Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Document No.: Rev

Caricato da

Inaam0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

214 visualizzazioni2 pagineWPS SAMPLE

Titolo originale

WPS

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoWPS SAMPLE

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

214 visualizzazioni2 pagineDocument No.: Rev

Caricato da

InaamWPS SAMPLE

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

PROJECT DOCUMENT NO.

Facility Vendor Unit Document Discipline Sequenc Revision Page No.:

91 of 156

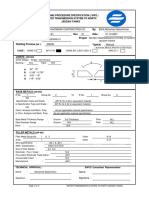

PROJECT: ITEM : CODE : ASME SEC .IX

WPS NO. : WP-1600-PV-44 SUPP. PQR NO. : PQ-PV-91 REV. NO. : 01

WELDING PROC.(es) : SMAW + SAW TYPE(es) : MANUAL /AUTOMATIC DATE : 16.May.2009

JOINTS (QW - 402) : DETAILS

JOINT DESIGN : BUTT JOINT/ X GROOVE

BACKING : YES( ) NO( x )

BACKING MATERIAL : N.A

shell to Shell

BASE METALS (QW - 403) :

P NO. : 1 Gr.No.: 2 TO P No.: 1 Gr.No. :2

SPECIFICATION TYPE AND GRADE : A516 Gr 70

TO SPECIFICATION TYPE AND GRADE : A516 Gr 70

BASE METAL : GROOVE: 30 - 65 mm FILLET :N.A

LAVAN REFINERY UPGRADING & REVAMPINGGROOVE: FILLET :

FILLER METALS (QW - 404) :

PROCESS : SMAW SAW

SPEC NO. (SFA) : 5.1 5.17

AWS NO. : E7018 EH12K

F-NO. : 4 6

A-NO. : 1 1

SIZE OF FILLER METALS : 4 mm 4 mm

FILLER METAL TRADE NAME : HYUNDAI AMA

--- ---

GROOVE : ≤ 7 mm ≤ 58 mm

DEPOSIED WELD METAL

FILLET : N.A N.A

ELECTRODE FLUX (CLASS) : BASIC BASIC

FLUX TRADE NAME : N.A OPTT-121

CONSUMABLE INSERT : N.A N.A

ELECTRODE BAKING CONDITION : NOTE 1 NOTE 1

Note1: ELECTRODE & FLUX BAKING ACCORDING TO ELECTRODE MANUFACTURER RECOMMENDATION

POSITIONS (QW - 405) :

POSITION(S) OF GROOVE : 1G

WELDING PROGRESSION : UP ( ) DOWN ( )

POSITION(S) OF FILLET : N.A

PREHEAT (QW - 406) :

PREHEAT TEMP. MIN. : 70 °c

INTERPASS TEMP. MAX. : 250 °c

PREHEAT MAINTENANCE : PROPAN HEATING TORCH

DOCUMENT No.: REV:

PROJECT DOCUMENT NO.

Facility Vendor Unit Document Discipline Sequenc Revision Page No.:

92 of 156

POSTWELD HEAT TREATMENT (QW - 407) :

TEMP. RANGE : 610 ± 10º C TIME RANGE : 135 min

HEATING RATE : ≤ 50 ºC COOLING RATE :≤ 80 ºC

GAS (QW - 408) : PERCENT COMPOSITION

GAS(es) MIXTURE FLOW RATE

SHIELDING N.A N.A N.A

TRAILING N.A N.A N.A

BACKING N.A N.A N.A

ELECTRICAL CHARACTRISTICS (QW - 409) :

CURRENT : AC( ) DC( × ) POLARITY : SP( ) RP( × )

AMPS RANGE : AS PER TABLE VOLTS RANGE : AS PER TABLE

TUNGSTAN ELECTRODE SIZE AND TYPE : N.A

MODE OF METAL TRANSFER FOR G.M.A.W : N.A

ELECTRODE WIRE FEED SPEED RANGE : N.A

TECHNIQUE (QW - 410) :

STRING OR WEAVE BEAD : STRING

ORIFICE OR GAS CUP : N.A

INITIAL OR INTERPASS CLEANING :BY GRINDING or BRUSHING PER PASS

MAXIMUM WEAVE BEAD : 3XøELECTROD

METHOD OF BACK GOUGING : BY GRINDING OR GOUGING

OSCILLATION : N.A

CONTACT TUBE TO WORK DISTANCE : 25 mm

MULTIPLE OR SINGLE PASS(PER SIDE) : MULTIPLE

MULTIPLE OR SINGLE ELECTRODES : SINGLE

TRAVEL SPEED RANGE : AS PER TABLE

PEENING : N.A

WELDING SEQ UENCE:

1)INITIAL CLEANING 2)ASSEMBLING TACK WELDING AND WELD CLEANING

3) WELDING LAYER 1~2 (INSIDE) BY SMAW

4) WELDING LAYER 3~N(INSIDE) BY SAW

5) BACK GOUGING (B.G)-OUTSIDE

6) LIQUID PENETRANT TEST(PT) OUTSIDE

7)WELDING LAYERS 1~N (OUTSIDE) WITH INTERPASS CLEANING BY SAW

FILLER METAL CURRENT TRAVEL

VOLT

WELD LAYER PROCESS AMP. SPEED MAX HEAT INPUT(J/Cm)

CLASS DIA.(mm) POLARITY RANGE

RANGE (Cm/min)

LAYER 1~2 (IN) SMAW E 7018 4 DCRP 120~160 23~28 12~19 22400

LAYER 3~N(IN) SAW EH12K 4 DCRP 450-600 28~32 45~55 25600

LAYER 1~N (OUT) SAW EH12K 4 DCRP 450-600 28~32 45~55 25600

DOCUMENT No.: REV:

Potrebbero piacerti anche

- Blank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Documento1 paginaBlank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)GMNessuna valutazione finora

- How To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineDocumento5 pagineHow To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineALP1981100% (2)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Documento6 pagineMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNessuna valutazione finora

- WPS PQRDocumento23 pagineWPS PQRHashim Khan88% (8)

- WPS, PQR 041Documento21 pagineWPS, PQR 041swamykommula100% (1)

- WPS Resrvoire Sous Pression Smaw SawDocumento6 pagineWPS Resrvoire Sous Pression Smaw SawDanem HalasNessuna valutazione finora

- Surface Tension Transfer (STT) Pipe WeldingDocumento3 pagineSurface Tension Transfer (STT) Pipe WeldingahmedNessuna valutazione finora

- 1-EN PQR List - 05.04.2019Documento6 pagine1-EN PQR List - 05.04.2019HAKANNessuna valutazione finora

- Smaw Wps FinalDocumento3 pagineSmaw Wps FinalsheikmoinNessuna valutazione finora

- 653 WPS-PQR PDFDocumento4 pagine653 WPS-PQR PDFETSNessuna valutazione finora

- Agoco Welding Procedure Specification: Gtaw Manual JOINTS (QW-402)Documento3 pagineAgoco Welding Procedure Specification: Gtaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- Fit-Up Dimensional Inspection: No. Drawing Dim. Actual Dim. Tolerance Remarks Location Deviation ResultDocumento4 pagineFit-Up Dimensional Inspection: No. Drawing Dim. Actual Dim. Tolerance Remarks Location Deviation ResultVanvien Le100% (1)

- QW-483 BlankDocumento2 pagineQW-483 BlankCraftyBob100% (1)

- Material Certificate Plate 16mmDocumento1 paginaMaterial Certificate Plate 16mmAdeoyeNessuna valutazione finora

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) YesDocumento4 pagineWelding Procedure Specification (WPS) Yes PREQUALIFIED - Qualified by Testing - or Procedure Qualification Records (PQR) Yesvarun100% (1)

- Welding Inspection Report NEWDocumento2 pagineWelding Inspection Report NEWtrinhminhkhoa100% (1)

- WOPQ Form English1Documento2 pagineWOPQ Form English1oaperuchenaNessuna valutazione finora

- Gmaw Complete Aws d1.6Documento1 paginaGmaw Complete Aws d1.6Hamza Nouman100% (1)

- API Welding ProcedureDocumento2 pagineAPI Welding ProcedureSamarakoon BandaNessuna valutazione finora

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocumento2 pagineName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNessuna valutazione finora

- Wqt-Visual-Mag - BS 2Documento24 pagineWqt-Visual-Mag - BS 2KyNessuna valutazione finora

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- Utoc Preliminary Wps Shell Project 270807 PDFDocumento55 pagineUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNessuna valutazione finora

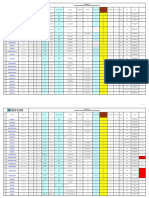

- Weld Matrix - PAGE 1&2Documento20 pagineWeld Matrix - PAGE 1&2abdulgafoor54Nessuna valutazione finora

- P91 Profile WpsDocumento6 pagineP91 Profile WpsManzar KhanNessuna valutazione finora

- Preliminary Welding Procedure Specification (PWPS)Documento1 paginaPreliminary Welding Procedure Specification (PWPS)AzriNessuna valutazione finora

- WPS - PQR (Sa516 GR.70)Documento4 pagineWPS - PQR (Sa516 GR.70)miltonangulomorrisNessuna valutazione finora

- PRES TIG Hot Wire Narrow Gap Welding enDocumento25 paginePRES TIG Hot Wire Narrow Gap Welding enRavishankarNessuna valutazione finora

- WPS Format For ASME IX - PQR-AllDocumento3 pagineWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- WPS Asme IxDocumento4 pagineWPS Asme Ixjcarlosherrerac7100% (1)

- TopCorbelco - WPS FCAW Sa 516 GR 70Documento6 pagineTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisNessuna valutazione finora

- Weldspec ASME PQRDocumento2 pagineWeldspec ASME PQRSunil KumarNessuna valutazione finora

- Welding Procedure Specification SampleDocumento2 pagineWelding Procedure Specification Samplesamer_saif8456100% (1)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocumento1 paginaWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- PQR Asme Template EDITABLEDocumento6 paginePQR Asme Template EDITABLErcpretoriusNessuna valutazione finora

- Electrodes EnglishDocumento139 pagineElectrodes Englishcostelino72Nessuna valutazione finora

- WPS SampleDocumento2 pagineWPS Sampleeetua100% (1)

- WPS ListDocumento2 pagineWPS ListAdeel OmerNessuna valutazione finora

- QW 482Documento2 pagineQW 482MuchamadAsyhariNessuna valutazione finora

- Template BUTTDocumento1 paginaTemplate BUTTDylan TriggNessuna valutazione finora

- PQR TipsDocumento4 paginePQR TipsWaqas WaqasNessuna valutazione finora

- Is 7310 RequirementsDocumento4 pagineIs 7310 RequirementsRavichandran Tirupattur SubramaniamNessuna valutazione finora

- PQRDocumento2 paginePQRalokbdasNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- Welding FormDocumento4 pagineWelding FormAnand SomanNessuna valutazione finora

- WPQ WeldCanada PDFDocumento1 paginaWPQ WeldCanada PDFAhmad DanielNessuna valutazione finora

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocumento2 pagineJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNessuna valutazione finora

- PWPS Eksperimen Super DuplexDocumento33 paginePWPS Eksperimen Super Duplexryan.sNessuna valutazione finora

- Welding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxDocumento4 pagineWelding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxLipika GayenNessuna valutazione finora

- Wps Sp14 Reva PDFDocumento9 pagineWps Sp14 Reva PDFravi00098Nessuna valutazione finora

- WPS&PQR For PipeDocumento5 pagineWPS&PQR For PipeKAMALNessuna valutazione finora

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocumento10 pagineWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Joint (QW-402)Documento3 pagineJoint (QW-402)Satyaprakash RayNessuna valutazione finora

- WPS No. ST-CS-02-2Documento1 paginaWPS No. ST-CS-02-2Hussein JassimNessuna valutazione finora

- Bharat Petroleum Corporation Limited M/S Durgapur EquipmentsDocumento3 pagineBharat Petroleum Corporation Limited M/S Durgapur EquipmentsSatyaprakash RayNessuna valutazione finora

- Piping WpsDocumento37 paginePiping WpsZulfokar FahdawiNessuna valutazione finora

- GMCo - WPSDocumento8 pagineGMCo - WPSMohamed AtefNessuna valutazione finora

- Fcaw Wps-001a PDFDocumento3 pagineFcaw Wps-001a PDFirfan bari100% (1)

- Final WPS - ItdcDocumento2 pagineFinal WPS - ItdcsarancivilrajNessuna valutazione finora

- WPS-PQR RepairDocumento16 pagineWPS-PQR RepairmohammedetaNessuna valutazione finora

- WPS 03 GtawDocumento3 pagineWPS 03 GtawBiswajit DeyNessuna valutazione finora

- BDS TCT Annular CutterDocumento12 pagineBDS TCT Annular CutterInaamNessuna valutazione finora

- Sciencedirect Sciencedirect SciencedirectDocumento8 pagineSciencedirect Sciencedirect SciencedirectInaamNessuna valutazione finora

- Carbide (TCT) Core Drills Short Carbide (TCT) Core Drills ShortDocumento3 pagineCarbide (TCT) Core Drills Short Carbide (TCT) Core Drills ShortInaamNessuna valutazione finora

- The Wind Power: Invoice ### Customer Ref. Date License Site LicenseDocumento9 pagineThe Wind Power: Invoice ### Customer Ref. Date License Site LicenseInaamNessuna valutazione finora

- Dokumen - Tips Soal Final Neuropsikiatri 2012 Acrom10nDocumento1 paginaDokumen - Tips Soal Final Neuropsikiatri 2012 Acrom10nariqNessuna valutazione finora

- Operator's ManualDocumento28 pagineOperator's ManualInaamNessuna valutazione finora

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocumento1 paginaB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNessuna valutazione finora

- Di PSSS 80991BDocumento7 pagineDi PSSS 80991BInaamNessuna valutazione finora

- BW FOX+CN+23 12-A EN 2018 GL 131 PreviewDocumento2 pagineBW FOX+CN+23 12-A EN 2018 GL 131 PreviewInaamNessuna valutazione finora

- Phoenix Blau: Unalloyed, Rutile Cellulose Coated Stick ElectrodeDocumento2 paginePhoenix Blau: Unalloyed, Rutile Cellulose Coated Stick ElectrodeInaamNessuna valutazione finora

- Maintenance Planning and Administration: Planned Maintenance System Learning Objectives: State Who HasDocumento48 pagineMaintenance Planning and Administration: Planned Maintenance System Learning Objectives: State Who HasInaamNessuna valutazione finora

- Utp A 80 M: ClassificationsDocumento1 paginaUtp A 80 M: ClassificationsInaamNessuna valutazione finora

- Sample United States Navy Maintenance Requirement Card PDFDocumento3 pagineSample United States Navy Maintenance Requirement Card PDFInaamNessuna valutazione finora

- An Investigation On Weld Quality Characteristics of Pulsed Current Micro Plasma Arc Welded Austenitic Stainless SteelsDocumento10 pagineAn Investigation On Weld Quality Characteristics of Pulsed Current Micro Plasma Arc Welded Austenitic Stainless SteelsInaamNessuna valutazione finora

- Weldability Investigation of Fine-Grained S1100Ql Steel: I. Samardžić, A. Ćorić, M. DunđerDocumento4 pagineWeldability Investigation of Fine-Grained S1100Ql Steel: I. Samardžić, A. Ćorić, M. DunđerInaamNessuna valutazione finora

- High-Strength and Ultra-High-Strength Thermomechanically Rolled Fine-Grained SteelsDocumento16 pagineHigh-Strength and Ultra-High-Strength Thermomechanically Rolled Fine-Grained SteelsInaamNessuna valutazione finora

- SDK TC-Python Quick Install Guide PDFDocumento7 pagineSDK TC-Python Quick Install Guide PDFInaamNessuna valutazione finora

- Perkins 1104DDocumento158 paginePerkins 1104Dsj1202100% (17)

- Africa's Youth Can Save The WorldDocumento21 pagineAfrica's Youth Can Save The WorldThe Wilson CenterNessuna valutazione finora

- Information & Operations Manual For Bavaria Cruiser 37Documento37 pagineInformation & Operations Manual For Bavaria Cruiser 37RDNessuna valutazione finora

- Operations Manual 18WDocumento137 pagineOperations Manual 18Wto_john100% (1)

- N42EH Grade Neodymium Magnets DataDocumento1 paginaN42EH Grade Neodymium Magnets DataSteve HsuNessuna valutazione finora

- Catalogo DynapacDocumento36 pagineCatalogo DynapacblaktionNessuna valutazione finora

- A Level Chemistry SyllabusDocumento105 pagineA Level Chemistry SyllabusSyedZain1993Nessuna valutazione finora

- Discussion & Conclusion Dry Fractionation MuzDocumento4 pagineDiscussion & Conclusion Dry Fractionation MuzAhmad MuzammilNessuna valutazione finora

- EHVT Unit 1Documento19 pagineEHVT Unit 1SumanranuNessuna valutazione finora

- RMG 4015 Crack Depth MeasurementDocumento4 pagineRMG 4015 Crack Depth MeasurementJozmel Blancas CamarenaNessuna valutazione finora

- Formal Report Expt 5 ColloidsDocumento6 pagineFormal Report Expt 5 ColloidsJessica Christel MaglalangNessuna valutazione finora

- THC 301D Operation ManualRev3Documento12 pagineTHC 301D Operation ManualRev3RC13Nessuna valutazione finora

- Basics of Petroleum GeologyDocumento23 pagineBasics of Petroleum GeologyShahnawaz MustafaNessuna valutazione finora

- 00.00.005Documento2.992 pagine00.00.005Maulana BirrwildanNessuna valutazione finora

- Research and Development: Applied Research IN Renewable Energy SystemsDocumento22 pagineResearch and Development: Applied Research IN Renewable Energy SystemsBilaljafraniNessuna valutazione finora

- Title - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsDocumento5 pagineTitle - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsIszysax MediaNessuna valutazione finora

- KP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFDocumento27 pagineKP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFUtku Can Kılıç100% (1)

- PORAM Standard SpecificationDocumento3 paginePORAM Standard SpecificationAristonNessuna valutazione finora

- ELCE201 Assignment 03Documento11 pagineELCE201 Assignment 03Eren UlanNessuna valutazione finora

- CS59201 DDocumento4 pagineCS59201 DJose M PeresNessuna valutazione finora

- Chapter-1 Physical WorldDocumento7 pagineChapter-1 Physical WorldAbhi AdiNessuna valutazione finora

- Area Handing OverDocumento6 pagineArea Handing OveronspsnonsNessuna valutazione finora

- 6202360Documento726 pagine6202360AlexeiNessuna valutazione finora

- Scaling of MosfetDocumento40 pagineScaling of MosfetSaumitra TripathiNessuna valutazione finora

- HW ProblemsDocumento34 pagineHW ProblemsMarkk ClainNessuna valutazione finora

- Final Project ReportDocumento23 pagineFinal Project ReportMayank SainiNessuna valutazione finora

- 10 Mechanical Properties of FluidsDocumento8 pagine10 Mechanical Properties of FluidsMokshNessuna valutazione finora

- Glossary of Heat Exchanger TerminologyDocumento2 pagineGlossary of Heat Exchanger Terminologypvwander100% (1)