Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gems &control

Caricato da

Jesus RodriguezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gems &control

Caricato da

Jesus RodriguezCopyright:

Formati disponibili

GEMS SENSORS & CONTROLS

OPERATING & INSTALLATION INSTRUCTIONS

31XX / 32XX SERIES

PLEASE READ CAREFULLY BEFORE INSTALLING

Part Number: 560550-0076 Issue: E

INTRODUCTION

Series 3100/3200 high output pressure transducers and transmitters are fitted with an Asic

providing various optional (at time of order) voltage outputs, and a 4-20mA current output

capable of being used in control and indicating loops without further amplification.

Series 3100/3200 conform with the essential protection requirements of the EMC Directive

2004/108/EC amended by certified type testing to BS EN 61326-1 and BS EN 61326-2-3

Series 3100/3200 with the CE0086 mark also complies with the requirements of the Pressure

Equipment Safety Regulations 2016 and can be used as part of a safety-related system on

Category IV pressure equipment.

HAZARDOUS PRODUCTS

The Consumer Protection Act of 1987, Section 6 of the Health and Safety at Work Act 1974 and

the Control of Substances Hazardous to Health Regulations 1988 require that we advise

recipients and users of our products of any potential hazards associated with their storage,

handling or use.

The products which our Company supplies may be classified as Electrical, Electro-Mechanical

and Electronic equipment.

These products are tested and supplied in accordance with our published specifications or

individual special requirements that are agreed in writing at time of order. They are constructed

so as not to affect adversely the safety of persons and property when properly installed,

maintained and used by qualified personnel, in the applications for which they were designed and

manufactured.

Conformity with the requirements of the CE mark only applies when the installation

conditions described in these instructions have been met. For units supplied without a

cable assembly connection to the transducer must be accomplished using Gems Sensors

approved cable. See APPROVED CABLE section.

GENERAL

* Transducer should not be subjected to greater than the maximum allowable pressure

(P.S.)

/ Temperature (T.S) as defined on the transducer label.

* Transducer should not be subjected to mechanical impact.

* In the event of fire the end user must ensure that the system pressure is vented to a safe

area.

560550-0076 Issue E Page 1 of 5

* The effects of decomposition of unstable fluids should be considered by the user when

placing this device in service.

* The pressure transducer has no means of draining or venting, this must be performed by

another component in the end users system.

* Pressure range must be compatible with the maximum pressure being measured.

* Pressure media must be compatible with the transducer/transmitter wetted parts listed in

these instructions.

* Liquid must not be allowed to freeze in the pressure port.

* The gasket must be fitted under the electrical connector.

MECHANICAL INSTALLATION

Mounting: Pressure Transducer is designed to be attached by the coupling thread only. Omni-

directional, self supported directly into the pipework. The Customer must ensure that the

pressure seal is suitable for the application. If in doubt contact Gems Sensors & Controls.

Observe the following maximum torques when tightening. Tightening / removal torque must be

applied to pressure port hexagon only, with electrical supply disconnected.

PRESSURE PORT MAX TORQUE NM OR

THREAD TYPE TIGHTENING INSTRUCTION

G1/4”A 35

G1/8”A 25

M12 30

M12 HP (Washer Seal) 35

M14 40

M18 35

5/16”-24UN ‘O’ Ring 10

7/16”-20UN ‘O’ Ring 20

7/16”-20UN Flare 16

9/16”-18UN Flare 28

2 to 2.5 FFFT (Flats from Finger

NPT or NPTF

Tight) 120 to 150 degrees

ELECTRICAL INSTALLATION

All types with the CE Mark include suppression devices providing transient protection to EN

61000-6-2 and EN 55022. Refer to Tables 1 and 2 for electrical connections. Supply voltages

are shown in Table 3.

RECOMMENDED CABLE

Gems Sensors & Controls uses cables comprising 2, 3 or 4 colour-coded cores, enclosed by either

a braided screen or aluminised polyester screen where the screen is in intimate contact with a

separate drain wire. Cable materials must compatible with the operating temperature.

560550-0076 Issue E Page 2 of 5

OPERATION

Having installed the transducers as instructed, they are ready for use. The transducer should not

be removed whilst the system is at pressure. Before applying power, check that the correct

polarity and excitation levels are being applied. See Tables 1 & 2 for electrical connections.

CALIBRATION

Transducers are calibrated to the datum requested at time of order; this can be identified by the

sixth letter of the identification code as follows:-

G - Gauge datum vented to atmosphere via the electrical connector or cable

S - Sealed Datum

LOAD CHARACTERISTICS (4-20mA Current Output)

The total resistive load in the loop (to include all the cable resistance) can be from 'zero to 50 x

(supply volts -7.5) ohms' e.g. with a 24V d.c. supply the permissible load is from zero up to 700

ohms.

OPERATIONAL LIFE:

Designed for 100M Cycles (maximum allowable pressure) limited to 10M in Category IV PED

Applications.

WARRANTY

We guarantee this instrument against faulty workmanship and material for a period of one year

from date of delivery. The Company undertake to repair, free of charge, ex-works any

instrument found to be defective within the specified period providing the instrument has been

used within the specification in accordance with these instructions and has not been misused in

any way.

Detailed notice of such defects and satisfactory proof thereof must be given to the Company

immediately after the discovery and the goods are to be returned free of charge to the Company,

carefully packed and accompanied by a detailed failure report. See "RETURN TO FACTORY".

WETTED PARTS

17-4 PH stainless steel , 304 stainless steel & Viton (FKM Elsatomer-Standard seal material)

SERVICING

The transducer cannot be repaired locally and if damaged should be returned to ourselves at the

address shown below or to accredited dealers when a replacement/repair is required:

Gems Sensors & Controls Gems Sensors Inc

Lennox Road 1 Cowles Road

Basingstoke Plainville, CT 06062

Hants. RG22 4AW U.S.A.

560550-0076 Issue E Page 3 of 5

RETURN TO FACTORY

PLEASE NOTE: To comply with Health and Safety requirements, the instrument must be clean

and safe to handle and accompanied by a formal statement to that effect duly signed by an

authorised officer of the Company.

Any instrument returned without certification will be quarantined and no action will occur until

cleared. It may ultimately be returned to you and subject to a transportation charge.

MAINTENANCE

Routine Inspection: Not required except for periodic inspection of the cable and connector to

ensure that these are neither damaged nor softened by incompatible liquid.

OUTPUT & SUPPLY VOLTAGE

CODE Output Supply Voltage

B 4 to 20mA 10V to 30V dc (24V dc maximum above 110°C)

C 1-6V 8V to 30V dc

S 0-10V 12V to 30V dc

N 0.5 to 4.5V Non Ratiometric 8V to 30V dc

T 0.5 to 4.5V Ratiometric 5V dc ±10%

H 1-5V 8V to 30V dc

R 0-5V 8V to 30V dc

ELECTRICAL CONNECTIONS

560550-0076 Issue E Page 4 of 5

560550-0076 Issue E Page 5 of 5

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Power System Protection Power System Stability: Substation Automation ProductsDocumento15 paginePower System Protection Power System Stability: Substation Automation ProductsRobert Mihayo100% (1)

- T & C Fastener Co, LTD.: Certified Material Test ReportDocumento1 paginaT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNessuna valutazione finora

- Internet Usage PolicyDocumento8 pagineInternet Usage PolicyRaven ShieldNessuna valutazione finora

- G240 (16 Speeds) CEI MERCEDES-4-307-231-242Documento12 pagineG240 (16 Speeds) CEI MERCEDES-4-307-231-242عبدالغني القباطي100% (3)

- GemsSensors MasterCatalogDocumento422 pagineGemsSensors MasterCatalogJesus RodriguezNessuna valutazione finora

- Selenium ToolDocumento24 pagineSelenium ToolSayali NagarkarNessuna valutazione finora

- Infinera Ebook Packet OpticalDocumento57 pagineInfinera Ebook Packet OpticalRamon CuevasNessuna valutazione finora

- BIM Applications of Rule-Based Checking in ConstruDocumento9 pagineBIM Applications of Rule-Based Checking in ConstrumounirNessuna valutazione finora

- Dpcompact DatasheetDocumento50 pagineDpcompact DatasheetJesus RodriguezNessuna valutazione finora

- Engineering, Inc.: PSW495BDocumento2 pagineEngineering, Inc.: PSW495BJesus RodriguezNessuna valutazione finora

- Pss 2a-1c13fDocumento24 paginePss 2a-1c13fJesus RodriguezNessuna valutazione finora

- DL-DT8x Users ManualDocumento394 pagineDL-DT8x Users ManualJesus RodriguezNessuna valutazione finora

- Northern XDDocumento2 pagineNorthern XDJesus RodriguezNessuna valutazione finora

- 4725 M1-PSI Data SheetDocumento3 pagine4725 M1-PSI Data SheetJesus RodriguezNessuna valutazione finora

- Liq Manual 51-5081A-HTDocumento114 pagineLiq Manual 51-5081A-HTJesus RodriguezNessuna valutazione finora

- UMB PulserDocumento28 pagineUMB PulserJesus RodriguezNessuna valutazione finora

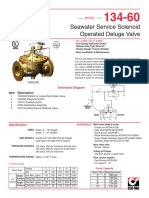

- Seawater Service Solenoid Operated Deluge Valve: ModelDocumento2 pagineSeawater Service Solenoid Operated Deluge Valve: ModelJesus RodriguezNessuna valutazione finora

- En LiquidPumpsDocumento13 pagineEn LiquidPumpsJesus RodriguezNessuna valutazione finora

- ProComSol HM-USB-ISO Data SheetDocumento2 pagineProComSol HM-USB-ISO Data SheetJesus RodriguezNessuna valutazione finora

- ProComSol HM-USB-ISO User ManualDocumento3 pagineProComSol HM-USB-ISO User ManualJesus RodriguezNessuna valutazione finora

- DC/DC Converters: FeaturesDocumento4 pagineDC/DC Converters: FeaturesJesus RodriguezNessuna valutazione finora

- Manual Universal Ivcm Water Cut Meter Temperature Compensation EnglishDocumento4 pagineManual Universal Ivcm Water Cut Meter Temperature Compensation EnglishJesus RodriguezNessuna valutazione finora

- ProComSol HM-USB-ISO User ManualDocumento3 pagineProComSol HM-USB-ISO User ManualJesus RodriguezNessuna valutazione finora

- Manual Coriolis Interface Module For Roc800 Series Floboss 107 Flow Managers Micro Motion en 132276 PDFDocumento82 pagineManual Coriolis Interface Module For Roc800 Series Floboss 107 Flow Managers Micro Motion en 132276 PDFJesus RodriguezNessuna valutazione finora

- Manual Universal Ivcm Water Cut Meter Temperature Compensation - English PDFDocumento118 pagineManual Universal Ivcm Water Cut Meter Temperature Compensation - English PDFJesus RodriguezNessuna valutazione finora

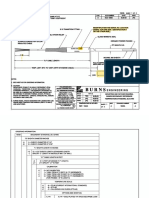

- XXXXXX - 1 1-: BurnsDocumento3 pagineXXXXXX - 1 1-: BurnsJesus RodriguezNessuna valutazione finora

- General Tire Supply Chain ProcessDocumento3 pagineGeneral Tire Supply Chain ProcessSyed Burhan AhmadNessuna valutazione finora

- Flyback Using Microcontroller AN2122 MicrochipDocumento70 pagineFlyback Using Microcontroller AN2122 MicrochipCarlos Zevallos100% (1)

- PCP - VersionDocumento33 paginePCP - VersionKiran JoshiNessuna valutazione finora

- Bullet Pixels 2: by Samurai CircuitsDocumento3 pagineBullet Pixels 2: by Samurai CircuitsdinhanhminhqtNessuna valutazione finora

- Event Management System1Documento24 pagineEvent Management System1Suchi UshaNessuna valutazione finora

- A5 EXPERIMENT LVDT and RVDTDocumento14 pagineA5 EXPERIMENT LVDT and RVDTDuminduJayakodyNessuna valutazione finora

- SPSD AssignmentDocumento21 pagineSPSD AssignmentHafidz Al-RizzoNessuna valutazione finora

- Samsung Ue40f5500 TrainingDocumento49 pagineSamsung Ue40f5500 TrainingLuizNessuna valutazione finora

- Bealls List of Predatory PublishersDocumento38 pagineBealls List of Predatory PublishersRandy The FoxNessuna valutazione finora

- Commutation Circuits SCR PDFDocumento2 pagineCommutation Circuits SCR PDFRhondaNessuna valutazione finora

- Split Charge InstructionsDocumento4 pagineSplit Charge InstructionsAugusto ZanlungoNessuna valutazione finora

- Web Development ProposalDocumento7 pagineWeb Development ProposalTaiwo PraiseNessuna valutazione finora

- Building A Computer: Electronic Numerical Integrator and Computer (ENIAC)Documento31 pagineBuilding A Computer: Electronic Numerical Integrator and Computer (ENIAC)Anonymous HsoXPyNessuna valutazione finora

- LH86 ModbusDocumento2 pagineLH86 ModbusMarcos Luiz AlvesNessuna valutazione finora

- Yale Smart Home Alarm Manual: Conexis L1Documento36 pagineYale Smart Home Alarm Manual: Conexis L1harari itirNessuna valutazione finora

- Byjusbusinesscanvasmodel 190201155441Documento5 pagineByjusbusinesscanvasmodel 190201155441Aarsh SoniNessuna valutazione finora

- ClassiCool MSP - English - Summary - EOSDocumento16 pagineClassiCool MSP - English - Summary - EOSMohammed KandeelNessuna valutazione finora

- Xds510pp PlusDocumento30 pagineXds510pp PlusgarriyakNessuna valutazione finora

- ATEX ComplianceDocumento2 pagineATEX ComplianceEfari BahchevanNessuna valutazione finora

- Types of MicsDocumento14 pagineTypes of Micsapi-462777064Nessuna valutazione finora

- Regional Development Plan PDFDocumento16 pagineRegional Development Plan PDFAlexandra FricosuNessuna valutazione finora

- Word Basics: Microsoft Office 2010: View Our Full Schedule, Handouts, and Additional Tutorials On Our WebsiteDocumento17 pagineWord Basics: Microsoft Office 2010: View Our Full Schedule, Handouts, and Additional Tutorials On Our Websitesanni abdulwahabNessuna valutazione finora

- MP3 Active/Passive Chassis: Installation & Operation ManualDocumento46 pagineMP3 Active/Passive Chassis: Installation & Operation ManualLuis Carlos SolanoNessuna valutazione finora