift solenoid

L11 ....... Frame raise solenoid

L12 ....... Brake solenoid

L13 ....... Vibrator solenoid

L14 ....... LH feed sensor

L15 ....... RH feed sensor

L16 ....... Travel/Pave solenoid

L17 ....... Burner/Spraydown pump & motor

300 Series & CR411 Electrical Troubleshooting 5 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map

1st Generation Version

Grayhound 300 Series Analog Display

24 23 22 21 20 19 18 17 16 15

1

2

3

4 12

5

6 14

7

8

9

13

10

11

1 ........... Engine breaker: 15 amp 13 ......... RH auger/conveyor proportional module

2 ........... Screed breaker: 15 amp 14 ......... LH auger/conveyor proportional module

3 ........... Control breaker: 15 amp 15 ......... K3 relay

4 ........... F/G/S breaker: 15 amp 16 ......... K4 relay

5 ........... Spraydown breaker: 15 amp 17 ......... K5 relay

6 ........... Light breaker: 15 amp 18 ......... K6 relay

7 ........... Flasher breaker: 15 amp 19 ......... K15 relay

8 ........... Gate breaker: 30 amp 20 ......... K16 relay

9 ........... Burner breaker: 50 amp 21 ......... K17 relay

10 ......... Key switch 22 ......... K18 relay

11 ......... K2 relay 23 ......... Spare relay

12 ......... K22 relay 24 ......... Flasher relay

300 Series & CR411 Electrical Troubleshooting 6 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map

1st Generation Version

Grayhound 300 Series Analog Display

10 9 8 7 6 5 4 3 2 1

11

12 13 16

20 14 15 17

19 18

25

21 22 23 24 26

30 29 27

31 28

36

32 37

33 35

34

28

30

31

29

16

1 ............. Travel control 19 ........... RH flow gate switch

2 ............. Differential lock switch 20 ........... LH flow gate switch

3 ............. Travel speed pot 21 ........... Hopper wing switch

4 ............. Rear frame compensator switch 22 ........... Truck hitch switch

5 ............. Screed assist switch 23 ........... Light switch

6 ............. Screed lift switch 24 ........... Travel range switch

7 ............. Screed vibrator switch 25 ........... Brake switch

8 ............. Engine stop/start/run switch 26 ........... Horn switch

9 ............. RH conveyor switch 27 ........... Throttle switch

10 ........... LH conveyor switch 28 ........... Audible alarm silence switch

11 ........... RH conveyor speed pot 29 ........... Low engine oil pressure indicator light

12 ........... LH conveyor speed pot 30 ........... RH mix no flow indicator light

13 ........... Permissive start switch 31 ........... LH mix no flow indicator light

14 ........... LH screed extension switch 32 ........... Oil temperature gauge

15 ........... RH screed extension switch 33 ........... Voltmeter

16 ........... Frame raise switch 34 ........... Fuel level gauge

17 ........... Steer assist switch 35 ........... Tachometer

18 ........... Flasher switch 36 ........... Water temperature gauge

37 ........... Oil pressure gauge

300 Series & CR411 Electrical Troubleshooting 7 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map

2nd Generation Version

Grayhound 300 Series Analog Display

23 22 21 20 19 18 17 16 15 14

1

2

3

4

5

6

7

8

9 13

10

11

12

1 ........... Engine breaker: 15 amp 13 ......... Feed Interface Module

2 ........... Screed breaker: 15 amp 14 ......... Cooler relay

3 ........... Control breaker: 15 amp 15 ......... K3 relay

4 ........... F/G/S breaker: 15 amp 16 ......... K4 relay

5 ........... Spraydown breaker: 15 amp 17 ......... K5 relay

6 ........... Light breaker: 15 amp 18 ......... K6 relay (flasher)

7 ........... Flasher breaker: 15 amp 19 ......... K15 relay

8 ........... Gate breaker: 30 amp 20 ......... K16 relay

9 ........... Burner breaker: 50 amp 21 ......... K17 relay

10 ......... Key switch 22 ......... K18 relay

11 ......... K2 relay 23 ......... K22 relay

12 ......... Cooler breaker: 50 amp

300 Series & CR411 Electrical Troubleshooting 8 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map

2nd Generation Version

Grayhound 300 Series Analog Display

10 9 8 7 6 5 4 3 2 1

13 16

20 19 18 14 15

25

21 22 23 24 26

30 29 27

31 28

36

37

32

33 35

34

28

30

31

29

16

1 ............. Travel control 19 ........... RH flow gate switch

2 ............. Steer assist switch 20 ........... LH flow gate switch

3 ............. Travel speed pot 21 ........... Hopper wing switch

4 ............. Differential lock switch 22 ........... Truck hitch switch

5 ............. Screed assist switch 23 ........... Light switch

6 ............. Screed lift switch 24 ........... Travel range switch

7 ............. Screed vibrator switch 25 ........... Brake switch

8 ............. Engine stop/start/run switch 26 ........... Horn switch

9 ............. RH conveyor switch 27 ........... Throttle switch

10 ........... LH conveyor switch 28 ........... Audible alarm silence switch

11 ........... N/A 29 ........... Low engine oil pressure indicator light

12 ........... N/A 30 ........... RH mix no flow indicator light

13 ........... Permissive start switch 31 ........... LH mix no flow indicator light

14 ........... LH screed extension switch 32 ........... Oil temperature gauge

15 ........... RH screed extension switch 33 ........... Voltmeter

16 ........... Frame raise switch 34 ........... Fuel level gauge

17 ........... N/A 35 ........... Tachometer

18 ........... Flasher switch 36 ........... Water temperature gauge

37 ........... Oil pressure gauge

300 Series & CR411 Electrical Troubleshooting 9 22478 (11/00)

Technical Manual

A Terex Company

Component Location Map

Grayhound 300 Series/CR411

Throttle

Solenoid Alternator

Murphy Temp

Sensor

Engine Temp

Sensor

Engine Oil

Pressure Sensor

RPM Pickup

Starter Sole- Starter K2 Starter

noid Relay

300 Series & CR411 Electrical Troubleshooting 10 22478 (11/00)

Technical Manual

A Terex Company

Engine Starting System

Grayhound 300 Series Analog Display

Grayhound CR411

ENGINE DOES NOT START

Main key switch ON

Brake switch ENGAGED

Travel switch in NEUTRAL position

Control circuit breaker SET

Stop/Start switch held in START position

Permissive start switch held closed

ENGINE DOES NOT CRANK

Check for low battery voltage, loose starter connections or faulty starter.

If no voltage

1 to 3 ......... Defective main key switch.

20 to 3 ........ Defective or tripped engine circuit breaker.

21 to 3 ........ Defective main key switch.

13 to 3 ........ Defective engine start/stop switch.

14 to 3 ........ Defective brake switch.

16 to 3 ........ Limit switch 3 on LH travel switch defective. (Track)

15 to 3 ........ Limit switch 3 on RH travel switch defective.

2 to 3 ......... Defective starter relay (K2).

If voltage, check starter motor.

300 Series & CR411 Electrical Troubleshooting 11 22478 (11/00)

Technical Manual

A Terex Company

Charging System

Grayhound 300 Series Analog Display

Grayhound CR411

ALTERNATOR NOT CHARGING (12.5 Vdc or less at battery)

Main key switch ON

Engine running at FULL THROTTLE

Voltage should be 13.5 Vdc to 15.5 Vdc from 1 to 3

If no voltage

1 to 3 .......... If no voltage or high voltage (>16 Vdc), defective main key switch or wiring.

20 to 3 ........ If no voltage, defective or tripped engine circuit breaker

21 to 3 ........ If no voltage, defective main key switch

22 to 3 ........ If no voltage, defective engine start/stop switch, loose connection or bad wire.

22 to 3 ........ If no voltage, at terminal of alternator, defective resistor or wiring.

If voltage is 12.5 volts or less at alternator (1to 3), repair or replace alternator.

If voltage at battery is more than 16 Vdc, check for defective ground connection(s) between

battery, frame, engine, and alternator before replacing alternator.

BATTERIES

Each battery should have about 12.6 Vdc with engine off. Lower readings than this is indicative

of a weak battery and should be serviced.

300 Series & CR411 Electrical Troubleshooting 12 22478 (11/00)

Technical Manual

A Terex Company

Throttle & Fuel

Grayhound 300 Series Analog Display

Grayhound CR411

ENGINE RUNS AT IDLE BUT NOT FULL THROTTLE

Main key switch ON, engine RUNNING, control circuit breaker SET.

1 to 3 .......... If no voltage, defective main key switch.

46 to 3 ........ If no voltage, defective control circuit breaker.

Throttle switch to FULL

48 to 3 ........ If no voltage, defective throttle switch.

If voltage, defective throttle solenoid or open wiring in solenoid.

ENGINE CRANKS BUT DOES NOT START

Main key switch ON, brake switch to ENGAGE, hold permissive start switch closed,

engine switch to RUN

If no voltage:

1 to 3 .......... defective main key switch

20 to 3 ........ defective or tripped engine breaker

21 to 3 ........ defective main key switch

22 to 3 ........ defective engine start switch

23 to 3 ........ broken wire or defective permissive start switch or relay

23 to 3 ........ If voltage defective fuel solenoid

ENGINE STOPS WHEN PERMISSIVE START SWITCH IS RELEASED

Main key switch ON, brake switch ENGAGED, hold permissive start switch CLOSED

After engine starts, the engine light should remain lit until the engine pressure rises above 5 psi

and the engine temperature is below 223° F.

Release permissive start switch after engine light goes out.

22 to 3 ........ If no voltage and engine dies, defective permissive start relay

300 Series & CR411 Electrical Troubleshooting 13 22478 (11/00)

Technical Manual

A Terex Company

Throttle & Fuel

Grayhound 300 Series Analog Display

Grayhound CR411

ENGINE LIGHT WILL NOT GO OUT AFTER ENGINE STARTS

If continuity across engine water temperature switch, check for overheated engine or defective

water temperature switch.

If continuity across engine oil pressure switch, check for low engine oil pressure or defective

engine oil pressure switch.

ENGINE DOES NOT STOP

Engine stop/start switch to STOP.

23 to 3 ........ If voltage, defective engine stop/start switch.

If no voltage, defective fuel solenoid.

ENGINE SHUTS OFF AFTER A PERIOD OF TIME

Check the engine oil pressure and water temperature. One of these has exceeded limits and

tripped the shutdown system.

300 Series & CR411 Electrical Troubleshooting 14 22478 (11/00)

Technical Manual

A Terex Company

Engine Start & Fuel - Elite Engine

Grayhound CR300 Series

Rubber Tire Pavers Track Pavers

ENGINE CRANKS BUT DOES NOT START

Main key switch ON, brake switch to ENGAGE, hold permissive start switch closed,

engine switch to START

If no voltage:

1 to 3 .......... defective main key switch

20 to 3 ........ defective or tripped engine breaker

21 to 3 ........ defective main key switch

22 to 3 ........ defective engine start switch

23A to 3 ..... defective K22 relay

23 to 3 ........ broken wire or defective permissive start switch or relay

23 to 3 ........ If voltage defective fuel solenoid

Note: Pull-in coil (wire 23A) has 12VDC only while cranking engine

300 Series & CR411 Electrical Troubleshooting 15 22478 (11/00)

Technical Manual

A Terex Company

Horn

Grayhound 300 Series Analog Display

Grayhound CR411

Main

Keyswitch 12 VDC

1 0 3

Power Horn

1 100 19 3

30 A

100 18 3

Horn Relay Horn Switch

HORN DOES NOT WORK

Hold horn switch ON.

1 to 3 .......... If no voltage, defective main key switch.

100 to 3 ...... If no voltage, defective power circuit breaker.

If voltage, check:

19 to 3 ........ If voltage, defective horn.

If no voltage, check:

100 to 18 ..... If 12 Vdc, replace K3 relay

If no voltage, check:

18 to 3 ........ If no voltage, defective K3 relay.

If voltage, defective horn switch

300 Series & CR411 Electrical Troubleshooting 16 22478 (11/00)

Technical Manual

A Terex Company

Gauges

Grayhound 300 Series Analog Display

Grayhound CR411

NO GAUGES WORK

20 to 3 ........ If no voltage, check engine circuit breaker

21 to 3 ........ If no voltage, defective main key switch

22 to 3 ........ If no voltage, check for defective start/stop switch, loose connection, or bad wiring.

INDIVIDUAL GAUGES DO NOT WORK

Water temperature:

22 to 3 ........ If no voltage, check for defective start/stop switch, loose connection, or bad wiring.

7 to 3 .......... 1500 ohms at 100° F, 125 ohms at 210° F

Oil pressure:

22 to 3 ........ If no voltage, check for defective start/stop switch, loose connection, or bad wiring.

8 to 3 .......... 0 to 80 ohms at 0 to 80 PSI.

Hydraulic temperature:

22 to 3 ........ If no voltage, check for defective start/stop switch, loose connection, or bad wiring.

9 to 31 ........ 1500 ohms at 100° F, 125 ohms at 210° F

Fuel level:

22 to 3 ........ If no voltage, check for defective start/stop switch, loose connection, or bad wiring.

10 to 3 ........ 0 to 90 ohms = empty to full

Hourmeter/tachometer: (requires a functional alternator for proper operation)

22 to 3 ........ If no voltage, check for defective start/stop switch, loose connection, or bad wiring.

11 to 3 ........ If voltage at tachometer is approximately. 8 Vac with engine running, replace

tachometer.

11 to 3 ........ If no voltage at tach., check at alternator, if no voltage, replace alternator.

300 Series & CR411 Electrical Troubleshooting 17 22478 (11/00)

Technical Manual

A Terex Company

Lights

Grayhound 300 Series Analog Display

Grayhound CR411

FLASHER LIGHTS/OPTIONAL STROBE DO NOT WORK

Main key switch ON, flasher and engine circuit breaker SET, flasher switch ON

engine switch to RUN position.

If no voltage:

1 to 3 .......... defective main key switch

20 to 3 ........ defective engine breaker

21 to 3 ........ defective main key switch

22 to 3 ........ defective engine switch

113 to 3 ...... defective flasher switch

113A to 3 ... defective flasher circuit breaker

If voltage 113 to 3 and if no voltage 114 to 3, defective flasher relay

111 to 3 ...... If no voltage, defective flasher. If voltage, check for bad light bulb

112 to 3 ...... If no voltage, defective flasher. If voltage, check for bad light bulb

LIGHTS DO NOT WORK

Main key switch ON, lights and engine circuit breaker SET, light switch ON,

engine switch to RUN position.

If no voltage:

1 to 3 .......... defective main key switch

20 to 3 ........ defective engine breaker

21 to 3 ........ defective main key switch

22 to 3 ........ defective engine switch

109 to 3 ...... defective light switch

109A to 3 ... defective light circuit breaker

If voltage 109 to 3 and no voltage 110 to 3, defective lights relay

110 to 3 ...... If no voltage, defective light switch. If voltage, check for bad light bulb

300 Series & CR411 Electrical Troubleshooting 18 22478 (11/00)

Technical Manual

A Terex Company

Brakes

Grayhound 300 Series Analog Display

Grayhound CR411

Main

Keyswitch 12 VDC

1 0 3

Control Engage Brake Release Sol.

1 46 Brake 34 34 3

15 A 'A' Release

BRAKES WILL NOT RELEASE

If SWITCH is defective, the brakes WILL remain ENGAGED. Travel speed controllers,

vibrators, automatic feed and screed control WILL NOT function.

If SOLENOID is defective, the brakes WILL NOT RELEASE. Travel speed controllers,

vibrators, automatic feed and screed control WILL function.

Check brake solenoid DIN connector for light. If light is ON:

(1) Check ground jumper pin 2 to GND pin on DIN connector for loose connection.

(2) Defective solenoid coil or hydraulic problem

If NO light:

34 to 3 ........ If no voltage is present, switch is defective.

If voltage, defective solenoid or DIN connector.

300 Series & CR411 Electrical Troubleshooting 19 22478 (11/00)

Technical Manual

A Terex Company

Travel/Pave (P2) System

Grayhound CR361 Analog Display

Main

Keyswitch 12 VDC

1 0 3

Range

Control

1 46

P/2

15 A 42 42 Range Sol. 3

Travel

Range

P/4 27

46

P/2

42

Range Switch

Rubber Tire Travel

RANGE SWITCH DOES NOT WORK

If range switch does not function:

Range switch in TRAVEL.

Check travel range solenoid valve DIN connector for light.

If light:

(1) Check ground jumper pin 2 to GND pin on DIN connector for loose or bad

connection.

(2) Defective solenoid coil or auxiliary hydraulic problem.

42 to 3 ........ If no voltage is present, switch is defective.

If voltage, defective solenoid or DIN connector.

300 Series & CR411 Electrical Troubleshooting 20 22478 (11/00)

Technical Manual

A Terex Company

Front Wheel Assist

Grayhound CR351 Analog Display

Grayhound CR411

Main

Keyswitch 12 VDC

1 0 3

P/4 27 Fwd Sol. 3

Control Range

1 46 P/2 Range Sol.

15 A 42 3

Travel

RANGE SWITCH DOES NOT WORK IN TRAVEL

Range switch in TRAVEL.

Check range solenoid DIN connector for light. If light is ON:

Check ground jumper pin 2 to GND pin for loose or bad connection.

If connection is good, defective solenoid or hydraulic problem.

If NO light:

42 to 3 ........ If no voltage is present, switch is defective.

If voltage, defective solenoid or DIN connector.

RANGE SWITCH DOES NOT WORK IN P4 (Front wheel assist only)

Range switch to P4 (front wheel assist).

Check front wheel assist solenoid DIN connector for light. If light is ON:

Check ground jumper pin 2 to GND pin for loose or bad connection.

If connection is good, defective solenoid or hydraulic problem.

If NO light:

27 to 3 ........ If no voltage is present, switch is defective.

If voltage, defective solenoid or DIN connector.

If DIN connector light is on, defective solenoid.

300 Series & CR411 Electrical Troubleshooting 21 22478 (11/00)

Technical Manual

A Terex Company

Travel Control

Grayhound CR351 Analog Display

Grayhound CR411

Main

Keyswitch 12 VDC

1 0 3

Control Brake Engage

1 46 46 34

15 A 'A' Release 77 3

4 Pin Packard RH

A B

34 Reverse

C Coils

73 73 3

B LH

3 3 A B

3

D

Travel 74 74 3

A LH

D C

Speed Forward

CW Coils

B Max 78 3

Controller RH

Paver

C D C

Speed

A 1K½

3 Pin Packard

TRAVEL SPEED CONTROL DOES NOT WORK (Neither drive wheel moves)

Main key switch ON, engine RUNNING, control circuit breaker SET, brakes RELEASED.

Carefully actuate the manual override lever on each travel pump. If pumps operate using the

manual override levers, proceed with checks. If pumps do not operate, refer to the Hydraulic

Troubleshooting section.

Without starting engine, main key switch ON, engine start/stop switch to RUN, control circuit

breaker SET.

1 to 3 .......... If no voltage, defective Main Key switch.

46 to 3 ........ If no voltage, defective control circuit breaker.

Release BRAKES, set the max paver speed dial to MAX and travel lever fully FORWARD.

34 to 3 ........ If no voltage, defective brake switch.

74 to 3 ........ Voltage should be 1.6 Vdc.

78 to 3 ........ Voltage should be 1.6 Vdc.

If no voltage, check the S1 limit switch on the travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set the max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If the voltage does not decrease to 0.15 Vdc, turn the main key switch off and remove wires 74

and 78 from the console terminal block.

Check the resistance of the console cable wiring:

74 to 3 ........ Resistance should be 15 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins C and D on the pump. Resistance should be 15 to 25 ohms.

78 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

300 Series & CR411 Electrical Troubleshooting 22 22478 (11/00)

Technical Manual

A Terex Company

Travel Control

Grayhound CR351 Analog Display

Grayhound CR411

Check resistance across pins D and C on the pump. Resistance should be 15 to 25 ohms.

Release BRAKES, set the max paver speed dial to MAX and the travel lever fully REVERSE.

34 to 3 ........ If no voltage, defective brake switch.

73 to 3 ........ Voltage should be 1.6 Vdc.

77 to 3 ........ Voltage should be 1.6 Vdc.

If no voltage, check the S1 limit switch on the travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set the max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If voltage does not decrease to 0.15 Vdc, turn the main key switch off and remove wires 73

and 77 from the console terminal block.

Check the resistance of the console cable wiring:

73 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms. Replace

EDCif open or shorted.

77 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms. Replace

EDC if open or shorted

CHECKING THE TRAVEL SPEED POT

Disconnect the plug to the travel speed pot and check the resistance of the pot.

A to B ........ 1000 ±100 ohms at all times

A to C ........ Ohms should vary as dial is rotated.

B to C ......... Ohms should vary as dial is rotated.

PAVER PULLS TO ONE SIDE

If paver turns severely to left:

Operate manual override on left pump. If left pump operates proceed with electrical checks. If not,

refer to hydraulic section.

Electrical Checks:

Check the resistance of the console cable wiring:

73 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms. Replace

EDC if open or shorted.

Check the resistance of the console cable wiring:

74 to 3 ........ Resistance should be 15 to 25 ohms.

300 Series & CR411 Electrical Troubleshooting 23 22478 (11/00)

Technical Manual

A Terex Company

Travel Control

Grayhound CR351 Analog Display

Grayhound CR411

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins C and D on the pump. Resistance should be 15 to 25 ohms.

If paver turns severely to right:

Operate manual override on right pump. If right pump operates, proceed with electrical checks. If

not refer to hydraulic section.

Electrical checks:

77 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms. Replace

EDC if open or shorted.

78 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

300 Series & CR411 Electrical Troubleshooting 24 22478 (11/00)

Technical Manual

A Terex Company

Travel Control & Steer Assist

Grayhound Rubber Tire Pavers

1999 & After w/46065-500-34 Module

300 Series & CR411 Electrical Troubleshooting 25 22478 (11/00)

Technical Manual

A Terex Company

Travel Control & Steer Assist

Grayhound Rubber Tire Pavers

1999 & After w/46065-500-34 Module

TRAVEL SPEED CONTROL DOES NOT WORK (Neither drive wheel moves)

Main key switch ON, engine RUNNING, control circuit breaker SET, brakes RELEASED.

Carefully actuate the manual override lever on each travel pump. If pumps operate using the

manual override levers, proceed with checks. If pumps do not operate, refer to the Hydraulic

Troubleshooting section.

Without starting engine, main key switch ON, engine start/stop switch to RUN, control circuit

breaker SET.

1 to 3 .......... If no voltage, defective Main Key switch.

46 to 3 ........ If no voltage, defective control circuit breaker.

Release BRAKES, set the max paver speed dial to MAX and travel lever fully FORWARD.

34 to 3 ........ If no voltage, defective brake switch.

74 to 3 ........ For 351, voltage should be 1.6 VDC. For 451/551, voltage should be 2.2 VDC.

78 to 3 ........ For 351, voltage should be 1.6 VDC. For 451/551, voltage should be 2.2 VDC.

If no voltage, check the S1 limit switch on the travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set the max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If the voltage does not decrease to 0.15 Vdc, turn the main key switch off and remove wires 74

and 78 from the console terminal block.

Check the resistance of the console cable wiring:

74 to 3 ........ Resistance should be 15 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins C and D on the pump. Resistance should be 15 to 25 ohms.

78 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins D and C on the pump. Resistance should be 15 to 25 ohms.

Release BRAKES, set the max paver speed dial to MAX and the travel lever fully REVERSE.

34 to 3 ........ If no voltage, defective brake switch.

73 to 3 ........ For 351, voltage should be 1.6 VDC. For 451/551, voltage should be 2.2 VDC.

77 to 3 ........ For 351, voltage should be 1.6 VDC. For 451/551, voltage should be 2.2 VDC.

If no voltage, check the S1 limit switch on the travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set the max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If voltage does not decrease to 0.15 Vdc, turn the main key switch off and remove wires 73 and

77 from the console terminal block.

Check the resistance of the console cable wiring:

73 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms. Replace

EDCif open or shorted.

300 Series & CR411 Electrical Troubleshooting 26 22478 (11/00)

Technical Manual

A Terex Company

Travel Control & Steer Assist

Grayhound Rubber Tire Pavers

1999 & After w/46065-500-34 Module

77 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms. Replace

EDC if open or shorted

CHECKING THE TRAVEL SPEED POT

Disconnect the plug to the travel speed pot and check the resistance of the pot.

A to B ........ 1000 ±100 ohms at all times

A to C ........ Ohms should vary as dial is rotated.

B to C ......... Ohms should vary as dial is rotated.

PAVER PULLS TO LEFT OR RIGHT

• Move harness plug-in connector from ASSIST position to BYPASS position. This eliminates

STEER ASSIST circuitry on Steer Assist Module.

If this corrects problem, replace Steer Assist Module.

If not, re-check wire connections between console and traction pumps as described above.

STEER ASSIST DOES NOT WORK IN P/2 OR P/4 RANGE

Steer assist is operational only in P/2 or P/4 Range.

Proper operation is indicated when paver pivot turns in the direction that STEER ASSIST switch is

held. DIFF. LOCK must also be functional. If DIFF. LOCK is not working, refer to that section first

before proceeding.

STEER ASSIST DOES NOT WORK IN LEFT POSITION

• Range switch in P/2 or P/4

• STEER ASSIST switch held in Left direction

• 79 to 3...........If no voltage, replace STEER ASSIST switch. If 12VDC:

• 75 to 3...........If no voltage, replace STEER ASSIST switch. If 12VDC:

• Check connections at Steer Assist Module, if OK replace Steer Assist Module.

STEER ASSIST DOES NOT WORK IN RIGHT POSITION

• Range switch in P/2 or P/4

• STEER ASSIST switch held in Right direction

• 79 to 3 ..........If no voltage, replace STEER ASSIST switch. If 12VDC:

• 76 to 3...........If no voltage, replace STEER ASSIST switch. If 12VDC:

• Check connections at Steer Assist Module, if OK replace Steer Assist Module.

300 Series & CR411 Electrical Troubleshooting 27 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

3 Pot Controller

Grayhound Tire Pavers

3 Pot

Travel Controller

Low Threshold

Reverse

Maximum Pot

Forward

Maximum Pot

CONTROL HANDLE ADJUSTMENT PROCEDURE

Initial Adjustment: (Electrical centering)

Main key switch ON; Engine switch ON; Brake switch RELEASED; Engine not running:

1. Turn both MAX adjustment pots on controller fully clockwise.

2. Travel lever full FORWARD, MAX PAVER SPEED dial to MIN: Adjust Low Threshold Pot

for 0.2 VDC from wire 74 to 3.

3. Travel lever full FORWARD, MAX PAVER SPEED dial to MAX: Adjust MAX Forward Pot

for 2.0 VDC from wire 74 to 3

4. Travel lever full REVERSE, MAX PAVER SPEED dial to MAX: Adjust MAX Reverse Pot for

2.0 VDC from wire 73 to 3

300 Series & CR411 Electrical Troubleshooting 28 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

3 Pot Controller

Grayhound Tire Pavers

Operational Adjustment:

Note: Center pumps prior to operational adjustments!

Wheels off ground; Engine at Full Throttle; Brake switch RELEASED:

1. With Control Handle full forward and MAX PAVER SPEED dial at MIN; wheels should not

turn. Adjust Low Threshold Pot so that wheels start to creep at dial setting of '1' to '1.5' but stop

at MIN.

2. Turn MAX PAVER SPEED dial to MAX with Control Handle full forward: Check speed of

wheel hubs with a tachometer and adjust Max Forward Pot until actual speed is at Maximum. If

in doubt, turn pot CCW until speed decreases then back to max speed.

3. Put Control Handle full reverse: Check speed of wheel hubs with a tachometer and adjust Max

Reverse Pot. until actual speed is at Maximum. If in doubt, turn pot CCW until speed decreases

then back to max speed.

4. Repeat steps 1-3 until adjustment is not necessary.

Bias Adjustment

Wheels off ground; Engine at Full Throttle; Brake switch RELEASED, balance lines blocked:

1. Control Handle full forward, MAX PAVER SPEED dial at MIN; Slowly increase MAX PAVER

SPEED dial until one or both wheels start to turn.

2. If one wheel is not turning carefully adjust neutral of non-turning side pump until both wheels are

turning the same speed.

300 Series & CR411 Electrical Troubleshooting 29 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

3 Pot Controller

Grayhound Track Pavers

3 Pot

Travel Controller

Low Threshold

Reverse

Maximum Pot

Forward

Maximum Pot

LH CONTROL HANDLE ADJUSTMENT PROCEDURE

Initial Adjustment: (Electrical centering)

Main key switch ON; Engine switch ON; Brake switch RELEASED; Engine not running:

1. Turn both MAX adjustment pots on controller fully clockwise.

2. Travel lever full FORWARD, MAX PAVER SPEED dial to MIN: Adjust Low Threshold Pot

for 0.2 VDC from wire 74 to 3.

3. Travel lever full FORWARD, MAX PAVER SPEED dial to MAX: Adjust MAX Forward Pot

for 2.0 VDC from wire 74 to 3

4. Travel lever full REVERSE, MAX PAVER SPEED dial to MAX: Adjust MAX Reverse Pot for

2.0 VDC from wire 73 to 3

300 Series & CR411 Electrical Troubleshooting 30 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

3 Pot Controller

Grayhound Track Pavers

3 Pot

Travel Controller

Low Threshold

Reverse

Maximum Pot

Forward

Maximum Pot

RH CONTROL HANDLE ADJUSTMENT PROCEDURE

Initial Adjustment: (Electrical centering)

Main key switch ON; Engine switch ON; Brake switch RELEASED; Engine not running:

1. Turn both MAX adjustment pots on controller fully clockwise.

2. Travel lever full FORWARD, MAX PAVER SPEED dial to MIN: Adjust Low Threshold Pot

for 0.2 VDC from wire 77 to 3.

3. Travel lever full FORWARD, MAX PAVER SPEED dial to MAX: Adjust MAX Forward Pot

for 2.0 VDC from wire 77 to 3

4. Travel lever full REVERSE, MAX PAVER SPEED dial to MAX: Adjust MAX Reverse Pot for

2.0 VDC from wire 78 to 3

300 Series & CR411 Electrical Troubleshooting 31 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

3 Pot Controller

Grayhound Track Pavers

Operational Adjustment:

Note: Center pumps prior to operational adjustments!

Engine at Full Throttle; Brake switch RELEASED, hydraulic fluid at operating temperature:

1. With Control Handle full forward and MAX PAVER SPEED dial at MIN; tracks should not

move.

2. Adjust Low Threshold Pot so that both tracks start to creep at dial setting of '1' to '1.5' but stop

at MIN.

3. Turn MAX PAVER SPEED dial slowly to MAX with Control Handles full forward: Adjust

each MAX Forward Pot so that track speeds match (Paver goes straight) and paver is at

maximum attainable speed. If in doubt, turn pot CCW until speed decreases then back to max

speed.

4. Turn MAX PAVER SPEED dial slowly to MAX with Control Handles full reverse: Adjust

each MAX Reverse Pot so that track speeds match (Paver goes straight) and paver is at

maximum attainable speed. If in doubt, turn pot CCW until speed decreases then back to max

speed.

5. Repeat steps 1-4 until adjustment is not necessary.

300 Series & CR411 Electrical Troubleshooting 32 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

Grayhound Tire Pavers Analog Display

w/Lever Control

MINIMUM Forward Pot

MINIMUM Reverse Pot

MAXIMUM Forward Pot

MAXIMUM Reverse Pot

CONTROL HANDLE ADJUSTMENT PROCEDURE

Initial Adjustment: (Electrical centering)

Main key switch ON; Engine switch ON; Brake switch RELEASED; Engine not running:

. Turn both MAX adjustment pots on controller fully clockwise.

. Travel lever full FORWARD, MAX PAVER SPEED dial to MIN: Adjust MIN Forward Pot for 0.2

VDC from wire 74 to 3.

. Travel lever full REVERSE, MAX PAVER SPEED dial to MIN: Adjust MIN Reverse Pot Clock-

wise until voltage increases from wire 73 to 3 then turn back. Should be about 0.2 VDC

. Travel lever full FORWARD, MAX PAVER SPEED dial to MAX: Adjust MAX Forward Pot for

2.0 VDC from wire 74 to 3

. Travel lever full REVERSE, MAX PAVER SPEED dial to MAX: Adjust MAX Reverse Pot for 2.0

VDC from wire 73 to 3

. While measuring voltage from 73 to 3, turn MAX PAVER SPEED dial slowly down from MAX to

MIN with handle in full reverse: Voltage should decrease smoothly down to about 0.2 VDC. If not

repeat steps 1-5.

. While measuring voltage from 74 to 3, turn MAX PAVER SPEED dial slowly down from MAX to

MIN with handle in full forward: Voltage should decrease smoothly down to about 0.2 VDC. If not

repeat steps 1-5.

300 Series & CR411 Electrical Troubleshooting 33 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

Grayhound Tire Pavers Analog Display

w/Lever Control

Operational Adjustment:

Note: Center pumps prior to operational adjustments!

Wheels off ground; Engine at Full Throttle; Brake switch RELEASED:

. With Control Handle full forward and MAX PAVER SPEED dial at MIN; wheels should not turn.

Adjust MIN Forward Pot so that wheels start to creep at dial setting of '1' to '1.5' but stop at MIN.

. With Control Handle full reverse and MAX PAVER SPEED dial at MIN; wheels should not turn.

Adjust MIN Reverse Pot so that wheels start to creep at dial setting of '1' to '1.5' but stop at MIN.

. Turn MAX PAVER SPEED dial to MAX with Control Handle full forward: Check speed of wheel

hubs with a tachometer and adjust Max Forward Pot until actual speed is at Maximum. If in doubt,

turn pot CCW until speed decreases then back to max speed.

. Put Control Handle full reverse: Check speed of wheel hubs with a tachometer and adjust Max

Reverse Pot. until actual speed is at Maximum. If in doubt, turn pot CCW until speed decreases then

back to max speed.

. Repeat steps 1-5 until adjustment is not necessary.

Bias Adjustment

Wheels off ground; Engine at Full Throttle; Brake switch RELEASED, balance lines blocked:

1. Control Handle full forward, MAX PAVER SPEED dial at MIN; Slowly increase MAX PAVER

SPEED dial until one or both wheels start to turn.

2. If one wheel is not turning carefully adjust neutral of non-turning side pump until both wheels are

turning the same speed.

300 Series & CR411 Electrical Troubleshooting 34 22478 (11/00)

Technical Manual

A Terex Company

Differential Lock

Grayhound CR351 Analog Display

Grayhound CR411

DIFFERENTIAL LOCK DOES NOT WORK IN P/2 OR P/4 RANGE

Differential Lock is operational only in P/2 or P/4 Range.

Proper operation is indicated when steering becomes difficult to impossible other than in a straight line.

To troubleshoot a suspected problem:

• Range switch in P/2 or P/4

• DIFF. LOCK switch held in ON position

Check Diff. Lock solenoid DIN connector for light

• If light is ON, check for magnetic field with a small screwdriver at the solenoid coil. If no field,

check ground jumper from pin 2 to GND pin in DIN connector for tightness. If connection is good,

check coil resistance for about 6 ohms. Replace solenoid if bad. If there was a magnetic field, refer

to Hydraulic Troubleshooting.

• If no light check:

• 46A to 3.........If no voltage, replace K20 relay. If 12 VDC, check:

• 79 to 3............If no voltage, replace DIFF. LOCK switch. If 12 VDC

• 79 to Ground at solenoid.....No voltage indicates defective wiring to solenoid.

12 VDC at the solenoid without a light indicates either a bad Ground or defective DIN connector.

DIFFERENTIAL LOCK FUNCTIONS IN TRAVEL RANGE

Differential Lock should NOT work in TRAVEL RANGE. If it is, check:

• DIN connector for light. If ON check:

• 46A to 3.........If no voltage, check wire 79 for cross short to 12 VDC

If 12 VDC, check:

• 42 to 3 at K20 relay.....If 12 VDC, unplug K20 relay. If Diff. Lock solenoid drops out, replace

K20 relay.

If no voltage, check for defective wiring in console.

• If DIN light is OUT, refer to Hydraulic Troubleshooting.

300 Series & CR411 Electrical Troubleshooting 35 22478 (11/00)

Technical Manual

A Terex Company

Steer Assist

Grayhound CR351 Analog Display

Grayhound CR411

STEER ASSIST DOES NOT WORK IN P/2 OR P/4 RANGE

Steer assist is operational only in P/2 or P/4 Range.

Proper operation is indicated when paver pivot turns in the direction that STEER ASSIST switch is held.

DIFF. LOCK must also be functional. If DIFF. LOCK is not working, refer to that section first before

proceeding.

STEER ASSIST DOES NOT WORK IN LEFT POSITION

• Range switch in P/2 or P/4

• STEER ASSIST switch held in Left direction

• 79 to 3 with .If no voltage, replace STEER ASSIST switch. If 12VDC:

• 75 to 3...........If no voltage, replace STEER ASSIST switch. If 12VDC:

• Is KL relay pulling in? If not, replace or swap with KR relay to check.

• If KL relay does pull in, check 74 to 3 in Forward or 73 to 3 in Reverse. Voltage should be 0. If

not, replace or swap KL relay with KR relay to check.

300 Series & CR411 Electrical Troubleshooting 36 22478 (11/00)

Technical Manual

A Terex Company

Steer Assist

Grayhound CR351 Analog Display

Grayhound CR411

STEER ASSIST DOES NOT WORK IN RIGHT POSITION

• Range switch in P/2 or P/4

• STEER ASSIST switch held in Right direction

• 79 to 3 ..........If no voltage, replace STEER ASSIST switch. If 12VDC:

• 76 to 3...........If no voltage, replace STEER ASSIST switch. If 12VDC:

• Is KR relay pulling in? If not, replace or swap with KL relay to check.

• If KR relay does pull in, check 78 to 3 in Forward or 77 to 3 in Reverse. Voltage should be 0. If

not, replace or swap KR relay with KL relay to check.

PAVER PULLS TO LEFT WITH STEER ASSIST IN RELEASED (OFF) POSITION

• Range switch in P/2 or P/4

• STEER ASSIST switch released

• 75 to 3 .........If 12VDC, replace STEER ASSIST switch. If no voltage check:

• 74 to 3 in Forward, 73 to 3 in Reverse. If voltage is 0, replace or swap KL relay with KR relay to

check. If voltage is identical to 78 to 3 in Forward or 77 to 3 in Reverse, refer to Hydraulic

Troubleshooting.

PAVER PULLS TO RIGHT WITH STEER ASSIST IN RELEASED (OFF) POSITION

• Range switch in P/2 or P/4

• STEER ASSIST switch released

• 76 to 3 .........If 12VDC, replace STEER ASSIST switch. If no voltage check:

• 78 to 3 in Forward, 77 to 3 in Reverse. If voltage is 0, replace or swap KR relay with KL relay to

check. If voltage is identical to 74 to 3 in Forward or 73 to 3 in Reverse, refer to Hydraulic

Troubleshooting.

300 Series & CR411 Electrical Troubleshooting 37 22478 (11/00)

Technical Manual

A Terex Company

LH Travel Speed Control

Grayhound CR361 Analog Display

Main

Keyswitch 12 VDC

1 0 3

Control Engage

1 46 Brake 34

46

15 A 'A' Release

4 Pin Packard

Forward

34

C Coil

73 73 3

A LH

A B 3

3 3

D

Left 74 74 3

Travel B LH

D C

Speed

Controller Reverse

B CW

Max Coil

Paver

C

Speed

A 1K

3 Pin Packard

Dual Speed Pot

LH TRAVEL SPEED CONTROL DOES NOT WORK

Main key switch ON, engine RUNNING, control circuit breaker SET, brakes RELEASED.

Carefully actuate the manual override lever on each travel pump. If pumps operate using the

manual override levers, proceed with checks. If pumps do not operate, refer to the Hydraulic

Troubleshooting section.

Without starting the engine, main key switch to ON, engine start/stop switch to RUN, control

circuit breaker SET.

1 to 3 .......... If no voltage, defective main key switch.

46 to 3 ........ If no voltage, defective control circuit breaker.

Release BRAKES. Set the max paver speed dial to MAX and the LH travel lever fully FORWARD.

34 to 3 ........ If no voltage, defective brake switch.

73 to 3 ........ Voltage should be 1.6 Vdc.

If no voltage, check the S1 limit switch on the LH travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set the max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If the voltage does not decrease to 0.15 Vdc, turn main key switch OFF and remove wire 73 from

the console terminal block.

Check the resistance of the console cable wiring:

73 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms.

Release BRAKES. Set the max paver speed dial to MAX and the LH travel lever fully REVERSE.

300 Series & CR411 Electrical Troubleshooting 38 22478 (11/00)

Technical Manual

A Terex Company

LH Travel Speed Control

Grayhound CR361 Analog Display

34 to 3 ........ If no voltage, defective brake switch.

74 to 3 ........ Voltage should be 1.6 Vdc.

If no voltage, check the S1 limit switch on the LH travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set the max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If voltage does not decrease to 0.15 Vdc, turn main key switch OFF and remove wire 74 from

the console terminal block.

Check the resistance of the console cable wiring:

74 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins C and D on the pump. Resistance should be 15 to 25 ohms.

CHECKING THE TRAVEL SPEED POT

Disconnect the plug to the travel speed pot and check the resistance of the pot.

A to B ........ 1000 ±100 ohms at all times

A to C ........ Ohms should vary as dial is rotated.

B to C ......... Ohms should vary as dial is rotated.

300 Series & CR411 Electrical Troubleshooting 39 22478 (11/00)

Technical Manual

A Terex Company

RH Travel Speed Control

Grayhound CR361 Analog Display

RH TRAVEL SPEED CONTROL DOES NOT WORK

Main key switch ON, engine RUNNING, control circuit breaker SET, brakes RELEASED.

Carefully actuate the manual override lever on each travel pump. If pumps operate using the

manual override levers, proceed with checks. If pumps do not operate, refer to the Hydraulic

Troubleshooting section.

Without starting engine, main key switch to ON, engine start/stop switch to RUN, control circuit

breaker is SET.

1 to 3 .......... If no voltage, defective main key switch.

46 to 3 ........ If no voltage, defective control circuit breaker.

Release the BRAKES, max paver speed dial to MAX and the RH travel lever fully FORWARD.

34 to 3 ........ If no voltage, defective Brake switch.

77 to 3 ........ Voltage should be 1.6 Vdc.

If no voltage, check the S1 limit switch on the RH travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set the max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If the voltage does not decrease to 0.15 Vdc, turn main key switch OFF and remove wire 77 from

the console terminal block.

Check the resistance of the console cable wiring:

77 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins A and B on the pump. Resistance should be 15 to 25 ohms.

300 Series & CR411 Electrical Troubleshooting 40 22478 (11/00)

Technical Manual

A Terex Company

RH Travel Speed Control

Grayhound CR361 Analog Display

Release BRAKES, set max paver speed dial to MAX and the RH travel lever fully REVERSE.

34 to 3 ........ If no voltage, defective brake switch.

78 to 3 ........ Voltage should be 1.6 Vdc.

If no voltage, check the S1 limit switch on the RH travel speed controller.

If voltage is 12 Vdc, check for an open pump coil or wiring to coil.

Set max paver speed dial to MIN. Voltage should decrease to 0.15 Vdc.

If voltage does not decrease to 0.15 Vdc, turn main key switch OFF and remove wire 78 from

the console terminal block.

Check the resistance of the console cable wiring:

78 to 3 ........ Resistance should be 15 to 25 ohms.

If wires are open or shorted, disconnect the harness from the appropriate pump.

Check resistance across pins C and D on the pump. Resistance should be 15 to 25 ohms.

CHECKING THE TRAVEL SPEED POT

Disconnect the plug to the travel speed pot and check the resistance of the pot.

A to B ........ 1000 ±100 ohms at all times

A to C ........ Ohms should vary as dial is rotated.

B to C ......... Ohms should vary as dial is rotated.

300 Series & CR411 Electrical Troubleshooting 41 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

Grayhound Track Pavers Analog Display

w/Lever Controls

MINIMUM Forward Pot

MINIMUM Reverse Pot

MAXIMUM Forward Pot

MAXIMUM Reverse Pot

LH CONTROL HANDLE ADJUSTMENT PROCEDURE

Initial Adjustment: (Electrical centering)

Main key switch ON; Engine switch ON; Brake switch RELEASED; Engine not running:

. Turn both MAX adjustment pots on controller fully counterclockwise.

. Travel lever full FORWARD, MAX PAVER SPEED dial to MIN: Adjust MIN Forward Pot for 0.2

VDC from wire 73 to 3.

. Travel lever full REVERSE, MAX PAVER SPEED dial to MIN: Adjust MIN Reverse Pot Clock-

wise until voltage increases from wire 74 to 3 then turn back. Should be about 0.2 VDC

. Travel lever full FORWARD, MAX PAVER SPEED dial to MAX: Adjust MAX Forward Pot for

2.0 VDC from wire 73 to 3

. Travel lever full REVERSE, MAX PAVER SPEED dial to MAX: Adjust MAX Reverse Pot for 2.0

VDC from wire 74 to 3

. While measuring voltage from 74 to 3, turn MAX PAVER SPEED dial slowly down from MAX to

MIN with handle in full reverse: Voltage should decrease smoothly down to about 0.2 VDC If not

repeat steps 1-5.

. While measuring voltage from 73 to 3, turn MAX PAVER SPEED dial slowly down from MAX to

MIN with handle in full forward: Voltage should decrease smoothly down to about 0.2 VDC If not

repeat steps 1-5.

300 Series & CR411 Electrical Troubleshooting 42 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

Grayhound Track Pavers Analog Display

w/Lever Controls

MINIMUM Forward Pot

MINIMUM Reverse Pot

MAXIMUM Forward Pot

MAXIMUM Reverse Pot

RH CONTROL HANDLE ADJUSTMENT PROCEDURE

Initial Adjustment: (Electrical centering)

Main key switch ON; Engine switch ON; Brake switch RELEASED; Engine not running:

. Turn both MAX adjustment pots on controller fully counterclockwise.

. Travel lever full FORWARD, MAX PAVER SPEED dial to MIN: Adjust MIN Forward Pot for 0.2

VDC from wire 77 to 3.

. Travel lever full REVERSE, MAX PAVER SPEED dial to MIN: Adjust MIN Reverse Pot Clock-

wise until voltage increases from wire 78 to 3 then turn back. Should be about 0.2 VDC

. Travel lever full FORWARD, MAX PAVER SPEED dial to MAX: Adjust MAX Forward Pot for

2.0 VDC from wire 77 to 3

. Travel lever full REVERSE, MAX PAVER SPEED dial to MAX: Adjust MAX Reverse Pot for 2.0

VDC from wire 78 to 3

. While measuring voltage from 78 to 3, turn MAX PAVER SPEED dial slowly down from MAX to

MIN with handle in full reverse: Voltage should decrease smoothly down to about 0.2 VDC If not

repeat steps 1-5.

. While measuring voltage from 77 to 3, turn MAX PAVER SPEED dial slowly down from MAX to

MIN with handle in full forward: Voltage should decrease smoothly down to about 0.2 VDC If not

repeat steps 1-5.

300 Series & CR411 Electrical Troubleshooting 43 22478 (11/00)

Technical Manual

A Terex Company

Travel Control Adjustment Procedure

Grayhound Track Pavers Analog Display

w/Lever Controls

Operational Adjustment:

Note: Center pumps prior to operational adjustments!

Engine at Full Throttle; Brake switch RELEASED, hydraulic fluid at operating temperature:

. With Control Handles full forward and MAX PAVER SPEED dial at MIN, tracks should not move.

. Both tracks should start moving at the same speed with a dial setting of '1' to '1.5'. If not, adjust each

MIN Forward Pot so that both tracks start to creep at dial setting of '1' to '1.5' but stop at MIN.

. With Control Handle full reverse and MAX PAVER SPEED dial at MIN, tracks should not move.

. Both tracks should start moving at the same speed with a dial setting of '1' to '1.5'. If not, adjust each

MIN Reverse Pot so that both tracks start to creep at dial setting of '1' to '1.5' but stop at MIN.

. Turn MAX PAVER SPEED dial slowly to MAX with Control Handles full forward.

. Adjust each MAX Forward Pot so that track speeds match (Paver goes straight) and paver is at

maximum attainable speed. Maximum attainable speed is when turning the MAX Forward pot CW

does not cause paver to turn but turning CCW will cause a turn.

. Turn MAX PAVER SPEED dial slowly to MAX with Control Handles full reverse.

. Adjust each MAX Reverse Pot so that track speeds match (Paver goes straight) and paver is at

maximum attainable speed. Maximum attainable speed is when turning the MAX Reverse pot CW

does not cause paver to turn but turning CCW will cause a turn.

. Repeat steps 1-8 until adjustment is not necessary.

300 Series & CR411 Electrical Troubleshooting 44 22478 (11/00)

Technical Manual

A Terex Company

Susmic 10 Dual Path Control

Calibration Procedures

Grayhound Track Pavers

Pavers 1999 & Before Pavers 1999 & After

Scope

This document covers the calibration procedures for asphalt pavers equipped with the Sauer-Sunstrand

Susmic 10 dual path controller.

When to Calibrate

These procedures are to be performed after initial vehicle assembly and when a sensor, EDC, pump or

motor is replaced. Before beginning these procedures, check to make sure that the Susmic 10 (S10) is

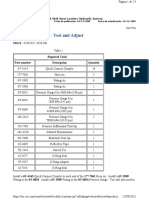

properly wired and all inputs are as expected. Table 1 shows all controller inputs and loads and their

expected ranges.

300 Series & CR411 Electrical Troubleshooting 45 22478 (11/00)

Technical Manual

A Terex Company

Susmic 10 Dual Path Control

Calibration Procedures

Grayhound Track Pavers

I n p ut Wire Pin Value

Forward switch 351 P1-9 Zero volts in forward

Reverse switch 352 P1-27 Zero volts in reverse

Zero volts in counter rotate

Counter rotation 353 P1-8

(pave mode only)

Calibrate 3 55 P1-15 Zero volts when calibrate held

Brake switch 34 P1-25 12 volts when brake is released

Steer sensor signal 332 P1-18 1 to 4 volts, left to right

Speed pot signal 342 P1-19 0.5 to 4.5 volts, min. to max.

Battery + 22 P1-1 12 volts

Battery + 22 P1-10 12 volts

Ignition 22 P1-12 12 volts

O ut p ut Wire Pin Value

Steer sensor power 331 P1-23 5 volts

Speed pot power 341 P1-24 5 volts

Left forward EDC 73 P1-7 0 to 3 volts*

Left reverse EDC 74 P1-20 0 to 3 volts*

Right forward EDC 77 P1-6 0 to 3 volts*

Right reverse EDC 78 P1-21 0 to 3 volts*

* Depends on Speed Pot Position

All Voltage measured made with respect to ground.

Ground @ pin P1-2, P1-3, P1-22, P1-13 and EDC Pins B & C.

System Function Check

A system function check should be performed whenever a component is changed and prior to

calibration. Check that all components are installed and that wiring is attached properly. Make sure that

all persons are clear of the machine and that space for machine movement exists to the front, rear and

both sides. The engine should be at low idle setting and the machine in the work range of operation.

1) Center the steering wheel. Turn the speed set potentiometer to its MINIMUM position. Move

the throttle switch to the IDLE position. Move the pave mode switch to the PAVE position.

Move the Counter Rotate switch to the NORMAL position. Move the FNR switch to the neutral

(N) position.

2) Start the vehicle. The tracks should not move.

3) Move the BRAKE switch to the RELEASE position. The tracks should not move.

4) Slowly turn the SPEED SET potentiometer clockwise. Neither track should move.

300 Series & CR411 Electrical Troubleshooting 46 22478 (11/00)

Technical Manual

A Terex Company

Susmic 10 Dual Path Control

Calibration Procedures

Grayhound Track Pavers

5) Turn the SPEED SET potentiometer to the MINIMUM position. Move the FNR switch to the

forward (F) position. The tracks should not move.

6) Slowly turn the SPEED SET potentiometer clockwise. Both tracks should begin to move slowly

forward (clockwise). As the SPEED SET pot is increased, the track speed should increase.

7) Slowly turn the STEERING WHEEL to the left. The left track should slow to stop as the wheel

is turned. Slowly center the STEERING WHEEL. The left track should speed up to its original

rate.

8) Slowly turn the STEERING WHEEL to the right. The right track should slow to stop as the

wheel is turned. Slowly center the STEERING WHEEL. The right track should speed up to its

original rate.

9) Move the FNR switch to the neutral (N) position. Both tracks should stop.

10) Move the FNR switch to the reverse (R) position. Both tracks should begin turning in reverse.

11) Slowly turn the STEERING WHEEL to the left. The left track should slow to stop as the wheel

is turned. Slowly center the STEERING WHEEL. The left track should speed up to its original

rate.

12) Slowly turn the STEERING WHEEL to the right. The right track should slow to stop as the

wheel is turned. Slowly center the STEERING WHEEL. The right track should speed up to its

original rate.

13) Slowly turn the SPEED SET potentiometer counterclockwise towards minimum. Both tracks

should slow to a stop by the time the speed pot is at its minimum position.

14) Move the FNR switch to the neutral (N) position. Both tracks should be stopped.

If the vehicle performs as described above, the system is prepared for calibration.

300 Series & CR411 Electrical Troubleshooting 47 22478 (11/00)

Technical Manual

A Terex Company

Susmic 10 Dual Path Control

Calibration Procedures

Grayhound Track Pavers

CALIBRATION: Calibration procedures are to be performed after initial vehicle assembly and when a

sensor, speed set dial, EDC, pump or motor is replaced. Before beginning these procedures, check to

make sure that the controller is properly wired and that all test values are as expected. Before beginning

calibration, move the vehicle to an open area with 30+ yard run-out.

1) ENGINE switch in STOP. PAVER SPEED dial at minimum. THROTTLE switch in IDLE.

RANGE switch in PAVE. COUNTER ROTATE switch in NORMAL. FNR switch in

neutral (N). STEERING WHEEL MUST BE CENTERED.

2) Hold the CAL-RUN switch in the CAL position while starting the vehicle. Do not release

CAL switch until Engine is brought to FULL THROTTLE.

3) Move the BRAKE switch to the RELEASE position.

4) Turn the STEERING WHEEL all the way to the left and hold.

5) Move the FNR switch to the forward (F) position. Watch the left track closely. As soon as the

track begins to move, flip the FNR switch back to neutral (N).

6) Move the FNR switch to the reverse (R) position. Watch the left track closely. As soon as the

track begins to move, flip the FNR switch back to neutral (N).

7) Turn the STEERING WHEEL all the way to the right and hold.

8) Move the FNR switch to the forward (F) position. Watch the right track closely. As soon as the

track begins to move, flip the FNR switch back to neutral (N).

9) Move the FNR switch to the reverse (R) position. Watch the right track closely. As soon as the

track begins to move, flip the FNR switch back to neutral (N).

10) Center the STEERING WHEEL.

11) Move the FNR switch to the forward (F) position.

12) Slowly turn the PAVER SPEED dial to MAXIMUM. Slowly turn PAVER SPEED dial

counterclockwise until the vehicle just starts to slow down. Make sure the paver will respond to

slight movements of the STEERING WHEEL. Steer paver in a straight path. After 5 seconds

without moving the STEERING WHEEL or PAVER SPEED dial, move the FNR switch to

the neutral (N) position.

13) Turn the PAVER SPEED dial to MINIMUM.

14) Move the FNR switch to the reverse (R) position.

15) Slowly turn the PAVER SPEED dial to MAXIMUM. Slowly turn PAVER SPEED dial

counterclockwise until the vehicle just starts to slow down. Make sure the paver will respond to

slight movements of the STEERING WHEEL. Steer paver in a straight path. After 5 seconds

without moving the STEERING WHEEL or PAVER SPEED dial, move the FNR switch to

the neutral (N) position.

16) Turn the PAVER SPEED dial to MINIMUM.

17) Press and release the CAL-RUN. Move the THROTTLE switch to the IDLE position. Move

the BRAKE switch to the ENGAGE position.

18) Wait 5 seconds.

19) Shut off the engine to store values.

300 Series & CR411 Electrical Troubleshooting 48 22478 (11/00)

Technical Manual

A Terex Company

Susmic 10 Dual Path Control

Calibration Procedures

Grayhound Track Pavers

Error Checks

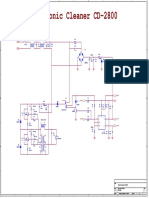

There are four (4) indicator lights (LED's) located on the side of the track steer controller module located

inside of the console; 2 green LED's, 1 yellow and 1 red. Their function is as follows:

1st Green Power Input OK if Lit

2 n d Gr e e n Power Output OK if Lit

Yellow Kernal (Program) Blinks if functional

R ed Error Error if lit

On earlier controllers, the red error light would be either ON or OFF, indicating an error. As of software

version S0029109 and later, an error code has been assigned to the red LED. The code is a series of

short and long flashes consisting of 4 flashes per error with a pause between each error(s). A short flash

indicates a "0" and a long flash represents a "1". The following table lists the error codes along with the

error associated with it:

Error Code Error Description

1000* Steering sensor input is higher than calibrated

1100* Steering sensor input is lower than calibrated

1010* Steering sensor calibrated too high

1110* Steering sensor calibrated too low

0100* Speed dial input is higher than calibrated

0010* Speed dial input is lower than calibrated

0110* Speed dial input is calibrated too high

0001* Speed dial input is calibrated too low

1001* LH FWD EDC calibration fault

0101* RH FWD EDC calibration fault

1101* LH REV EDC calibration fault

0011* RH REV EDC calibration fault

1011 Sensor power fault

0111 LH EDC fault

1111 RH EDC fault

*Attempt to clear errors by re-calibrating first per complete calibration procedure.

300 Series & CR411 Electrical Troubleshooting 49 22478 (11/00)

Technical Manual

A Terex Company

Hopper

Grayhound 300 Series Analog Display

Grayhound CR411

Main

Keyswitch 12 VDC

1 0 3

CONTROL Hopper Raise 65 Raise Sol. 3

1 46 Wings

Lower 66 Lower Sol. 3

15 A

HOPPER WINGS DO NOT RAISE

Press Manual Override button on solenoid valve.

If not functional, refer to Hydraulic Troubleshooting.

If functional, proceed with Electrical checks.

Check DIN connector for light.

If light is ON:

Check for 12 Vdc from pin 1 to pin 2 on DIN connector.

If voltage, check solenoid resistance. Should be approximately 6 ohms. Replace if open.

If no voltage, Check ground jumper from pin 2 to GND pin for tightness.

If NO light:

Check 65 to 3.....If no voltage, replace switch.

If voltage, (12 Vdc) check pin 1 of DIN to frame ground.

If no voltage, check harness.

If voltage, check ground through solenoid to frame for continuity. Correct if necessary.

Replace DIN connector if above checks are OK but problem persists.

HOPPER WINGS DO NOT LOWER

Press Manual Override button on solenoid valve.

If not functional, refer to Hydraulic Troubleshooting.

If functional, proceed with Electrical checks.

Check DIN connector for light.

If light is ON:

Check for 12 Vdc from pin 1 to pin 2 on DIN connector.

If voltage, check solenoid resistance. Should be approximately 6 ohms. Replace if open.

If no voltage, Check ground jumper from pin 2 to GND pin for tightness.

If NO light:

Check 66 to 3.....If no voltage, replace switch.

If voltage, (12 Vdc) check pin 1 of DIN to frame ground.

If no voltage, check harness.

If voltage, check ground through solenoid to frame for continuity. Correct if necessary.

Replace DIN connector if above checks are OK but problem persists.

300 Series & CR411 Electrical Troubleshooting 50 22478 (11/00)

Technical Manual

A Terex Company

Truck Hitch (Optional)

Grayhound 300 Series Analog Display

Grayhound CR411

Main

Keyswitch 12 VDC

1 0 3

Optional Engage 61 Engage Sol. 3

Control

1 46 Truck Hitch

15 A Release 62 Release Sol. 3

TRUCK HITCH DOES NOT ENGAGE

Press Manual Override button on solenoid valve.

If not functional, refer to Hydraulic Troubleshooting.

If functional, proceed with Electrical checks.

Check DIN connector for light.

If light is ON:

Check for 12 Vdc from pin 1 to pin 2 on DIN connector.

If voltage, check solenoid resistance. Should be approximately 6 ohms. Replace if open.

If no voltage, Check ground jumper from pin 2 to GND pin for tightness.

If NO light:

Check 61 to 3.....If no voltage, replace switch.

If voltage, (12 Vdc) check pin 1 of DIN to frame ground.

If no voltage, check harness.

If voltage, check ground through solenoid to frame for continuity. Correct if necessary.

Replace DIN connector if above checks are OK but problem persists.

TRUCK HITCH DOES NOT RELEASE

Press Manual Override button on solenoid valve.

If not functional, refer to Hydraulic Troubleshooting.

If functional, proceed with Electrical checks.

Check DIN connector for light.

If light is ON:

Check for 12 Vdc from pin 1 to pin 2 on DIN connector.

If voltage, check solenoid resistance. Should be approximately 6 ohms. Replace if open.

If no voltage, Check ground jumper from pin 2 to GND pin for tightness.

If NO light:

Check 62 to 3.....If no voltage, replace switch.

If voltage, (12 Vdc) check pin 1 of DIN to frame ground.

If no voltage, check harness.

If voltage, check ground through solenoid to frame for continuity. Correct if necessary.

Replace DIN connector if above checks are OK but problem persists.